Double composite production line with hot attaching process device and process for producing sidewall by using same

A process device, dual-composite technology, applied in the direction of lamination device, layered products, lamination, etc., can solve the problem of easy lifting of batch films, and achieve the effect of solving the bubble phenomenon, ensuring quality, and ensuring the quality of film lamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

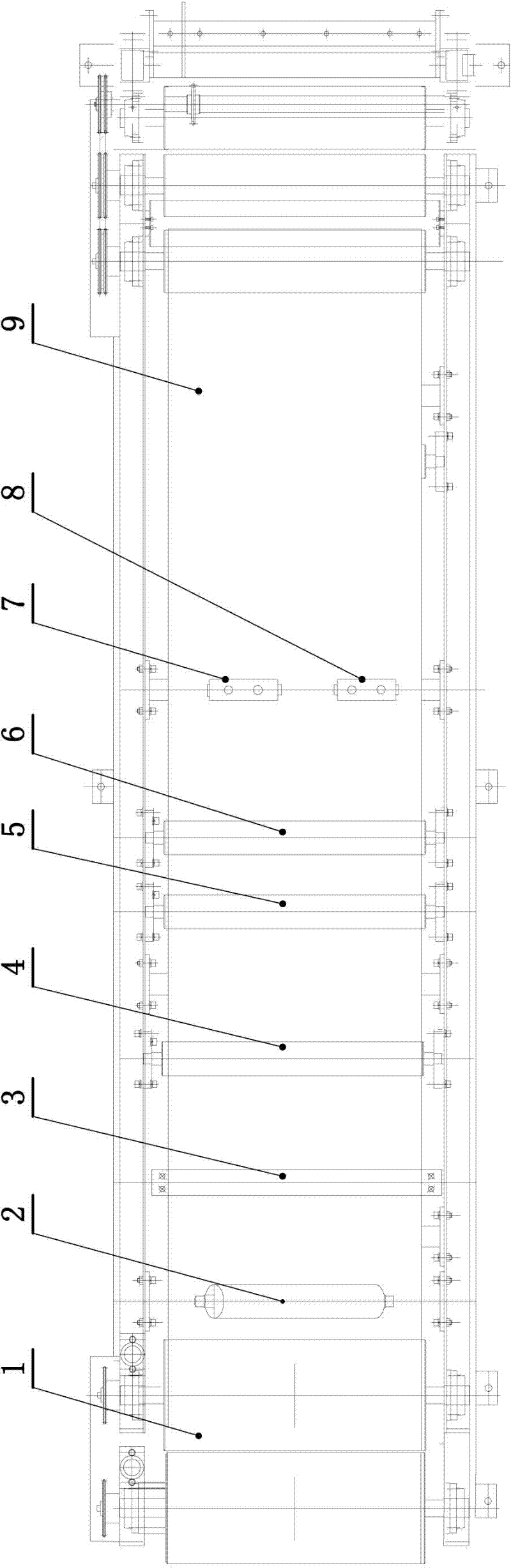

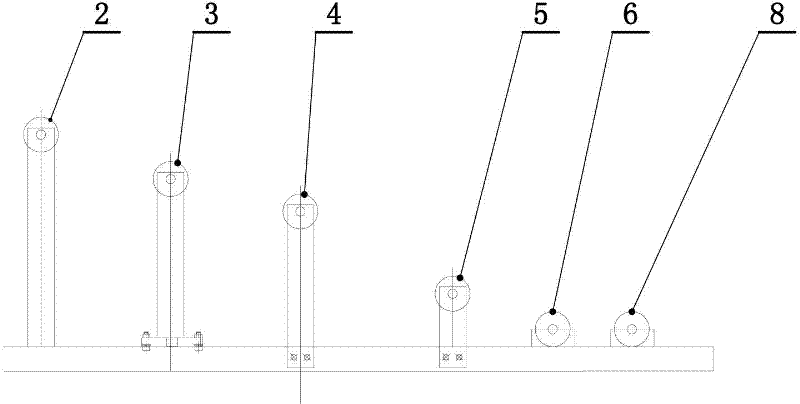

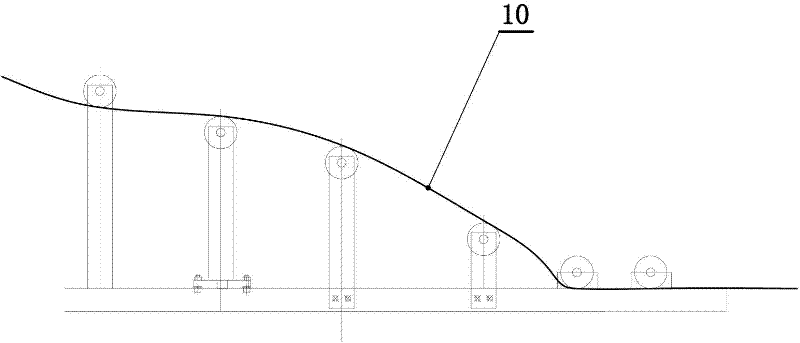

[0017] A double compound production line with thermal bonding process device, such as figure 1 , figure 2 , image 3 As shown, including the linkage line 9, the front end of the linkage line 9 is provided with a two-roll calender 1, and the 1# flat roller 2 is installed on the linkage line 9 for relative rotation, and the 1# flat roller 2 is located at the rear side of the two-roll calender 1. 2# horizontal roller 3, 3# horizontal roller 4 and 4# horizontal roller 5 are also installed in relative rotation on 9, 2# horizontal roller 3, 3# horizontal roller 4 and 4# horizontal roller 5 are arranged in sequence on 1# flat roller 2 On the rear side, 1# rubber roller 6 is also relatively rotatably installed on the linkage line 9, and 1# rubber roller 6 is located at the rear side of 4# horizontal roller 5; 1# flat roller 2, 2# horizontal roller 3, 3# h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com