Axial precompression method for combined ball hinged rubber elastic element and product obtained thereby

An elastic element and pre-compression technology, applied in the direction of elastic shock absorbers, bogies, railway couplings, etc., can solve the problems of uneven stress and high concentricity, and achieve uniform thickness, large axial stiffness, and smooth design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

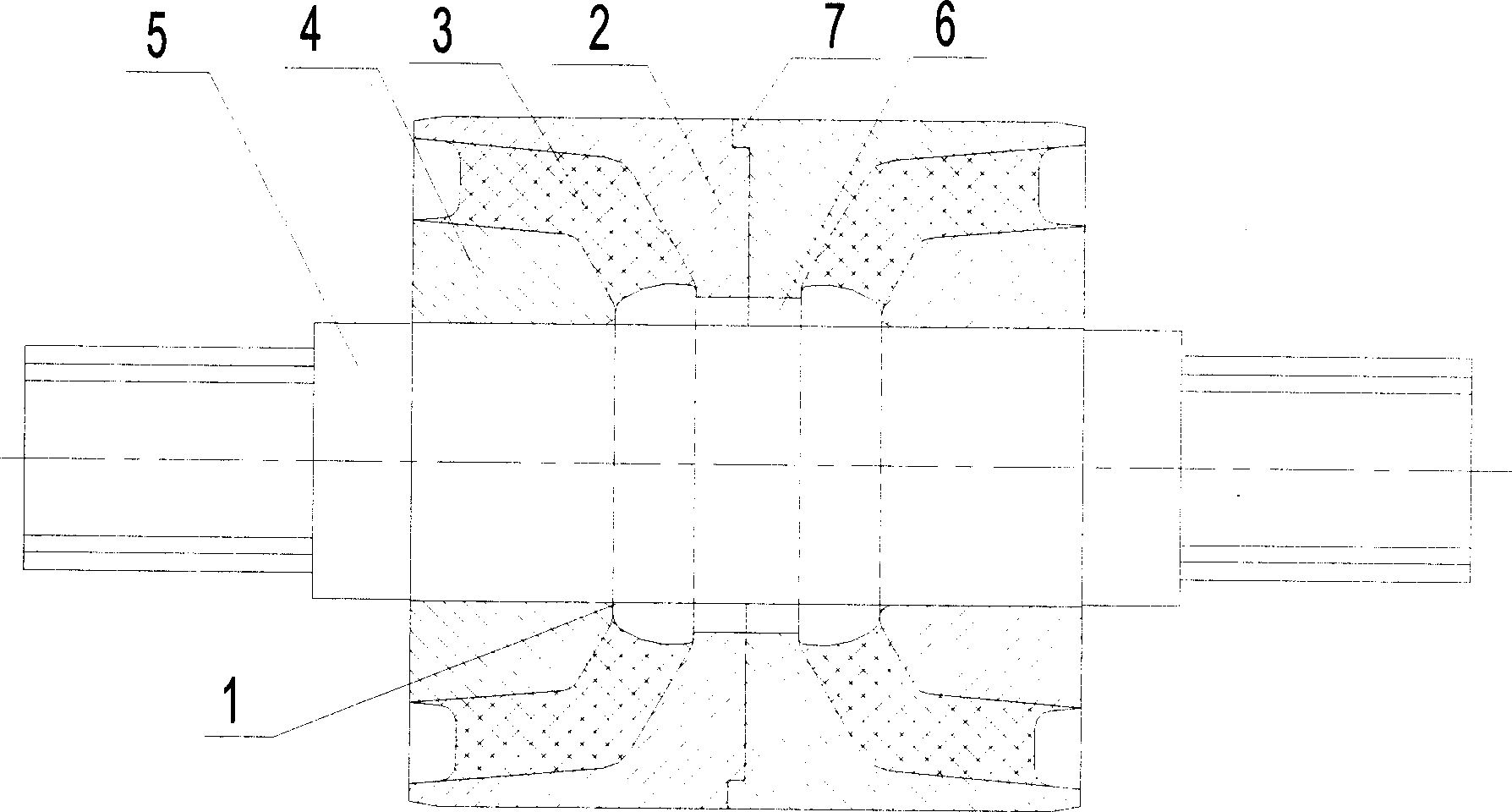

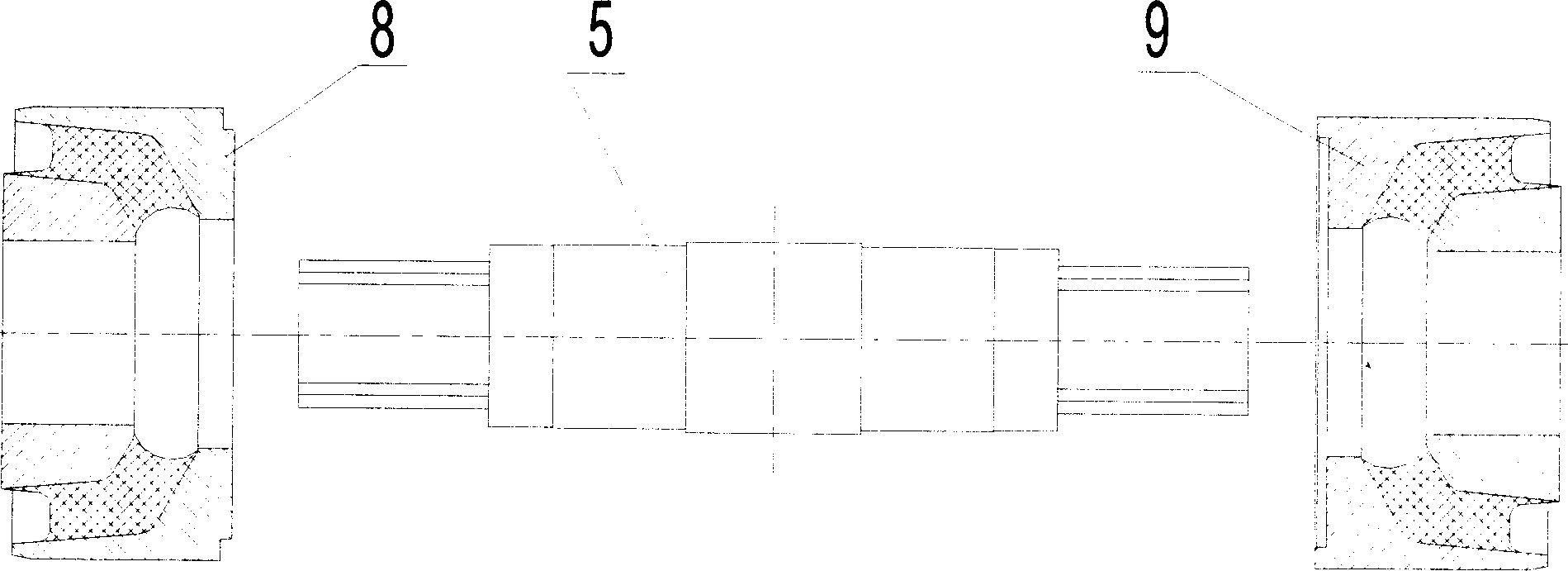

[0015] It can be seen from the drawings that the spherical hinge rubber elastic element 1 includes a metal outer casing 2, an elastic rubber body 3, a metal inner casing 4 and a mandrel 5, and the elastic rubber body 3 is located between the metal outer casing 2 and the metal inner casing 4, And the outer surface of the elastic rubber body 3 is bonded to the metal outer casing 2, the inner surface of the elastic rubber body 3 is bonded to the metal inner casing 4, and the metal inner casing 4 is tightly sleeved on the mandrel 5 through an interference fit. It is characterized in that the pre-compression stress of the elastic rubber body 3 of the ball-hinge rubber elastic element 1 is provided by an axial compression, and the metal jacket 2, the elastic rubber body 3, and the metal The inner sleeve 4 is a two-stage combined structure independent of each other. First, the metal inner sleeve 4, the metal outer sleeve 2 and the elastic rubber body 3 are vulcanized as a whole to for...

