Patents

Literature

217results about "Clock support devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

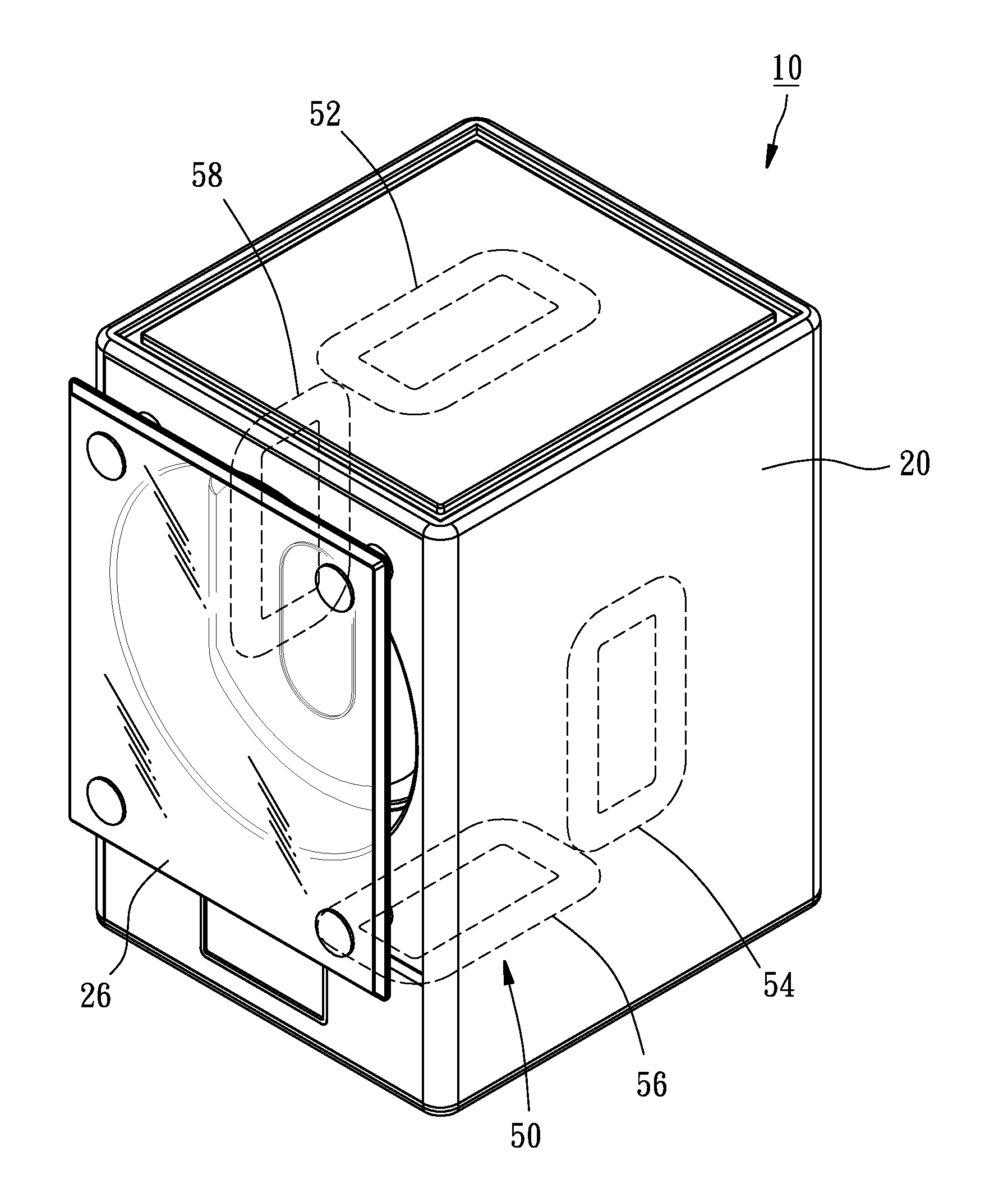

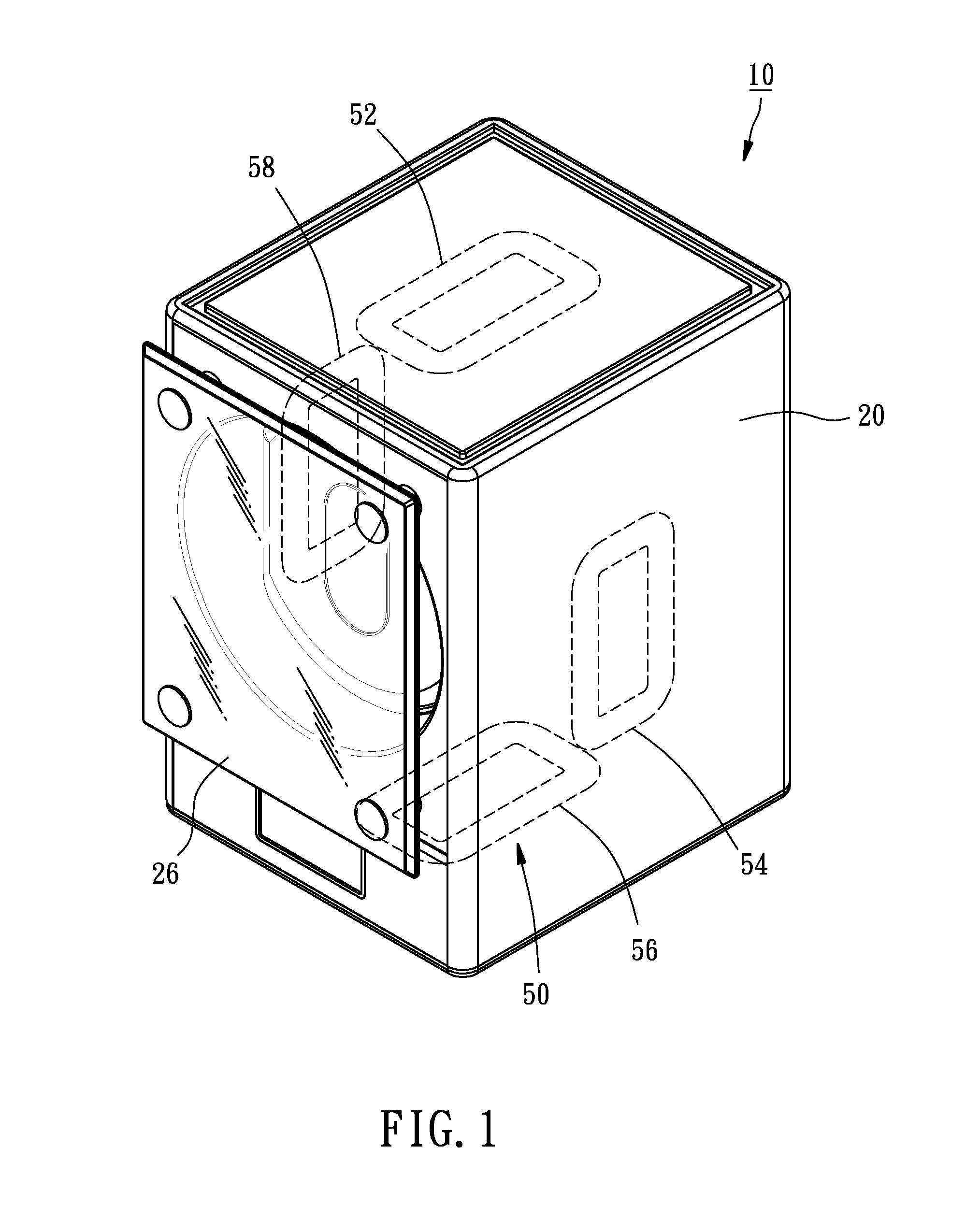

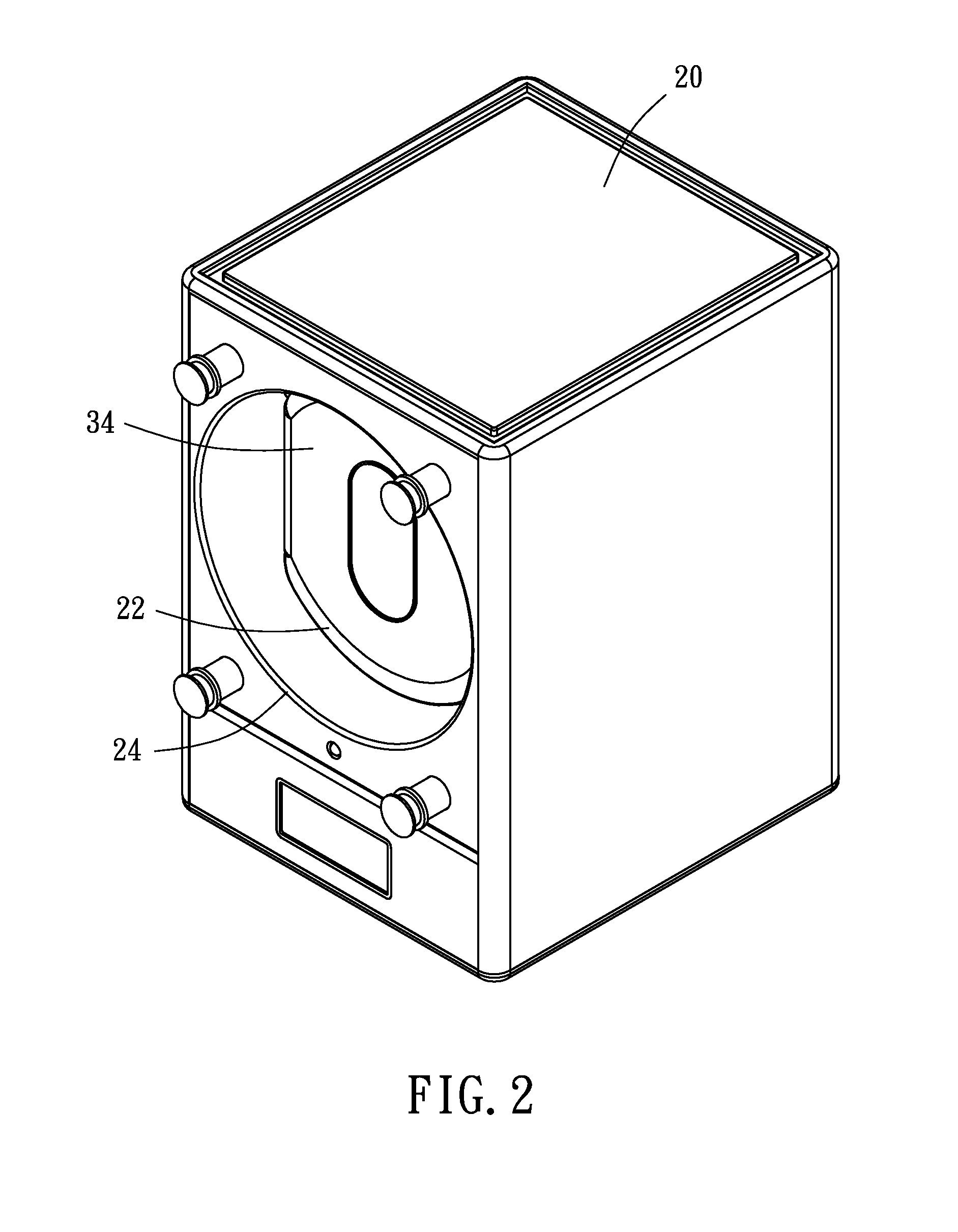

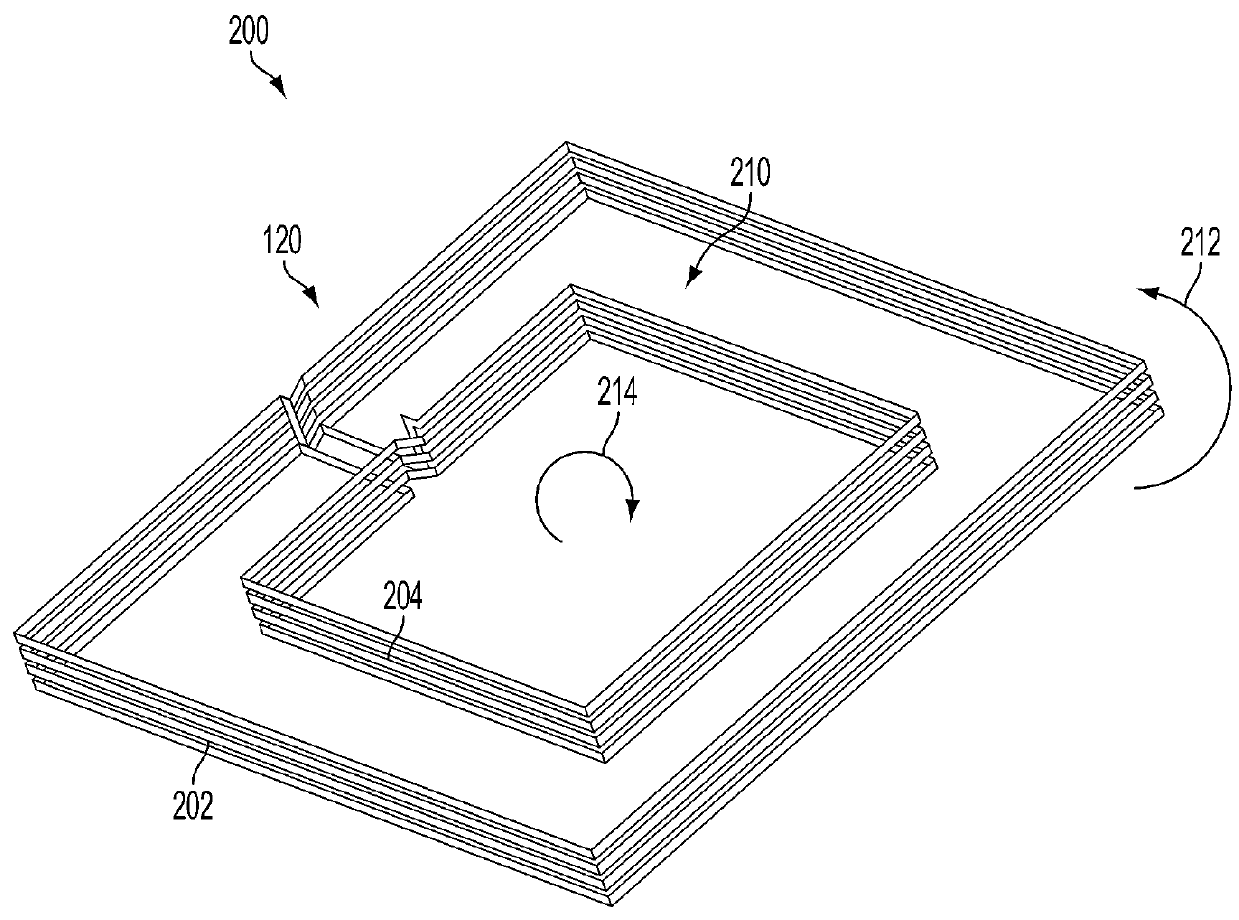

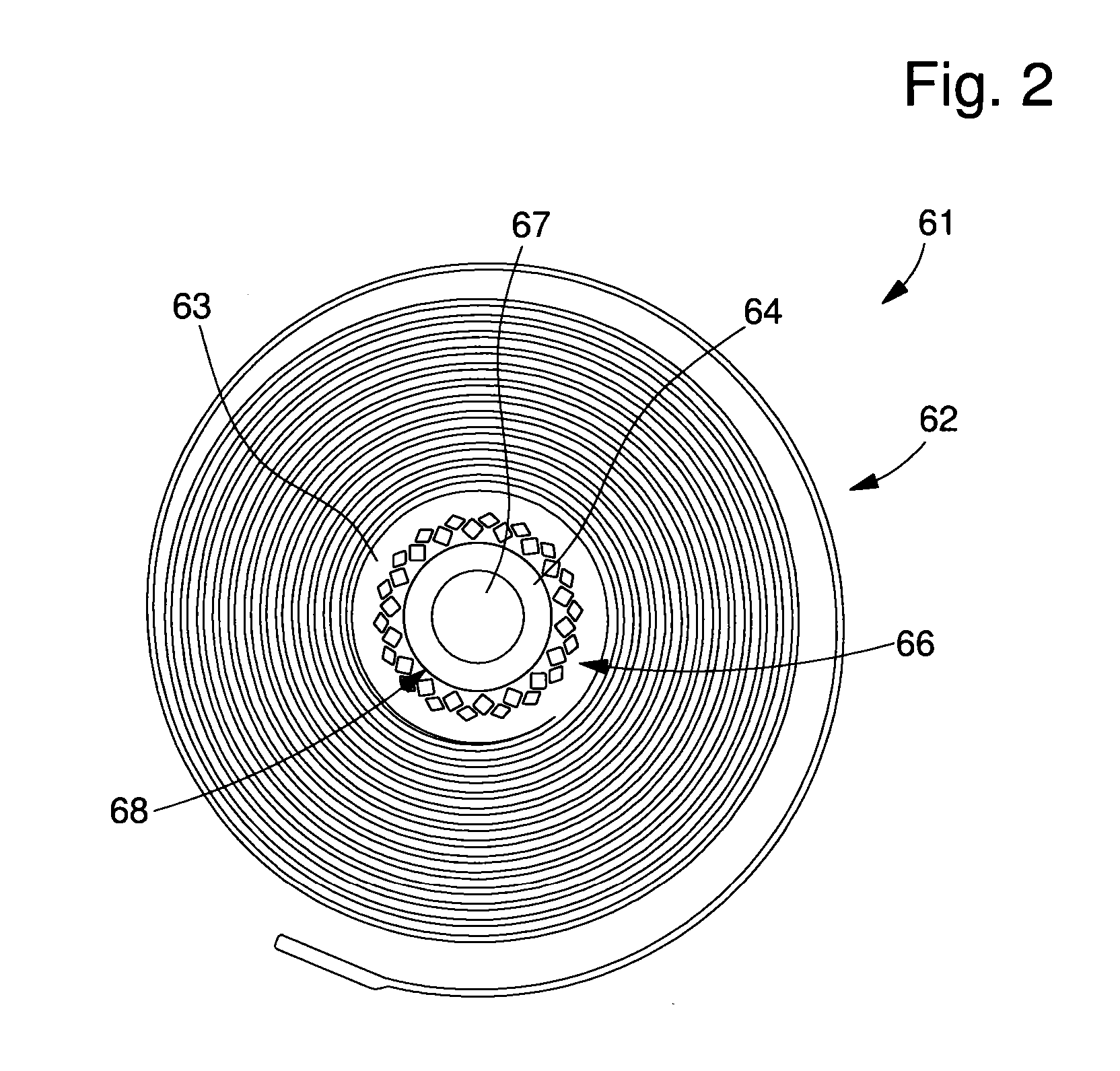

Watch winder having wireless energy transferring function

InactiveUS8714813B2Increase contactBatteries circuit arrangementsElectric windingTransmitter coilElectricity

A watch winder includes a housing, a power supply disposed in the housing, a transmitter coil mounted at one side of the housing and electrically connected with a circuit board of the power supply, and a receiver coil mounted at another side of the housing and electrically connected with a circuit board of the power supply. The fist coil can be actuated by the power supply to transmit a signal, and the receiver coil can be used to receive a signal and convert the signal into an electrical current that can be transmitted to the circuit board for charging the power supply. Therefore, the electrical energy of the watch winder can be wireless transmitted through a non-contact interface.

