Guide rail spline oriented drilling tool

A technology of directional drilling and guide rail, which is applied in directional drilling and other directions, can solve the problems of reducing travel pin wear, force deformation, uneven force, etc., and achieve the effect of reducing travel pin wear and force deformation, intuitive state, and large power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

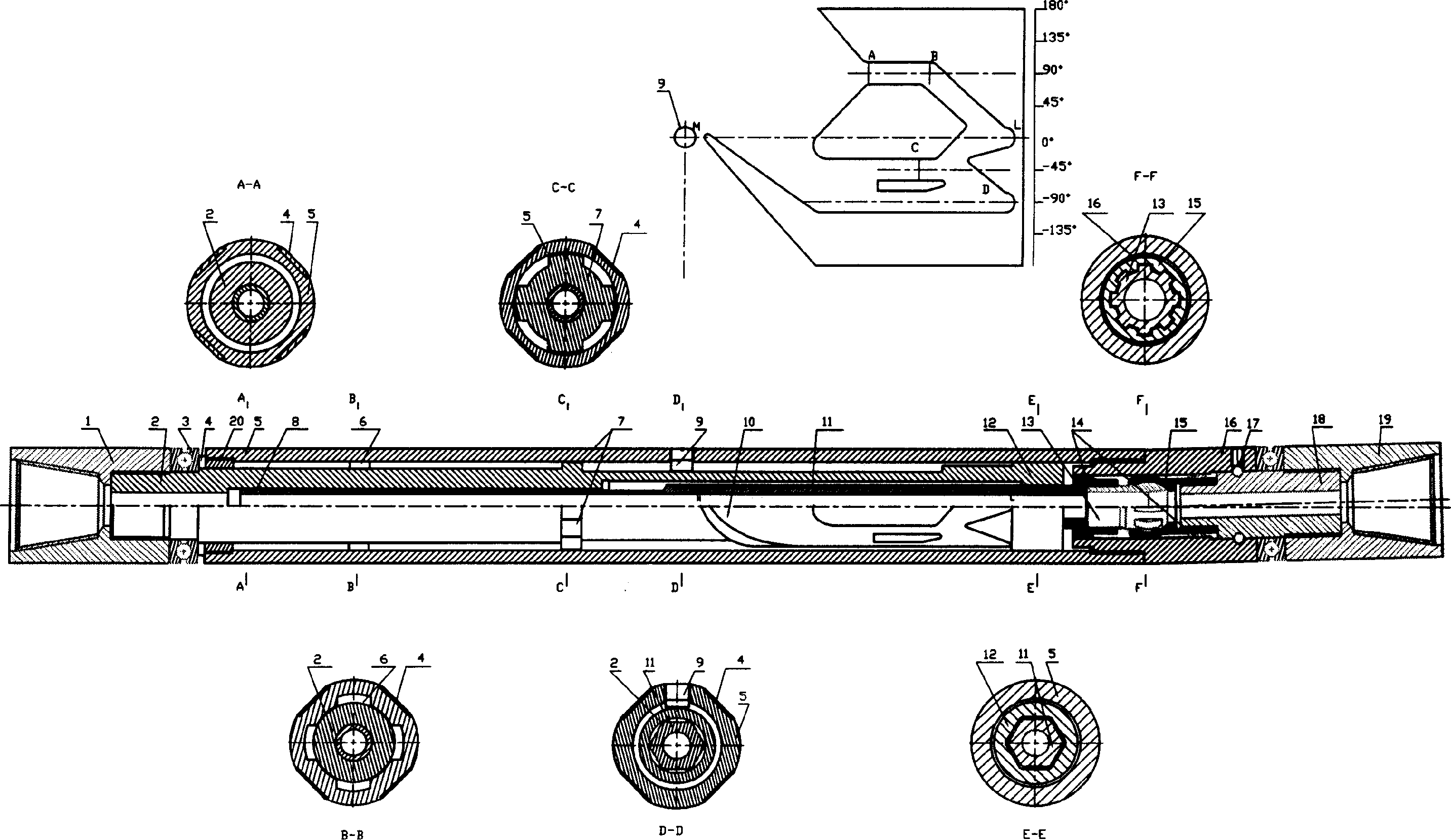

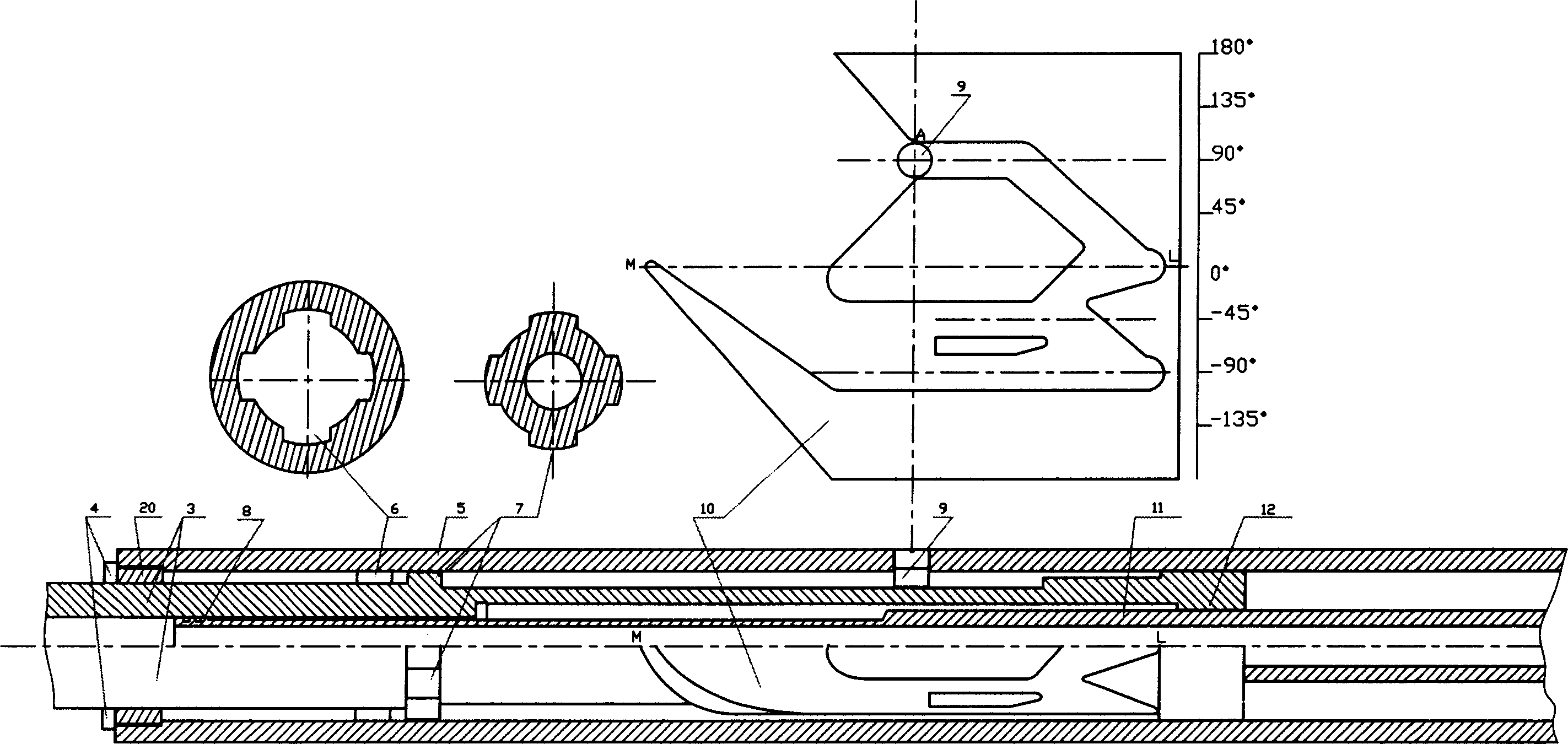

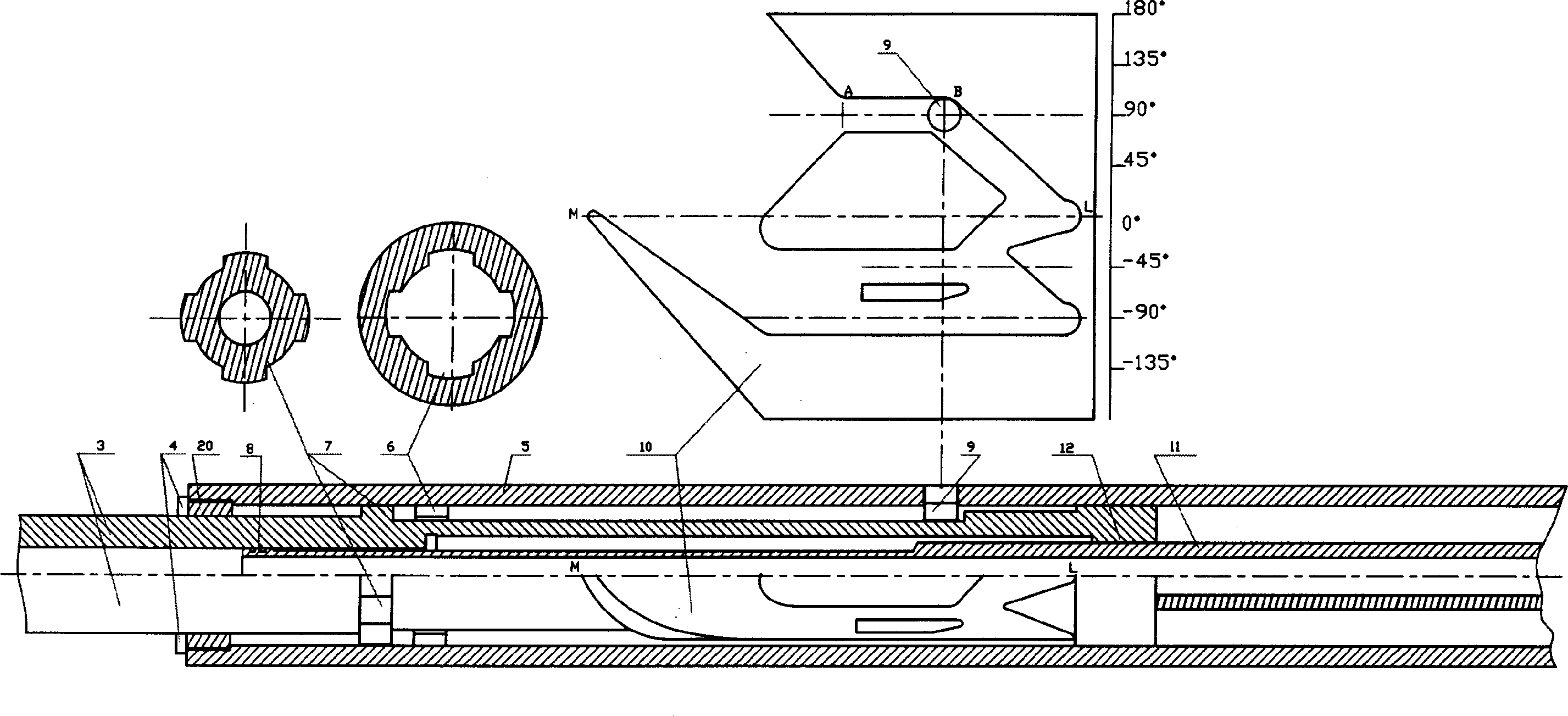

[0022] Working principle of the present invention and embodiment can refer to accompanying drawing: Figure 1 to Figure 6 In the figure, the upper middle is the expanded view of the travel pin guide rail, and the scale on the right side of the expanded view indicates the angle value on the corresponding circle. In the figure, 1 is the upper joint, 2 is the driving shaft, 3 is the thrust bearing, 4 is the spring leaf, 5 is the shell, 6 is the inner spline, 7 is the outer spline, 8 is the floating seal, 9 is the free pin, 10 is a guide rail, 11 is a driven shaft, 12 is an inner hexagon, 13 is an inner ball key, 14 is a sealing ring, 15 is an outer ball key, 16 is a skewer, 17 is a limit bearing, 18 is a connector, 19 is Drill joint, 20 is a sealing assembly, 21 is a flute, and 22 is a welding port.

[0023] figure 2 It is the positional relationship of each component when the floating pin of the drilling tool is lifted to point A.

[0024] image 3 It is the positional rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com