Thermo-magnetic coupling field cooperated selective laser-melting device and heating method thereof

A laser melting and selective technology, applied in the directions of additive manufacturing, additive processing, process efficiency improvement, etc., can solve problems such as coarse grains, achieve uniform structure and properties, refine grains, and improve hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

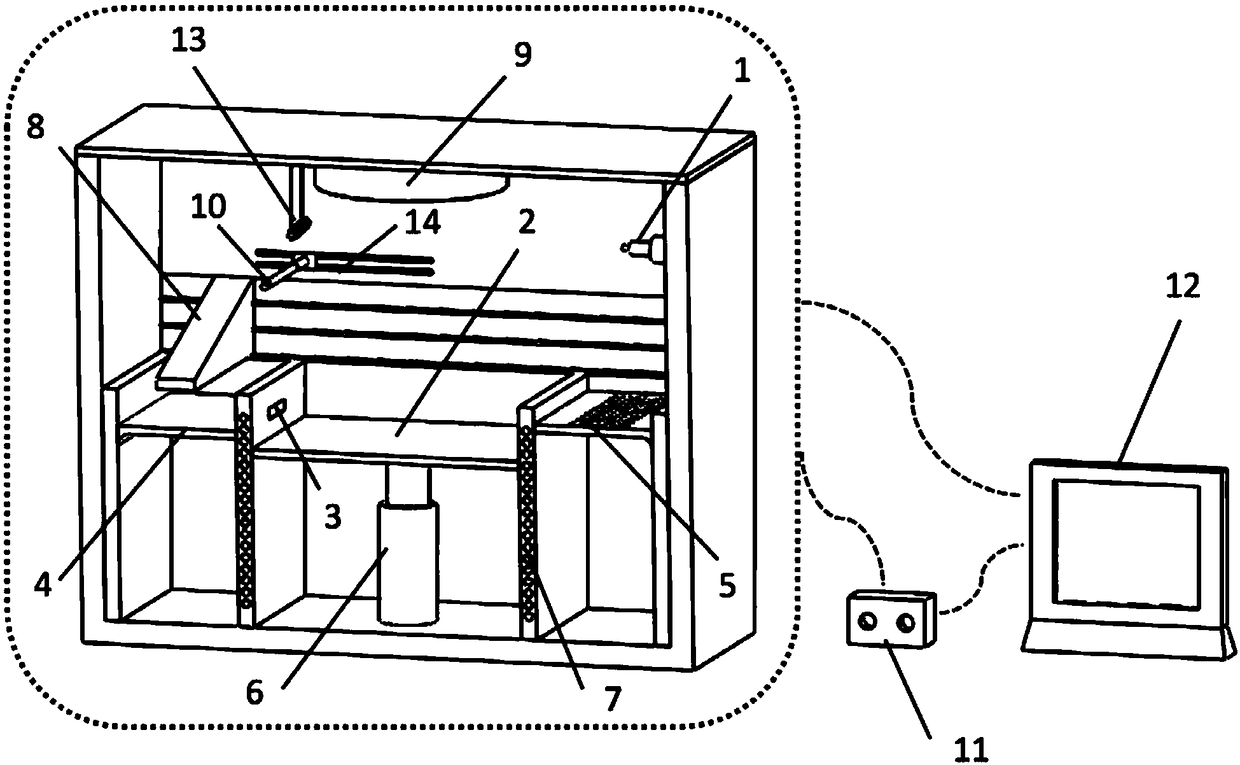

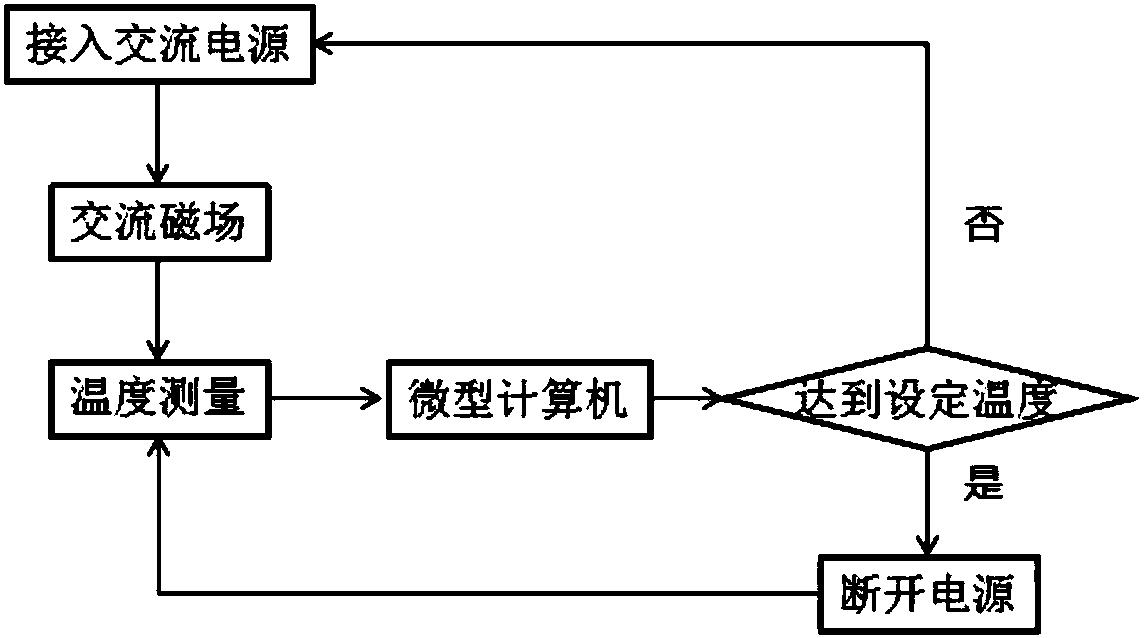

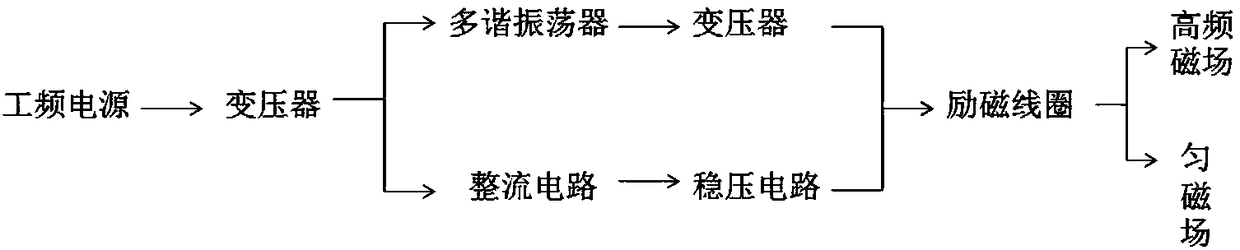

[0037] figure 1 It is a schematic diagram of the device of the present invention, the structure includes: laser 1, forming cylinder, temperature measuring instrument 3, powder feeding device 4, powder recovery device 5, hydraulic lifter 6, cooling device 7, powder spreader 8, magnetic field generator 9 , Magnetic field detector 10, power converter 11, control system 12, mirror 13, mobile bracket 14. The side wall of the forming cylinder is provided with a cooling device 7, and a liftable workbench 2 is provided in the forming cylinder, and a laser heating device, a magnetic field generator 9 and a magnetic field detector 10 are arranged above the workbench 2, and the magnetic field The detector 10 is installed above the workbench 2 through a horizontal moving device, the magnetic field generated by the magnetic field generator 9 is detected by the magnetic field detector 10, and then fed back to the control system 12, and the control system 12 controls the magnetic field gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com