Full-automatic watch full-lamination all-in-one machine

A fully-fitted, all-in-one technology, which is applied to watches, clocks, clock support equipment, etc., can solve the problems of no quick fixing device for fittings, no quick fixing of fittings, and no buffering device. The effect of improving continuous operation time, improving market reputation and reducing rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

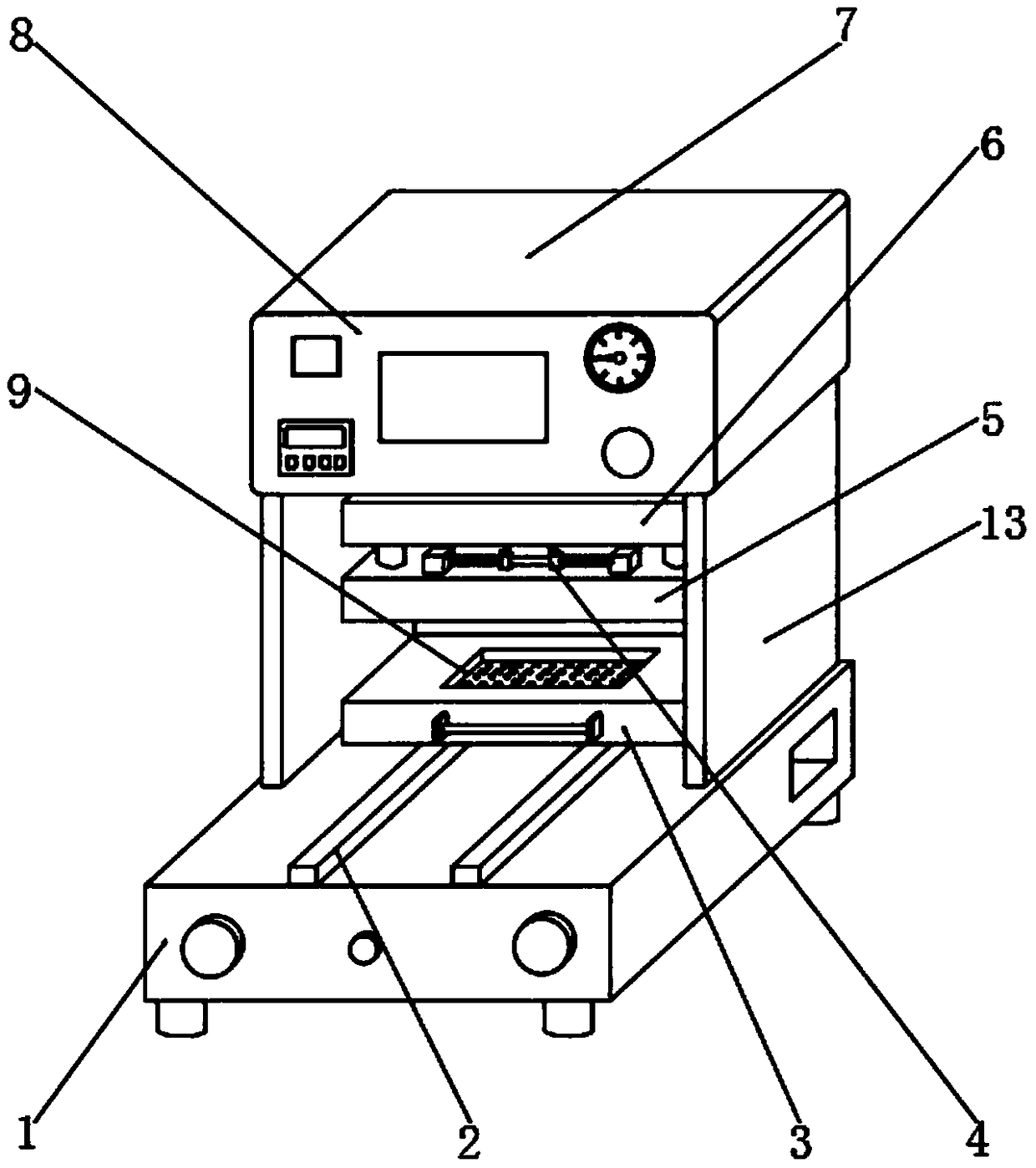

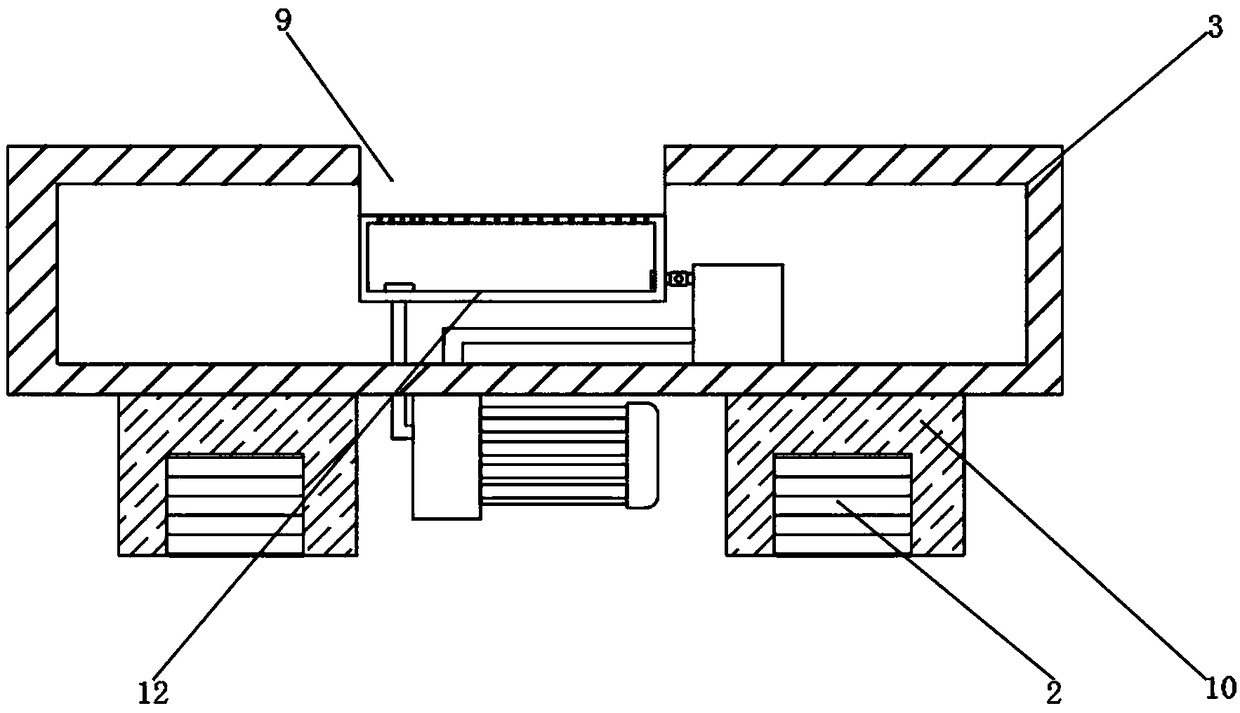

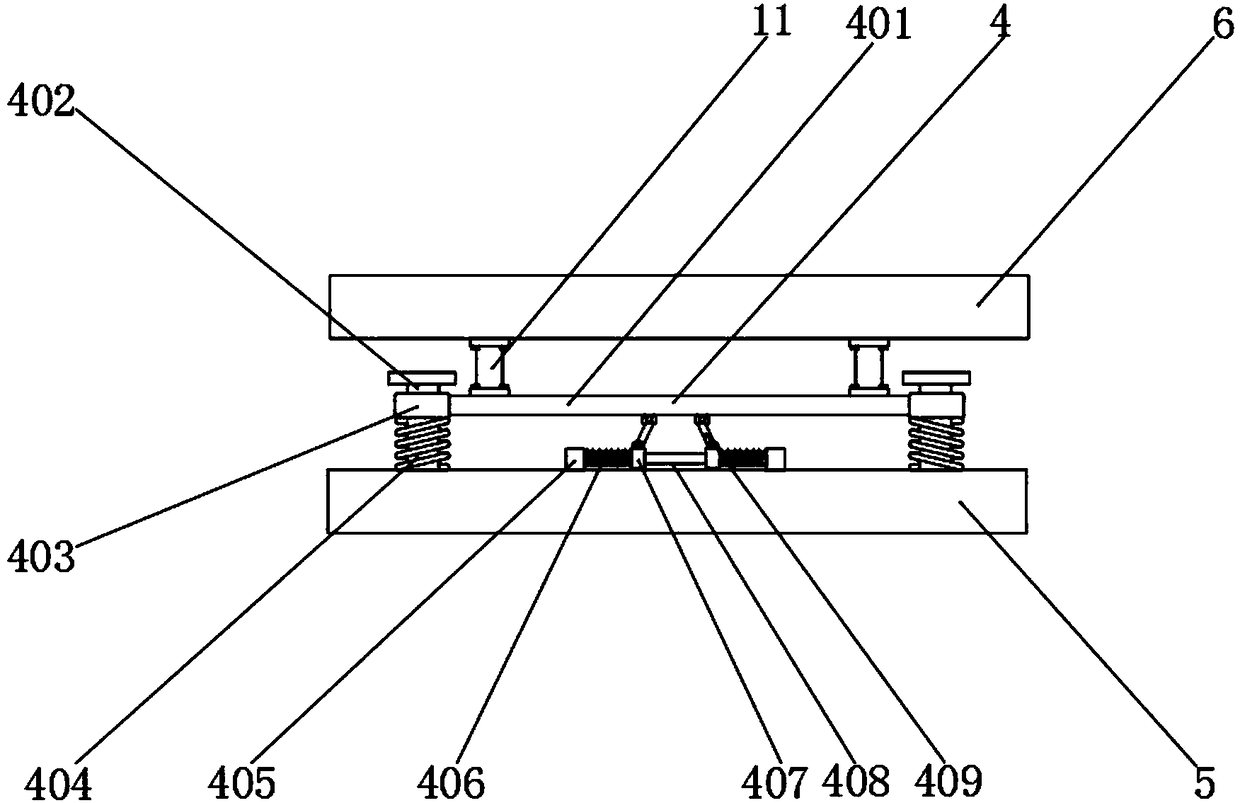

[0024] Example: refer to Figure 1-5 , the present invention provides a technical solution, a full-automatic watch all-in-one machine, including a base 1, the top of the base 1 is provided with a box 7, and the base 1 and the box 7 are fixedly connected by a frame 13, the base A slide rail 2 is fixed on the upper surface of the base 1, and a lower fitting plate 3 is arranged above the base 1, and the bottom of the lower fitting plate 3 is slidingly connected with the slide rail 2 through a chute 10, and the upper surface of the lower fitting plate 3 is provided with a sticking plate. Fitting parts are placed groove 9, and the interior of lower fitting board 3 is provided with fitting parts fast fixing device 12 at the position corresponding to fitting parts placing groove 9, and the front surface of box body 7 is provided with control panel 8, and the front surface of box body 7 is provided with The bottom is connected with a pressing plate 6, and an upper laminating plate 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com