Owner:GOOTEN INNOLIFE CORP

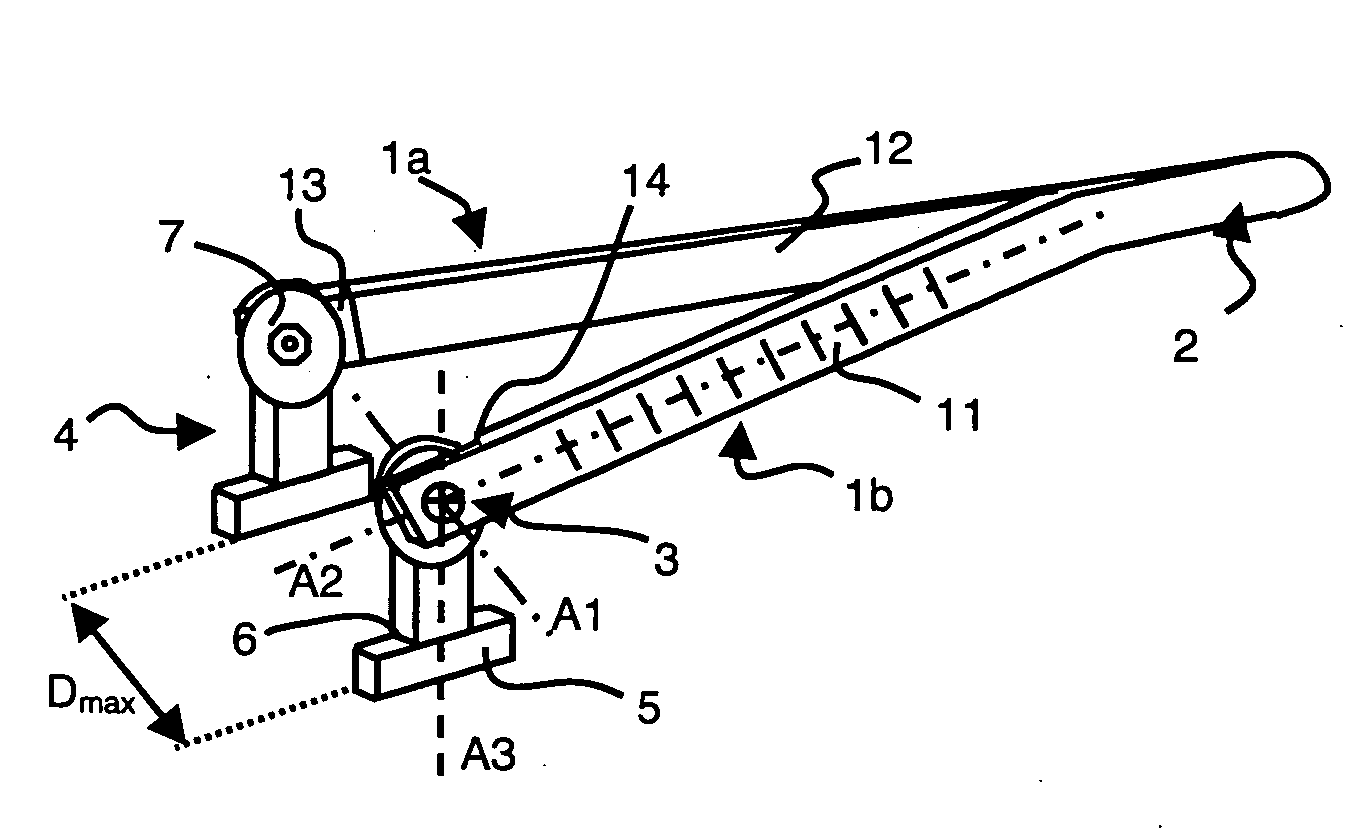

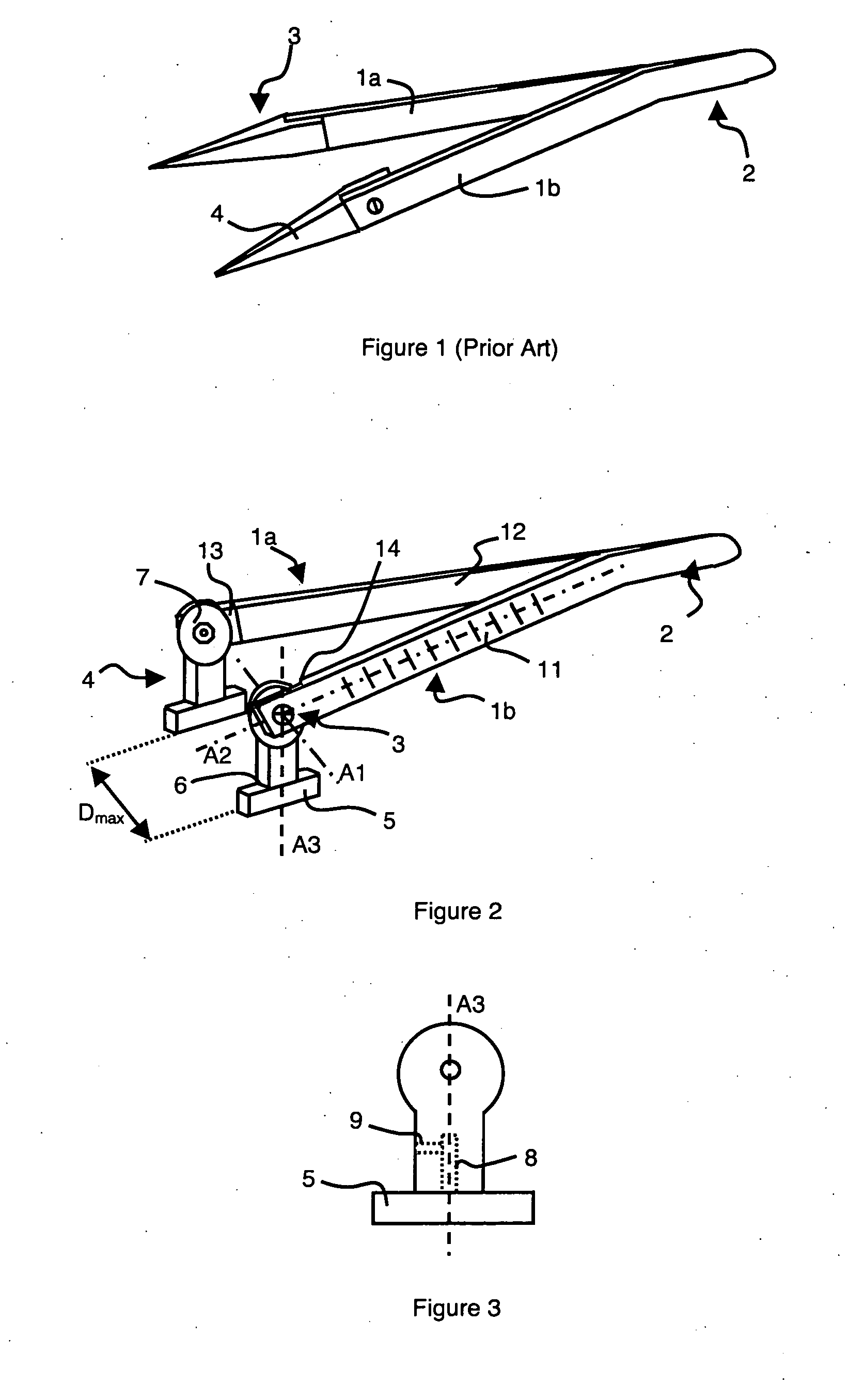

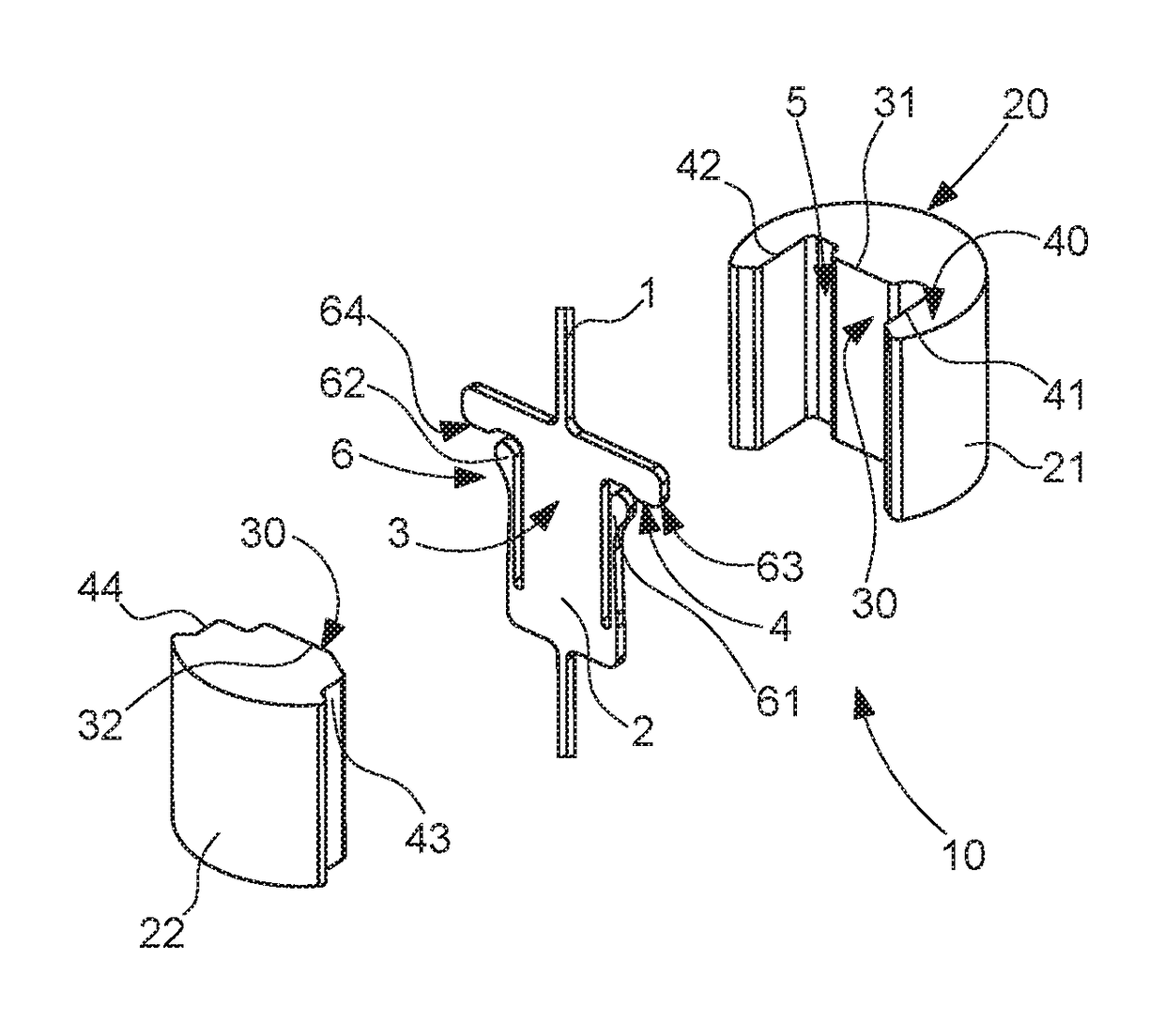

Tweezers with gripping elements mounted swivelling on branches

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

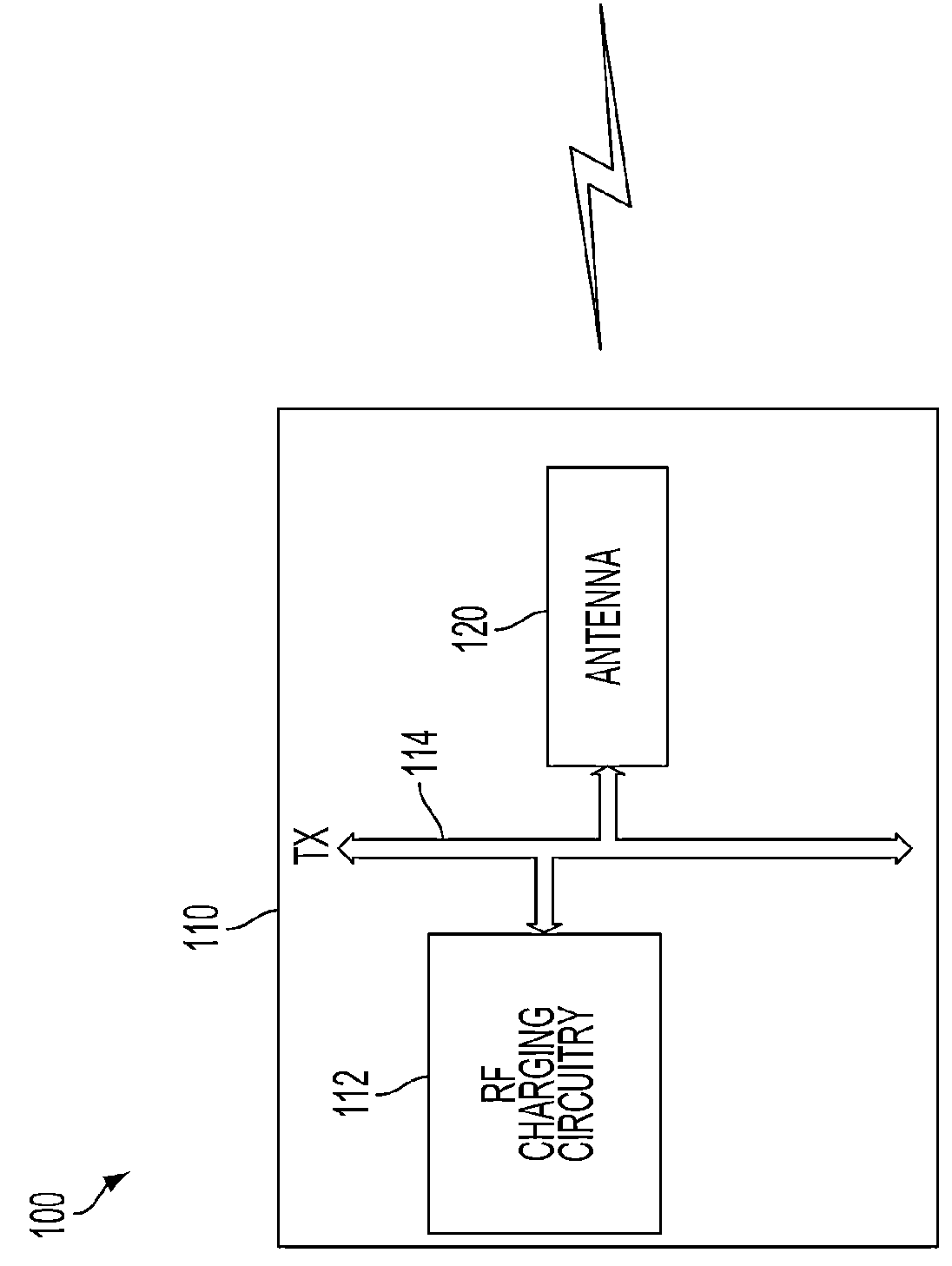

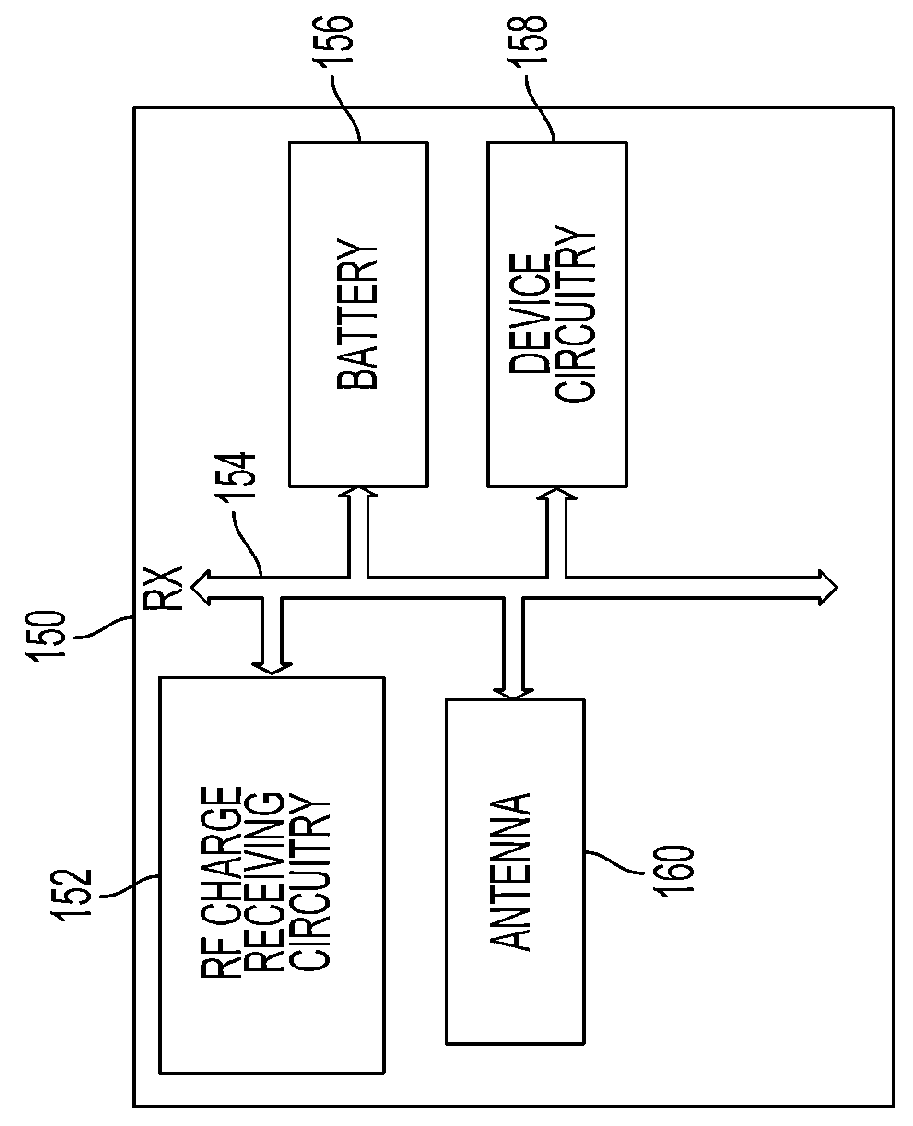

Wireless charging systems and methods

An embodiment of a system for wirelessly charging a wrist-worn device may include a radio frequency (RF) charging energy generating element, and an antenna configured to radiate the RF charging energy, the antenna comprising a first coil and a second coil, the first coil and the second coil each comprising a plurality of windings, the windings of the first coil being wound in a direction opposite the direction of the windings of the second coil. An embodiment of a wrist-worn charge-receiving device may include an antenna coil adapted to receive radio frequency (RF) charging energy, the antenna coil comprising non-uniform windings; and a rechargeable power source coupled to the antenna coil, the antenna coil adapted to provide the RF charging energy to the rechargeable power source.

Owner:QUALCOMM INC

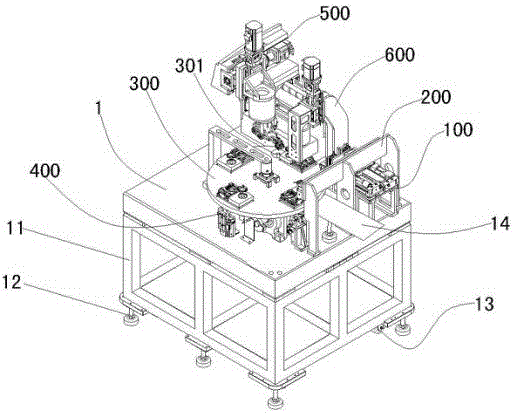

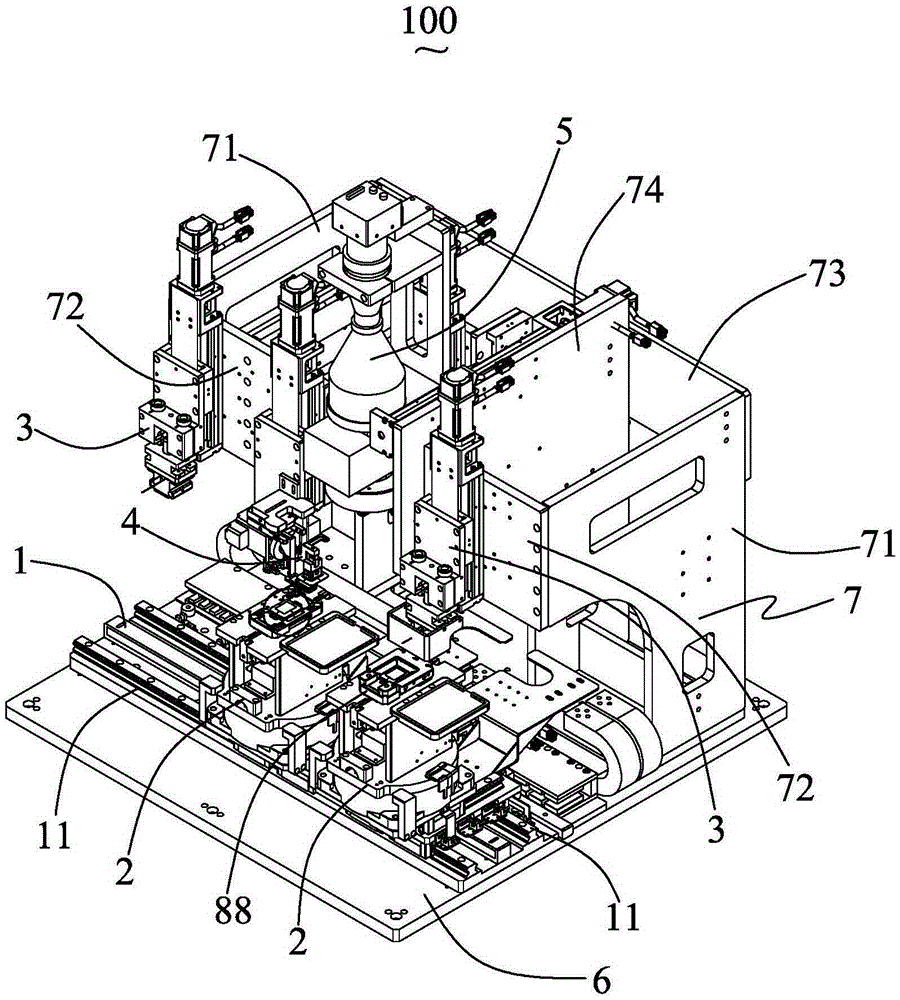

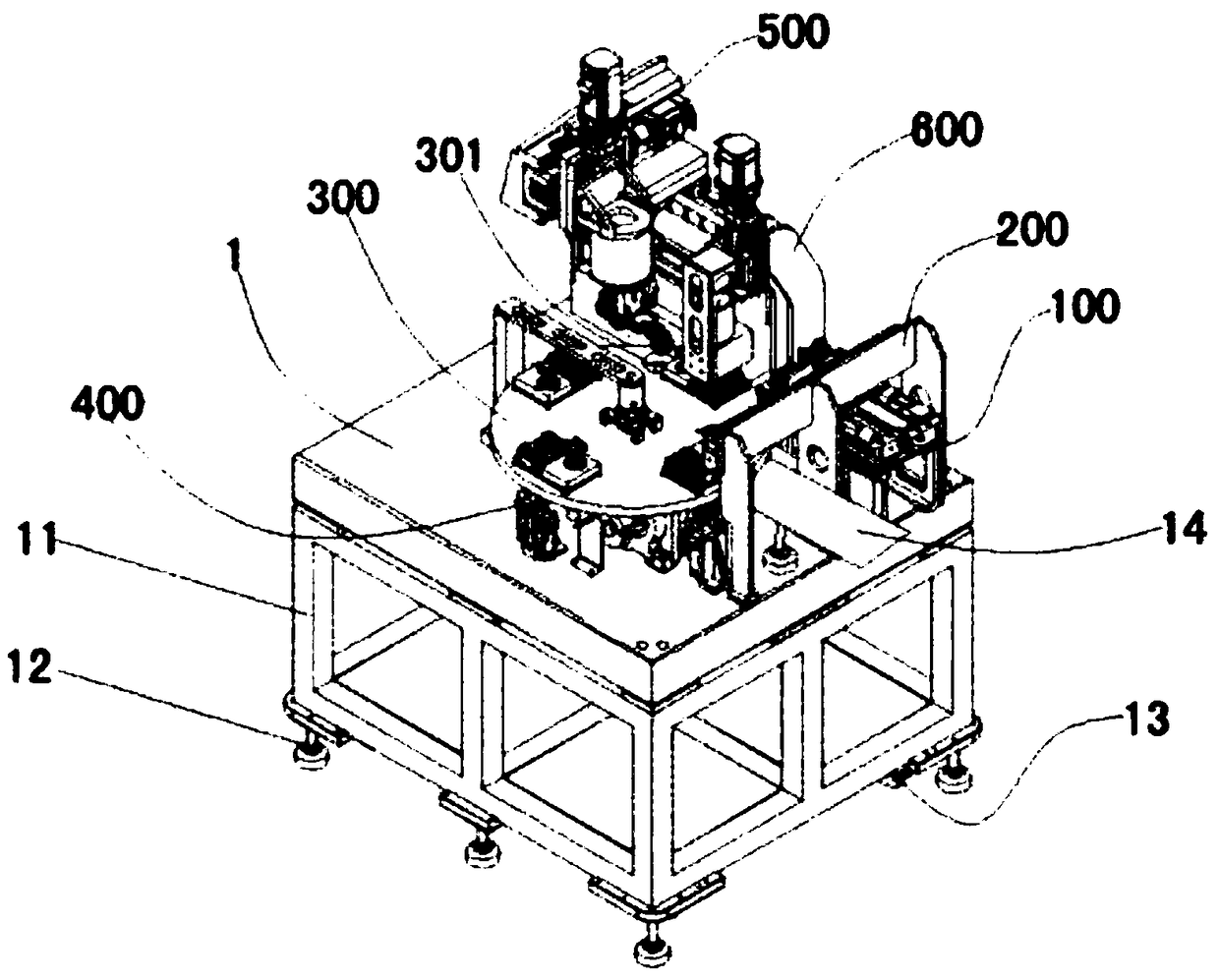

Rear shell positioning assembly device of watch and processing technology thereof

ActiveCN106773605ARealize automatic photo detectionIncrease temperatureClock support devicesEngineeringMechanical engineering

The invention discloses a rear shell positioning assembly device of watch and processing technology thereof. The assembly device comprises a working bench and a turntable assembly of the working bench. The turntable assembly is provided with a charging component, a gripping component, a contraposition component and a CCD component. The rear shell positioning assembly device of watch has the advantages of CCD automatic camera detection, accurate positioning and assembly, high temperature equipment, high installation accuracy, high production efficiency, good quality.

