A rolling formation based manufacture method for metal bipolar plate of proton exchange membrane fuel cell

A proton exchange membrane and metal bipolar plate technology, which is applied to fuel cell parts, battery electrodes, manufacturing tools, etc., can solve the problems of restricting the realization of mass production, extremely high processing accuracy requirements, and reduced processing efficiency. Achieve the effects of reducing manufacturing errors, precision forming, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

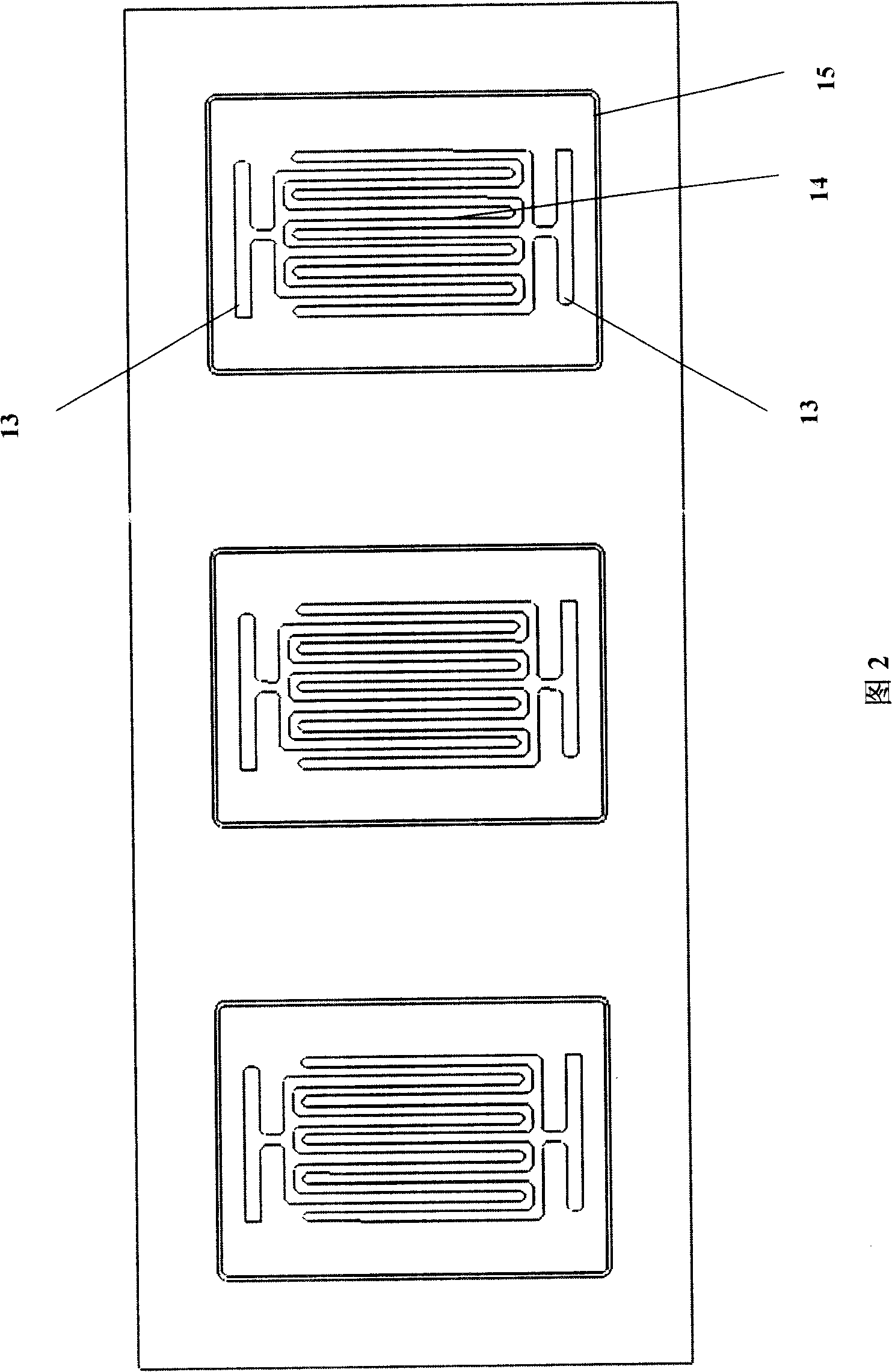

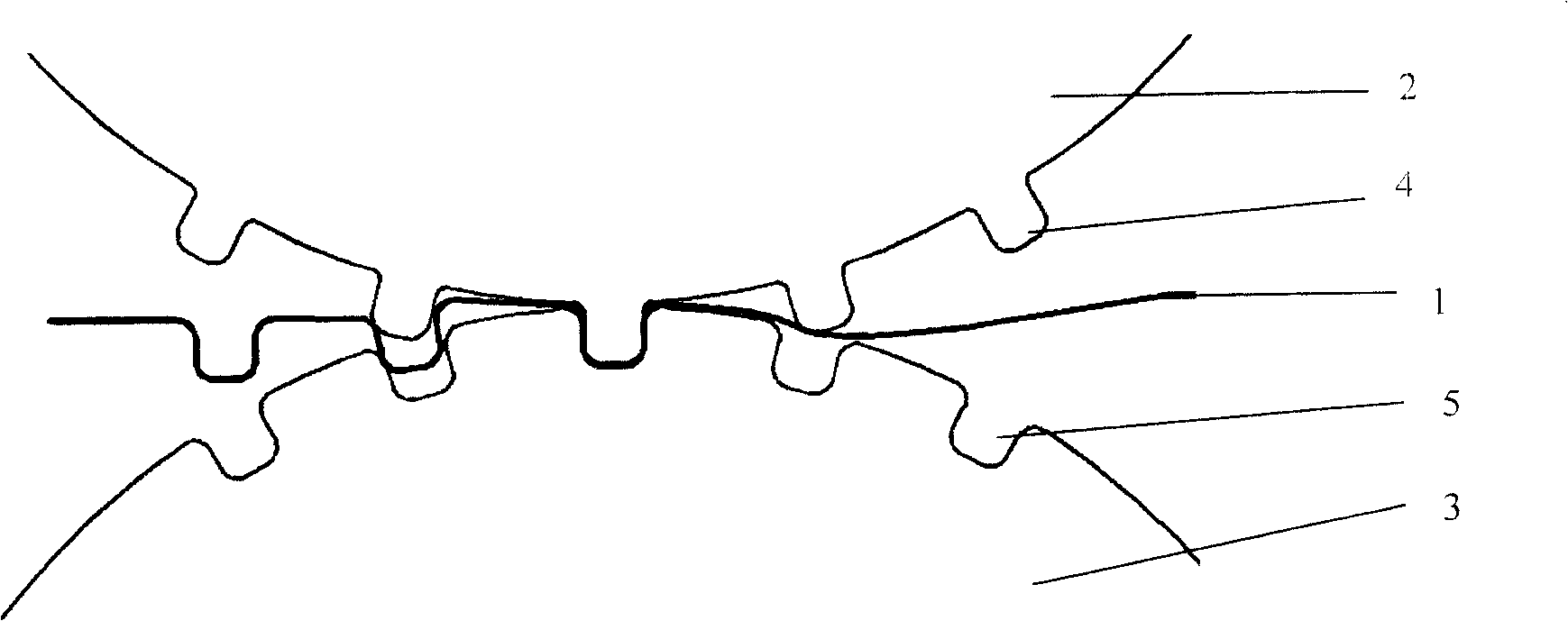

[0024] In this embodiment, in order to adapt to the structural characteristics of the roller mold and reduce the difficulty of mold processing, an interdigitated bipolar plate structure is adopted. The plate material used is 0.1mm 