Backpack type electric airflow picking machine for cotton fruits and method for same

A knapsack and picking machine technology, which is applied in the direction of picking machines, agricultural machinery and implements, harvesters, etc., can solve the problems of farmers' income loss, cotton grade reduction, and mu yield reduction, etc., to achieve light weight, high cotton grade, compact design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

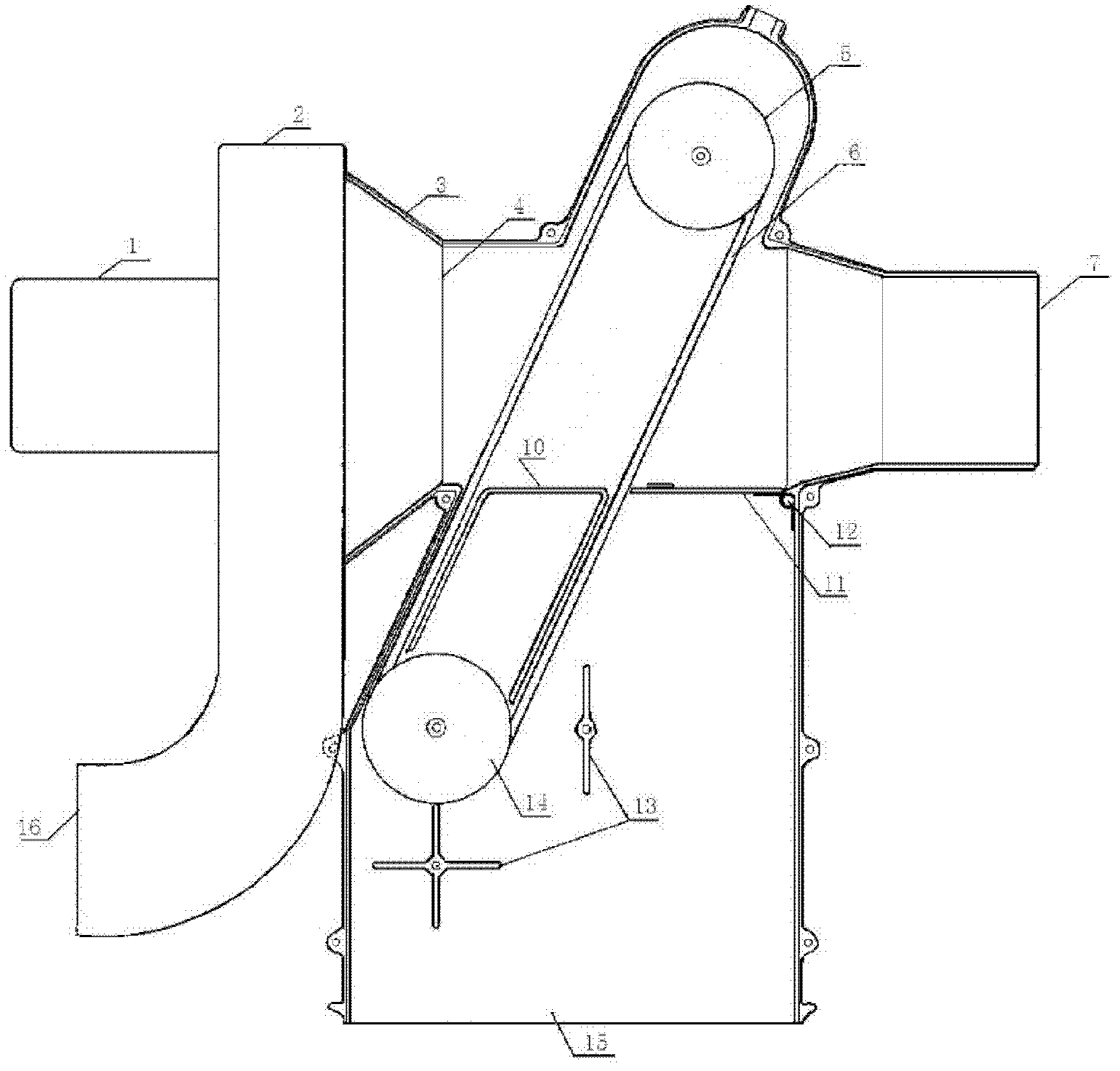

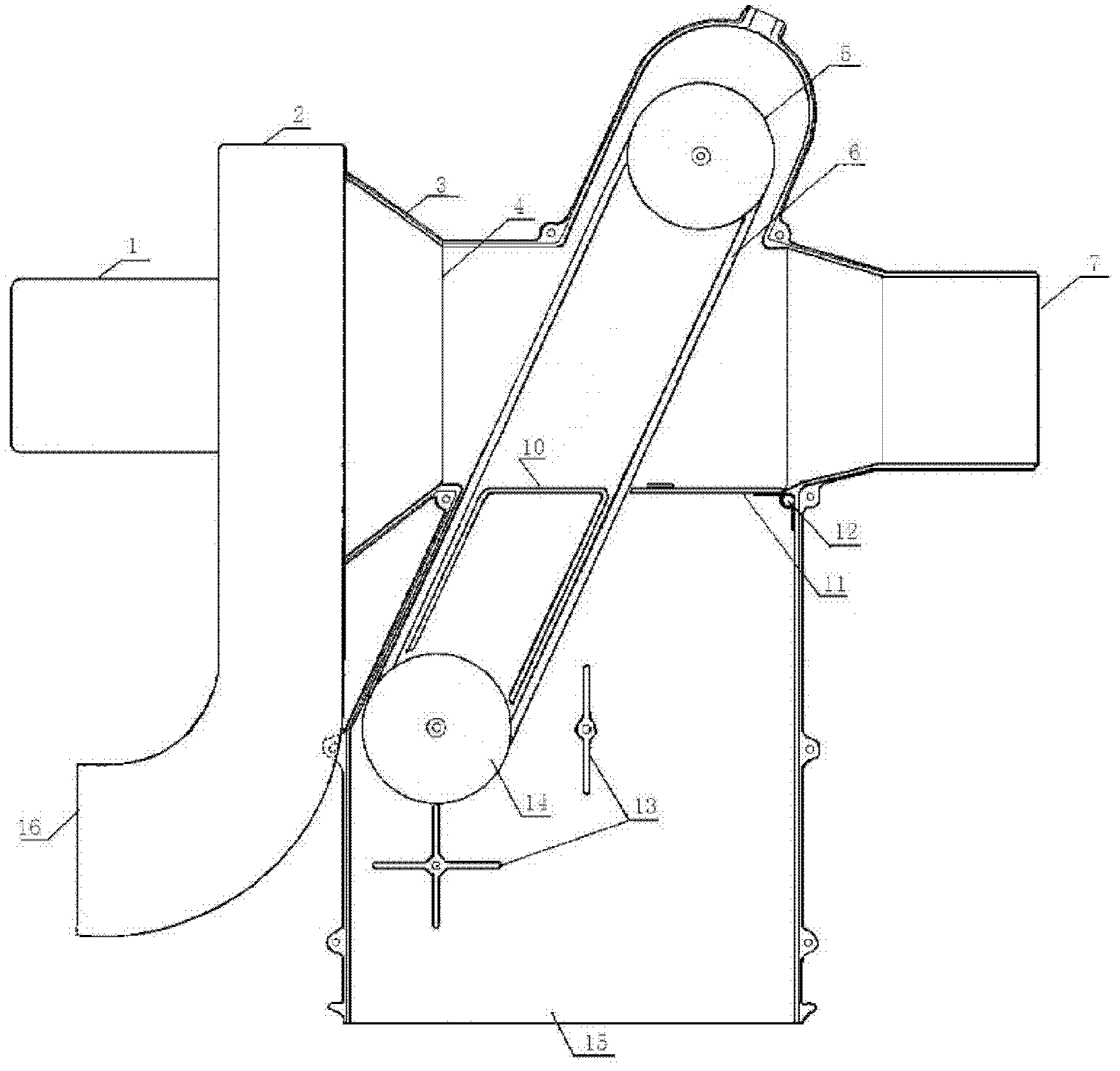

[0015] The present invention will be further described in conjunction with the accompanying drawings. The present invention can manufacture the equipment of the present invention through injection molding process and assembly, and the injection molded parts can be distributed by all processing units without workshop and equipment. is very clear.

