Strainer for oil supply mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

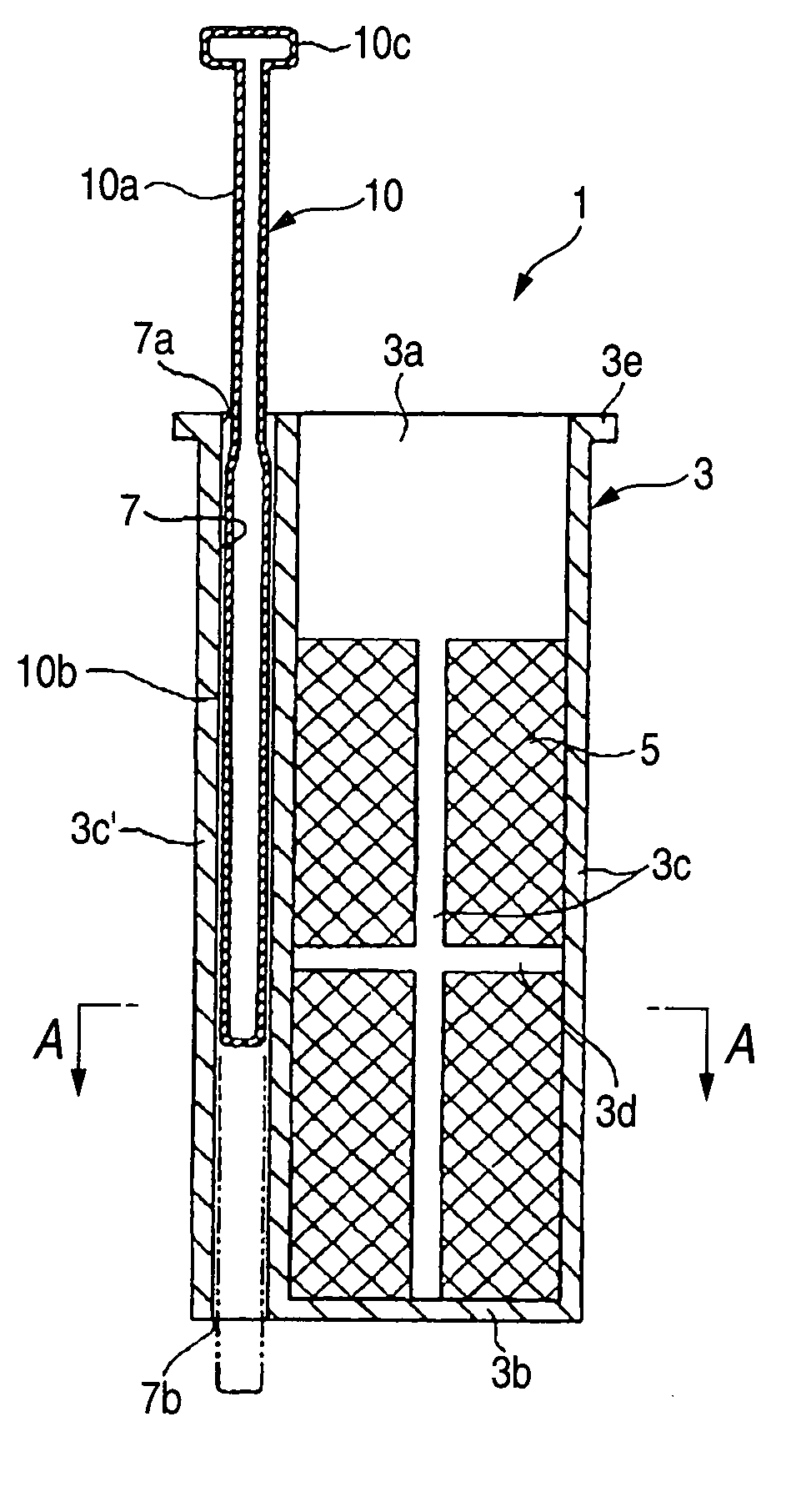

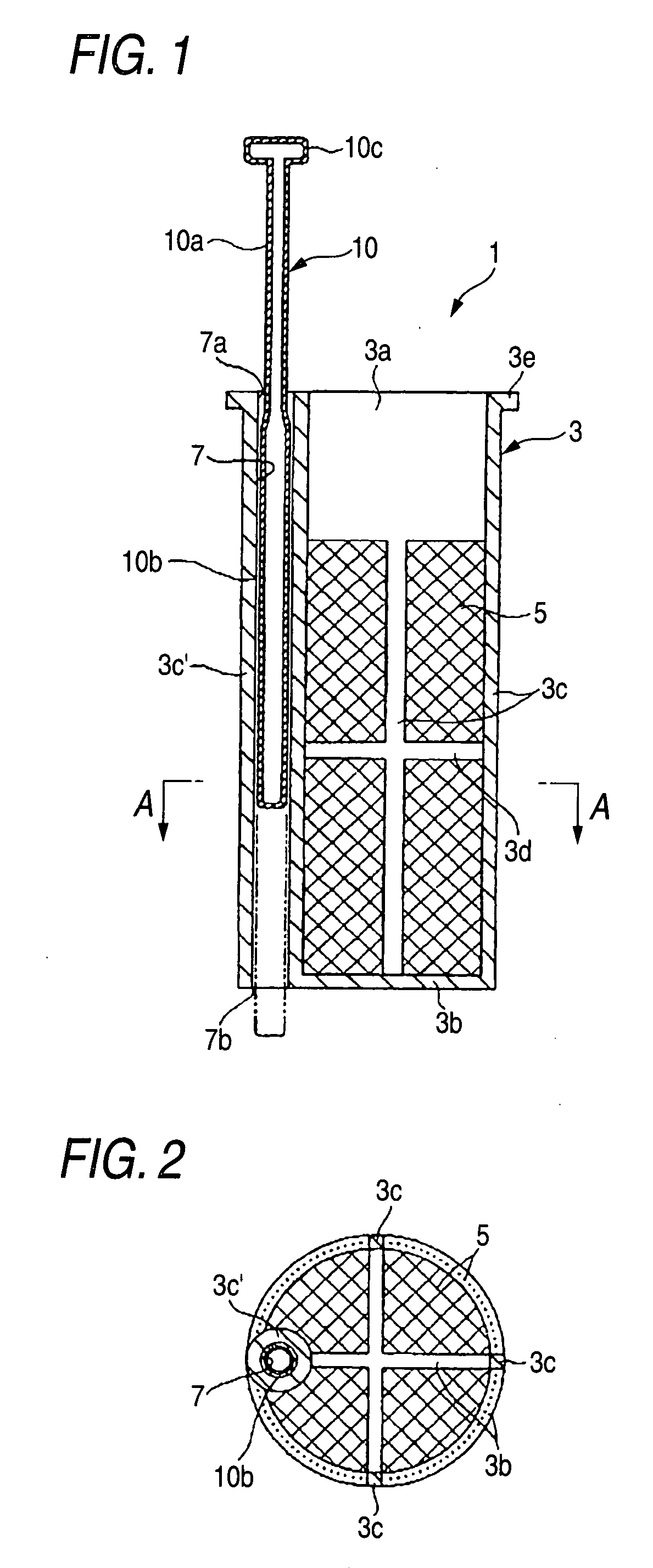

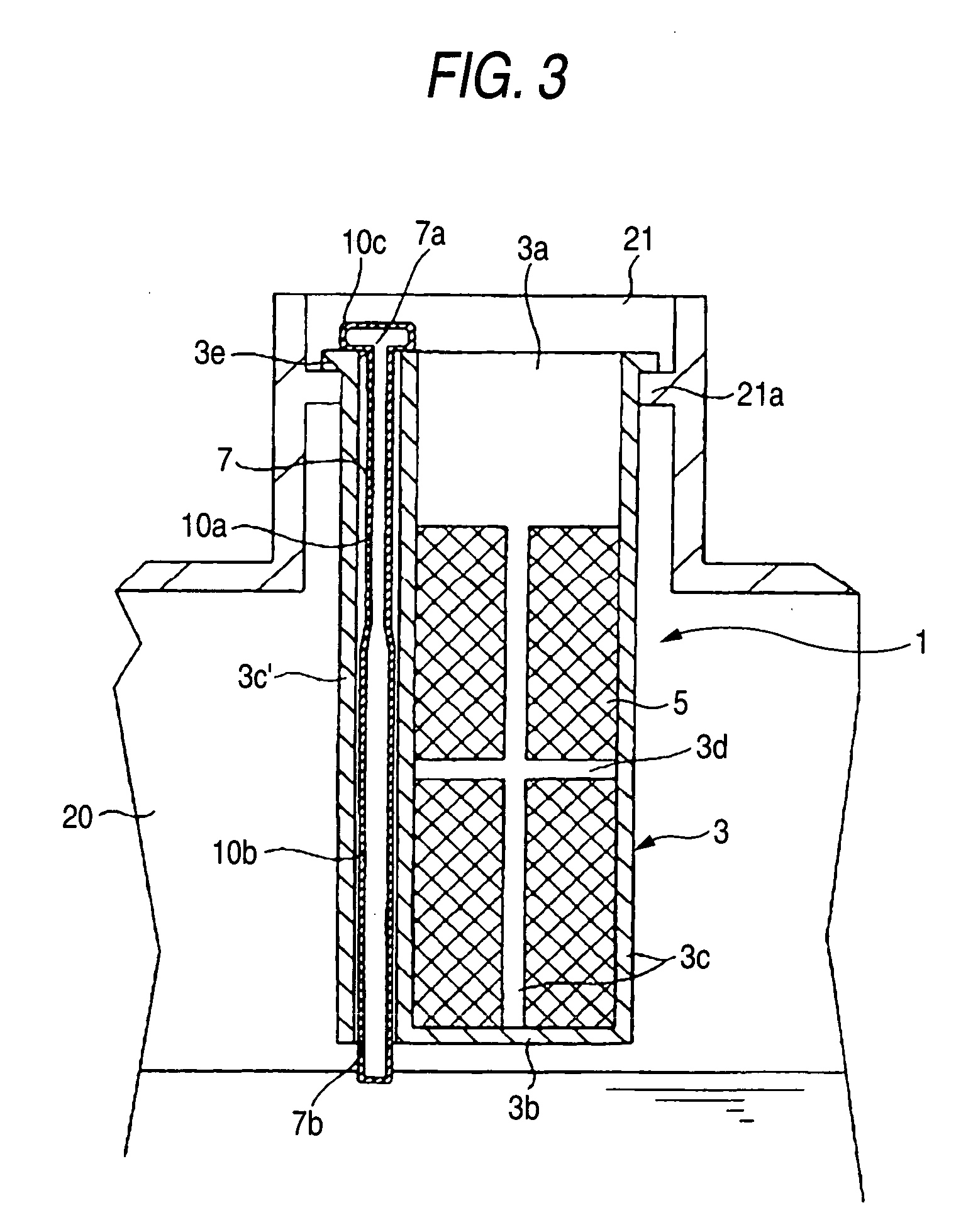

[0043] FIGS. 1 to 5B are views showing the strainer according to the invention, in which FIG. 1 is a vertical cross sectional view of the strainer, FIG. 2 is a plan view along A-A line of FIG. 1, FIG. 3 is a vertical cross sectional view showing the condition of attaching the strainer shown in FIG. 1 to the oil supply mouth, FIG. 4 is a vertical cross sectional view showing the condition where the liquid level of the oil rises (the condition of the reference liquid level) after the strainer is attached to the oil supply mouth, and FIGS. 5A and B show the structural examples of the floats, respectively.

[0044] The strainer body is formed to be cylindrical (almost cup shaped) with a bottom opening upward, and according to the present embodiment, the strainer 1 is formed as a circular cylinder having a bottom corresponding to a diameter of the oil supply mouth 21 of the oil tank 20. The body 1 has a frame body 3 maintaining its inherent rigidity and avoiding breakage, and a net part 5 (...

