Power semiconductor device comprising metal plate and substrate arranged on the metal plate

A technology of power semiconductors and metal plates, which is applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as high heat load, cracks in ceramic plates, etc., and achieve efficient cooling and good thermal connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

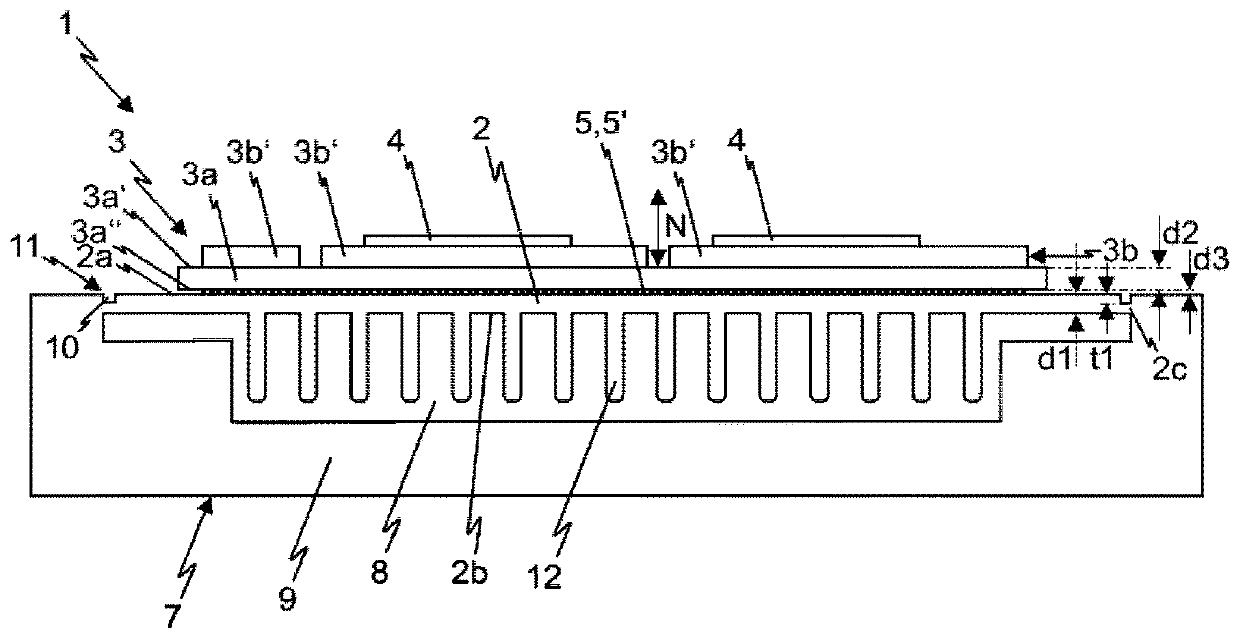

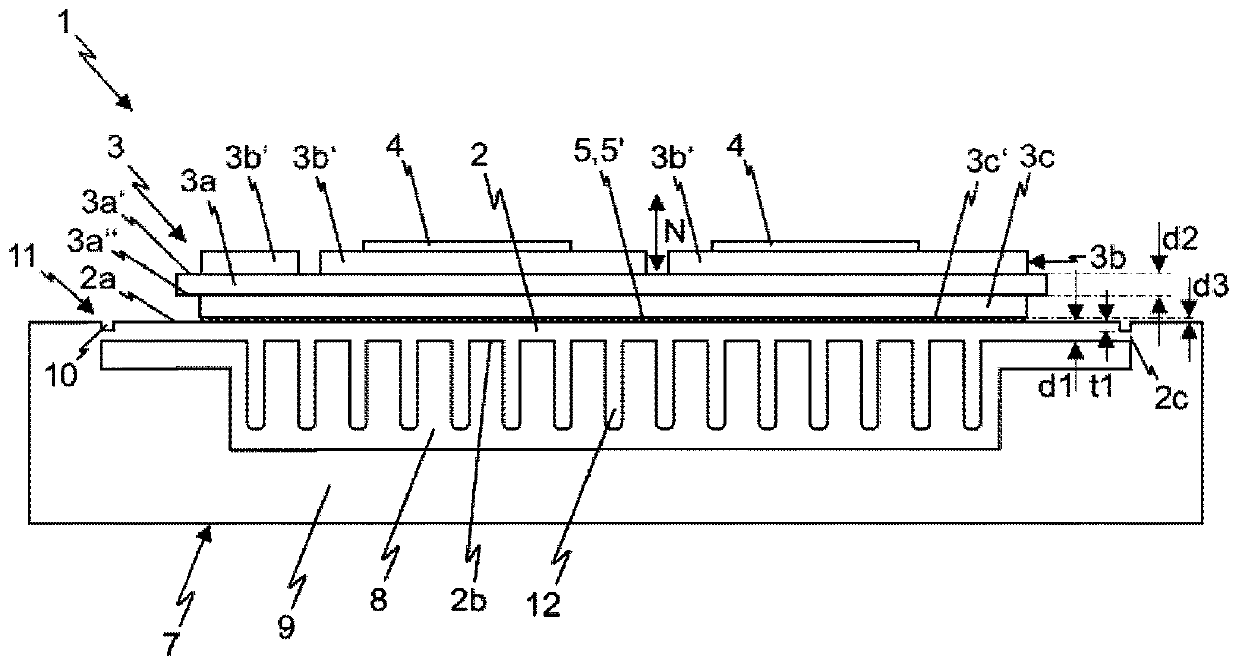

[0032] figure 1 A cross-sectional view of an embodiment of the power semiconductor device according to the present invention is shown. figure 2 Showing a cross-sectional view of another embodiment of a power semiconductor device according to the present invention,

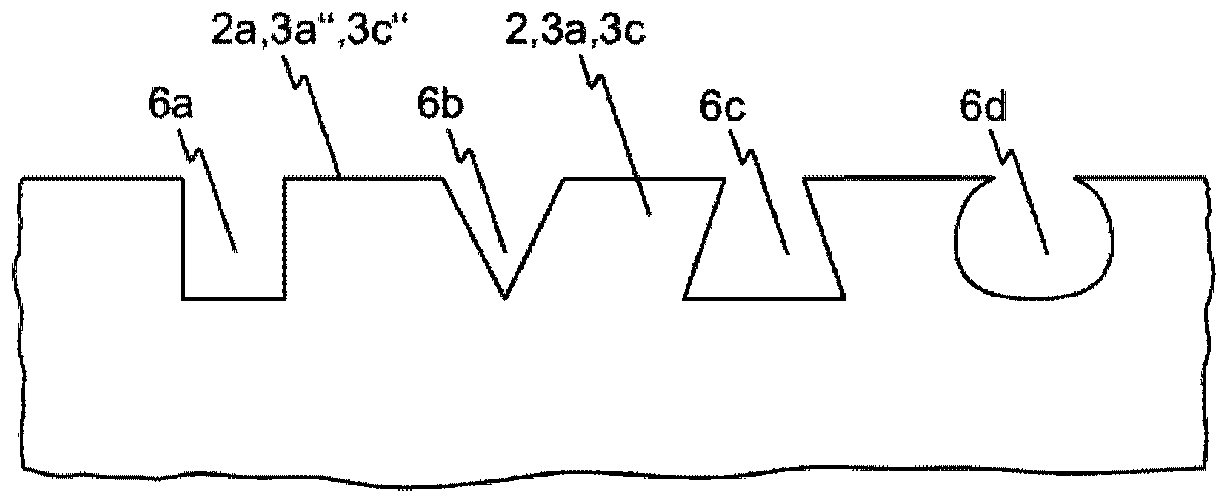

[0033] The corresponding power semiconductor device 1 according to the present invention has a metal plate 2 and a substrate 3 arranged on the metal plate 2. The base plate 3 has a ceramic plate 3a, and a first main side 3a' of the ceramic plate 3a facing away from the metal plate 2 is coated with a first metallization layer 3b configured to form a conductor track 3b'. The conductor tracks 3b' are arranged on the ceramic plate 3a at a distance from each other. The conductor tracks 3b' are arranged on the ceramic plate 3a in a manner electrically insulated from each other. For example, the substrate 3 can be formed as a direct copper-bonded substrate (DCB substrate) or as an active metal brazing substrate (AMB substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com