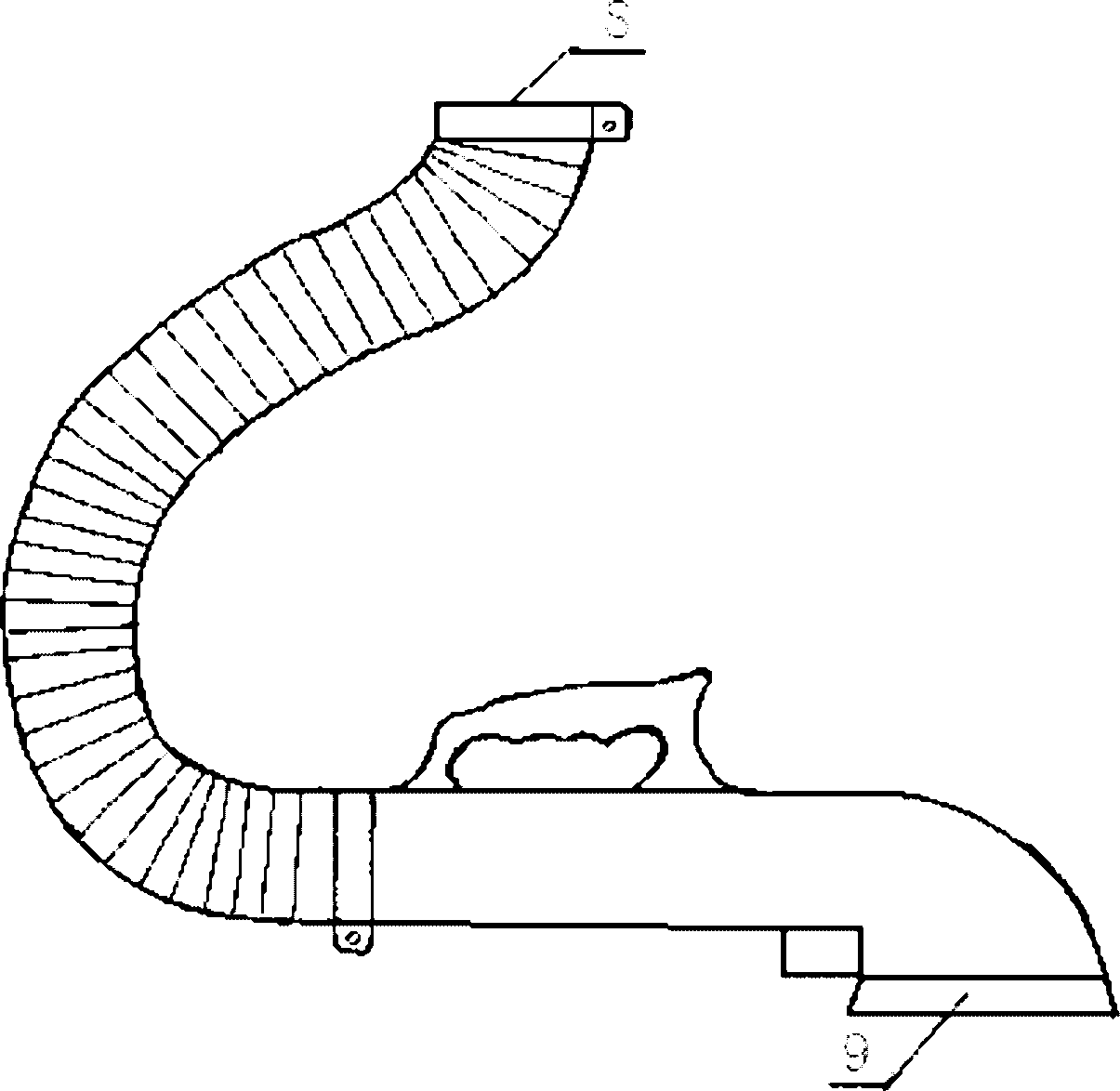

[0016] Such as figure 1 , figure 2 Shown, the present invention comprises the structure that comprises DC motor structure, rectifier blower structure, cotton puller and the drive wheel that can drive chain-belt filter screen device to rotate, the structure of chain-belt filter screen, the adjusting wheel that drive wheel rotates, its It is characterized in that the said knapsack-type electric airflow cotton fruit picking machine consists of a complete machine shell and a DC motor arranged in the complete machine shell, a rectifier fan, a chain-belt filter device, an up and down cotton pulling wheel, an inverted U-shaped windshield,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com