Tensioner lever

a technology of tensioner lever and tensioner body, which is applied in the direction of belt/chain/gearring, mechanical equipment, and mechanical components, etc., can solve the problems of tensioner lever deformation, deformation of the lever body itself as the tensioner lever ages, and deformation of the stopper pin lock hole, etc., to achieve suppressed chain bouncing, simple configuration, and high spring load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

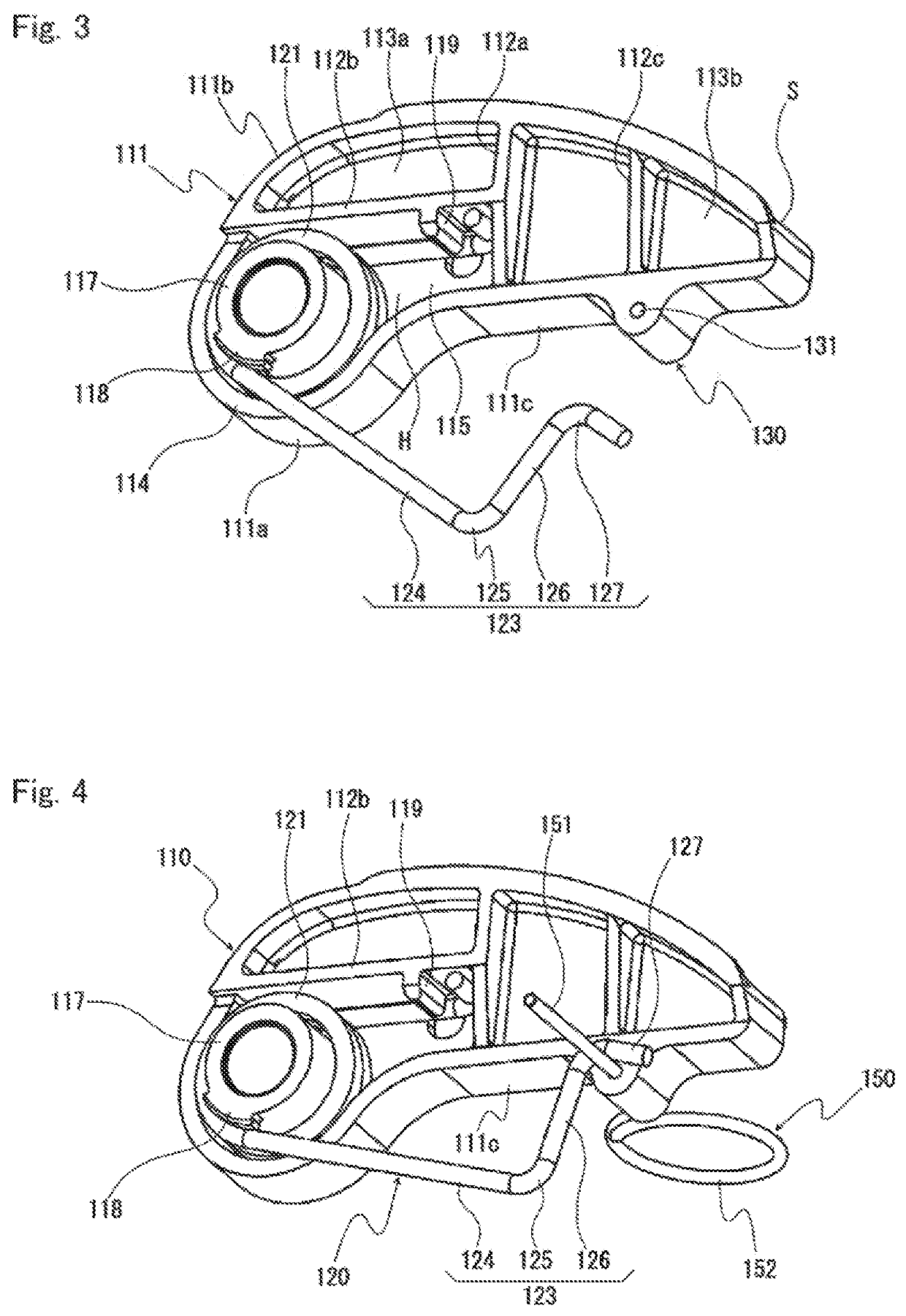

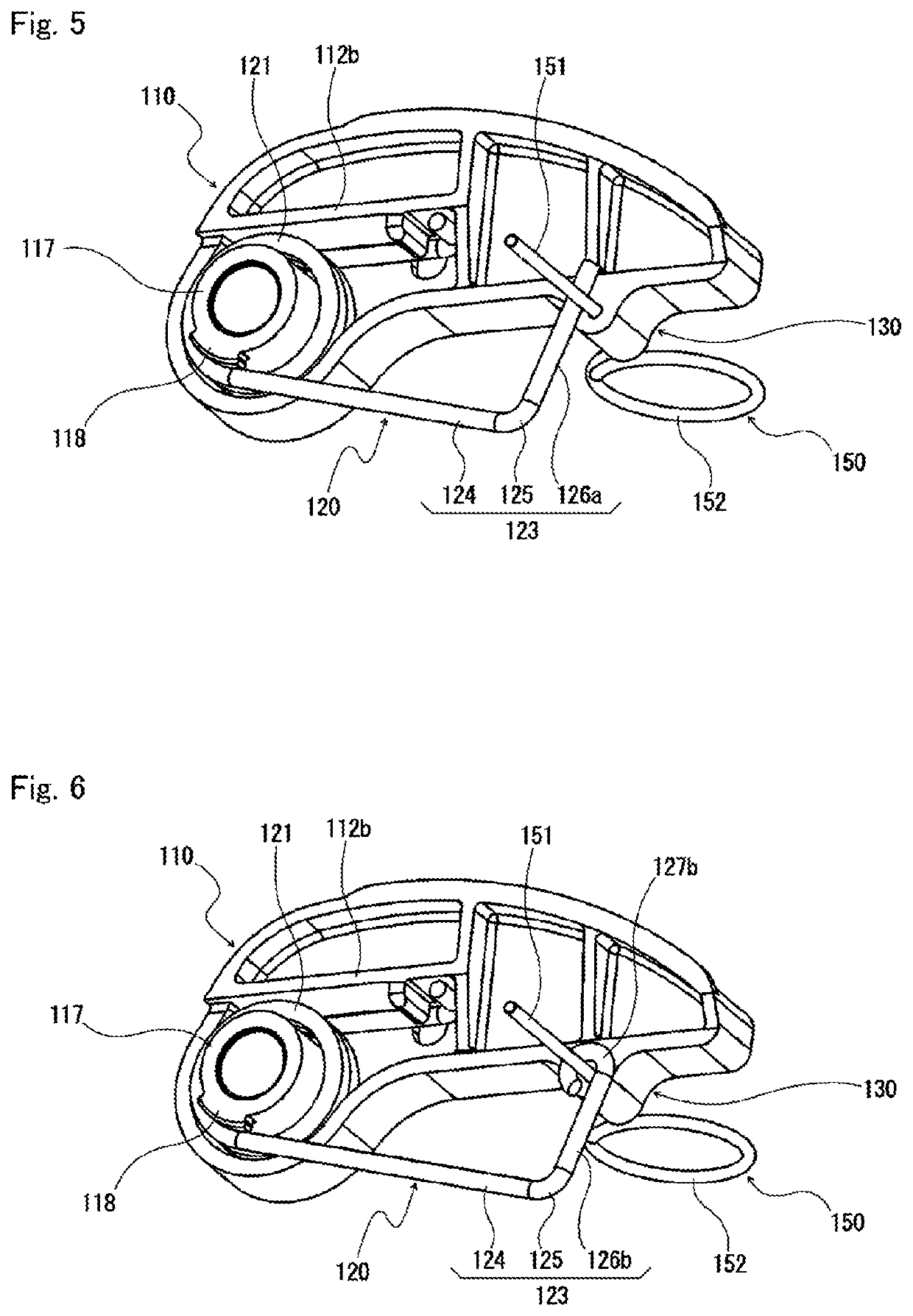

[0020]A tensioner lever that is one embodiment of the present invention will be hereinafter described with reference to the drawings.

