Dispenser for discharging liquid to pasty materials

A dispenser, slurry technology, applied in the field of storage bags, can solve the problems of material vibration pressure, product overflow, impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

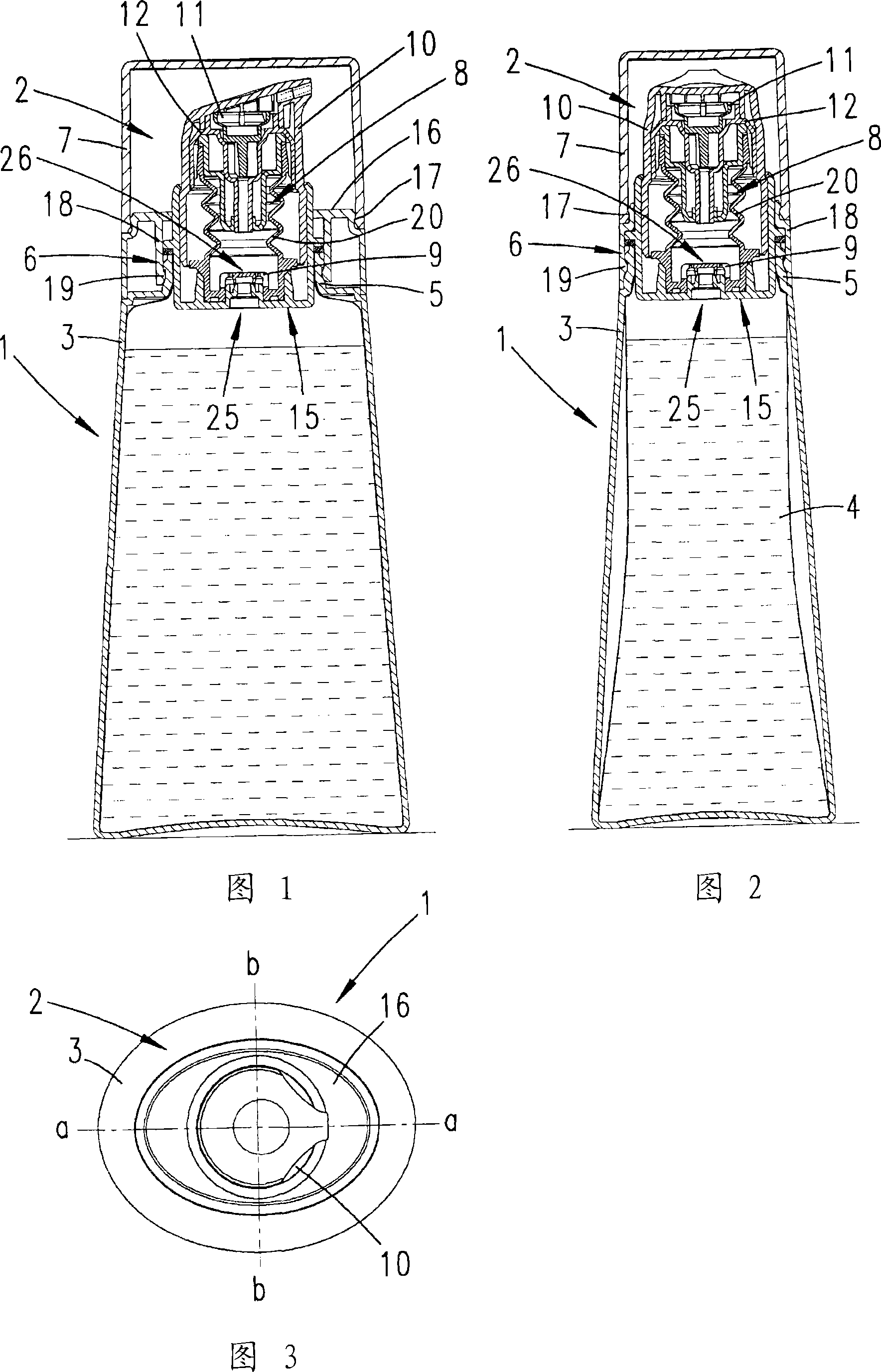

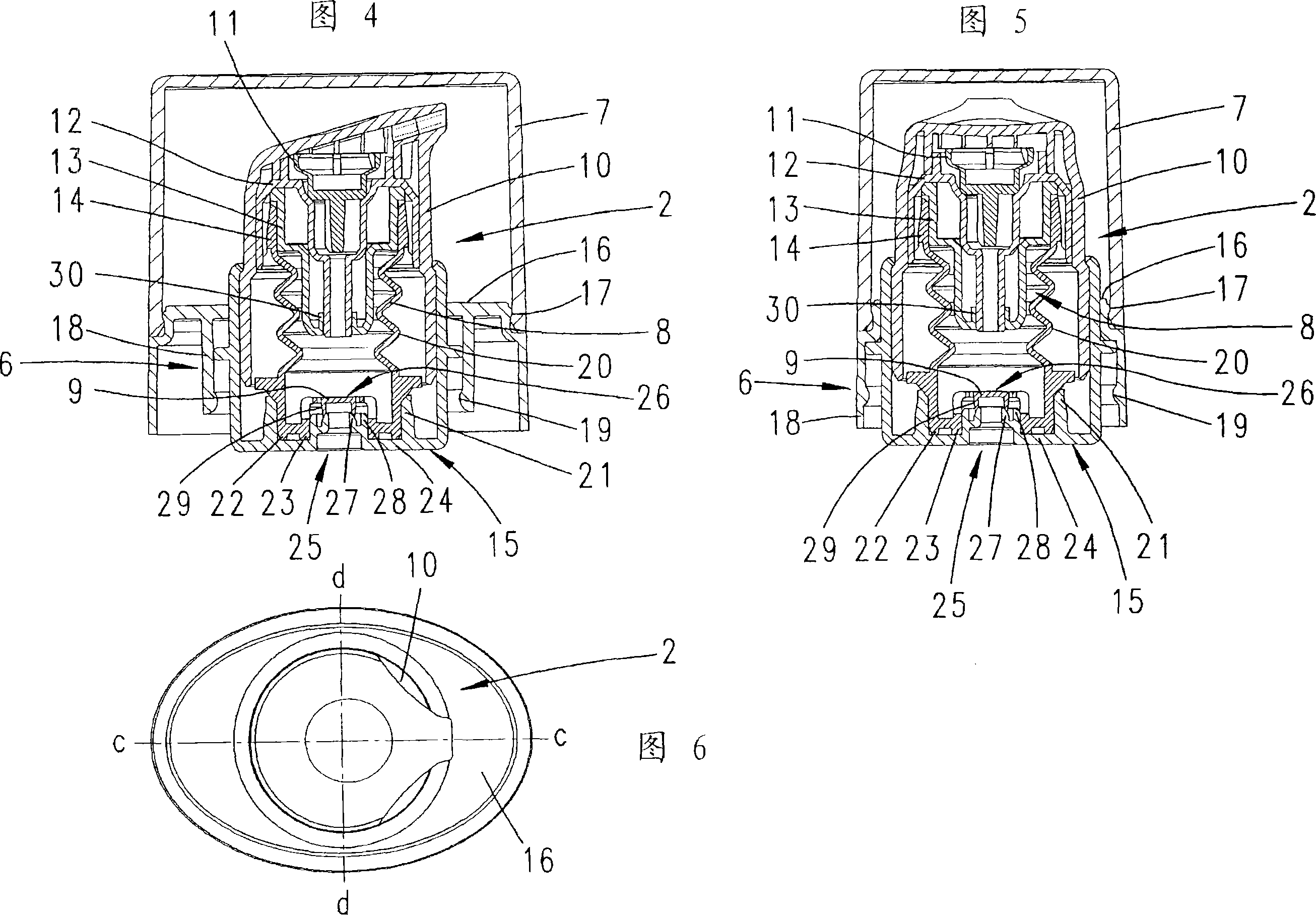

[0020] A dispenser 1 consisting of a pump head 2 and a storage container 3 is firstly illustrated and described with reference to FIGS. 1 and 2 . Inside the storage container 3 is basically loosely placed an inner bag 4 containing the material to be dispensed. The inner bag 4 can be connected to the base in the area of the base of the storage container 3 either in points or in lines to prevent the inner bag from rolling over.

[0021] Furthermore, the inner bag 4 is fastened to the storage container 3 in the neck region 5 of the storage container.

[0022] At the same time, it can be fixed by clamping the pump head 2. The pump head 2 is designed in a modular manner and can be introduced into the storage container 3 from above. According to FIGS. 1 and 2 , the connection between the storage container 3 and the pump head 2 can be realized via an adapter part 6 which, according to the circular configuration of the pump head 2, is made of telescopic sockets with different cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com