Pipeline welding process

A welding process and pipeline technology, used in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of centrifugal force generated by the pipeline, affecting the tight quality of the pipeline, and cumbersome rotation of long pipelines, so as to ensure the welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

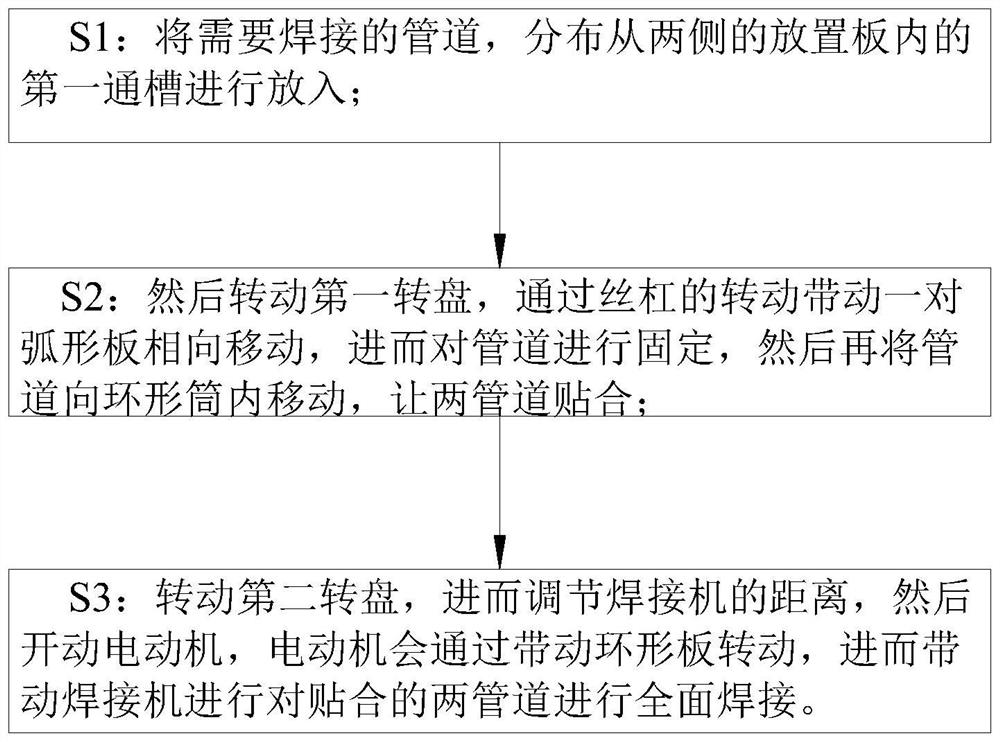

[0032] Such as Figure 1 to Figure 6 Shown, the welding process of a kind of pipeline of the present invention, this process step is as follows:

[0033] S1: Distribute the pipes to be welded into the first through grooves 11 in the placement plates 1 on both sides;

[0034] S2: Then turn the first turntable 24, the rotation of the lead screw 23 drives the pair of arc-shaped plates 22 to move toward each other, and then fix the pipeline, and then move the pipeline into the annular cylinder 12, so that the two pipelines fit together;

[0035] S3: Rotate the second turntable 43 to further adjust the distance of the welding machine 14, and then start the motor 44. The motor 44 will drive the ring plate 13 to rotate, and then drive the welding machine 14 to fully weld the two attached pipes.

