One-section forming method and one-section forming machine for producing radial tire with two-time method

A radial tire and molding method technology, applied in the field of rubber machinery, can solve problems such as the inability to achieve flat drum fit, and achieve the effects of reducing labor intensity, improving tire quality, and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

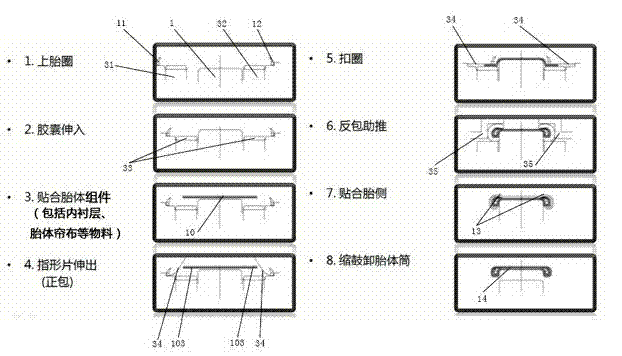

Method used

Image

Examples

Embodiment 1

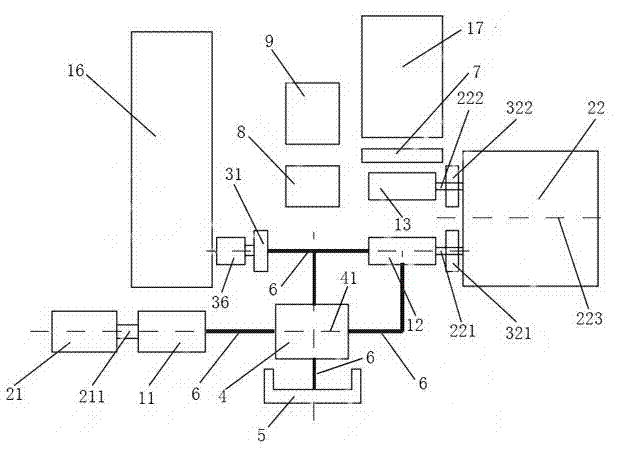

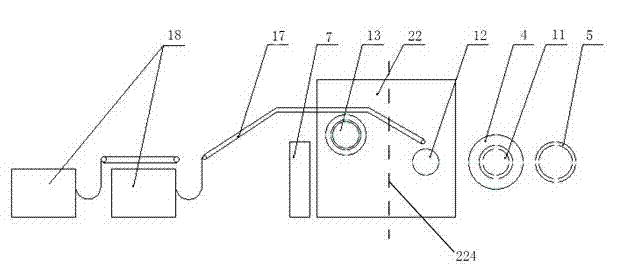

[0039] Example 1, such as Figure 3-Figure 5 As shown, the present invention applies the two-time method to produce a one-stage forming machine for radial tires, including a laminating drum 11, a laminating drum chassis 21, a first forming drum 12, a second forming drum 13, a forming drum chassis 22, and a left front and back wrap Device 31, first right front and back wrapping device 321, second right front and back wrapping device 322, transfer ring 4, bead presetting device 5, rolling device 7, tire unloading device 8, conveying device 9; the feeding device includes Carcass feeding frame 16, side wall feeding frame 17, feeding trolley 18.

[0040] The output shaft 211 of the laminating drum casing 21 is connected with the axial end of the laminating drum 11; 13 are connected at one axial end. Such as image 3 As shown, the position of the first forming drum 12 is the front and back wrapping station, the left front and back wrapping device 31 is located at its axial left e...

Embodiment 2

[0061] Example 2, such as Figure 12 As shown, the first output shaft 221 and the second output shaft 222 are arranged symmetrically with respect to the longitudinal centerline 224, distributed at the left and right ends of the forming drum case 22, and can rotate around the longitudinal centerline 224 under the driving action of the forming drum case 22 The positions are exchanged, so that the first forming drum 12 and the second forming drum 13 connected thereto are driven to exchange positions with each other.

[0062] All the other structures and procedures are the same as those in Example 1, and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com