Owner:SHENZHEN RUIHUI BELL & WATCH

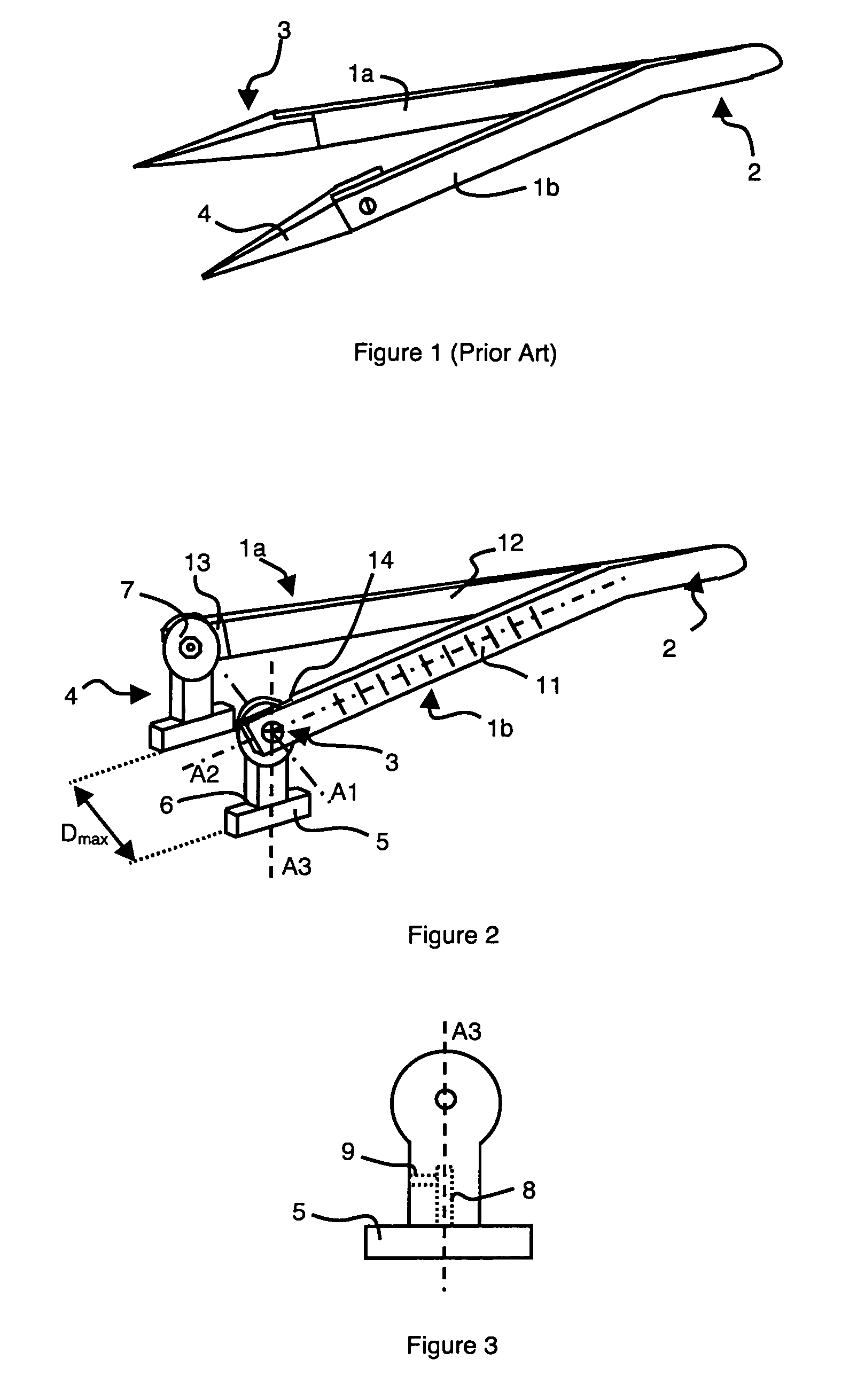

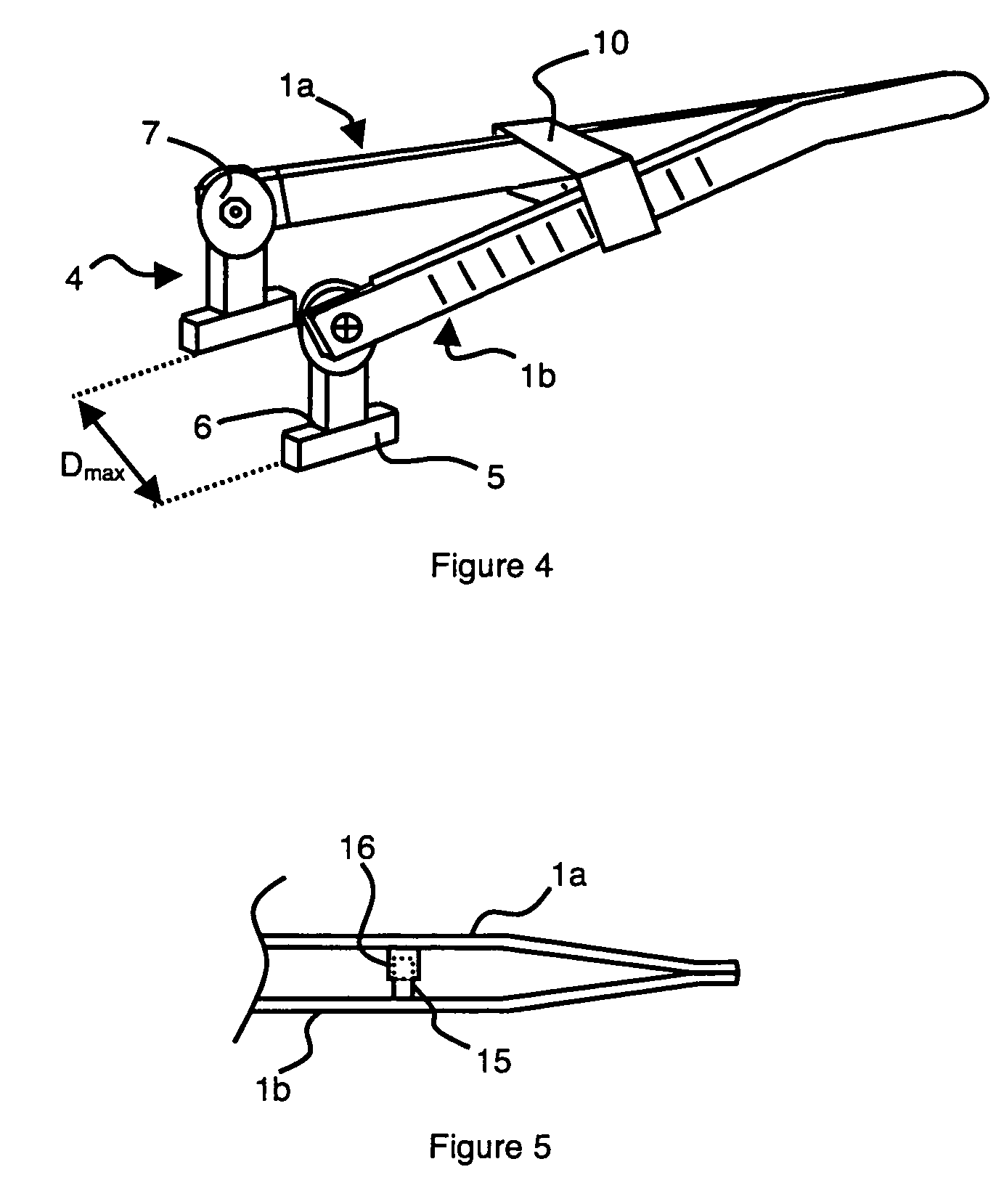

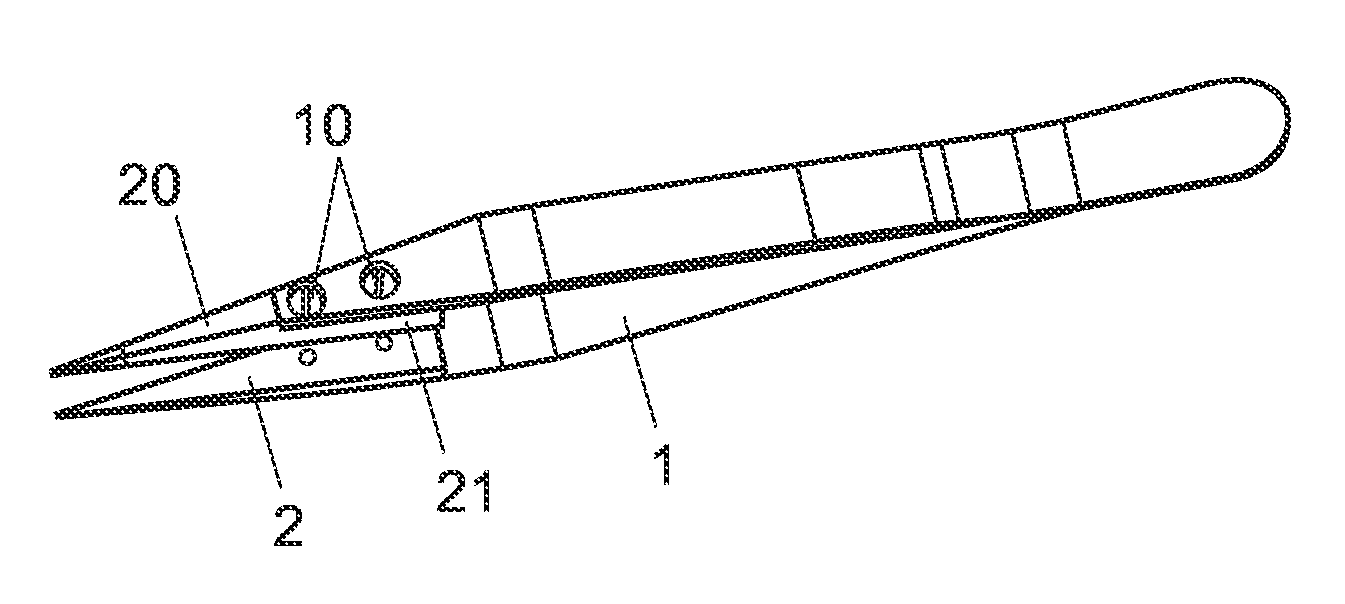

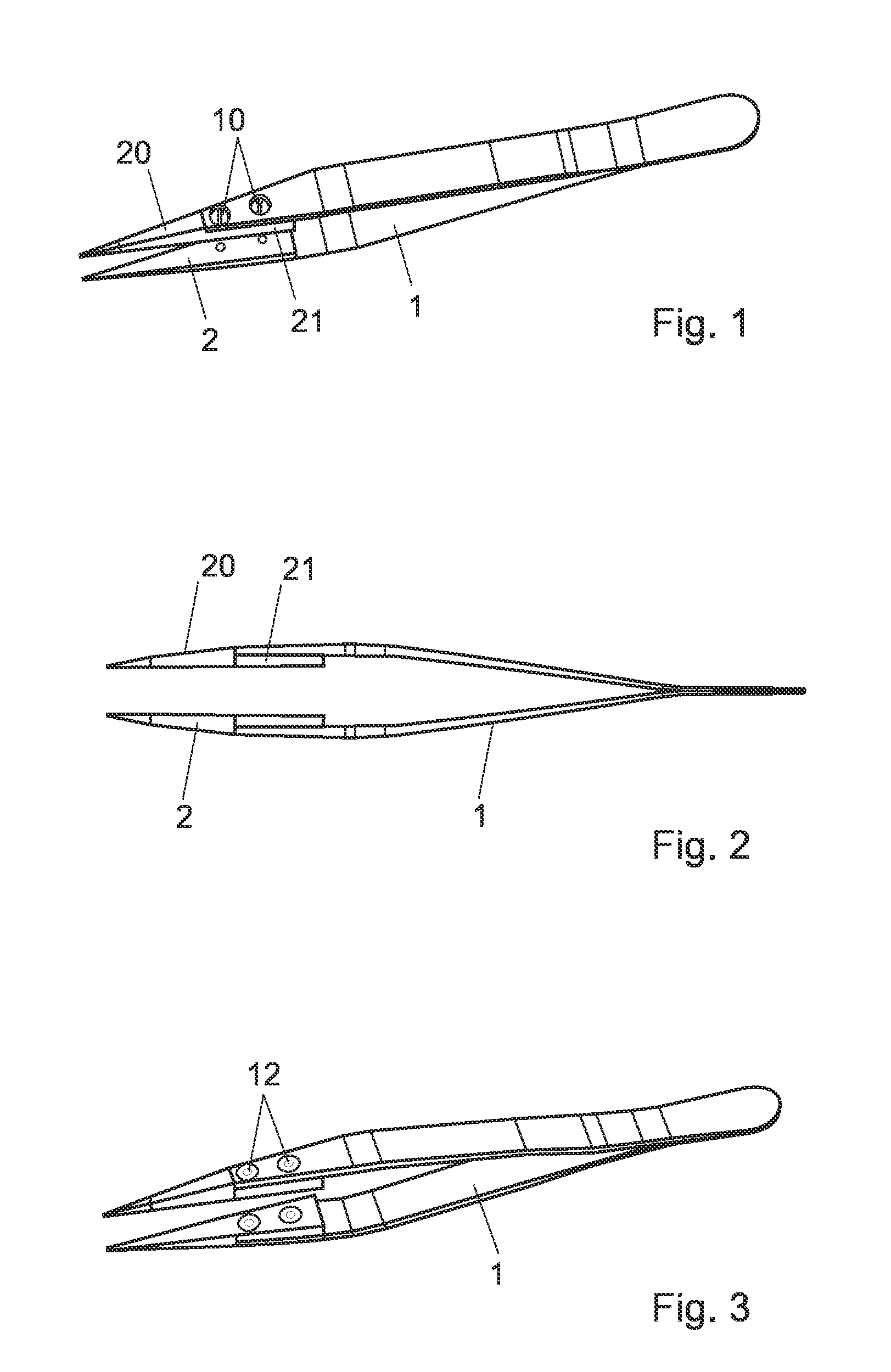

Tweezers with gripping elements mounted swivelling on branches

The tweezers comprises two branches joined at a first end, a second end of each branch comprising a gripping element. The gripping element of each branch is mounted rotating freely around a swivel axis at the second end of said branch. The gripping element of each branch comprises a longitudinal axis perpendicular to the corresponding swivel axis, and a pad is fixed to a free end of said gripping element perpendicularly to said longitudinal axis of the gripping element.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