Embodiment 2

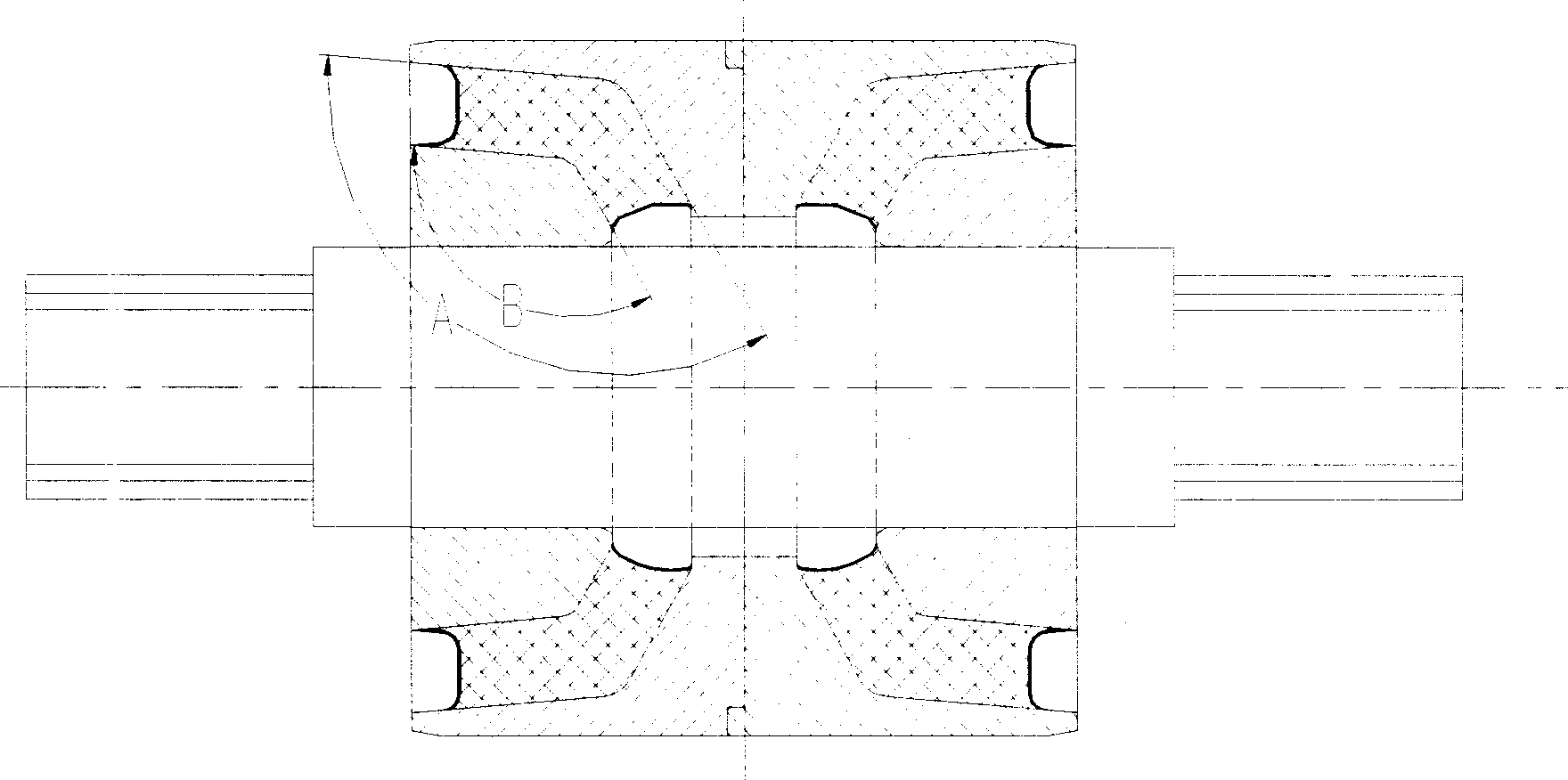

[0017] The structure of the second embodiment is the same as that of the first embodiment, except that each section of the elastic rubber body can be a non-axial linear curved arc shape or a bent shape, and the arc angle or bending angle A or B of the arc is 160° , The ratio of the diameter to the shaft stiffness of the ball joint type rubber elastic element can reach about 5:1. In this way, relatively high radial stiffness can be obtained.

Embodiment 3

[0019] The structure of the third embodiment is the same as that of the first embodiment, except that each section of the elastic rubber body can be a non-axial linear curved arc shape or a bent shape, and the arc angle or bending angle A or B of the arc is 120° , The diameter-to-axis stiffness ratio of the ball joint type rubber elastic element can reach about 3:1. In this way, a relatively uniform radial and axial stiffness can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com