Wire material electric arc fused deposition and laser shock forging composite additive and subtractive manufacturing method and device

A laser shock and manufacturing method technology, applied in the field of additive and subtractive material manufacturing, can solve the problems of poor control of residual stress, restriction of wire arc deposition technology, poor surface quality of formed parts, etc., and achieve precise part size , Low processing cost and fast molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

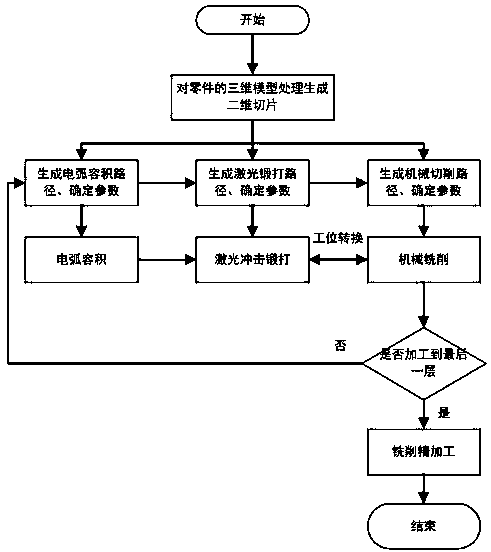

[0034] Such as figure 1 Shown is the flow chart of the wire arc deposition and laser shock forging compound addition and subtraction material manufacturing method of the present invention, including the following steps:

[0035] S1. Use the computer 1 to slice and layer the three-dimensional part model to generate a processing path, which includes arc deposition path, laser shock forging path and milling path; set processing parameters according to the processing path, and the processing parameters include welding machine 9 parameters, laser beam parameters and milling parameters, generate numerically controlled machining codes according to the machining parameters, and extract the machining path and input it to the controller 8;

[0036] S2. The controller 8 instructs the arc deposition system to start wire feeding, and then melts the welding wire according to the arc deposition path in step S1 to form a cladding layer;

[0037] S3. When forming the cladding layer in step S2, ...

Embodiment 2

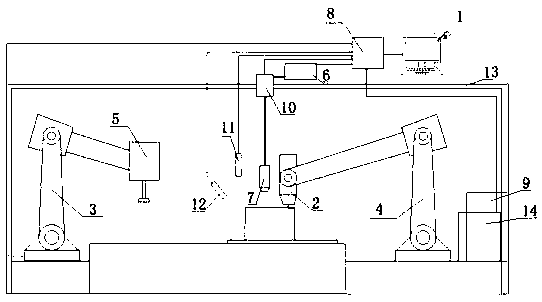

[0044] Such as figure 2 Shown is an embodiment of the wire arc deposition and laser shock forging composite addition and subtraction material manufacturing device of the present invention, including a controller 8 and an arc deposition system connected to the controller 8, a laser shock forging system, and a mechanical milling system. System and computer 1, arc deposition system, laser shock forging system, and mechanical milling system are provided with a casing; a workbench is provided inside the casing, and the workpiece is movable on the workbench; the workpiece can be placed between the deposition forging station and the milling station Convert between bits.

[0045] Such as figure 1 As shown, the arc deposition system includes a welding machine 9, a gas storage tank 14 connected to the welding machine 9, a first six-axis robot arm 3 connected to the controller 8, and a welding torch 2 connected to the welding machine 9, and the welding torch 2 is connected to The free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com