Water surface aircraft seakeeping test constant force unloading device and method

An unloading device and seakeeping technology, applied in the direction of aircraft component testing, etc., can solve the problems of inability to achieve constant force unloading to meet the seakeeping test, long initial rope length of elastic rope, small elastic coefficient of elastic rope, etc., and achieve great long-term significance. and value, promote development, and solve the effect of technical difficulties in research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

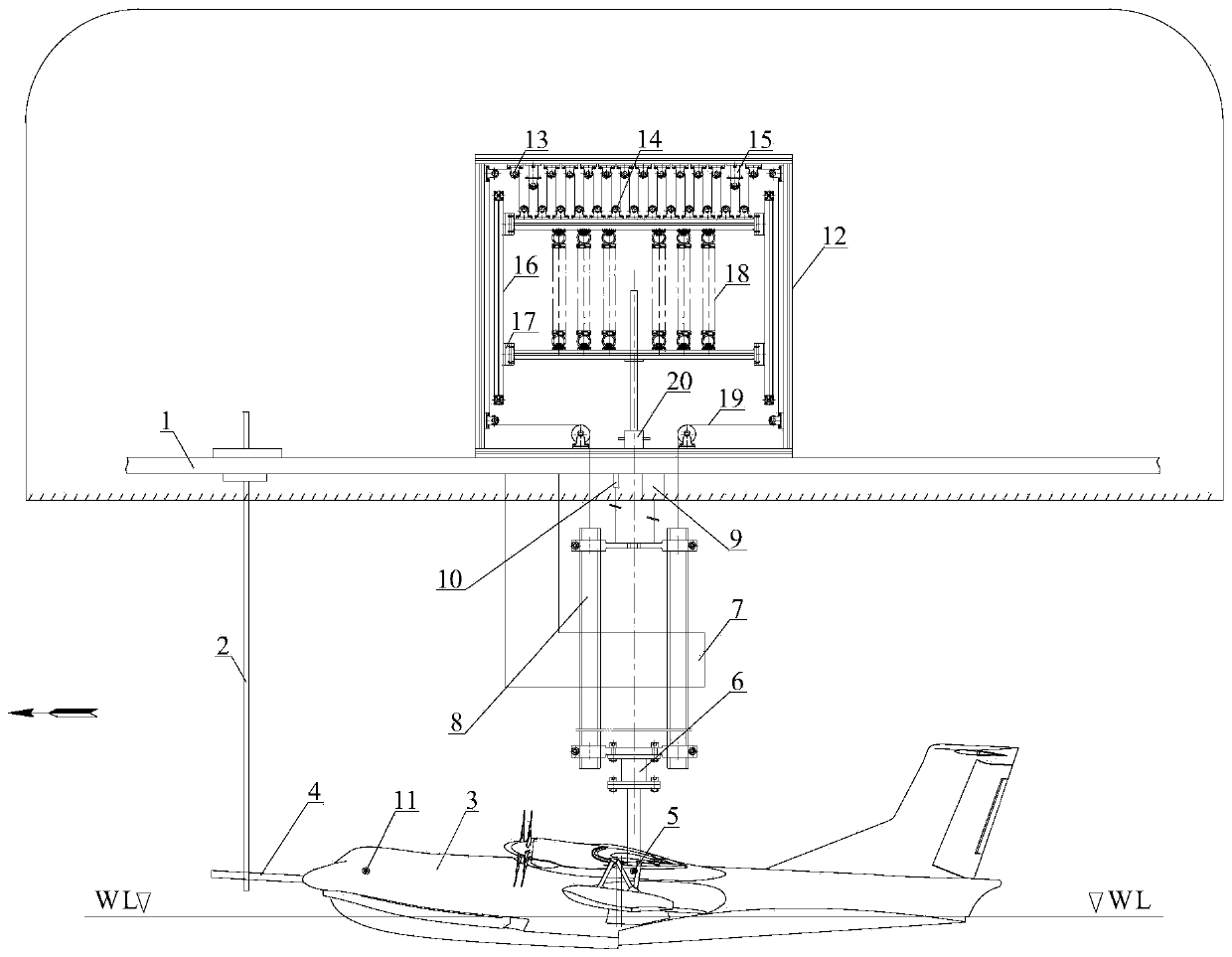

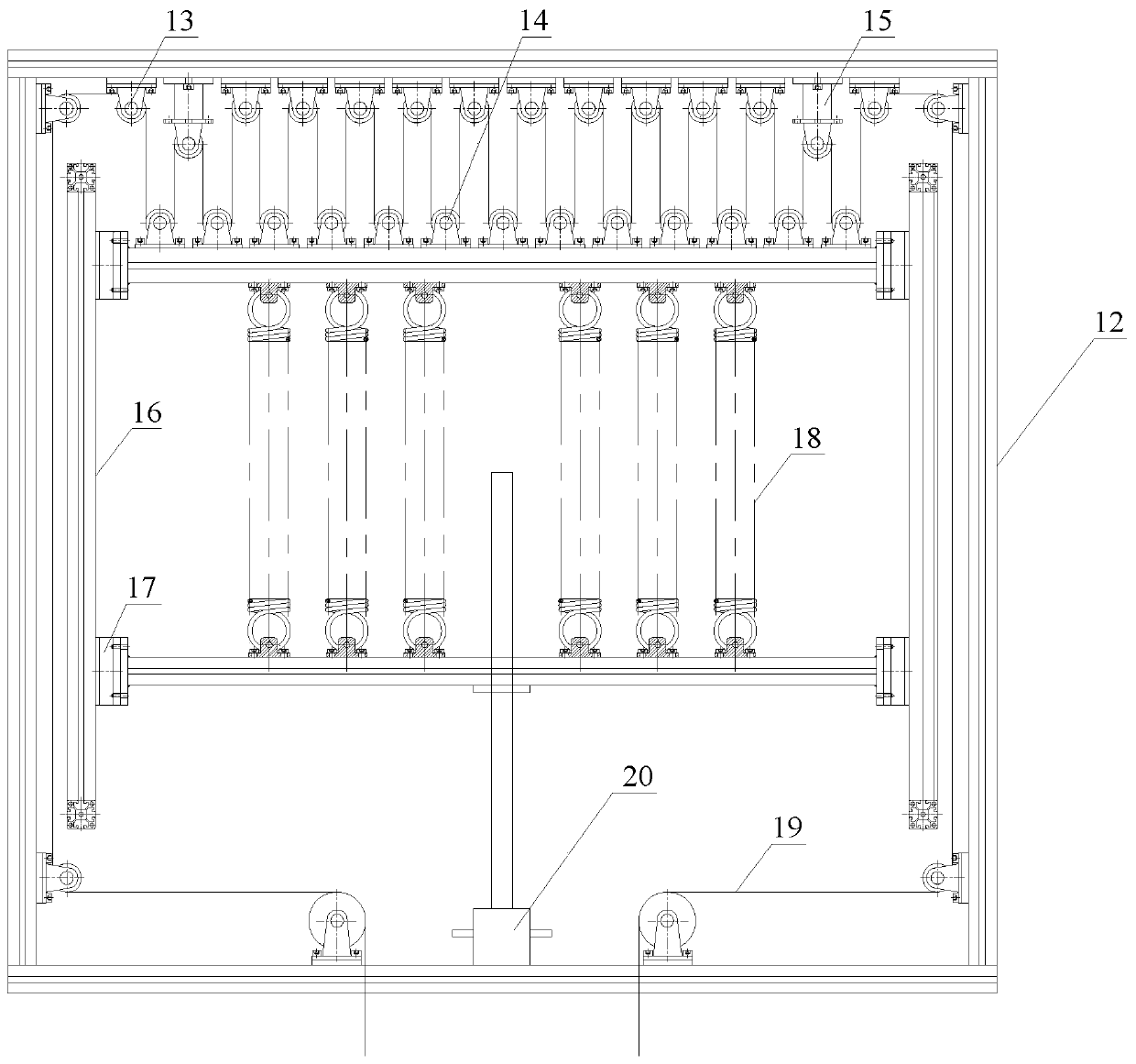

[0041] Such as figure 1 , figure 2 As shown, a constant force unloading device for water surface aircraft seakeeping test, including trailer measuring bridge 1, navigation rod 2, model 3, navigation piece 4, angle sensor 5, resistance sensor 6, limit guide rail 7, heave bar 8 , remote control electric hoist 9, displacement sensor 10, overload sensor 11, fixed frame 12, fixed pulley 13, movable pulley 14, tension sensor 15, linear slide rail 16, slider 17, spring 18, Kevlar rope 19 and rocker 20 .

[0042]The limit guide rail 7 is fixed on the trailer measuring bridge 1, and the heave rod 8 passes through the limit guide rail 7 and then is limited up and down, so that the heave rod 8 has a sufficient stroke along the limit guide rail 7 to meet the requirements of the heave motion of the model 3; The resistance sensor 6 is fixed on the lower end of the heave rod 8, and the fixed rocker at the lower end of the resistance sensor 6 is hinged to the center of gravity correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com