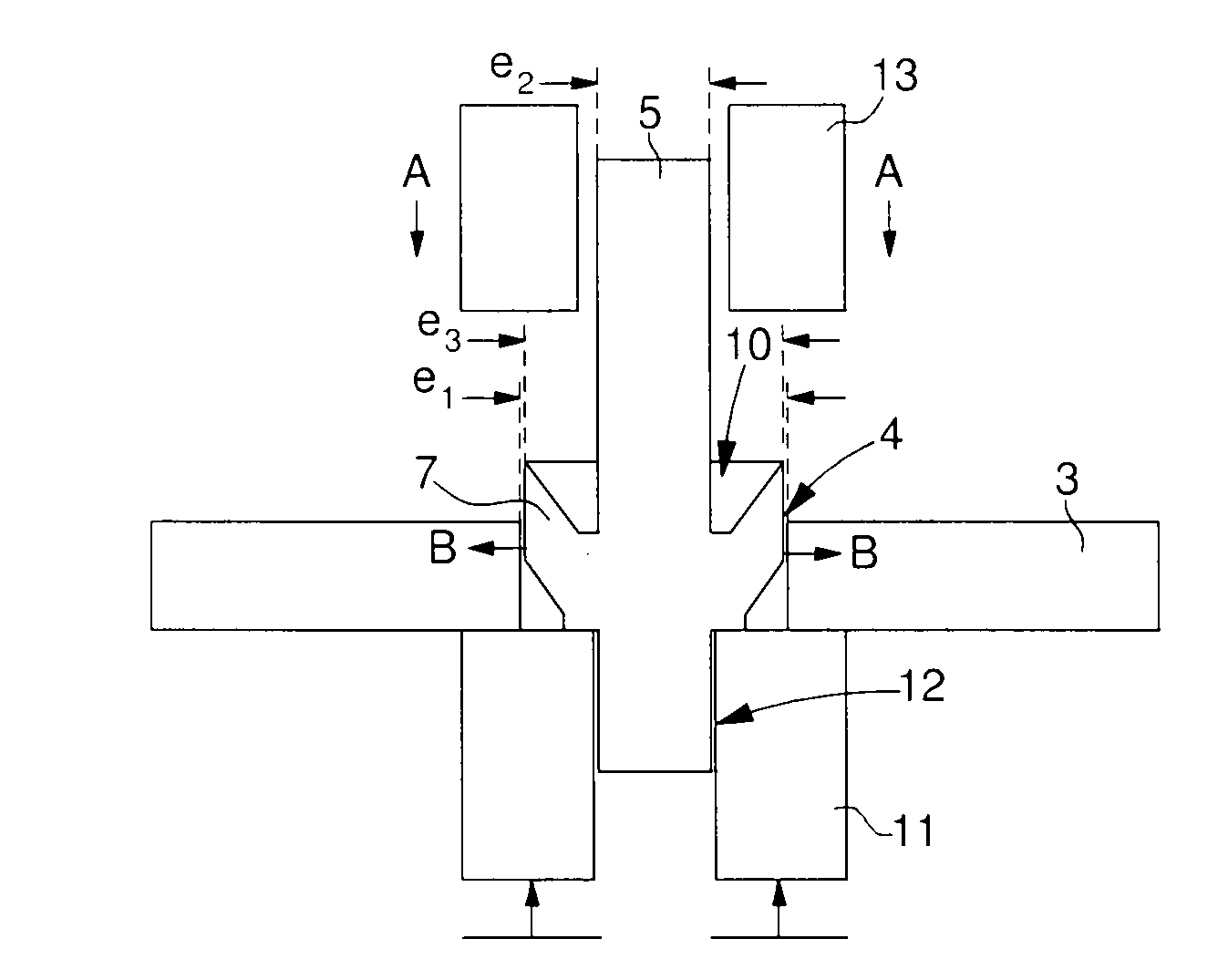

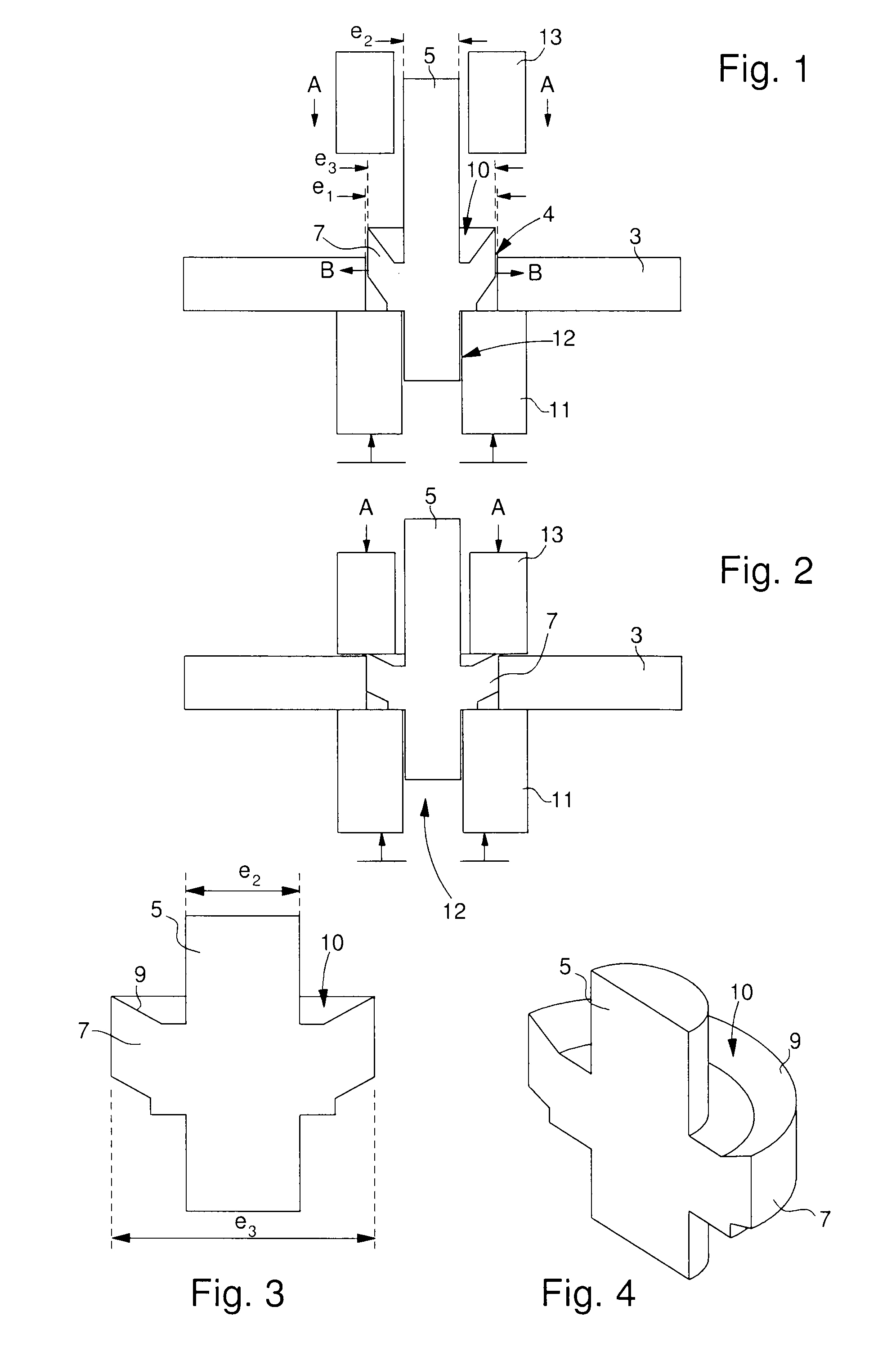

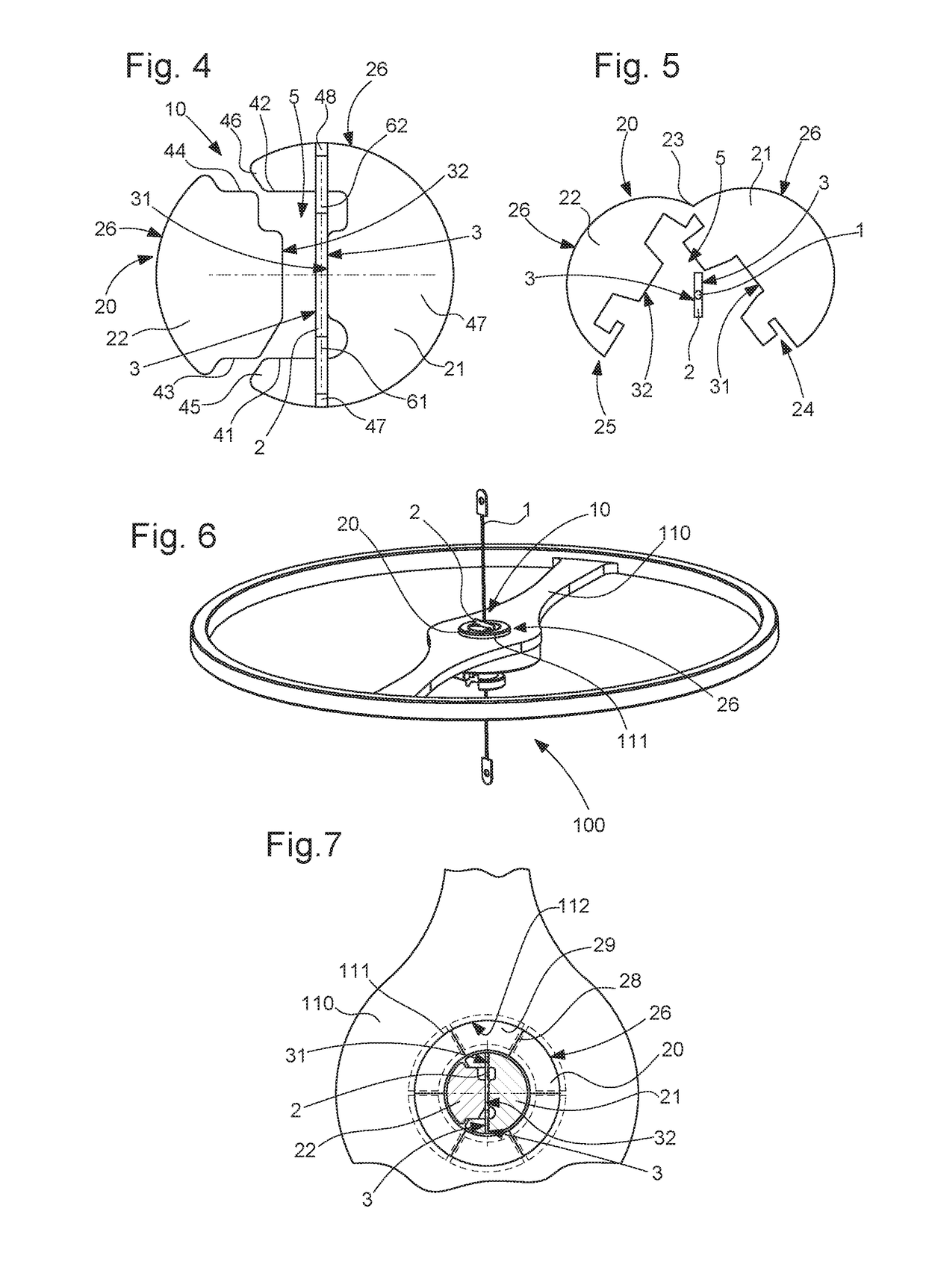

Assembly of a part that has no plastic domain

An assembly of an axially extending member, made of a first material, in an aperture of a part, made of a second material having no plastic domain. The part includes pierced holes forming an elastic deformation mechanism distributed around the aperture thereof. Further, the member includes an elastically and plastically deformed, radially flared portion that radially grips a wall of the part surrounding the aperture by stressing the elastic deformation mechanism, so as to secure the assembly in a manner that is not destructive for the part. The assembly can be used in the field of timepieces.