316 stainless steel sheet. The width of the reaction gas flow field of the plate is designed to be 1 mm, the depth is 0.8 mm, the channel spacing (boss) is 1 mm, and the gas channels are designed to be 2 mm wide and 0.8 mm deep. The air inlet and outlet are designed as square holes of 20mm×20mm, and the inlet and outlet of coolant are both square holes of 10mm×10mm. Around the reaction gas flow field area, a sealing groove with a width and a depth of 0.5 mm is designed. The two unipolar plates are completely symmetrical in design and have the same structural configuration.

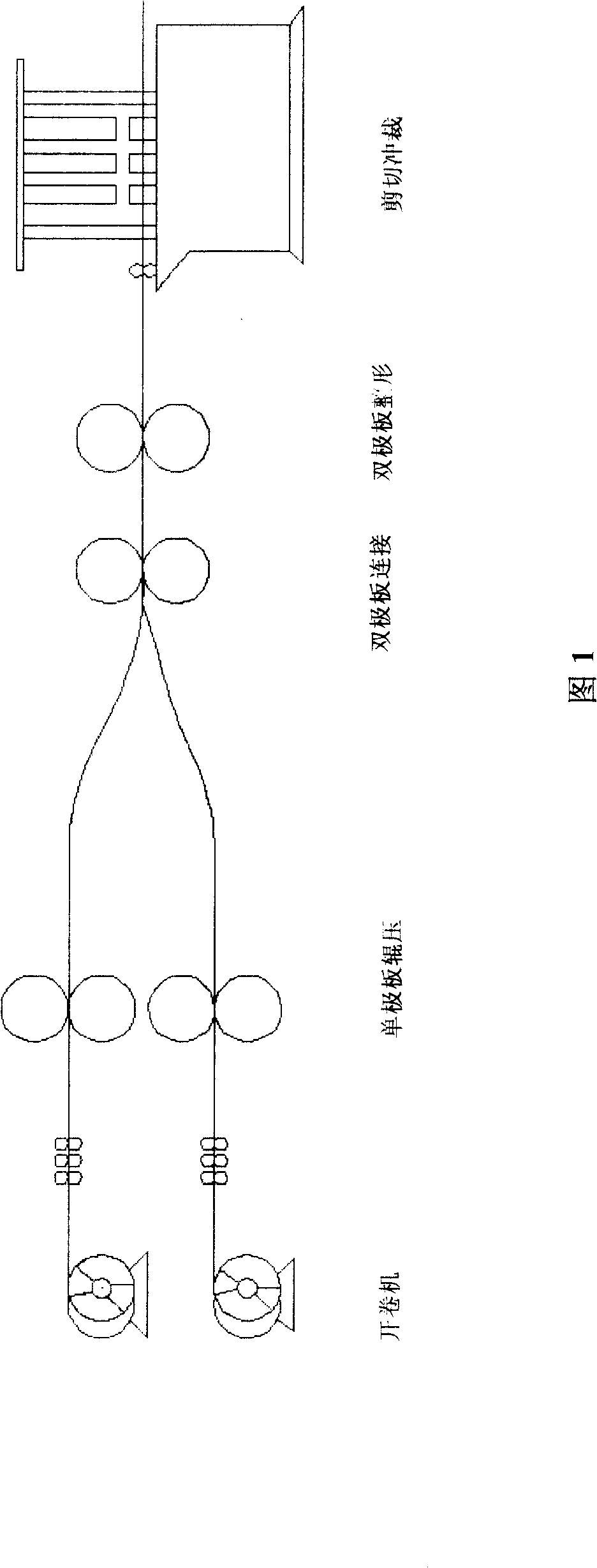

[0025]According to the structure configuration of the pole plate, the roller pairs of each process are generated through mapping processing, including the roller pair of unipol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com