second embodiment

[0055] FIGS. 6 to 9 are views showing the strainer according to the invention, in which FIG. 6 is a vertical cross sectional view of the strainer, FIG. 7 is a plan view along B-B line of FIG. 6, FIG. 8 is a vertical cross sectional view showing the condition of attaching the strainer shown in FIG. 6 to the oil supply mouth, and FIG. 9 is a vertical cross sectional view showing the condition where the liquid level of the oil rises (the condition of the reference liquid level) after the strainer is attached to the oil supply mouth.

[0056] Similarly to the above mentioned embodiment, of the plural frames composing the frame body 3, one of the vertical frames 3c is formed with a swelling part 3f in a half-pillar shape inside of the strainer body 1, and is here unified as one body with the guide hole 7 being hollow and opening at the upper and lower end. The float 10 for an oil level gauge is inserted movably in the vertical directions into the guide hole 7. In this case, the swelling par...

third embodiment

[0059] FIGS. 10 to 13 are views showing the strainer according to the invention, in which FIG. 10 is a vertical cross sectional view of the strainer, FIG. 11 is a plan view along C-C line of FIG. 10, FIG. 12 is a vertical cross sectional view showing the condition of attaching the strainer shown in FIG. 10 to the oil supply mouth, and FIG. 13 is a vertical cross sectional view showing the condition where the liquid level of the oil rises (the condition of the reference liquid level) after the strainer is attached to the oil supply mouth.

[0060] Similarly to the above mentioned embodiment, of the plural frames composing the frame body 3, one of the vertical frames 3c is formed with a swelling part 3g in a half-pillar shape outside of the strainer body 1, and is here unified as one body with the guide hole 7 being hollow and opening at the upper and lower end. The float 10 for an oil level gauge is inserted movably in the vertical directions into the guide hole 7. The swelling part 3g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com