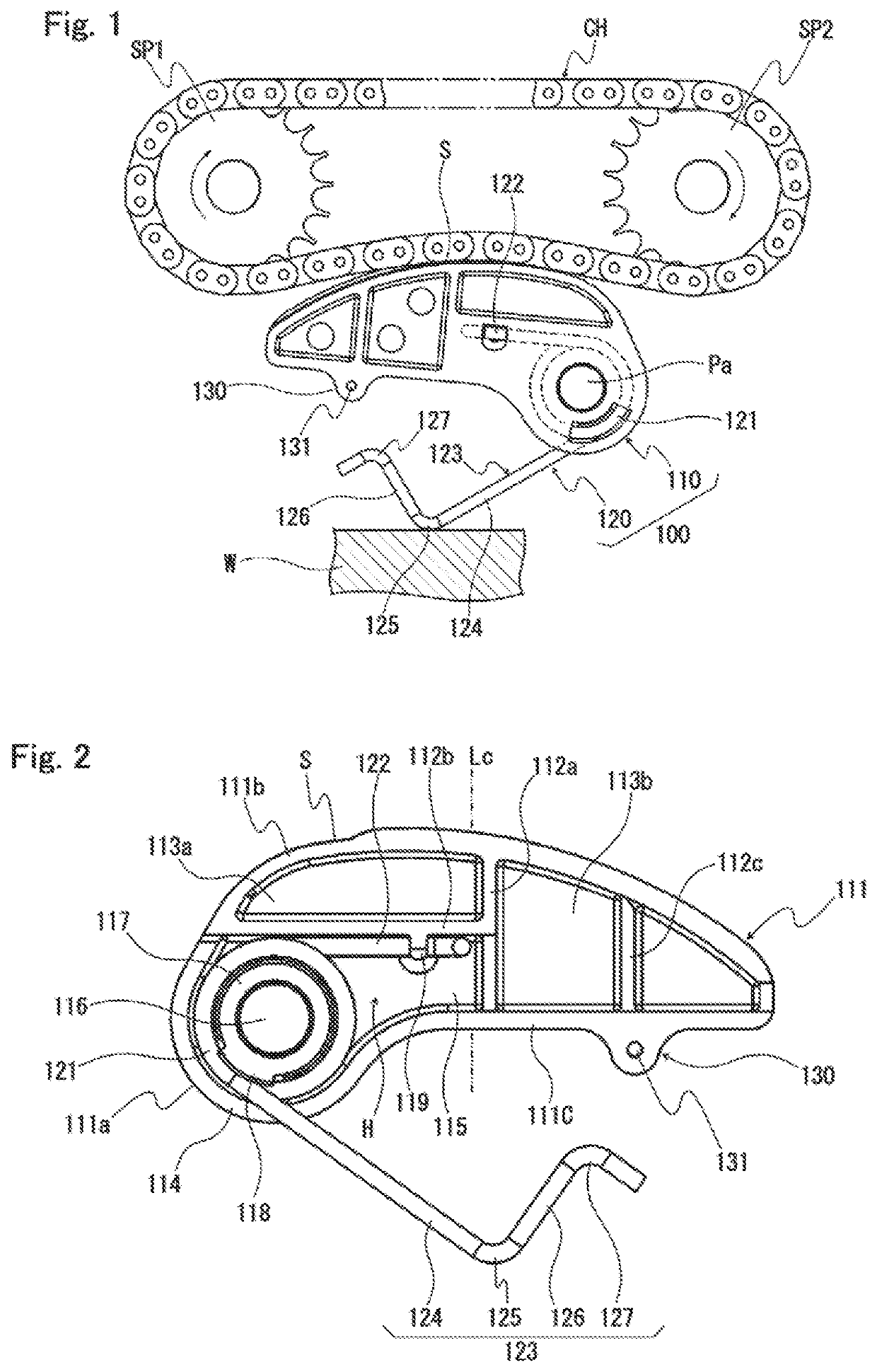

[0021]The tensioner lever 100, as shown in FIG. 1, is pivotably mounted on a pivot shaft Pa protruding from an attachment surface (not shown) of an engine block (not shown) or the like to slidably guide a chain CH passed over between a drive-side sprocket SP1 attached to a crankshaft and a driven-side sprocket SP2 attached to a shaft of an auxiliary machine to keep an appropriate chain tension.

[0022]The tensioner lever 100 includes a lever body 110 having a shoe surface S formed along a longitudinal direction for slidably guiding the chain CH and a base end rotatably supported on an attachment surface, and a torsion coil spring 120 interposed between the lever body 110 and the attachment surface to press the shoe surface S toward the chain CH. As illustrated in FIG. 1, the resilient force of the torsion coil spring 120 exerts a torque on the lever body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com