Owner:ETA SA MFG HORLOGERE SUISSE

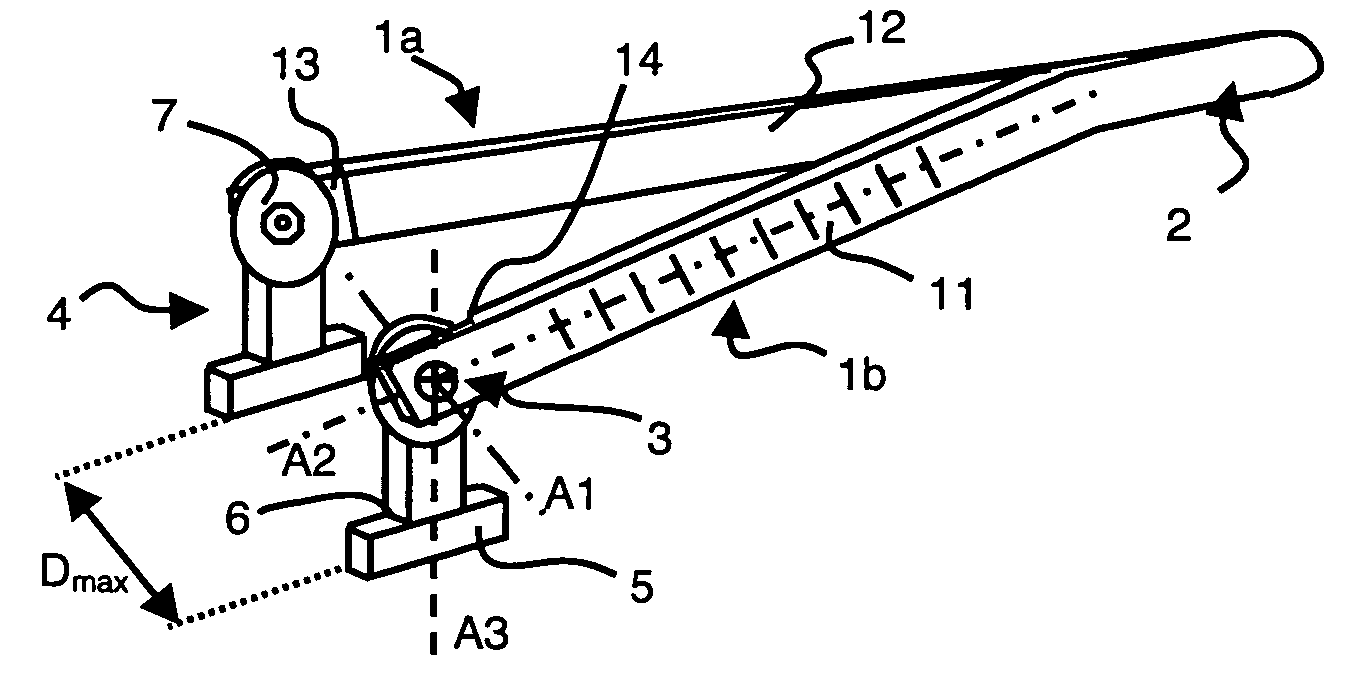

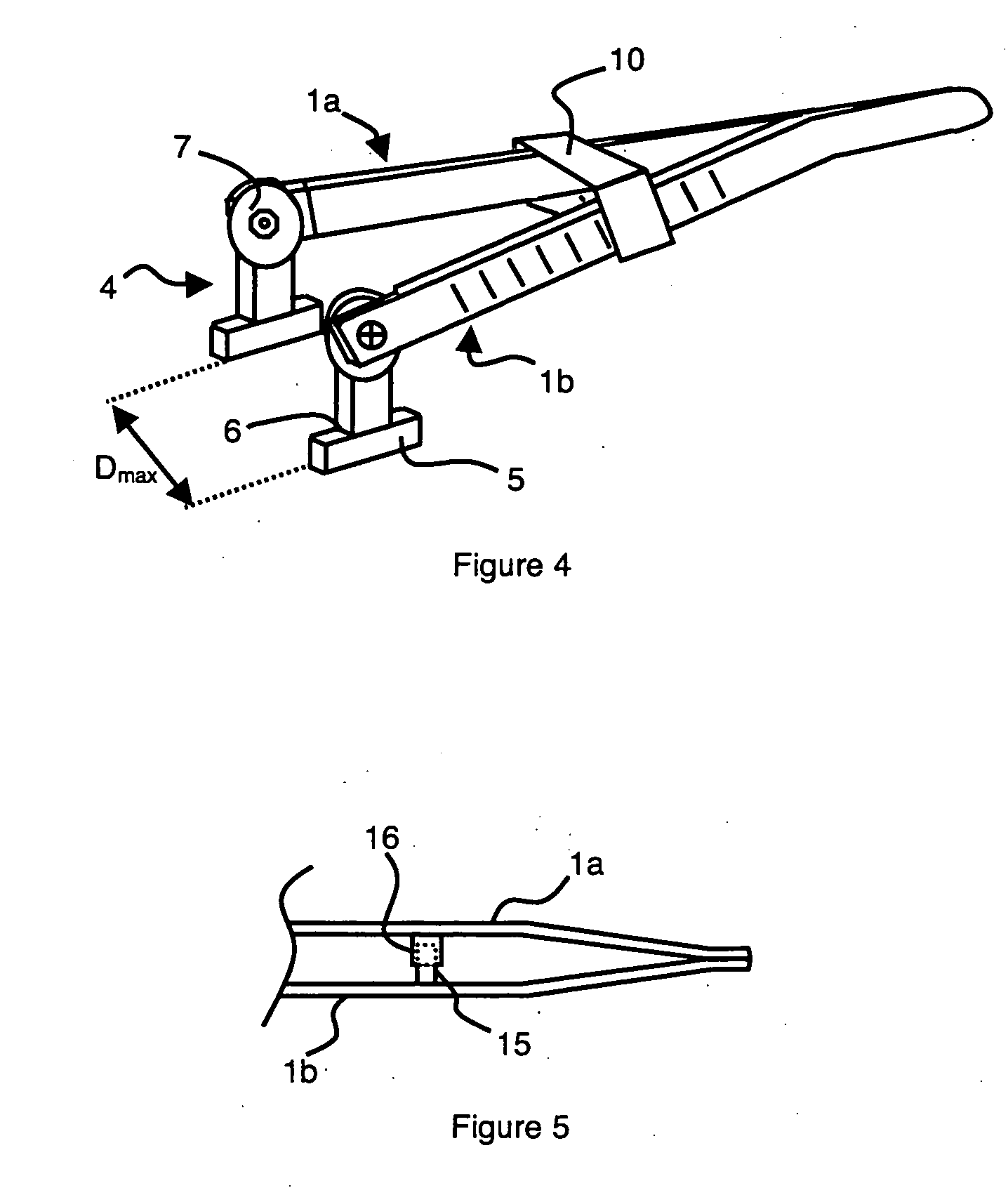

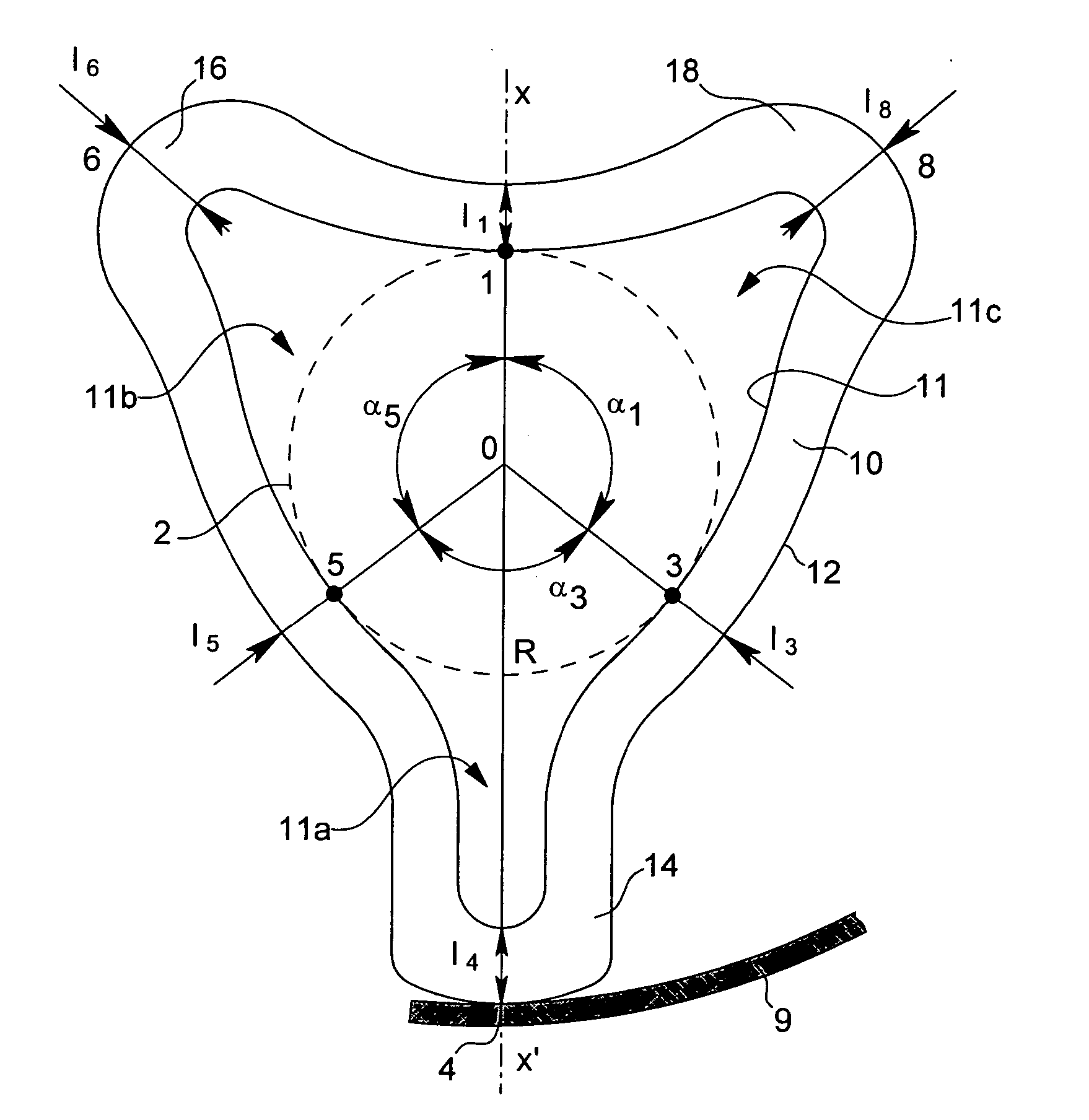

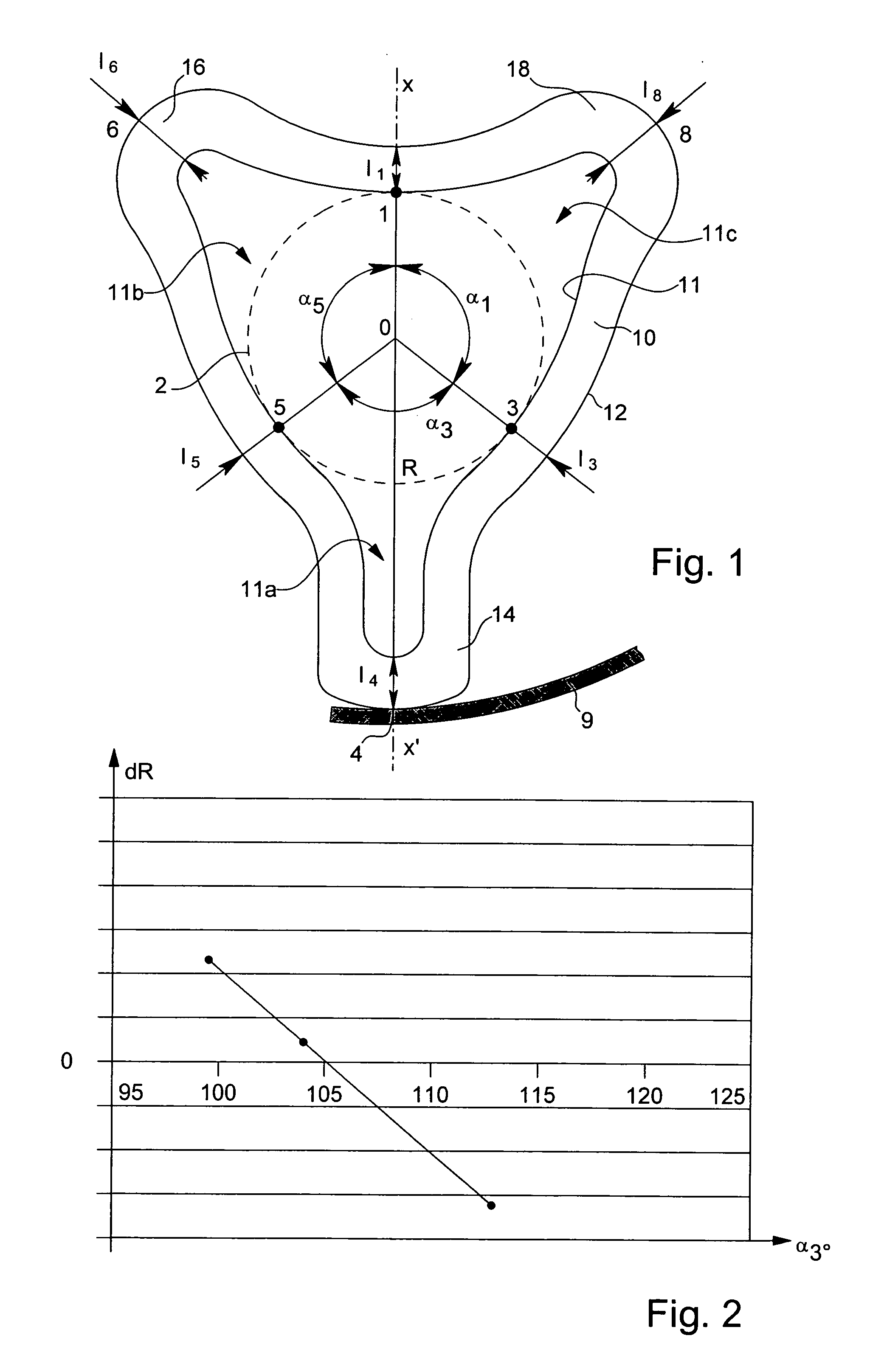

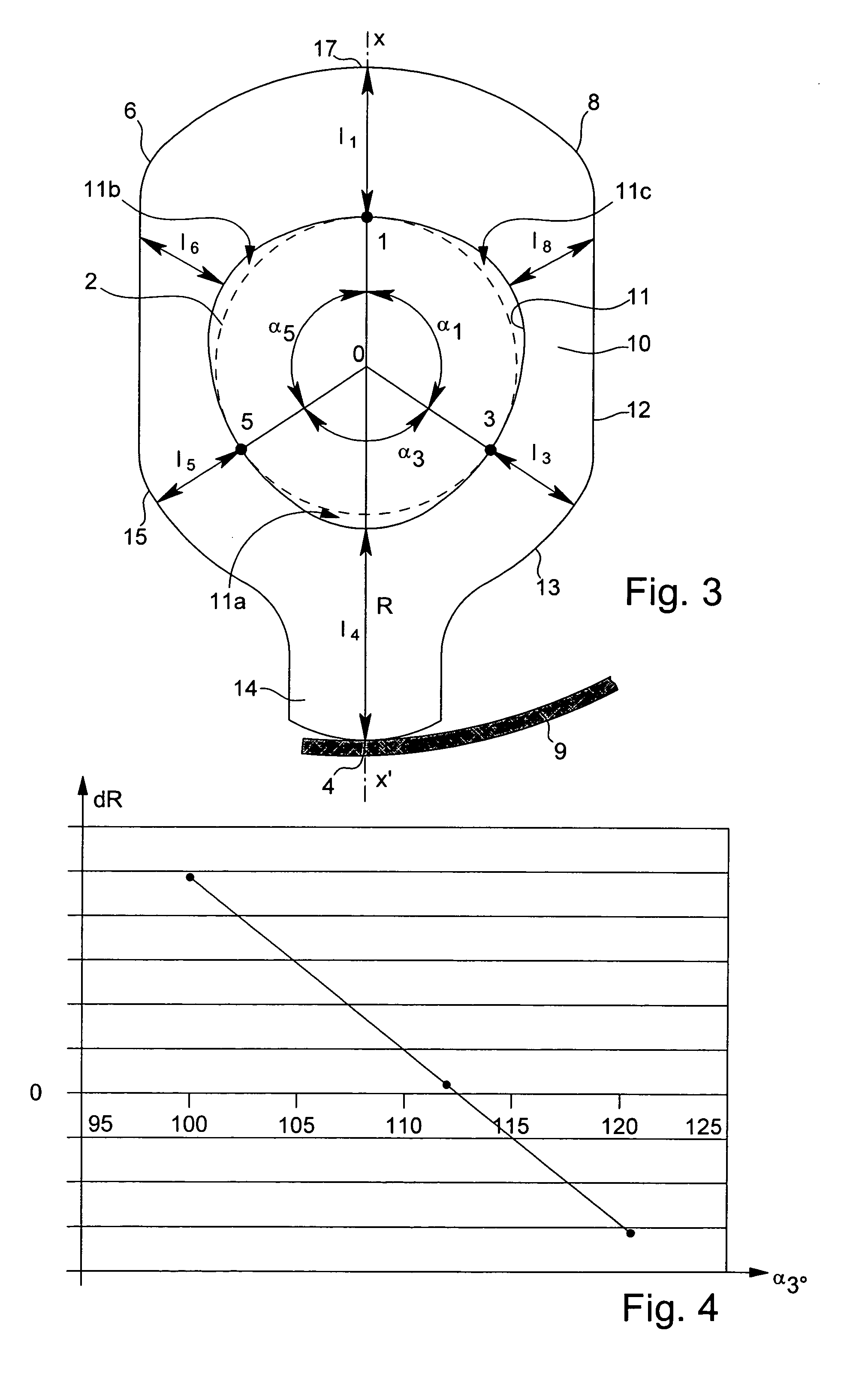

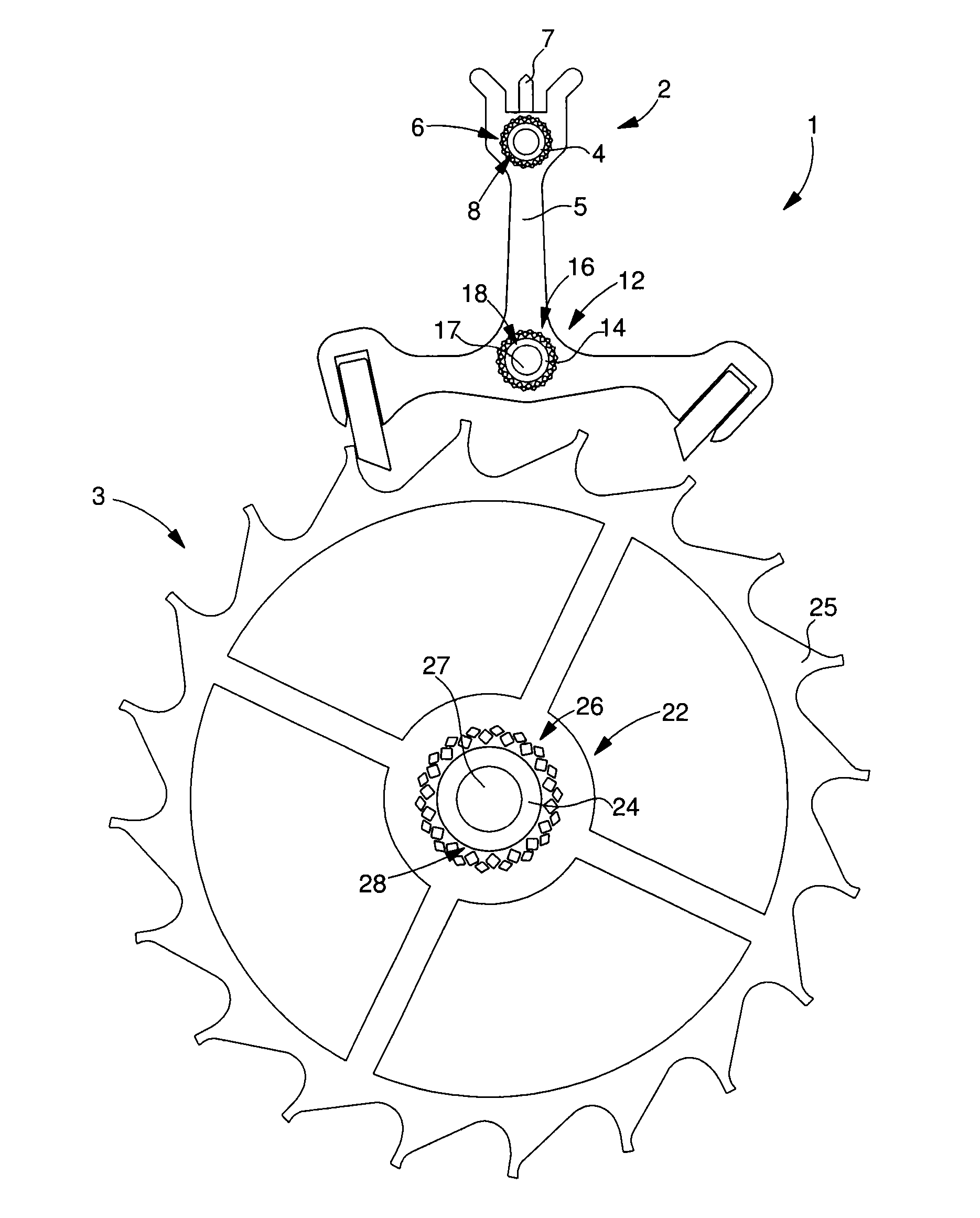

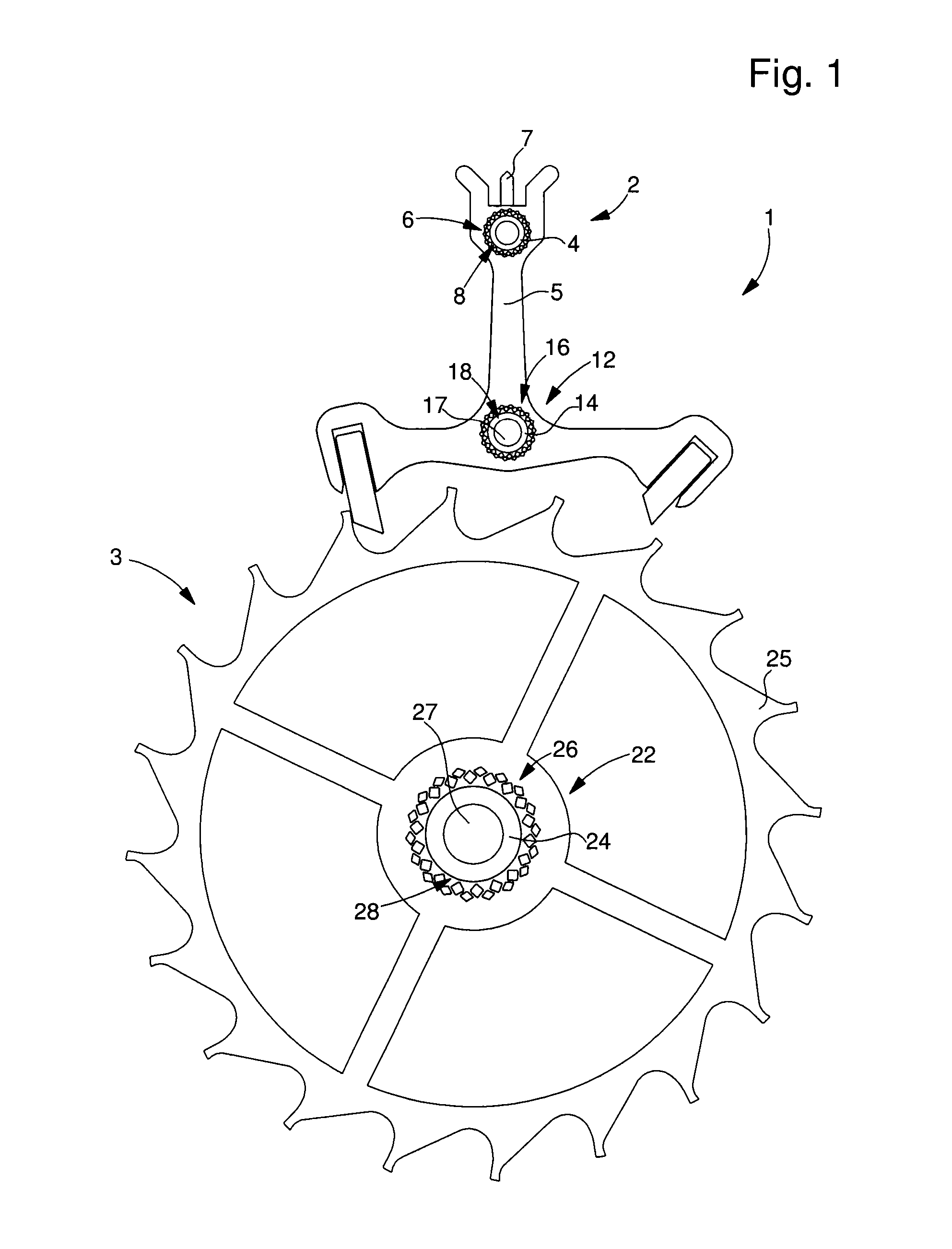

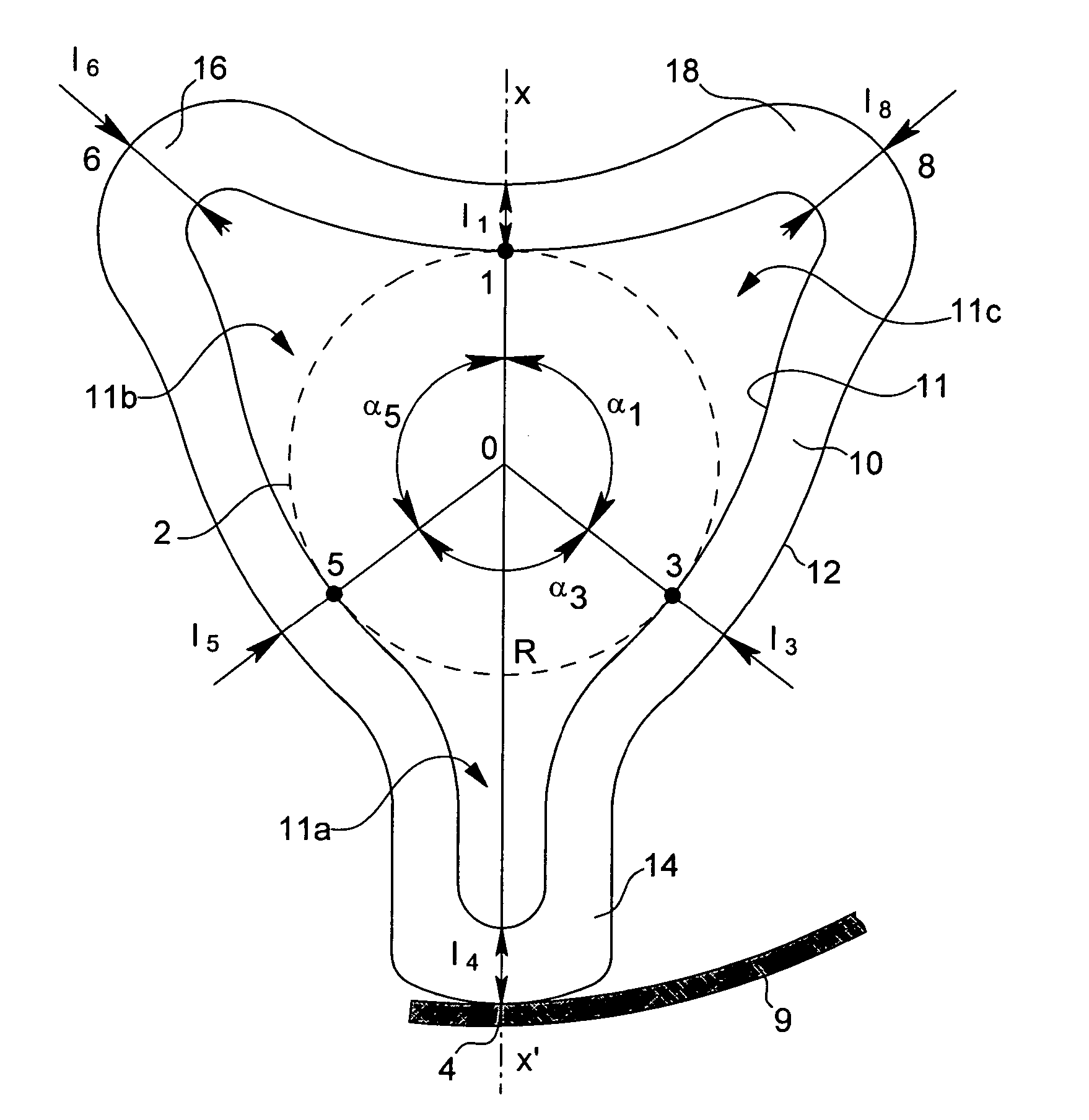

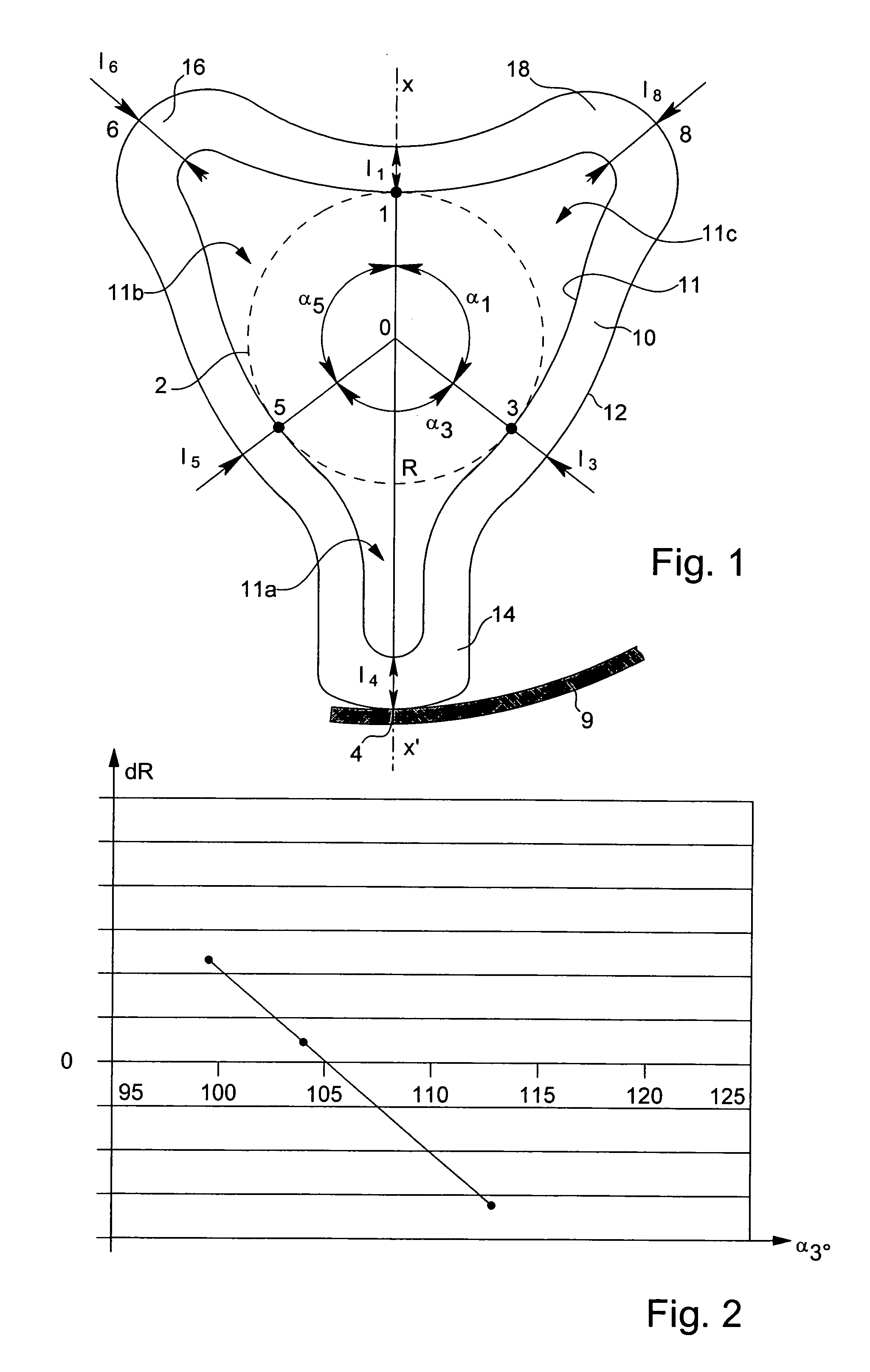

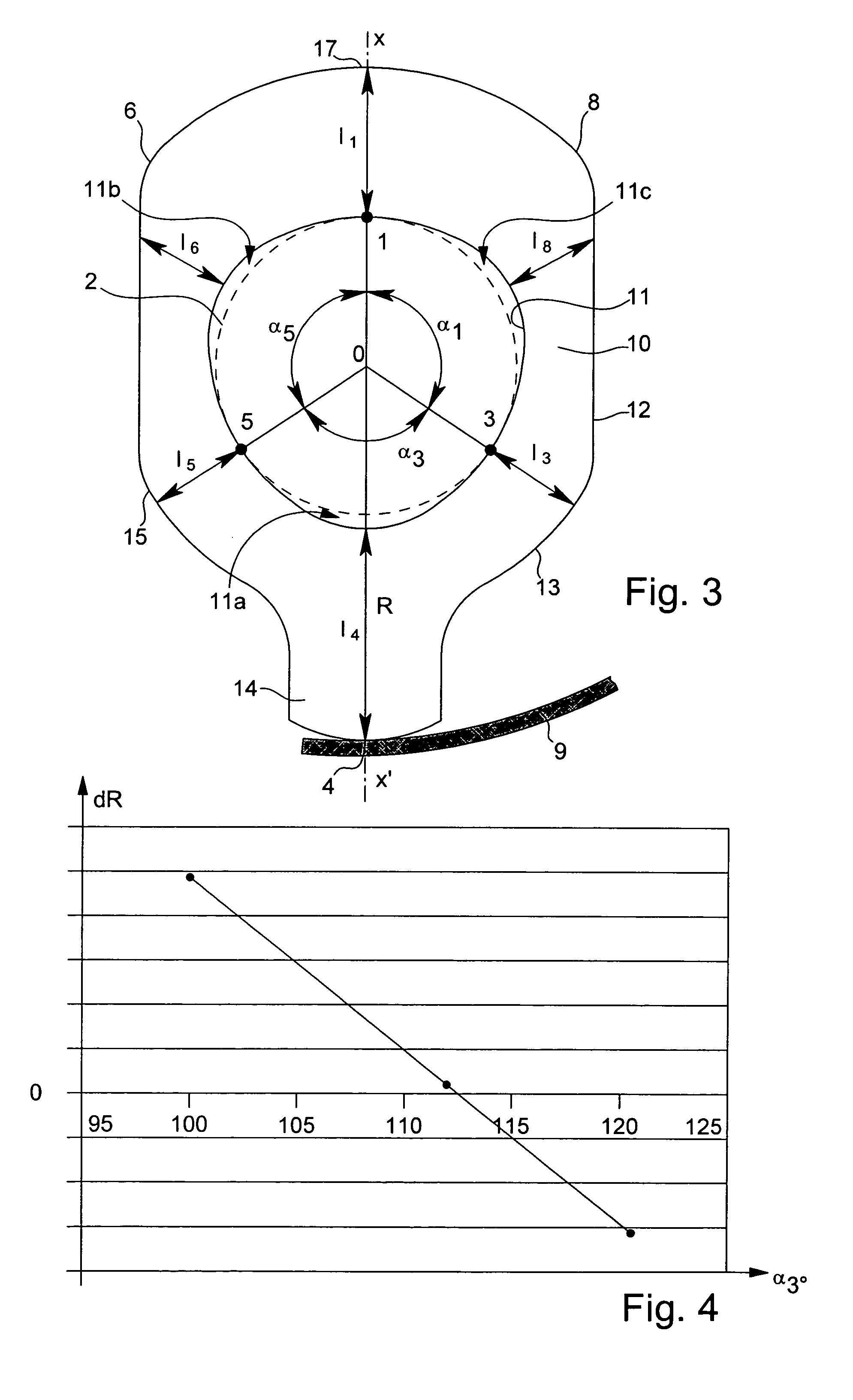

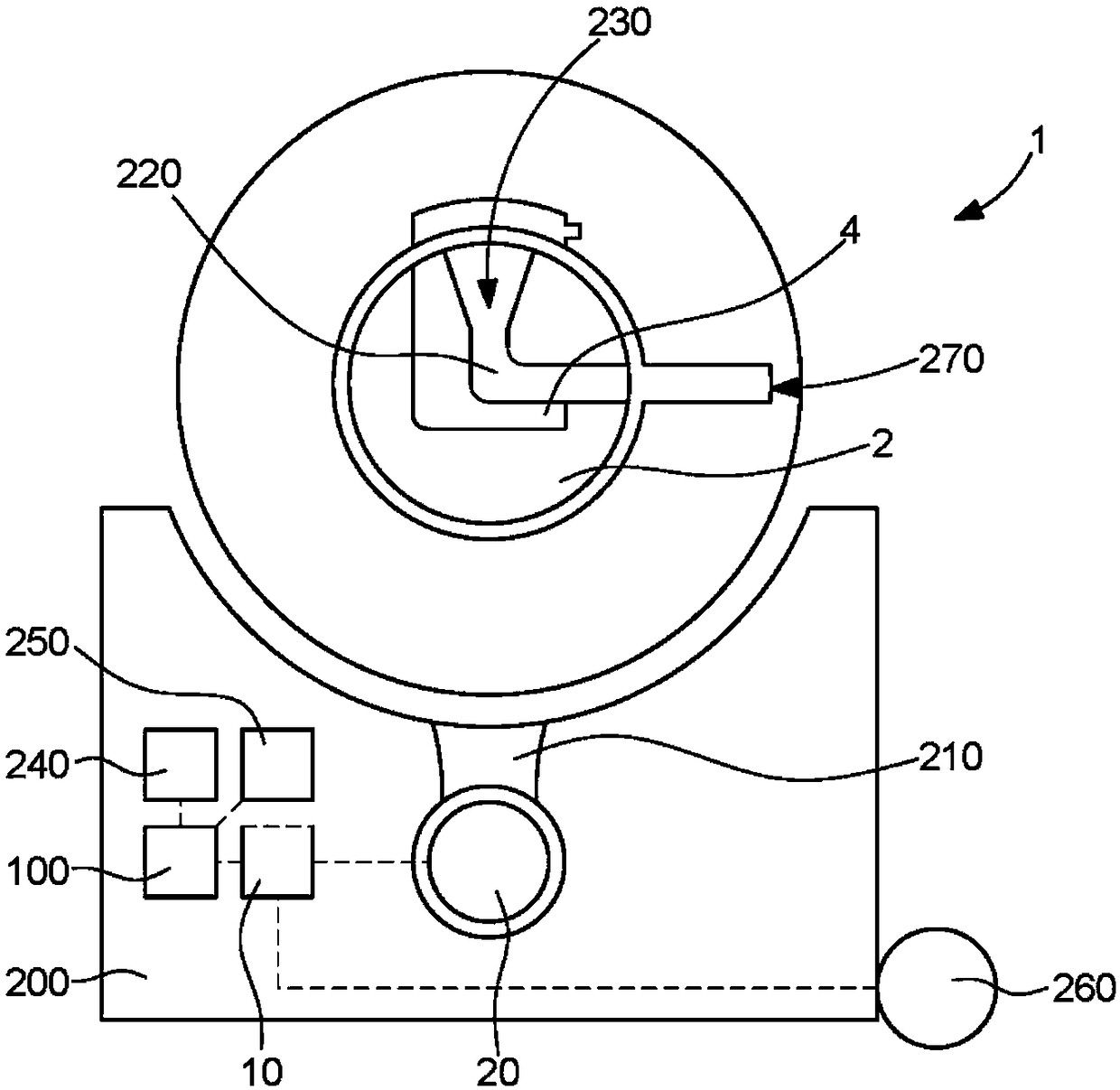

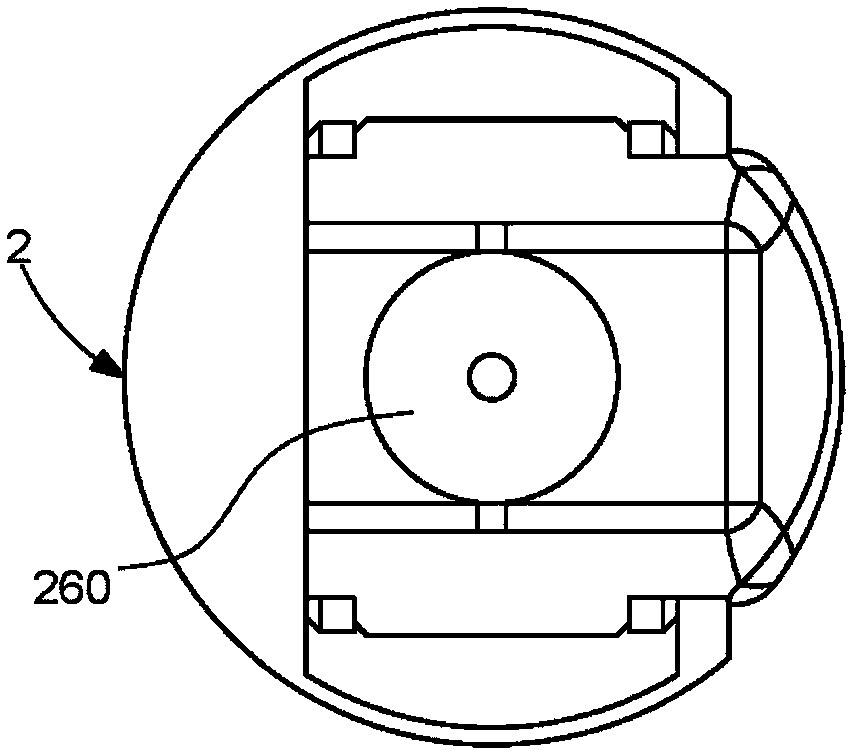

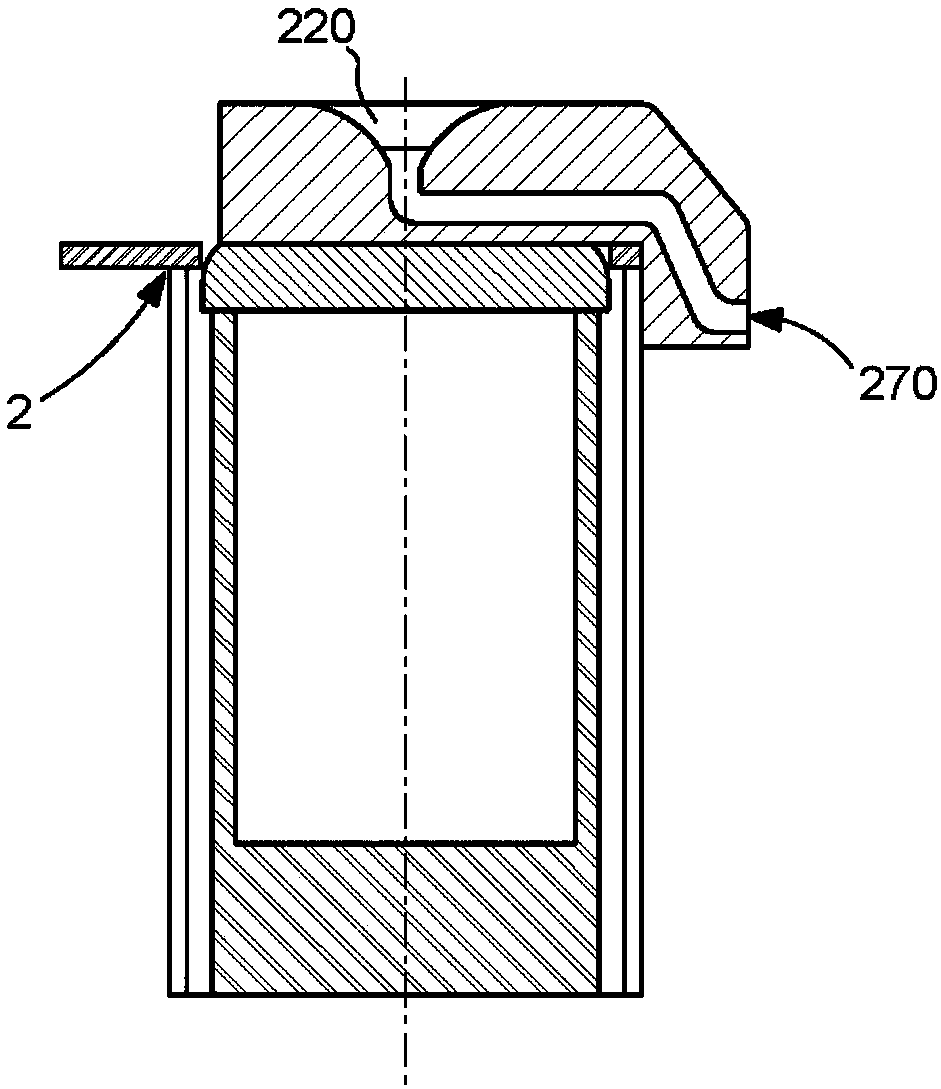

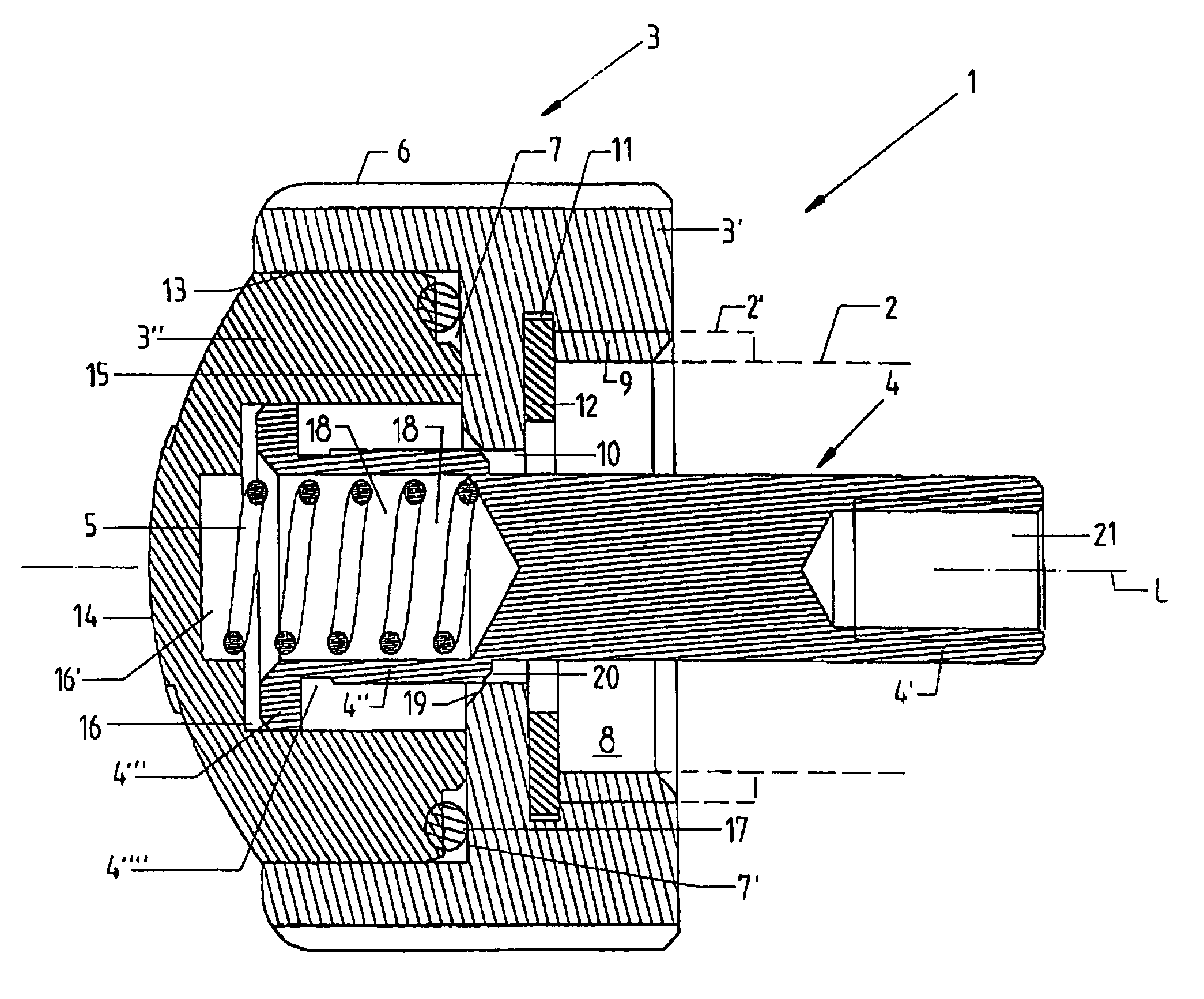

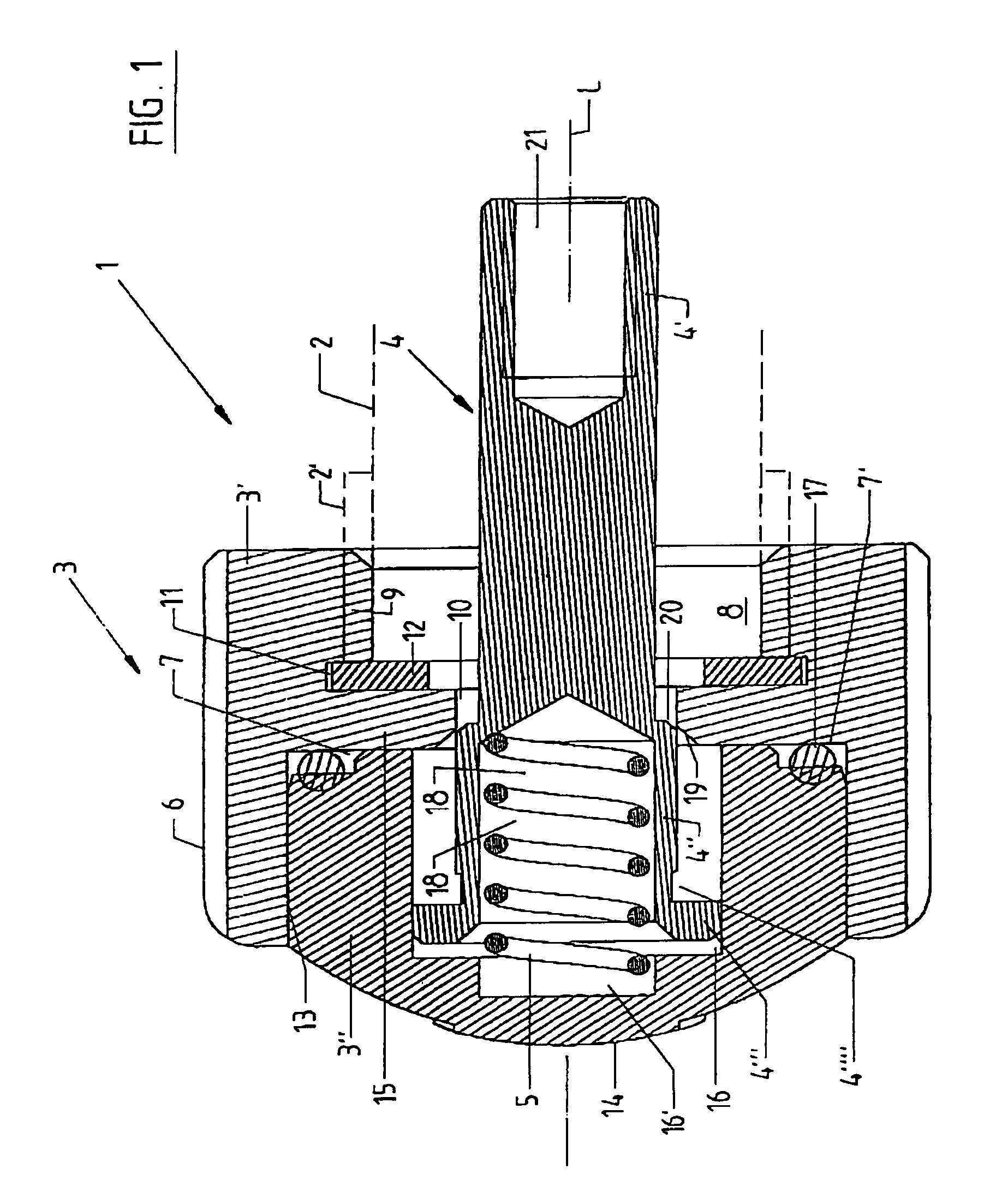

