Novel high-power light emitting diode (LED) light source structure based on non-metal-based printed circuit board

An LED light source, non-metal technology, applied in the field of LED semiconductor lighting, can solve the problems of high interface thermal resistance, low heat generation, and the interface 1 is not tightly attached, so as to reduce interface thermal resistance, chip junction temperature, and production cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

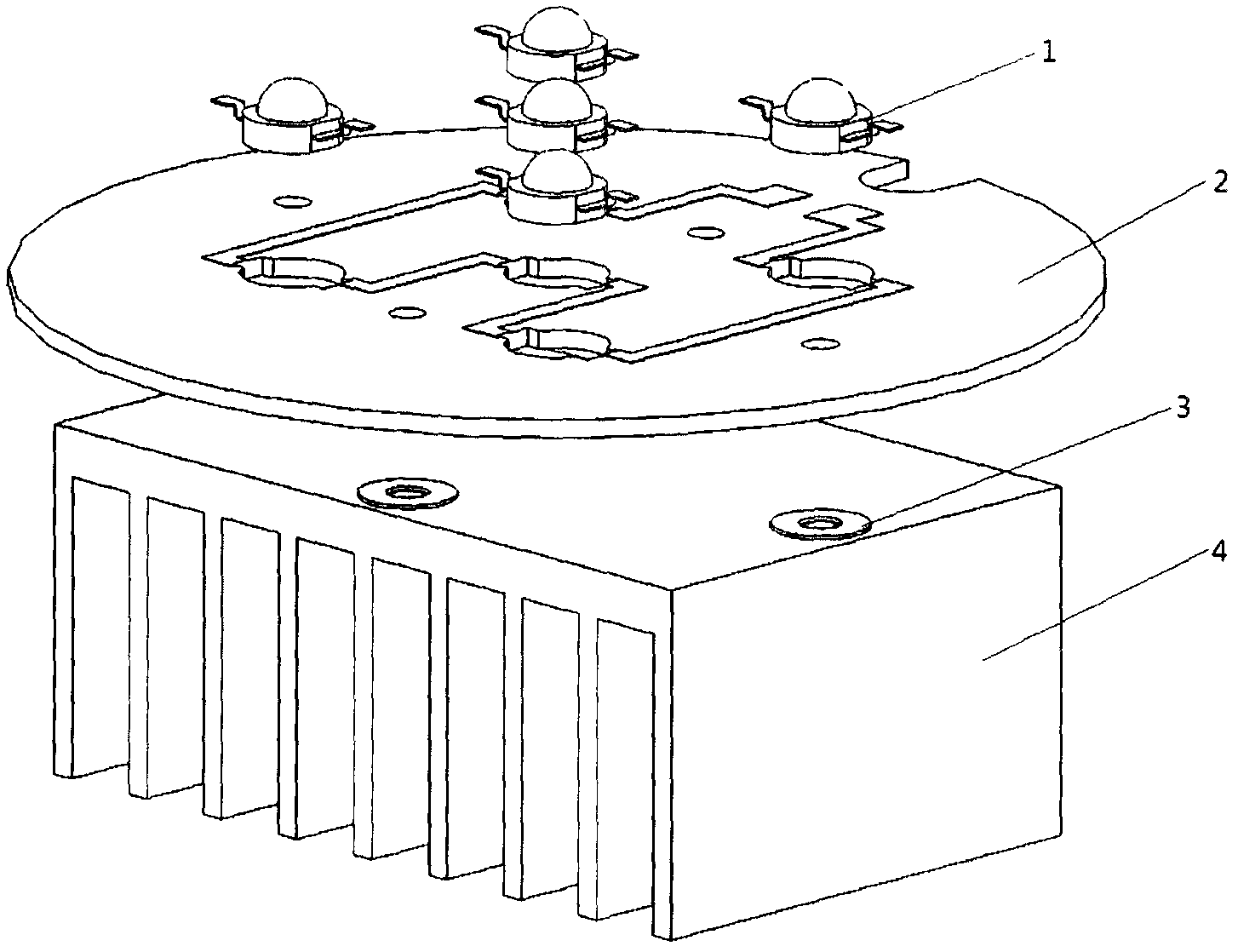

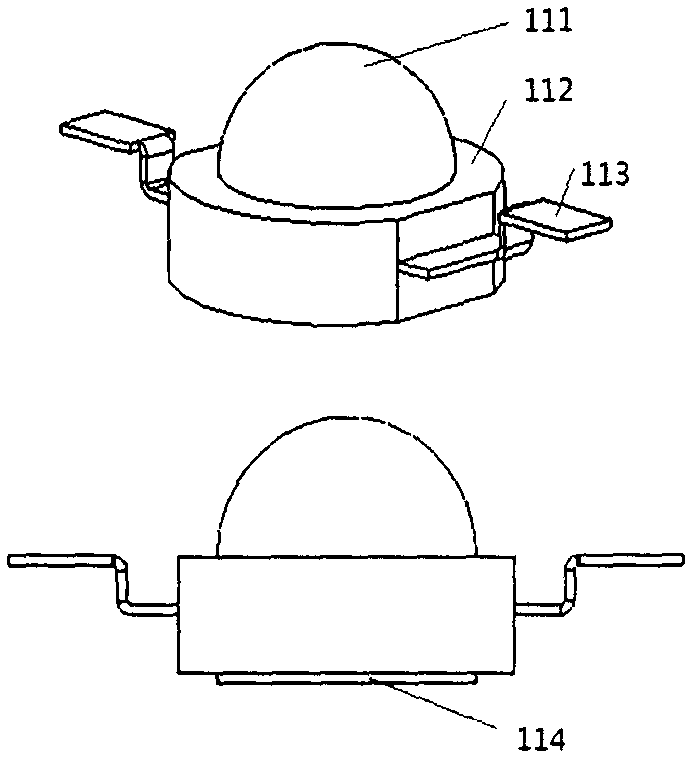

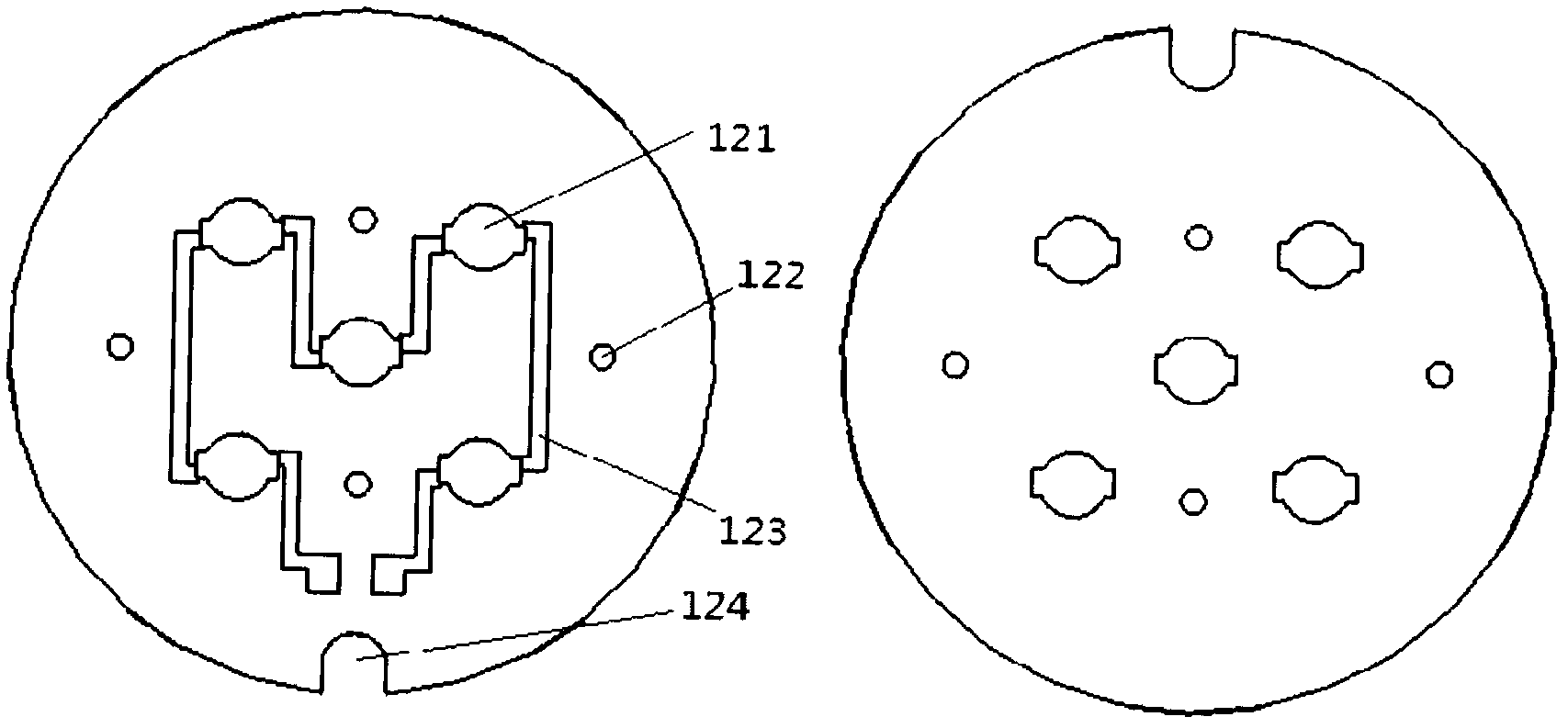

[0022] such as explosion figure 1 As shown, a new structure of high-power LED light source based on non-metal base circuit board, including LED1, non-metal base PCB2, gasket 3, and heat sink 4. Wherein, the pin 113 of the LED1 is upward, and the LED installation through hole 121 is provided on the PCB2, and the diameter of the through hole 121 is slightly larger than the diameter of the plastic bracket 112 of the LED1. The front side of the PCB 2 is coated with copper 123 , and the front side is a light-emitting surface. The gasket 3 is preferably a non-metallic flat gasket with strong deformation resistance. Each through hole 121 on the PCB2 is correspondingly embedded with an LED1, and the pin 113 of the LED1 is soldered to the copper foil 123 on both sides of the corresponding through hole to form an electrical connection. The base 114 of the LED1 can be in direct contact with the top 141 of the heat sink through the through hole. The base 114 is coated with heat-conduct...

Embodiment 2

[0024] such as explosion Figure 6As shown, a new structure of high-power LED light source based on non-metal base circuit board, including LED5, non-metal base PCB6, insulating gasket 7, and radiator 4. Wherein the pin 253 of the LED5 is downward, and the LED installation through hole 261 is arranged on the PCB 6 , and the diameter of the through hole 261 is slightly larger than the diameter of the plastic bracket 252 of the LED5. Copper 264 is covered on the reverse side of the PCB 6 , and the reverse side is a non-light-emitting surface. Each through hole 261 on the PCB6 is correspondingly embedded with an LED5, and the pin 253 of the LED5 is located on the opposite side of the PCB6, and is soldered to the copper foil 264 on both sides of the corresponding through hole to form an electrical connection. An insulating spacer 7 is installed between the PCB 6 and the top 141 of the heat sink, and the insulating spacer 7 mainly plays the role of pin insulation and fastening. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com