Battery module with liquid cooling member

A battery module and cooling module technology, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of difficult heat dissipation and high assembly density, and achieve high rationality, light weight, and simple manufacturability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

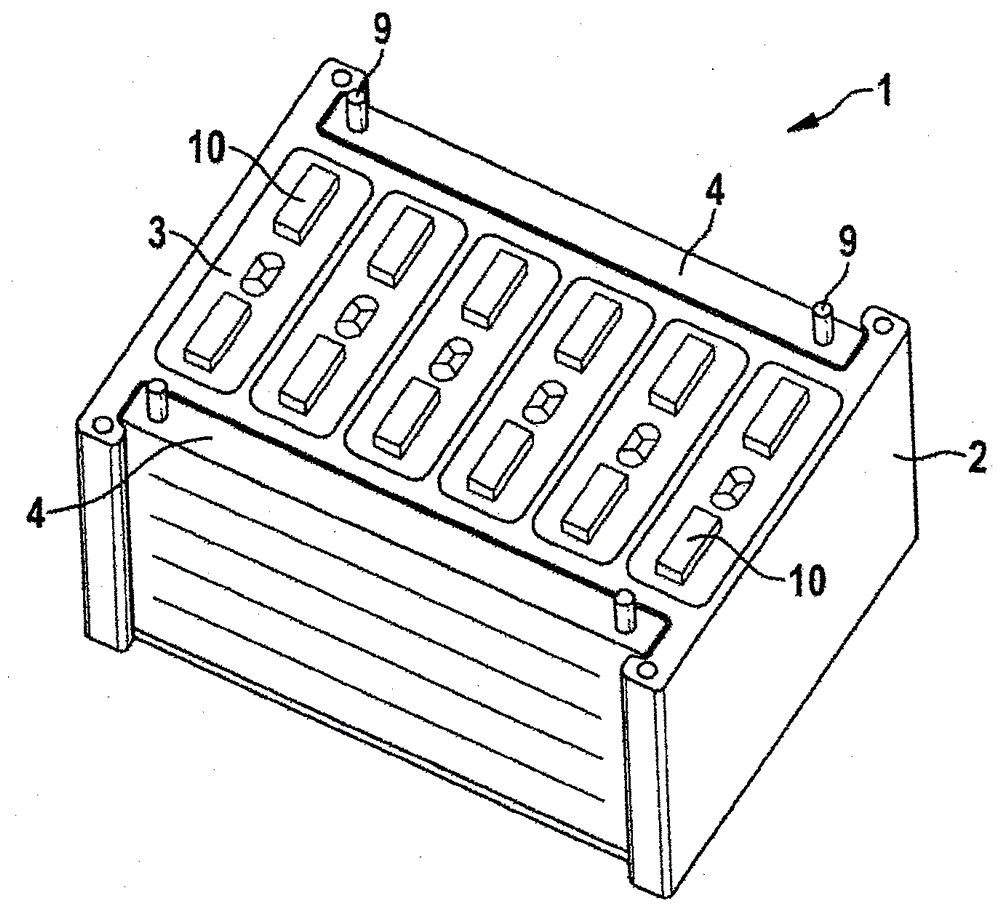

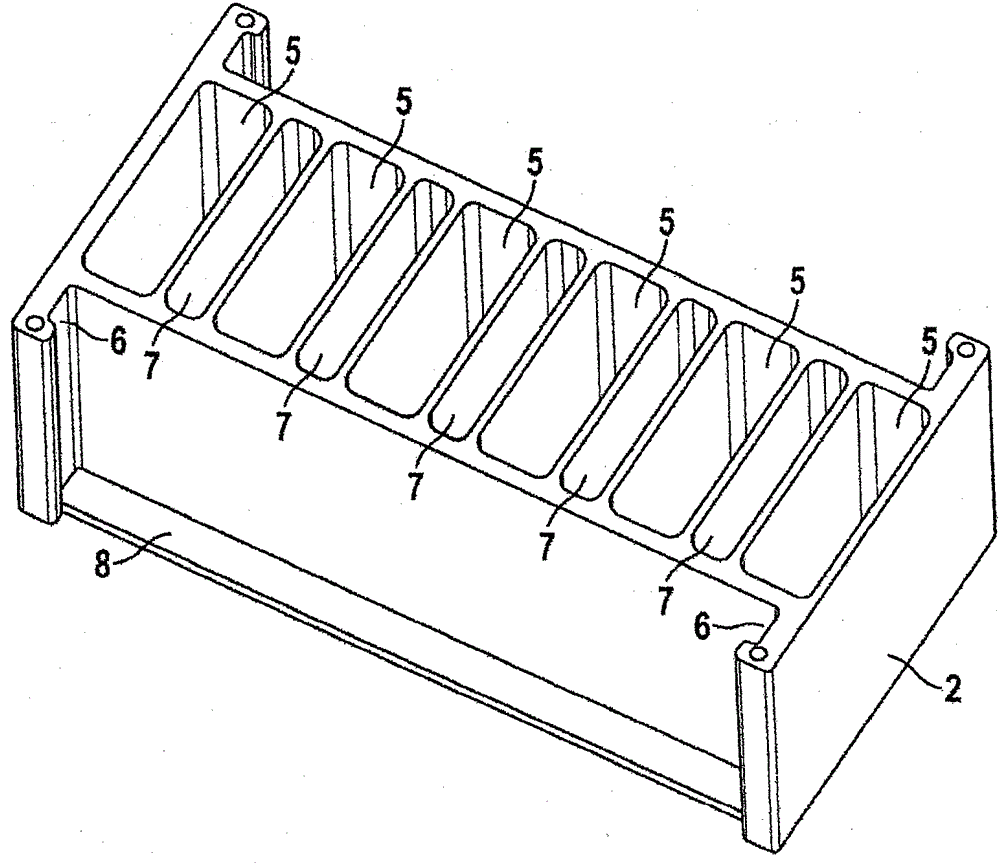

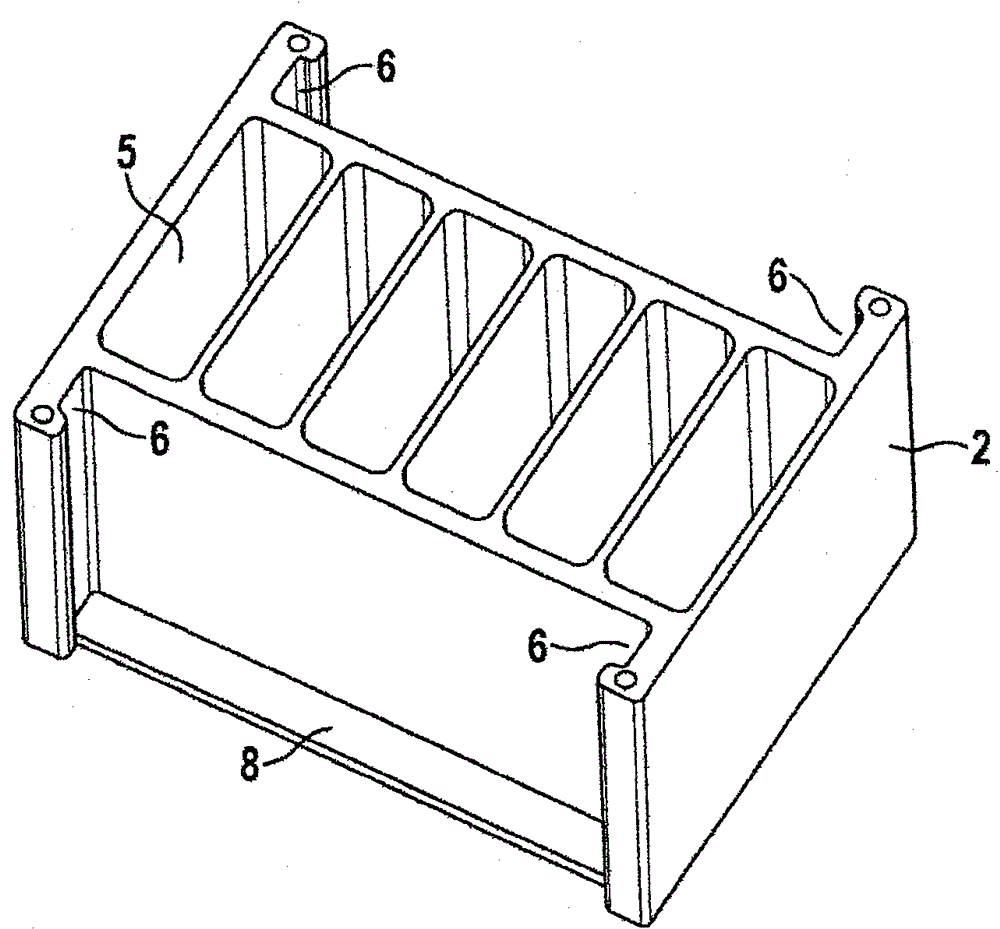

[0027] figure 1 A preferred exemplary embodiment of a battery module 1 is shown with a battery module housing 2 into which six battery cells 3 are inserted. The six battery cells 3 can be cooled by two laterally arranged cooling modules 4 . The battery module housing 2 has an internal rib structure, through which, as figure 2 The six inner first cells 5 are formed as shown. One battery cell 3 can be inserted in each of the six compartments 5 . Furthermore, two outer, lateral recesses 6 are formed by the rib structure, as part of the left and right rail, into which a cooling module 4 can be inserted in each case. Depend on figure 1 It can be seen that the battery cell 3 is positively connected to the first inner compartment 5 . Likewise, the cooling module 4 is positively connected to the outer, lateral recess 6 and thus prevented from falling out. The battery module housing 2 is substantially cuboid-shaped. The projection of the battery module 1 on its bottom surface d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com