Method for generating Marangoni effect

A Marangoni effect technology, applied in the field of Marangoni effect, can solve the problem of limiting the application field of photo-induced Marangoni effect to drive liquid flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

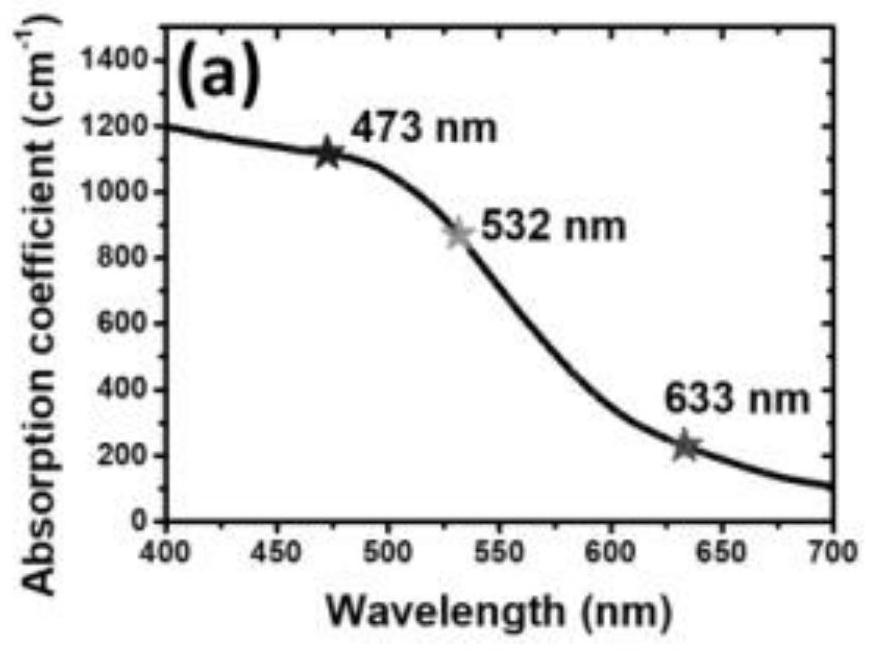

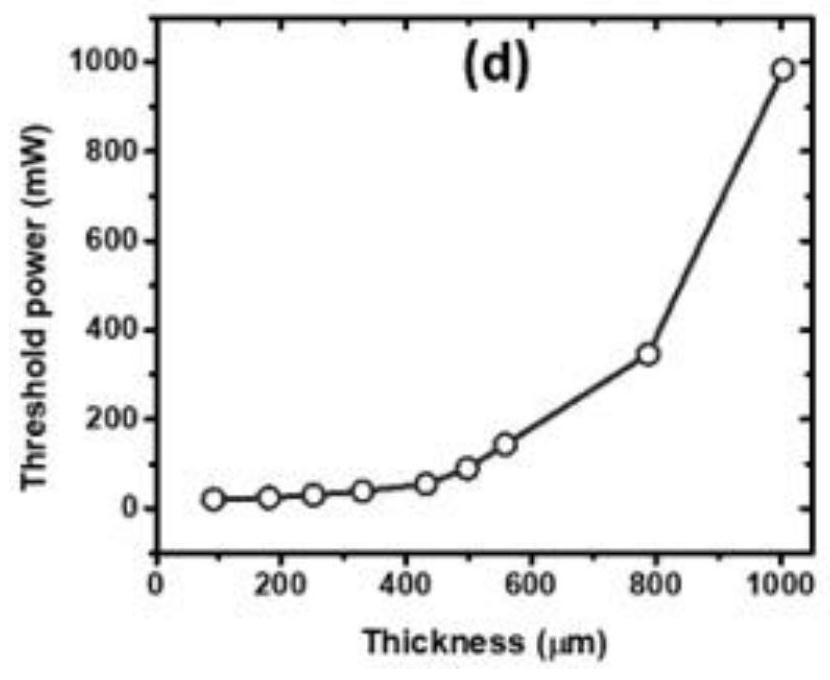

[0133] This embodiment provides an engraving method, including: 532nm continuous laser irradiating the ferrofluid, the ferrofluid absorbs energy to generate a local temperature difference, produces the Marangoni effect, and makes the ferrofluid form pits;

[0134] image 3 The relationship between the critical power of the 532nm continuous laser engraving and the thickness of the ferrofluid, the abscissa is the thickness of the ferrofluid, and the ordinate is the critical power of the laser.

[0135] Specific embodiment mode 1:

[0136] 1. If Figure 4 As shown in (a), an engraving method, under the irradiation of unfocused 532nm continuous laser (spot diameter is about 0.5mm, laser power 20mw), ferrofluid absorbs energy to generate local temperature difference, resulting in Marangoni effect, iron The ferrofluid deforms, forming dimples.

[0137] The thickness of the ferrofluid is 250 μm; the pit shape is circular.

[0138] The pit formation process includes:

[0139] (1)...

specific Embodiment approach 3

[0172] Such as Figure 5 As shown in (a), use a focused 532nm red commercial laser pointer to produce a red laser beam to irradiate the ferrofluid, which produces the Marangoni effect, and pits are formed on the surface of the ferrofluid; the shape of the pits is a character; the ferrofluid The thickness is 25μm;

[0173] Adjust the laser power according to the relationship between the critical power and the thickness of the ferrofluid.

[0174] The bottom area of ferrofluid is 2375mm 2 In the petri dish, a magnetic bar is arranged below the petri dish.

[0175] Text engraved with a red laser beam can be easily erased by sliding the magnetic stick under the Petri dish;

[0176] Figure 5 (a1)-(a5) are images of characters U, E, S, T, and C engraved by the red laser beam.

specific Embodiment approach 4

[0178] Such as Image 6 Shown in (a), the 532nm green laser beam of focusing produces Marangoni effect on the irradiation ferrofluid thin film, makes ferrofluid surface form pit; Described pit shape is literal; The thickness of ferrofluid film is 250μm;

[0179] Adjust the laser power according to the relationship between the critical power and the thickness of the ferrofluid.

[0180] The bottom area of ferrofluid is 2375mm 2 In the petri dish, a magnetic bar is arranged below the petri dish.

[0181] Text engraved with a green laser beam can be easily erased by sliding the magnetic stick under the Petri dish;

[0182] Text engraved with a green laser beam can be easily erased by sliding a magnetic stick under the substrate;

[0183] Image 6 (a1)-(a5) are pictures of characters U, E, S, T, and C engraved by the green laser beam.

[0184] It can be seen from this embodiment that even if a commercial laser pointer is used, a macroscopic Marangoni effect can be generate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption coefficient | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com