Oil strainer structure of engine and oil return structure of engine

a technology of oil strainer and engine, which is applied in the direction of pressure lubrication, lubricant mounting/connection, lubrication elements, etc., can solve the problems of significant limitation in flexibility in positioning difficult to secure a sufficient area of the strainer, and difficult to arrange the oil suction hole, etc. achieve the effect of reliably performing gas-liquid separation, high flexibility, and enhancing flexibility in position determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0046] the present invention will be described with reference to FIGS. 1 to 9.

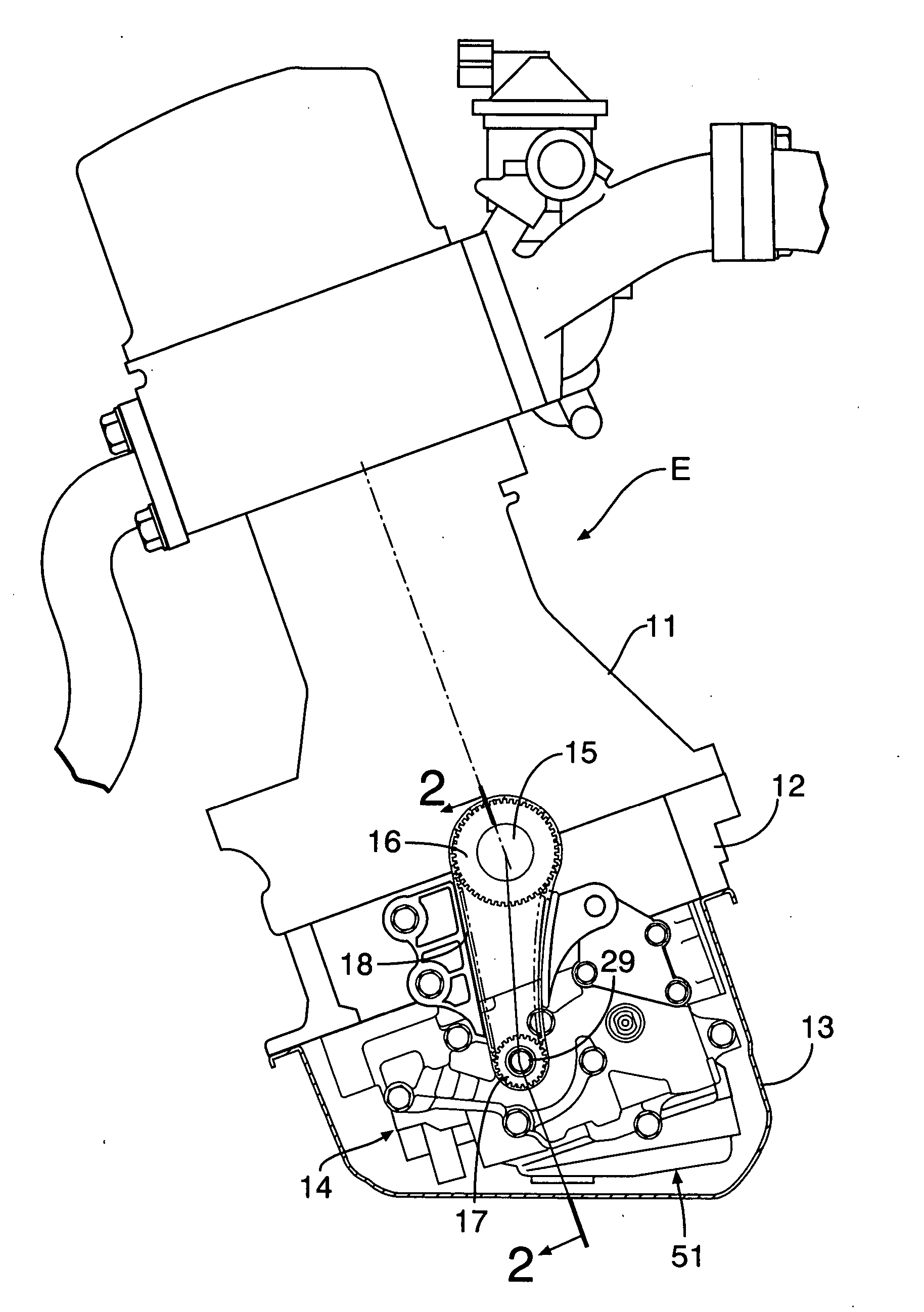

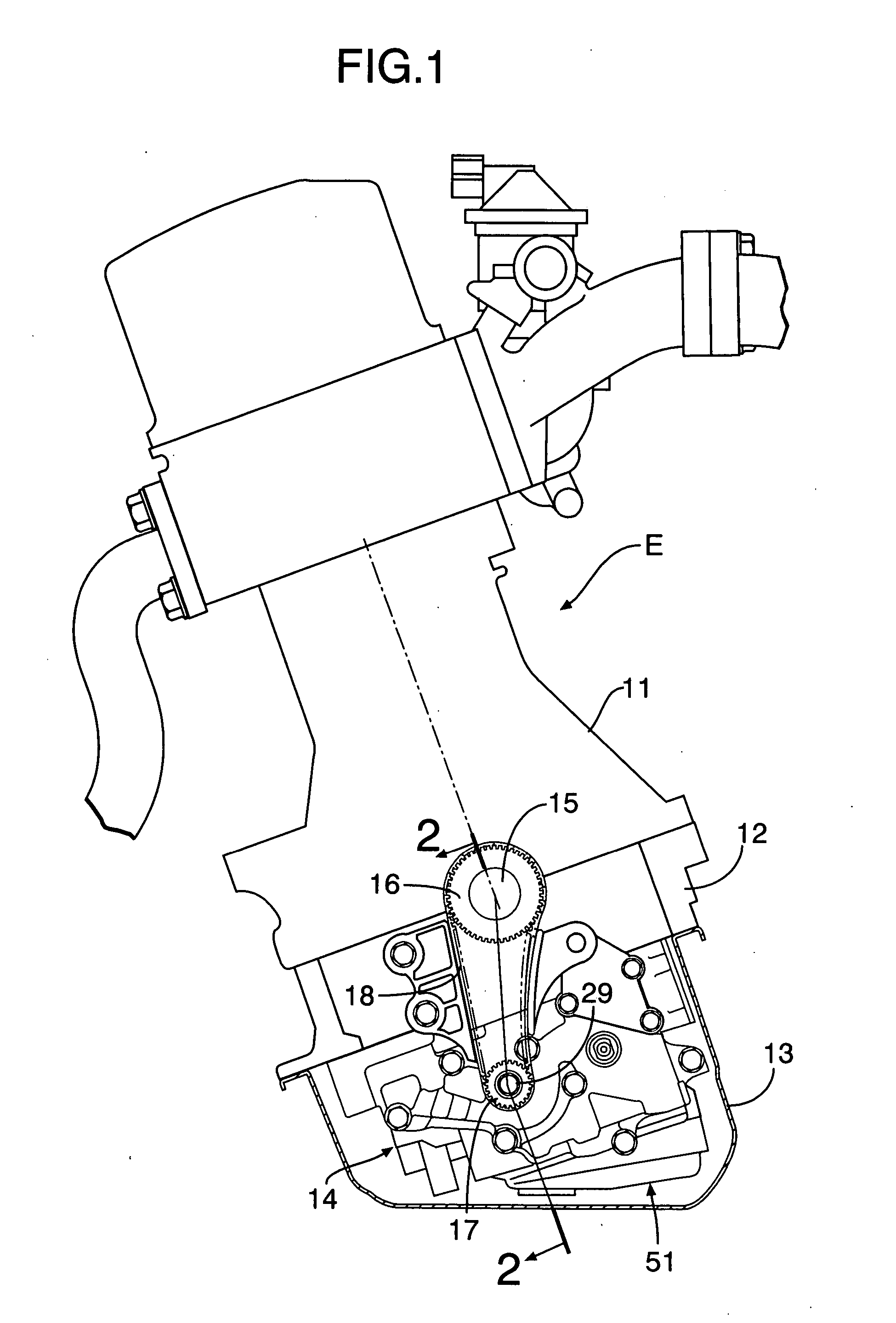

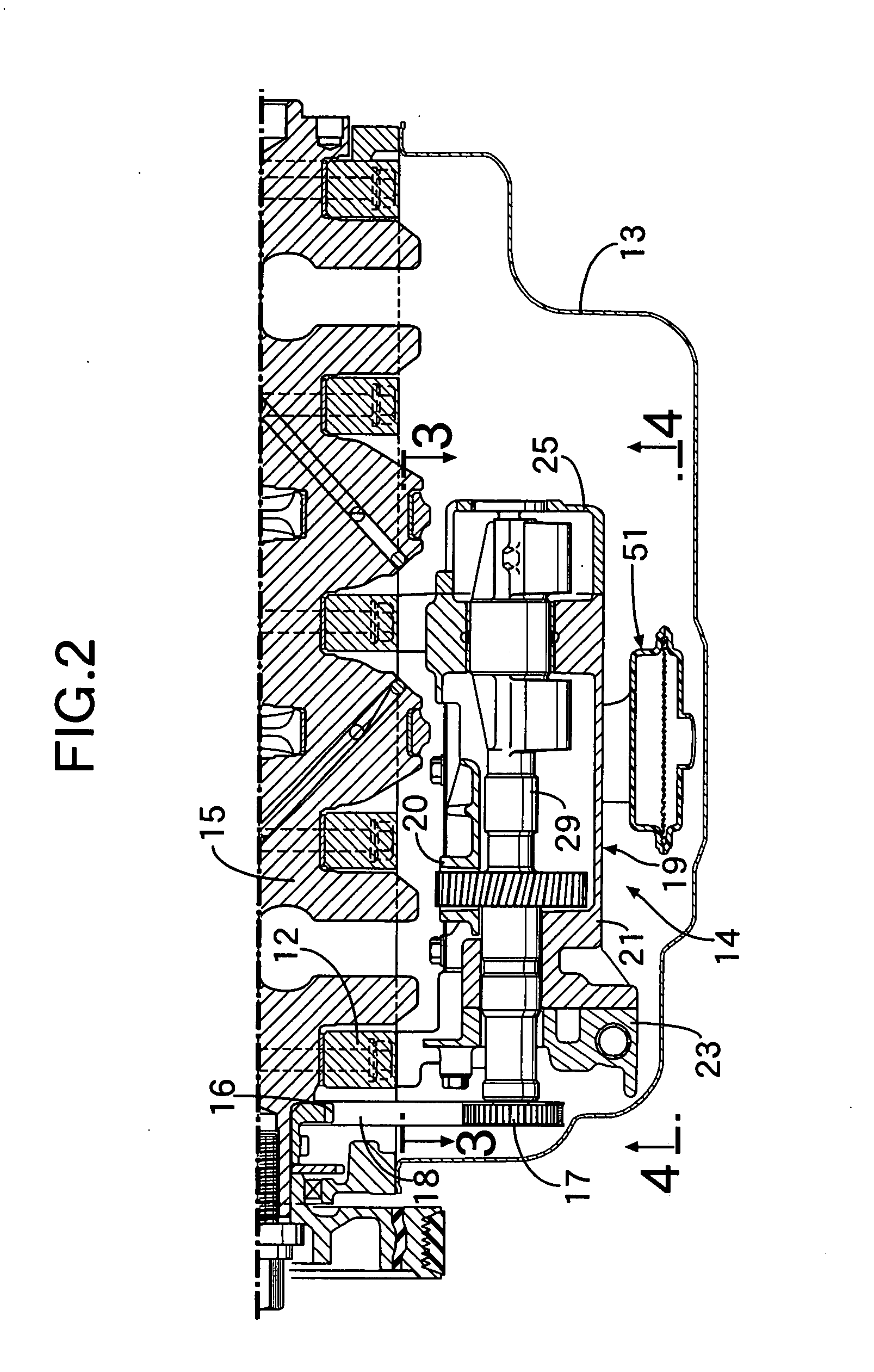

[0047]FIGS. 1 and 2 show the following structural arrangement. A lower block 12 is fixed to a lower surface of a cylinder block 11 of a diesel engine E of an automobile. An oil pan 13 is fixed to the lower surface of the lower block 12. Provided on a lower surface of the lower block 12 is a balancer device 14 which reduces secondary vibration of the engine E, and which is housed in the oil pan 13. A crankshaft 15 is rotatably supported between the cylinder block 11 and the lower block 12. A drive sprocket 16 is provided at an end of the crankshaft 15. A driven sprocket 17 is provided at an end of a drive balancer-shaft 29 of the balancer device 14. An endless chain 18 is wound around the drive and driven sprockets 16 and 17.

[0048] FIGS. 3 to 6 show the following structural arrangement. The balancer device 14 has a balancer housing 19 including an upper housing part 20 and a lower housing part 21. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com