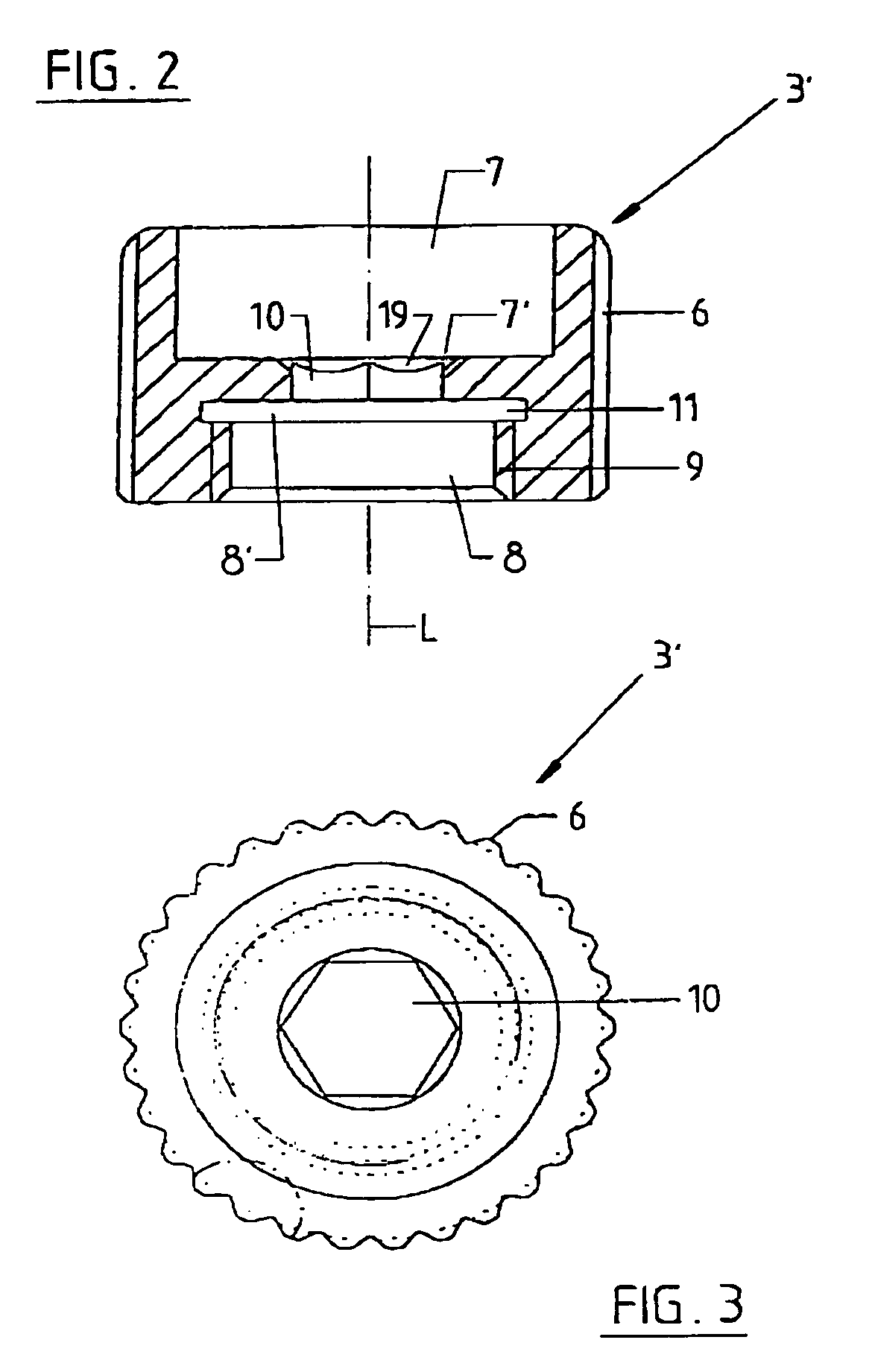

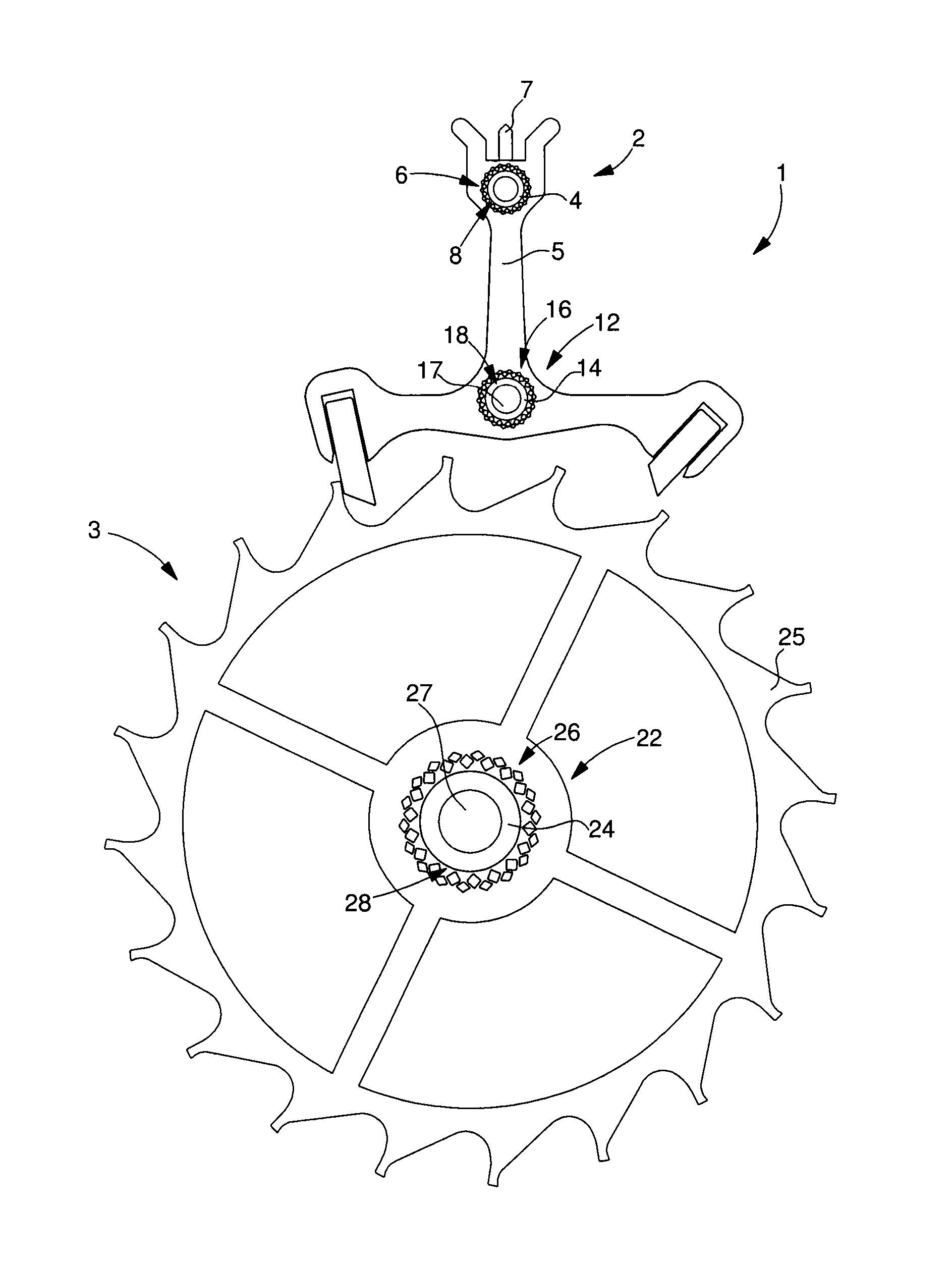

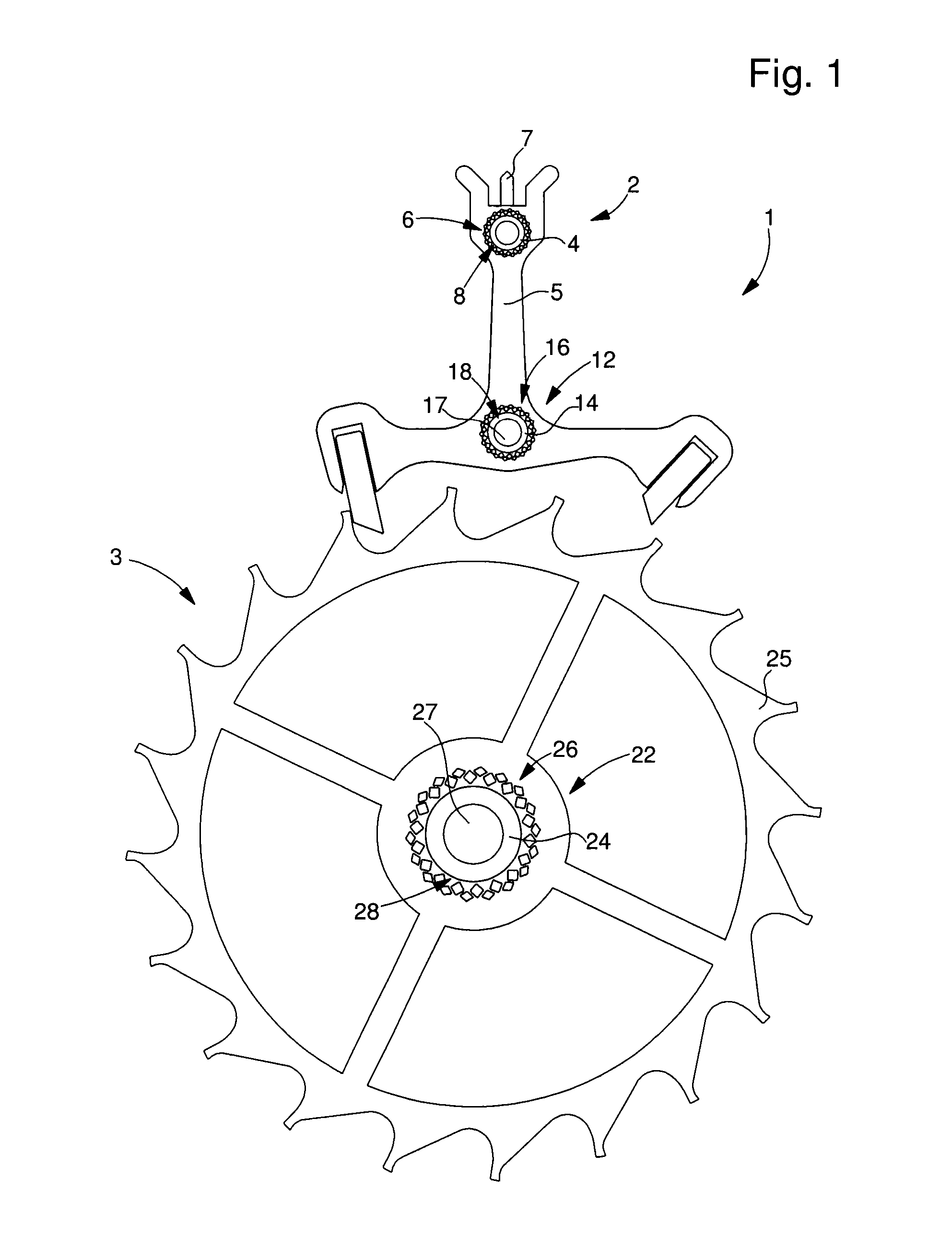

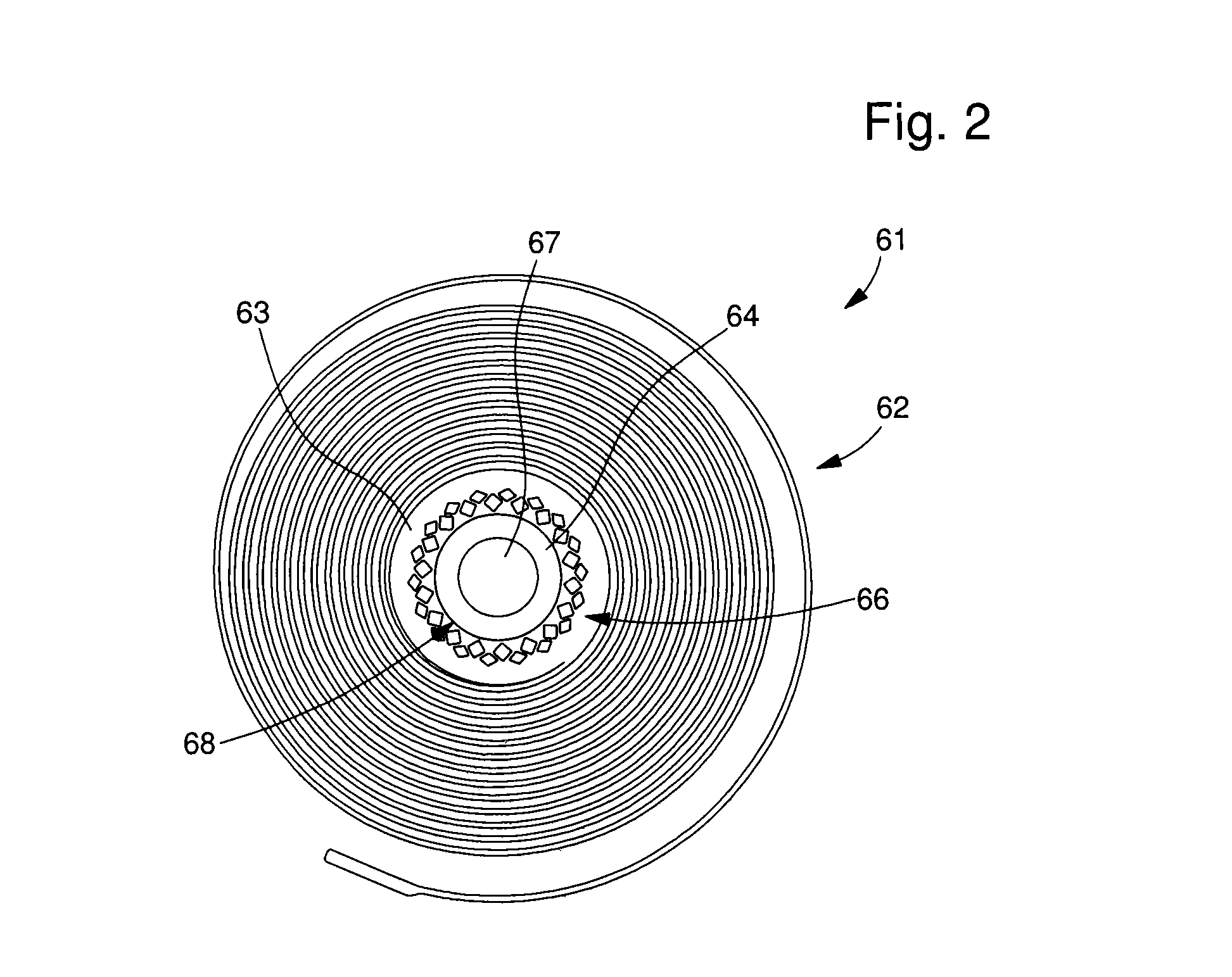

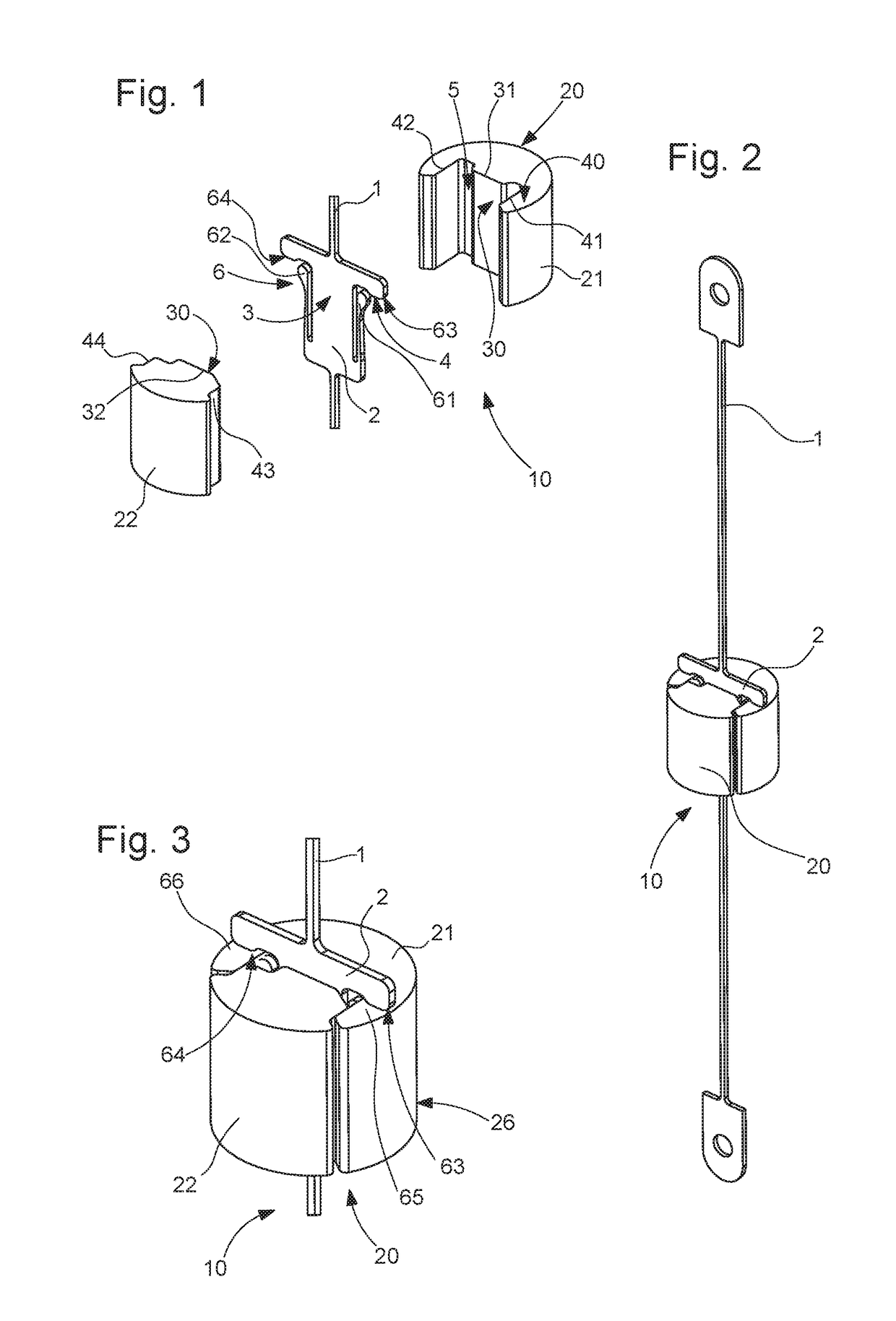

Collet without deformation of the fixation radius of the balance-spring and manufacturing method of the same

ActiveUS20050219957A1Easy to controlEasy to operateFrequency stabilisation mechanismClock support devicesFriction torqueEngineering

The collet is formed by a metal band (10) whose inner contour (11) delimits the recesses (11a, 11b, 11c) for driving the collet onto a balance staff (2) and whose outer contour (12) includes a function point (4) between the collet and the balance spring (9) located at the end of an arm (14) at a distance R from the centre 0 of the staff (2) greater than that of any other point (6, 8, 13, 15, 17) of the outer contour (12). It is characterised in that the inner contour (11) includes a discrete number of points of contact (1, 3, 5, 7) with the staff (2) distributed along identical or different angular apertures α and in that width “I” of the band (10) varies such that the compression forces of the contact points (1, 3, 5, 7) on the staff (2) do not substantially alter the distance R after driving in, leading to a friction torque allowing angular orientation of the collet on the staff (2) and not introducing any unbalance.

