Two-constituent optical compensation zoom lens

A technology of optical compensation and zoom lens, applied in the direction of optics, optical components, diffraction grating, etc., can solve the problems that the stability of optical components and mechanical components affects the qualified rate of assembly products, affects the assembly efficiency of operators, and increases manpower and material resources. , to achieve the effect of improving optical stability, efficiency, and image quality pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the patented technology will be described below in conjunction with the accompanying drawings. It should be noted that the purpose of the accompanying drawings is only to facilitate the description of specific embodiments of the patented technology, and is not a redundant description or a limitation on the scope of the patented technology.

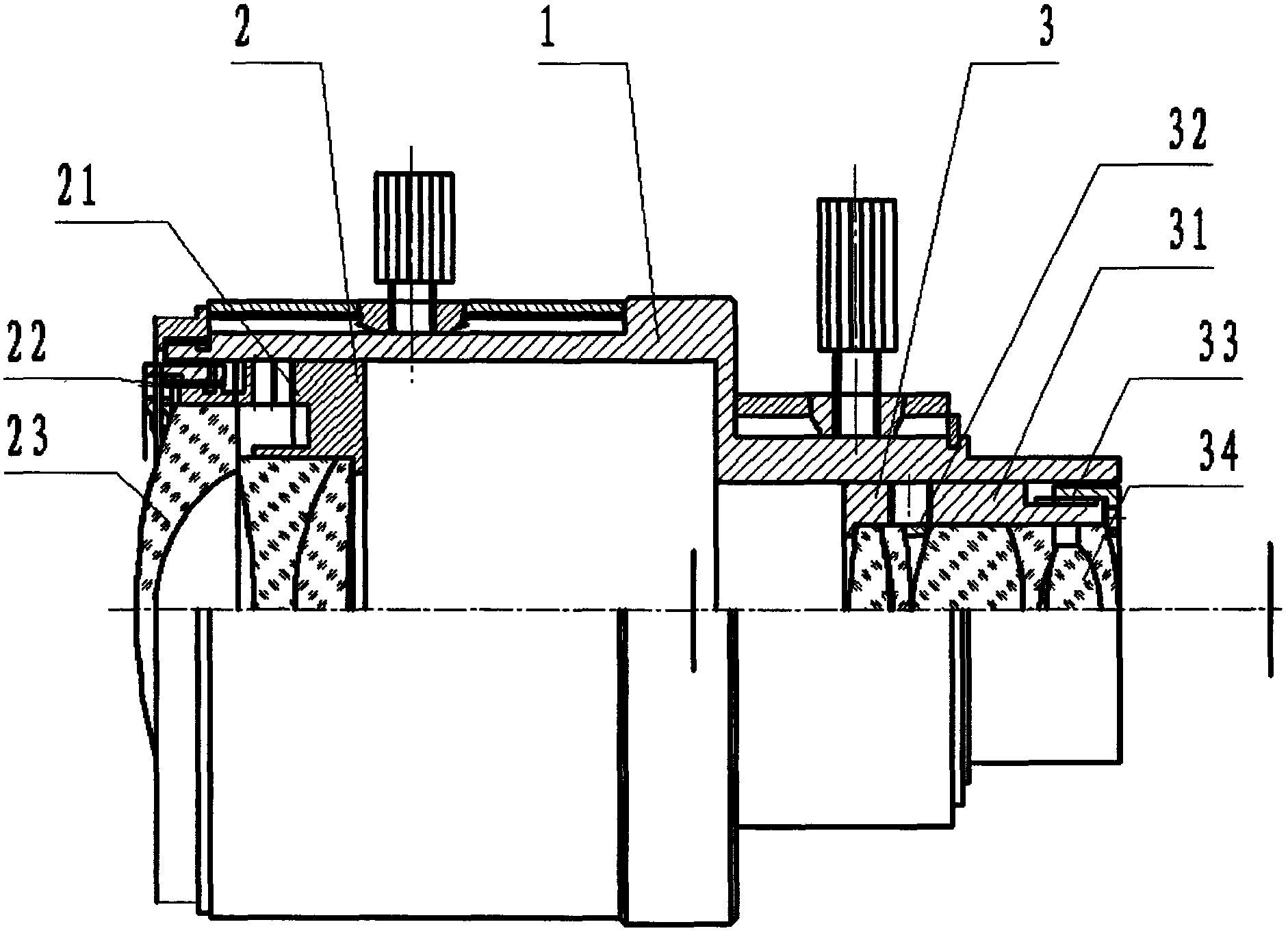

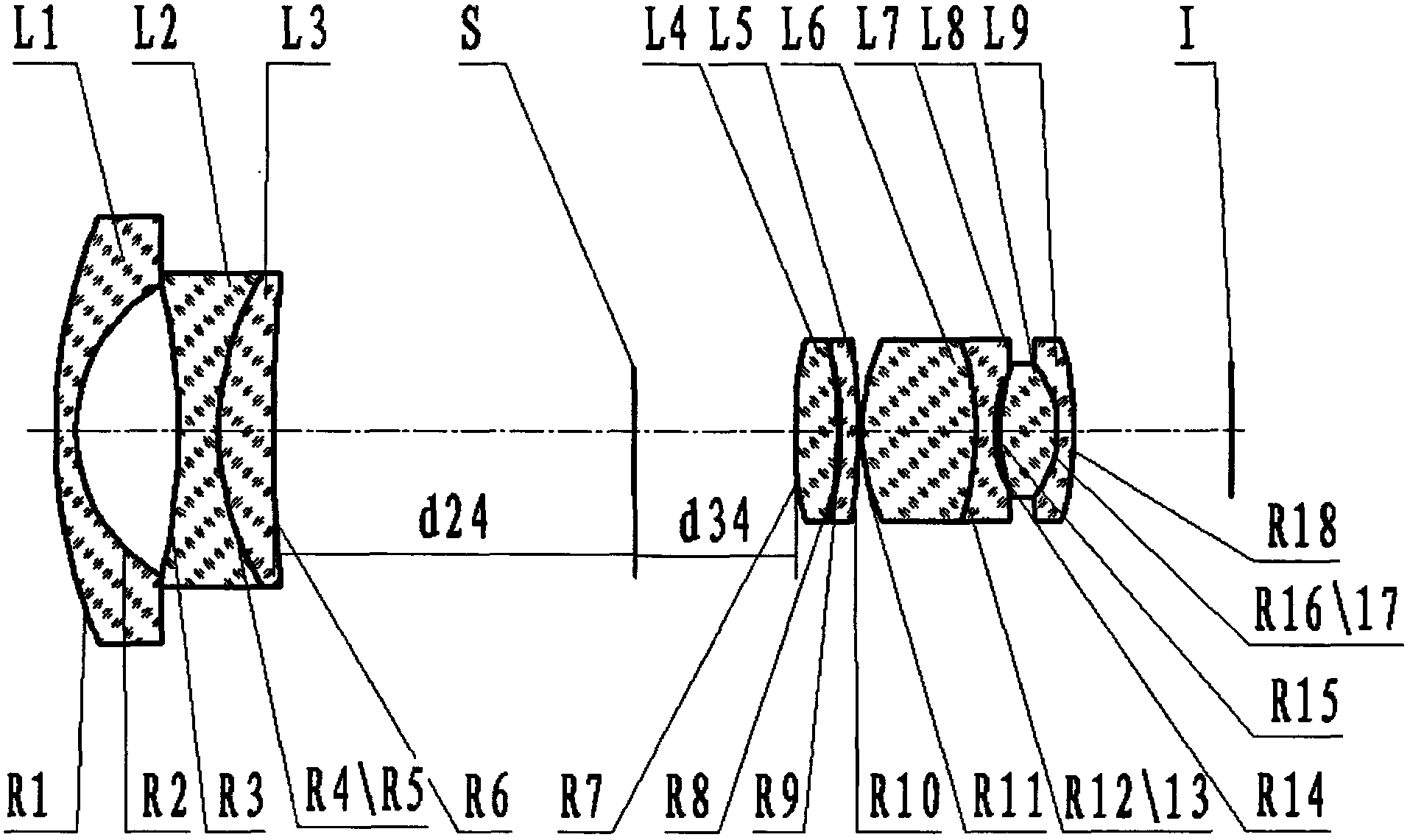

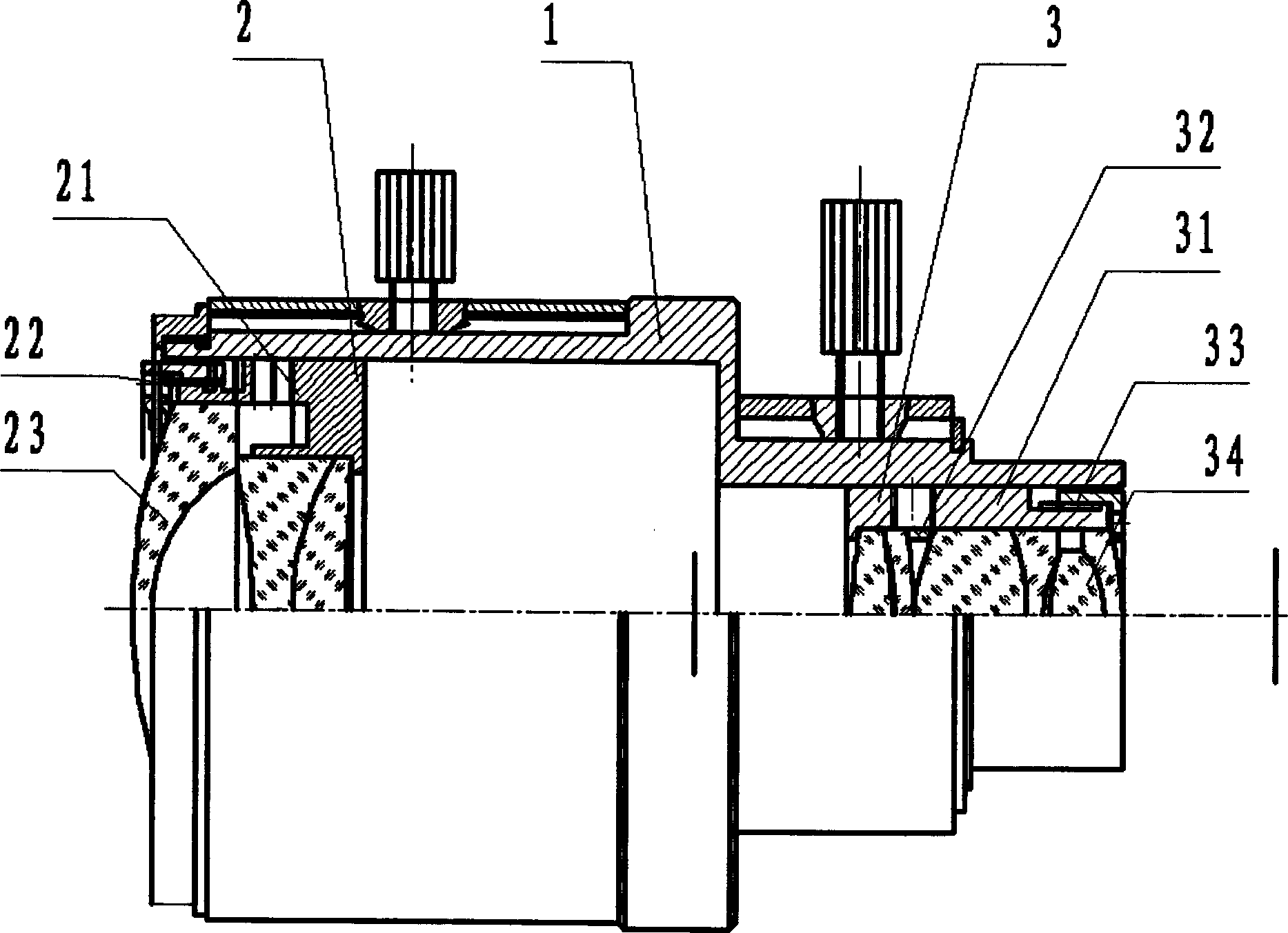

[0014] as attached figure 1 As shown, the two-element optical compensation zoom lens of the patented technology includes a main barrel assembly 1 , a front assembly 2 , and a rear assembly 3 . The front assembly 2 includes a front group lens barrel 21 , a front group pressure ring 22 and a compensation lens group 23 . The rear assembly 3 includes a rear group lens barrel 31 , a spacer ring 32 , a rear group pressure ring 33 and a zoom lens group 34 . The compensation lens group 24 and the zoom lens group 34 are provided with nine lenses in total, including at least three cemented lenses. The front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com