Methods for installing and welding three-facet rubber tiles on liquidized natural gas ship

A technology of liquefied natural gas and trihedron, which is applied in the direction of assembly machines, auxiliary devices, welding equipment, etc., can solve the problems of large differences in operators, and achieve the effect of saving cost and time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific examples, but the protection scope of the present invention should not be limited thereby.

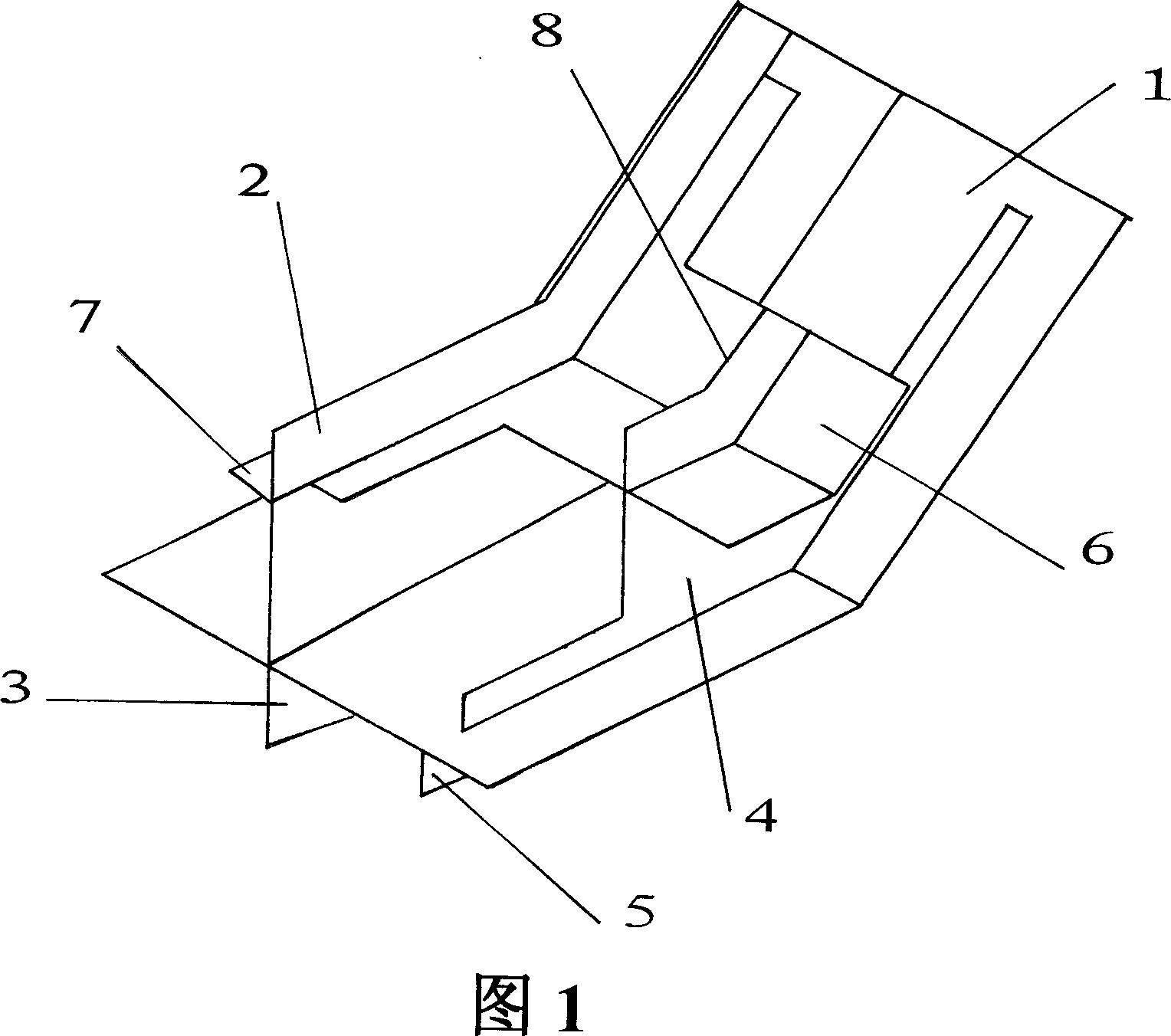

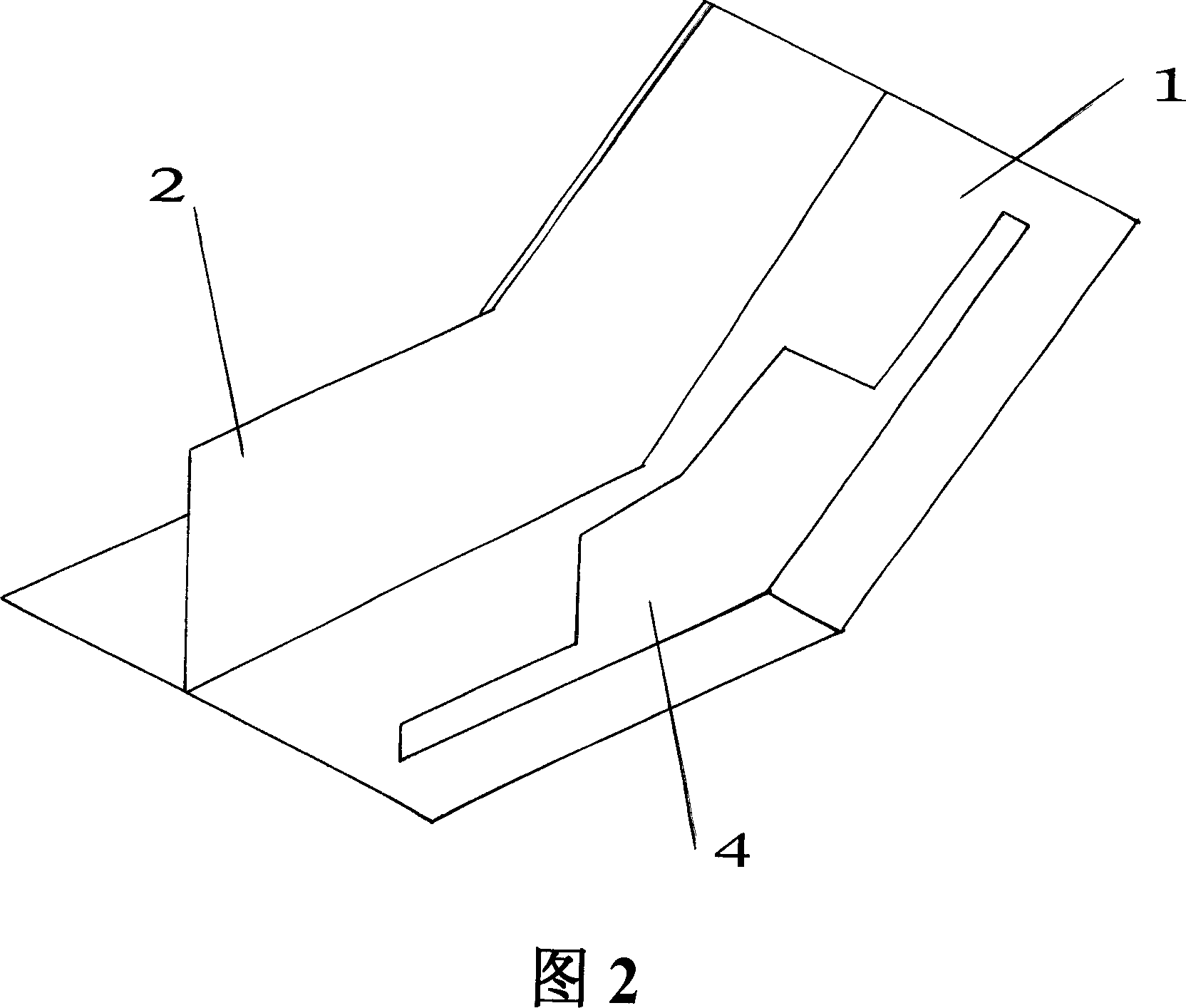

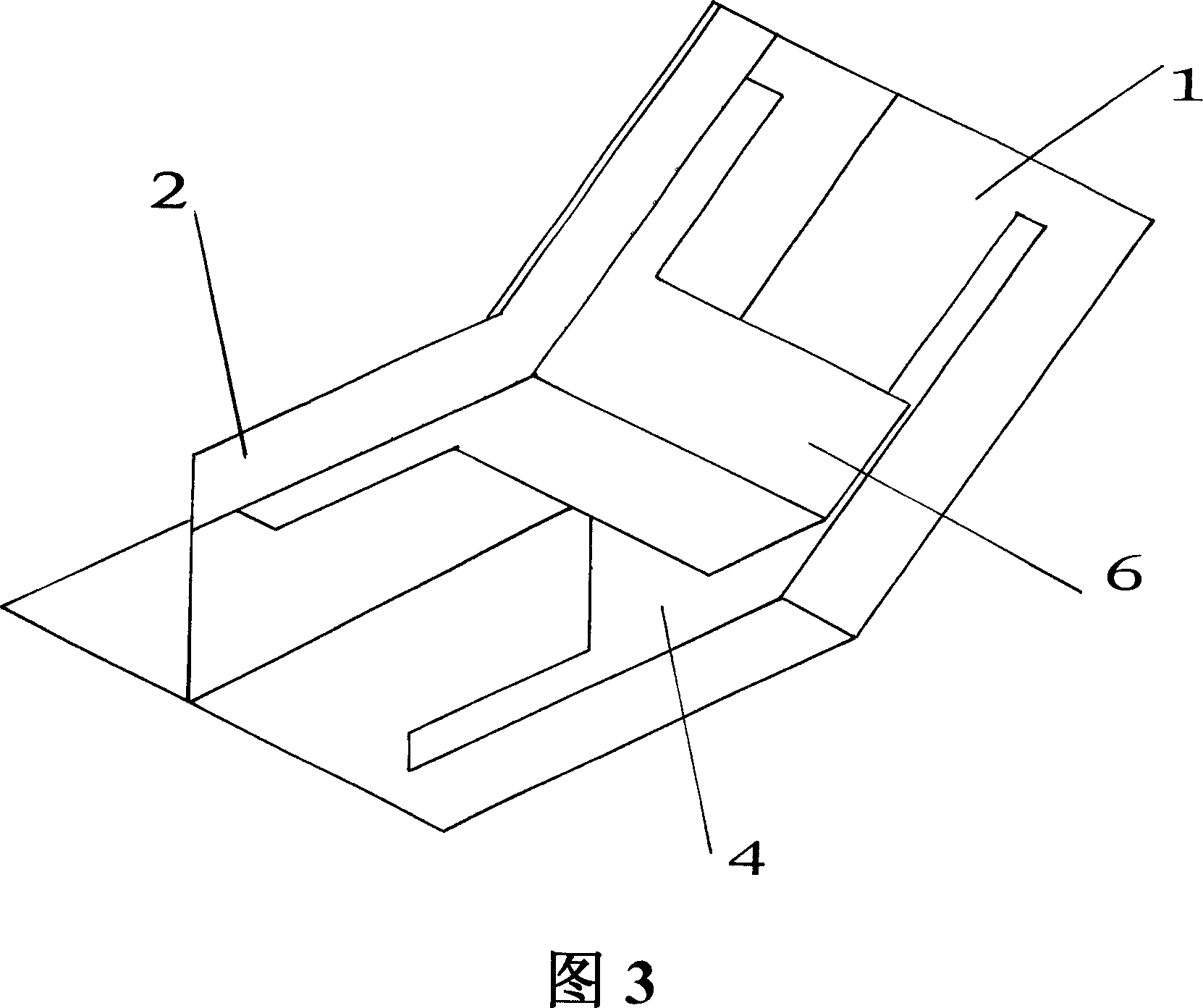

[0042] The Invar trihedron is composed of eight designed and manufactured component plates, and the eight scattered component plates are assembled and welded into a complete Invar trihedron. The method of the present invention includes the assembly method of the Invar trihedron and the Invar trihedron welding method, the assembly method of the Invar trihedron is to form the Invar trihedron plate No. 1, No. 2, No. 3, No. 4, No. 5, No. 6 The method of assembling the plate 6, the seventh plate 7 and the eighth plate 8 into an Invar trihedron by using the internal support plate and the angle support plate;

[0043] The described Invar trihedral assembling method comprises the steps:

[0044] ①According to the drawings, on the first plate 1, the second plate 2, the third plate 3, the fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com