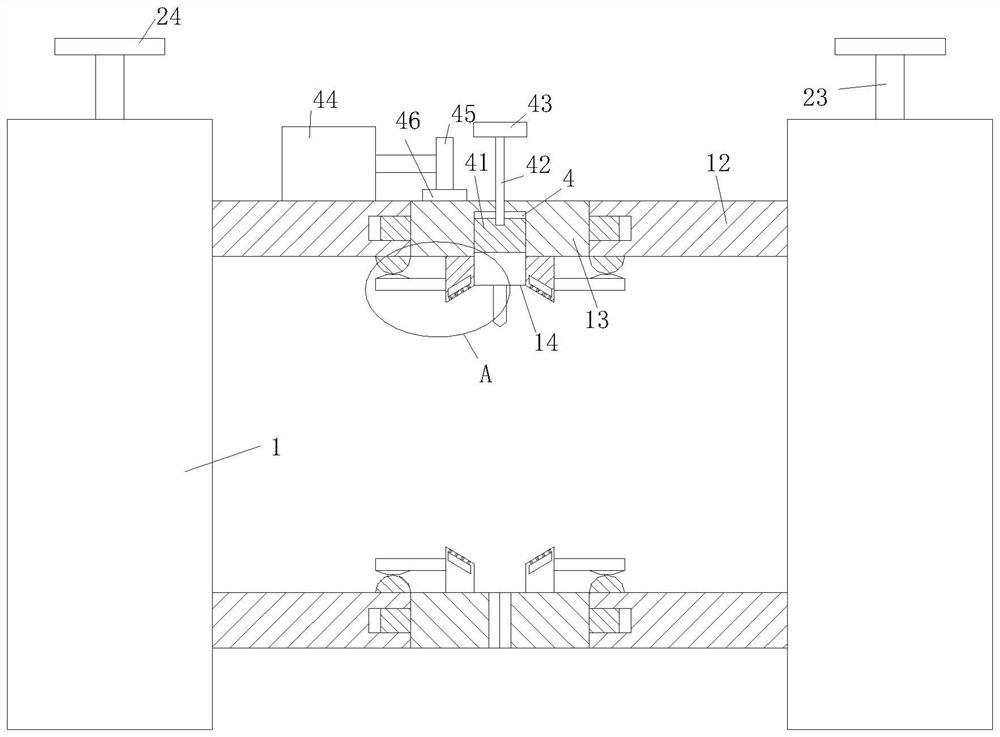

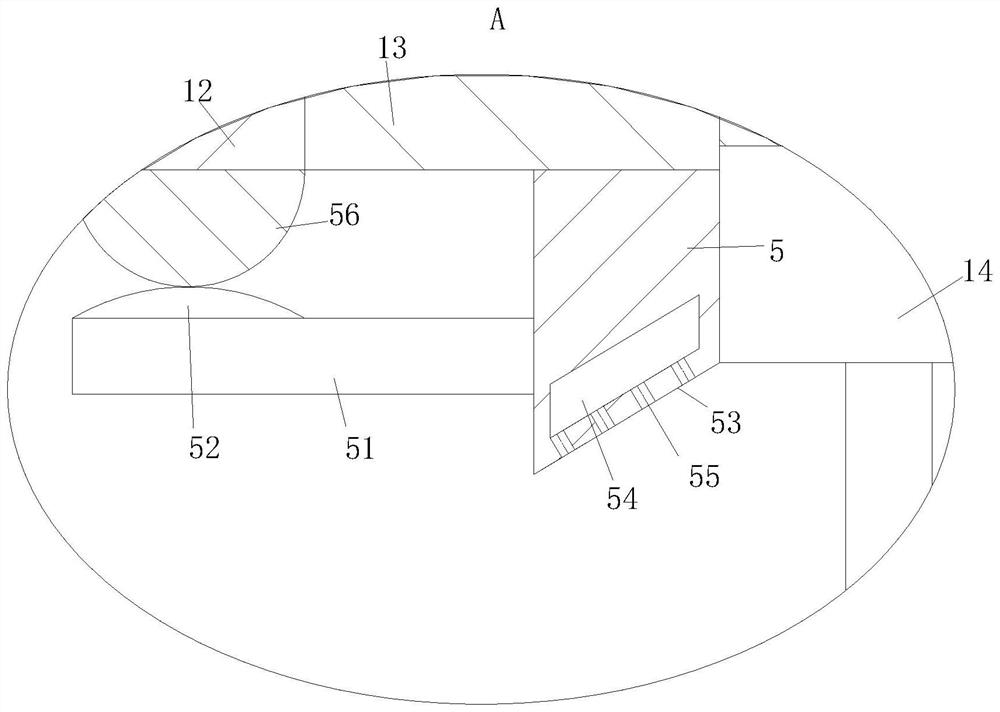

[0036]It includes a placement plate 1; a pair of said placement plates 1 side walls are provided with a first through groove 11; a pair of said placement plates 1 is fixed with an annular c...

Embodiment 2

[0045] Such as Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, a layer of anti-skid pad 58 is fixedly attached to the outer wall of the roller 32; the anti-skid pad 58 is made of rubber; An anti-slip pad 58 is provided on the top, which can avoid the horizontal and axial sliding of the pipeline on the roller 32, can ensure the stability of the fixed welding, and then ensure the welding effect of the two pipelines.

[0046] Working principle: When the long pipe needs to be welded, the two pipes can be distributed, and the welding end can be extended into the annular cylinder 12 through the first through groove 11, and then the long pipe can be welded through the clamping piece in the first through groove 11. fixed, then by rotating the annular plate 13, and then through the welding machine 14 to fully process the fitted pipe wall, through the rotation of the welding machine 14, the influence of centrifugal force on the pipe fitting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com