Center hole radial circle run-out detection tool and batch detection method

A technology for detecting tooling and circular runout, which is applied in measuring devices, mechanical measuring devices, mechanical counters/curvature measurement, etc. It can solve the problem that the radial runout value of the detection data has a great influence and cannot meet the needs of batch testing and finishing. and other problems, to achieve the effect of saving auxiliary operation time, saving detection time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

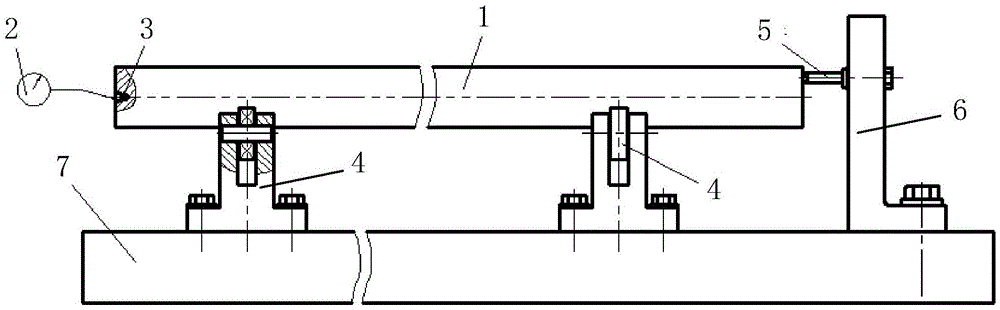

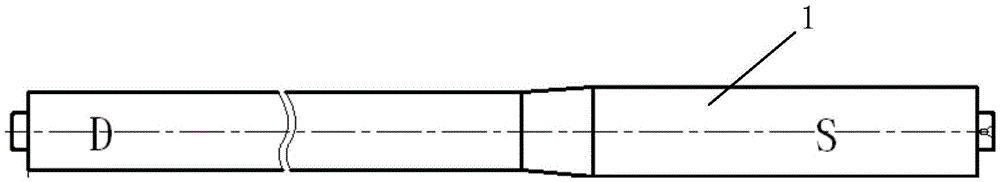

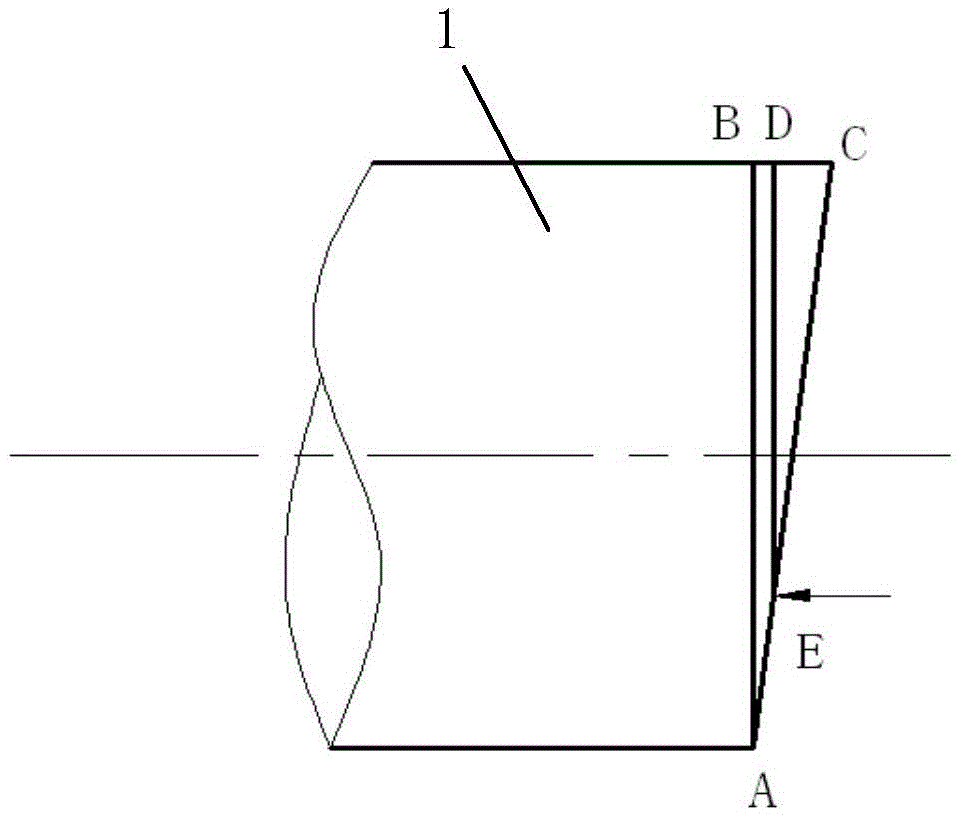

[0059] Such as Figure 6 , Figure 7 and Figure 8 A center hole radial runout detection tool is shown, including a horizontal base 8, two support bearings 4 that horizontally support the billet 1 to be detected and can translate back and forth on the horizontal base 8, and are located on the horizontal base 8. 8. The positioning support 11 above the front side, the positioning ring 9 installed on the upper rear side of the positioning support 11 and positioning the detection end of the billet 1 to be detected, the dial indicator frame 10 located on the front side of the positioning support 11 and For the lever dial indicator 2 installed on the dial indicator frame 10, the front end of the billet 1 to be detected is the detection end and the center hole opened in the center is the center hole 3 to be detected. The bar blank 1 to be detected is arranged horizontally and parallel to the horizontal base 8 . The structure and size of the two support bearings 4 are the same and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com