Owner:NIVAROX FAR

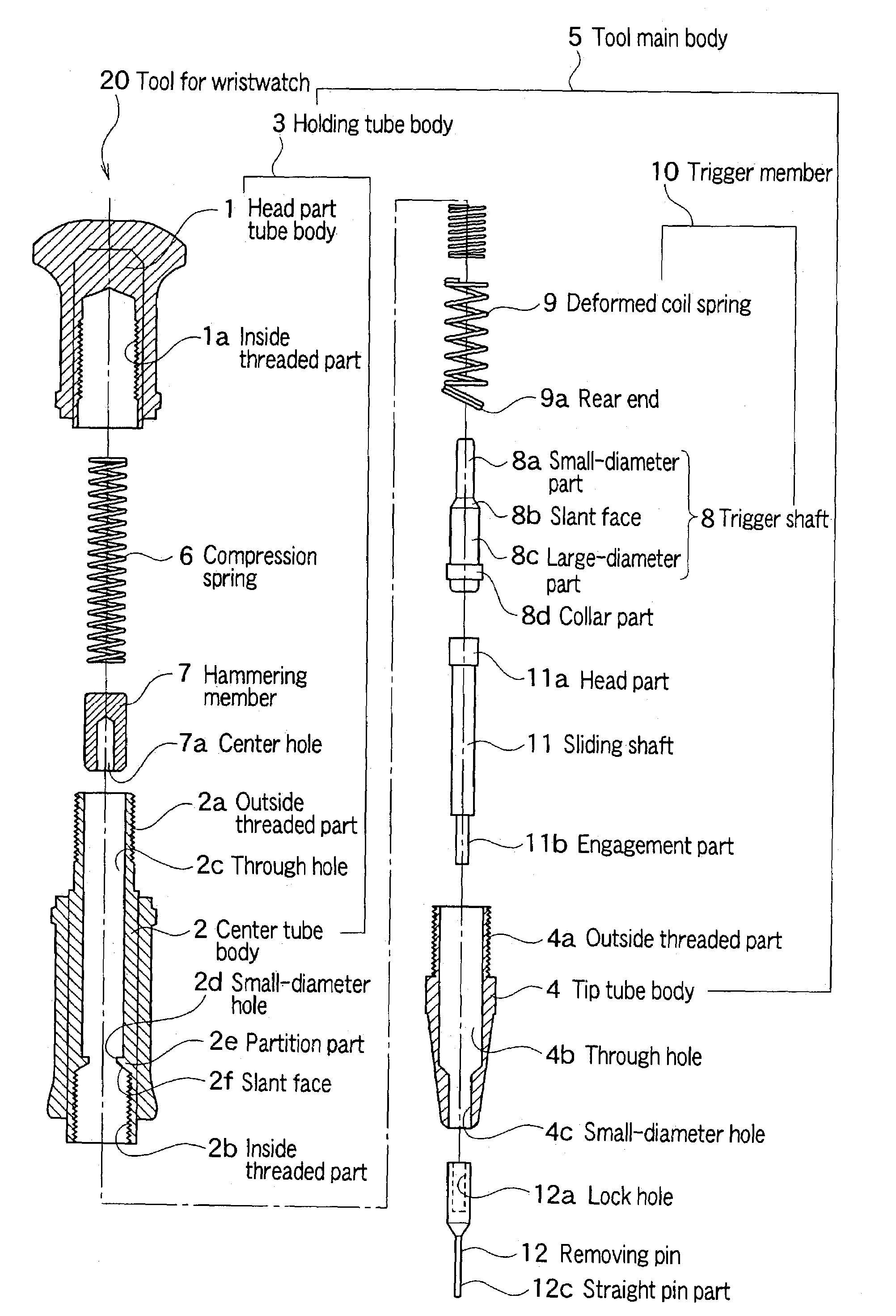

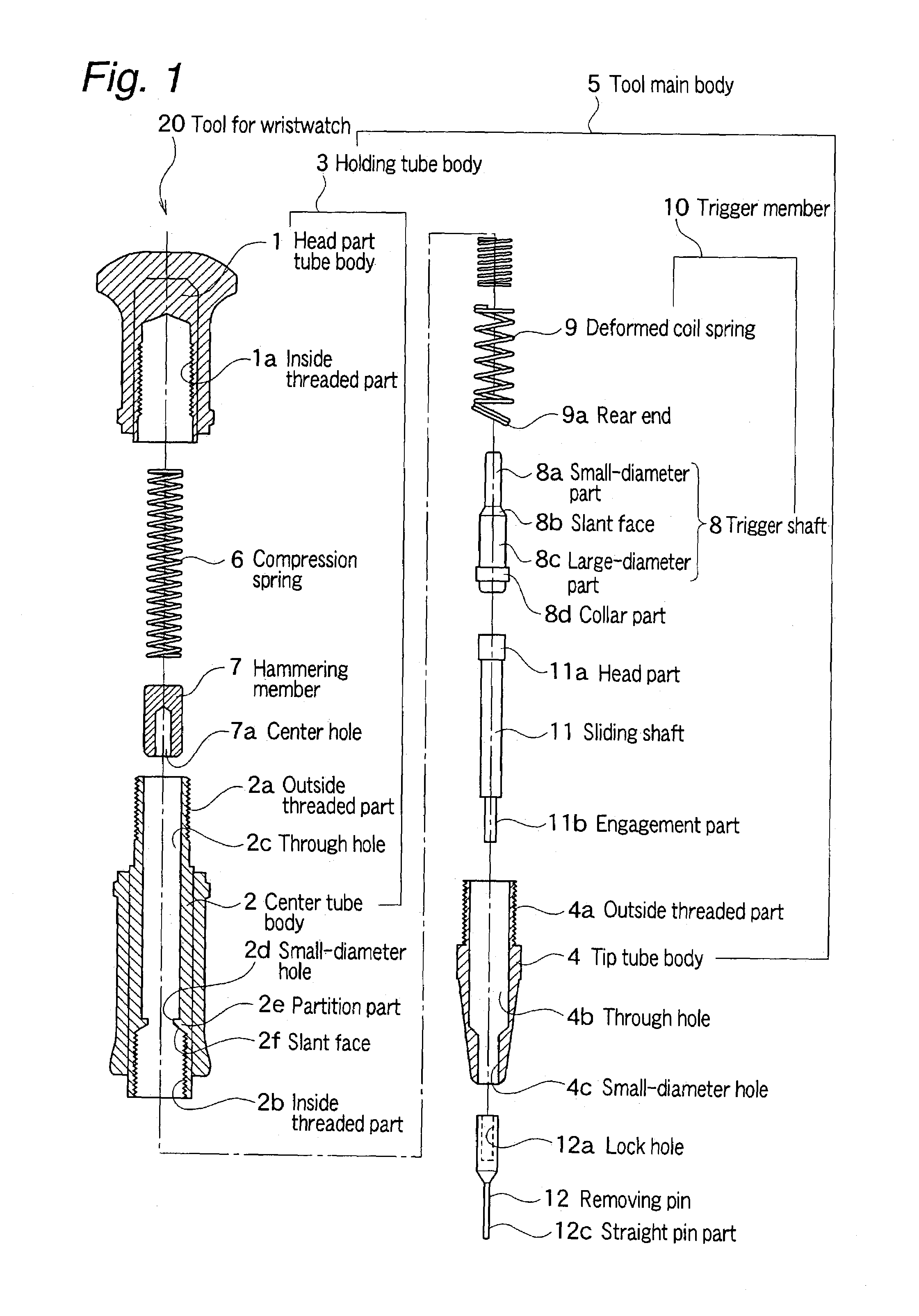

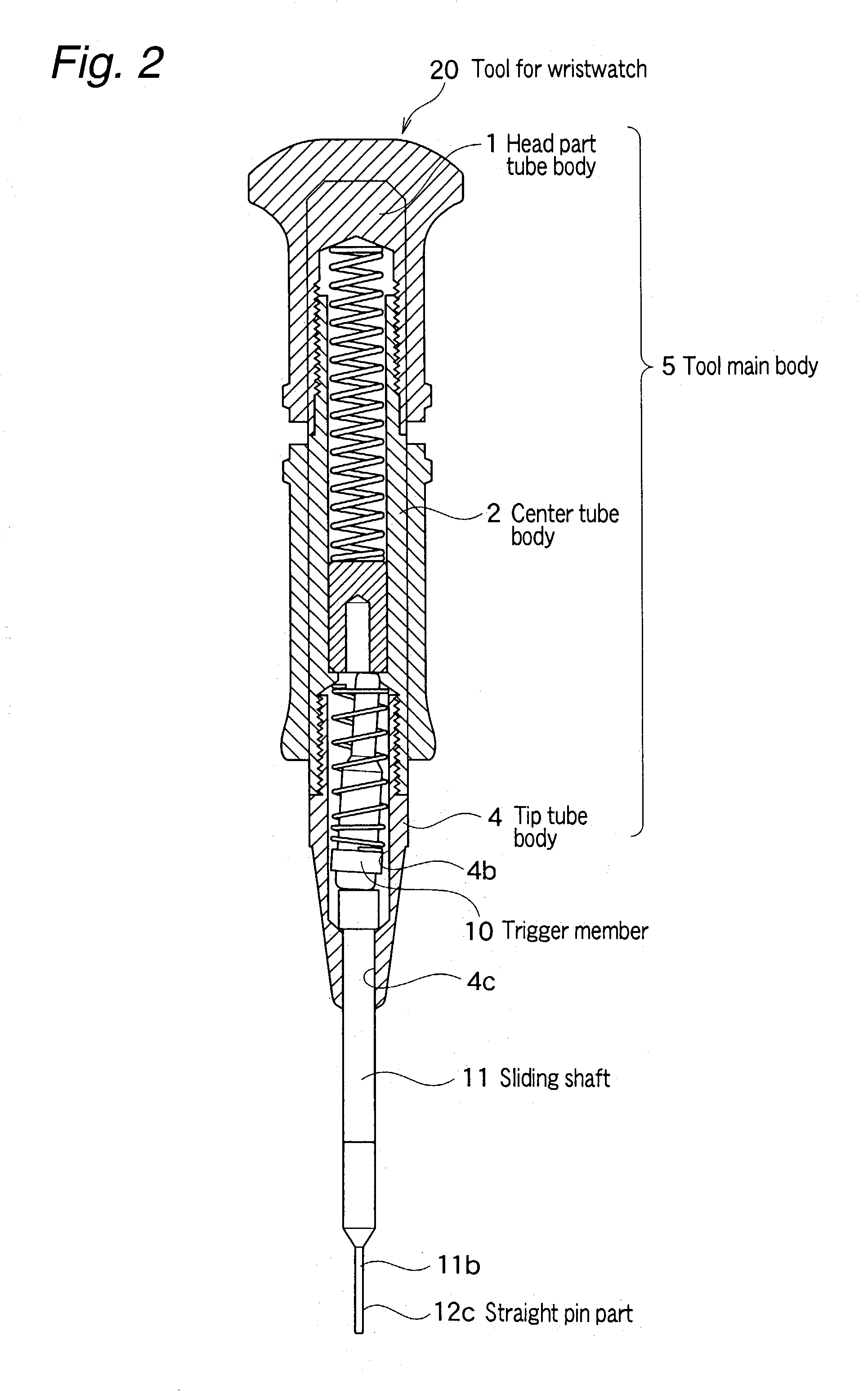

Tool for wristwatch

InactiveUS7121165B2Easy to disassemblePrevent fallingVisual indicationConstructionsCoil springScrew thread

Substantially cylindrical head tube body, center tube body and tip tube body threadedly engage each other to thereby construct a tool main body of a tool for wristwatch. The through hole of the center tube body is provided with a partition part having a small-diameter hole and slant face. A hammering member and compression spring are slidably accommodated in the through hole. A trigger shaft includes a small-diameter part which can be inserted in a center hole of the hammering member, and a large-diameter part continuing therefrom through the slant face, which can pass through the small-diameter hole. A deformed coil spring has the large-diameter part of the trigger shaft fitted therein in wound form, and energizes the trigger shaft toward sliding shaft while slanting the trigger shaft so as to cause the small-diameter part to shift toward the inside wall of the tool main body. The sliding shaft at its rear end includes large-diameter head part and at its front end includes an engagement part to which a wristwatch tool component can be replaceably fixed. The engagement part interlocks a small-diameter hole of the tip tube body with a play, and the front end of the engagement part protrudes from the tip tube body.

Owner:CITIZEN WATCH CO LTD

Precision tweezers

Tweezers having two arms designed to be grasped between the thumb and the index for seizing small objects, at least one of said arms being provided with an interchangeable tip. The arms are made of metal or ceramics whilst at least one of the interchangeable tips is made of wood, preferably of boxwood or hornbeam.

Owner:MFGS DOUTILS DUMONT

Assembly of a part that has no plastic domain

Owner:ETA SA MFG HORLOGERE SUISSE

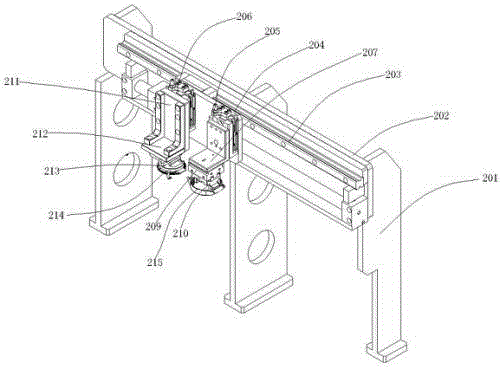

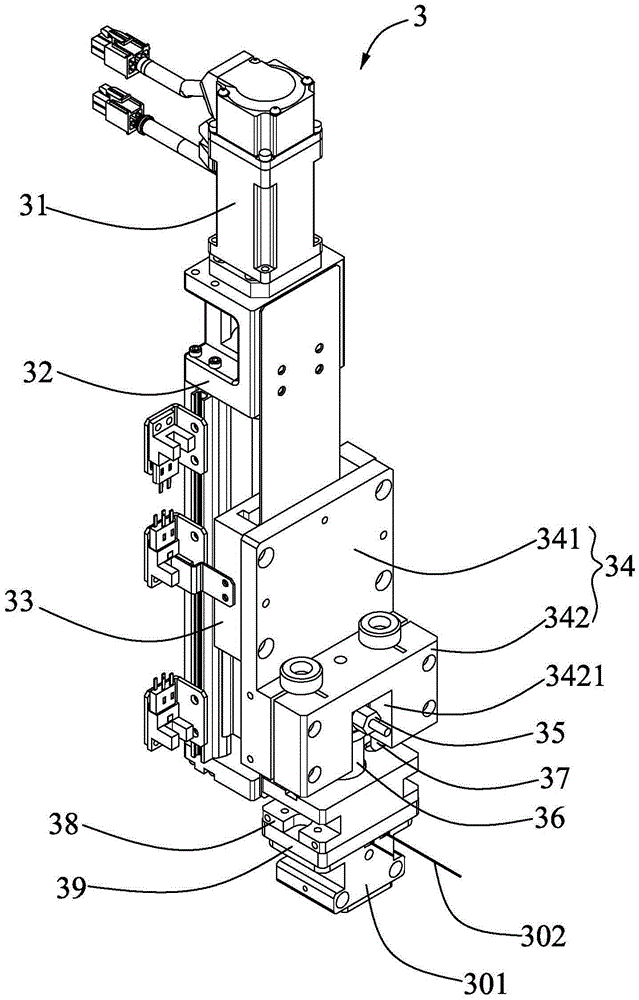

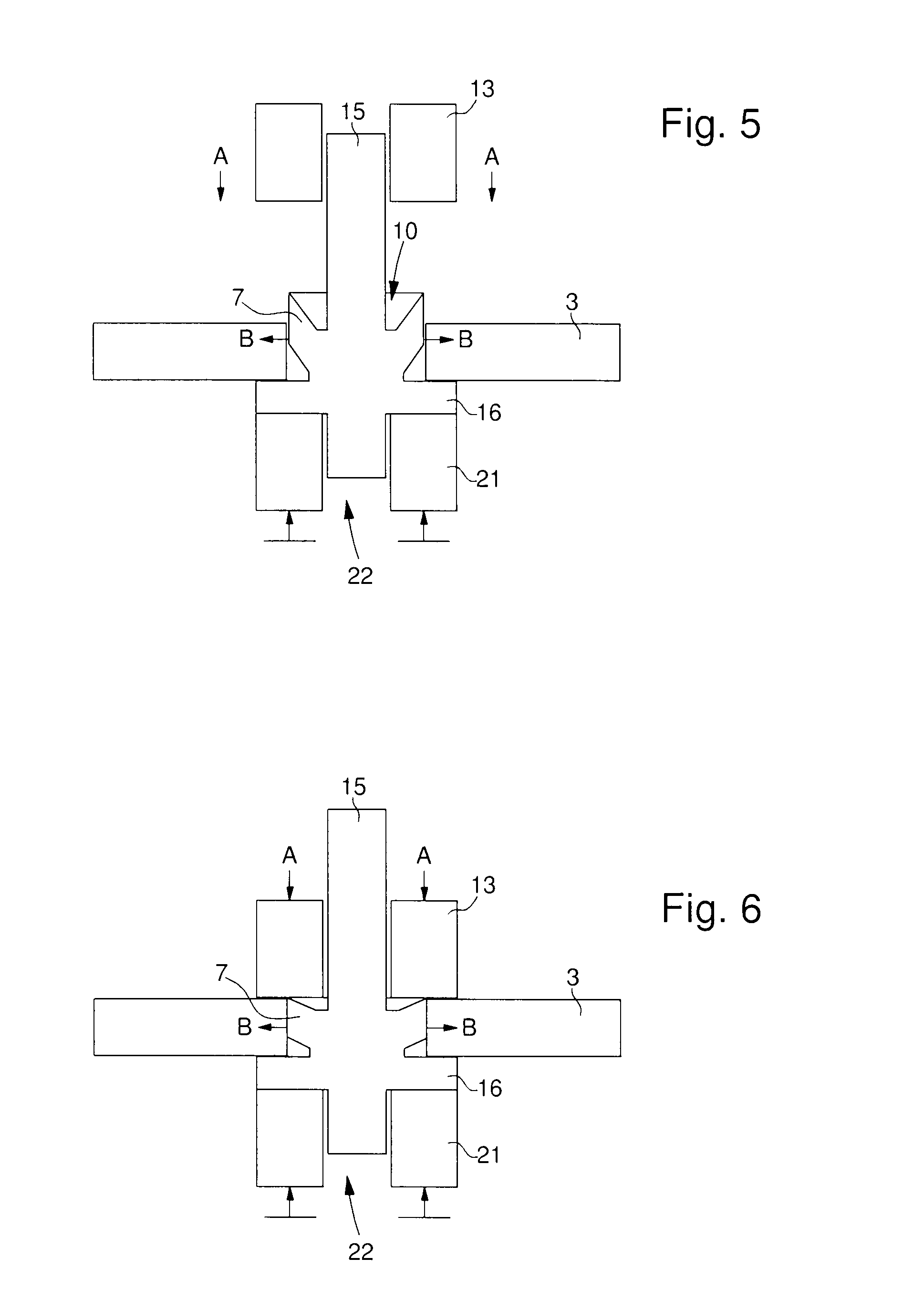

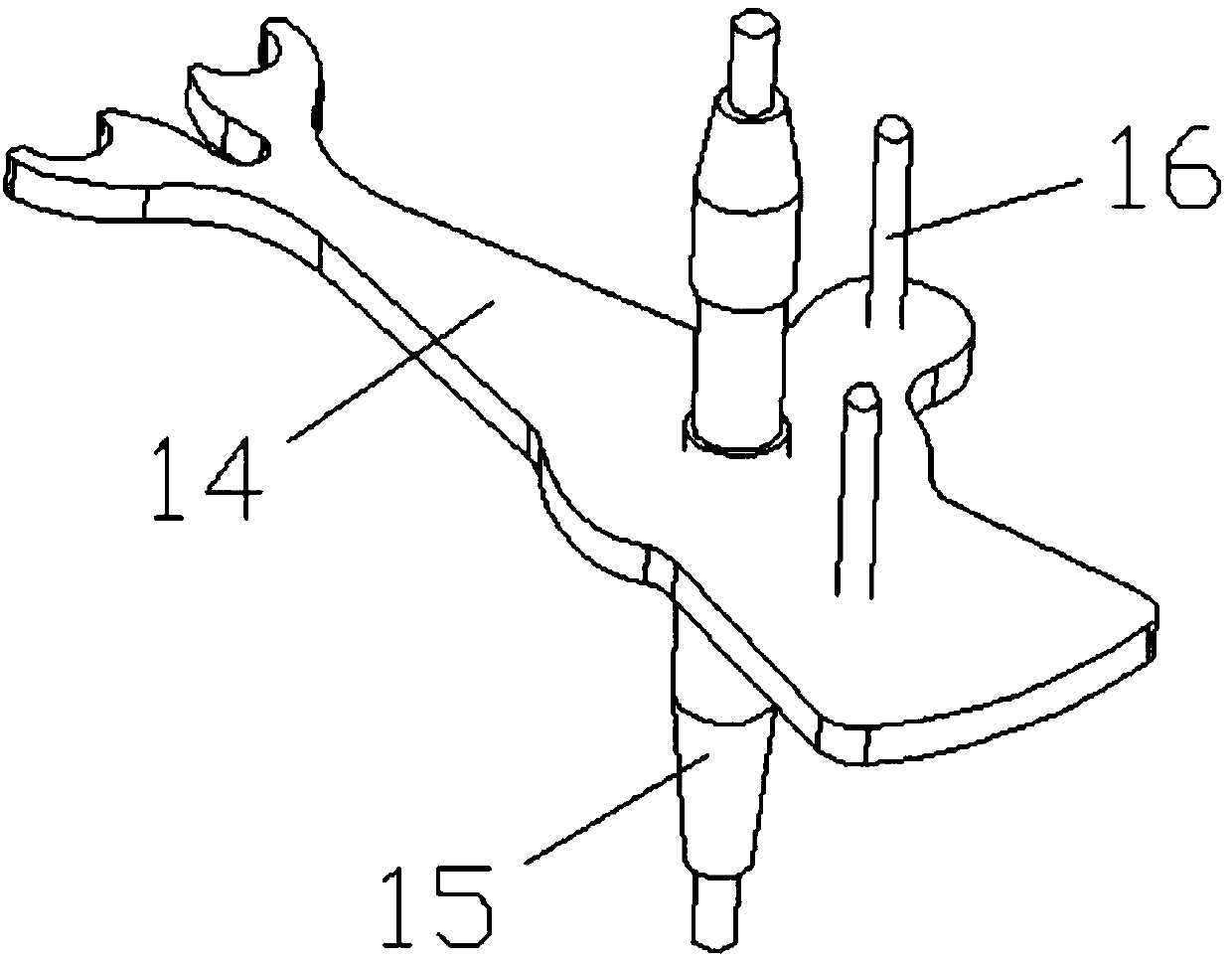

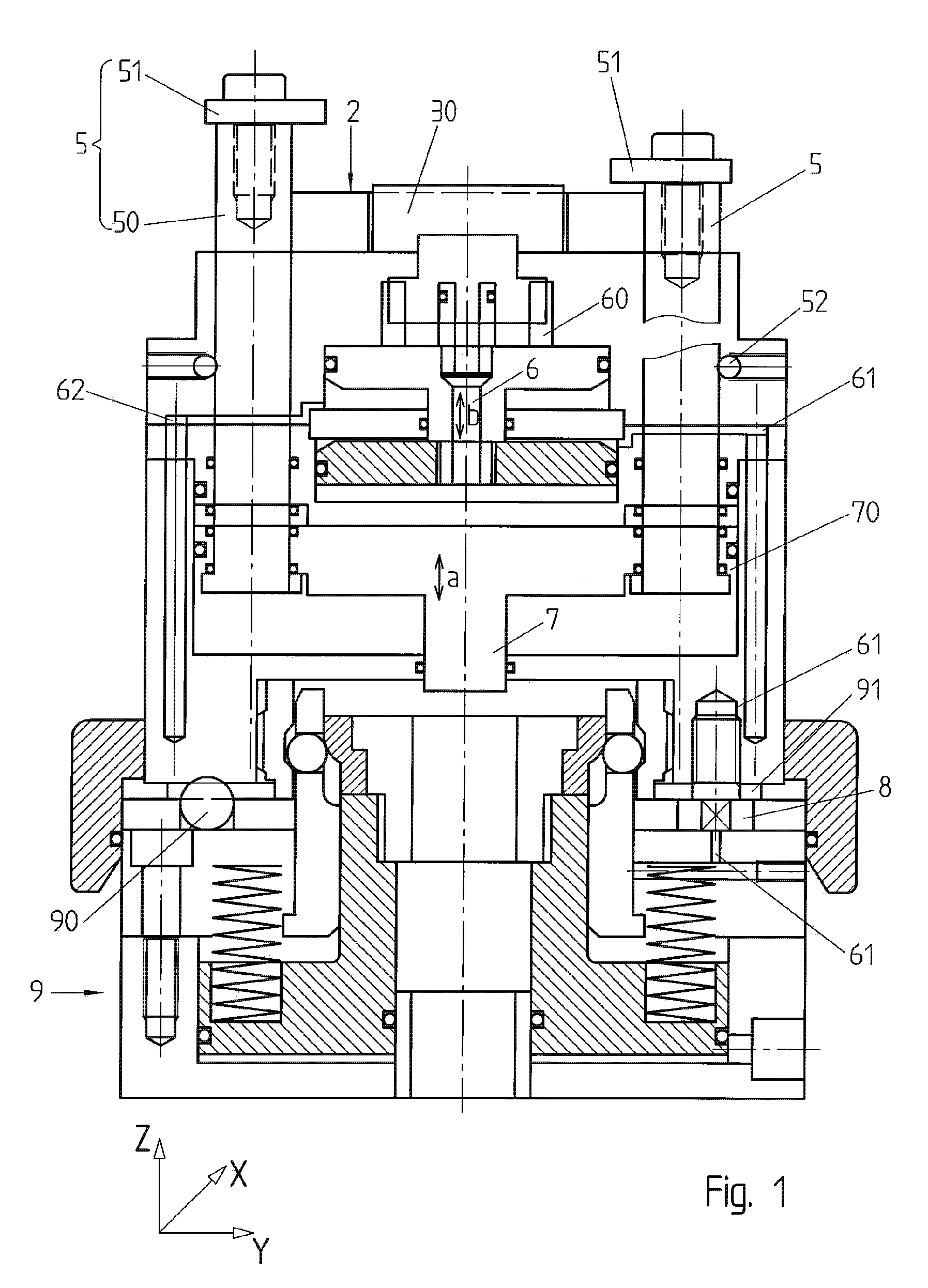

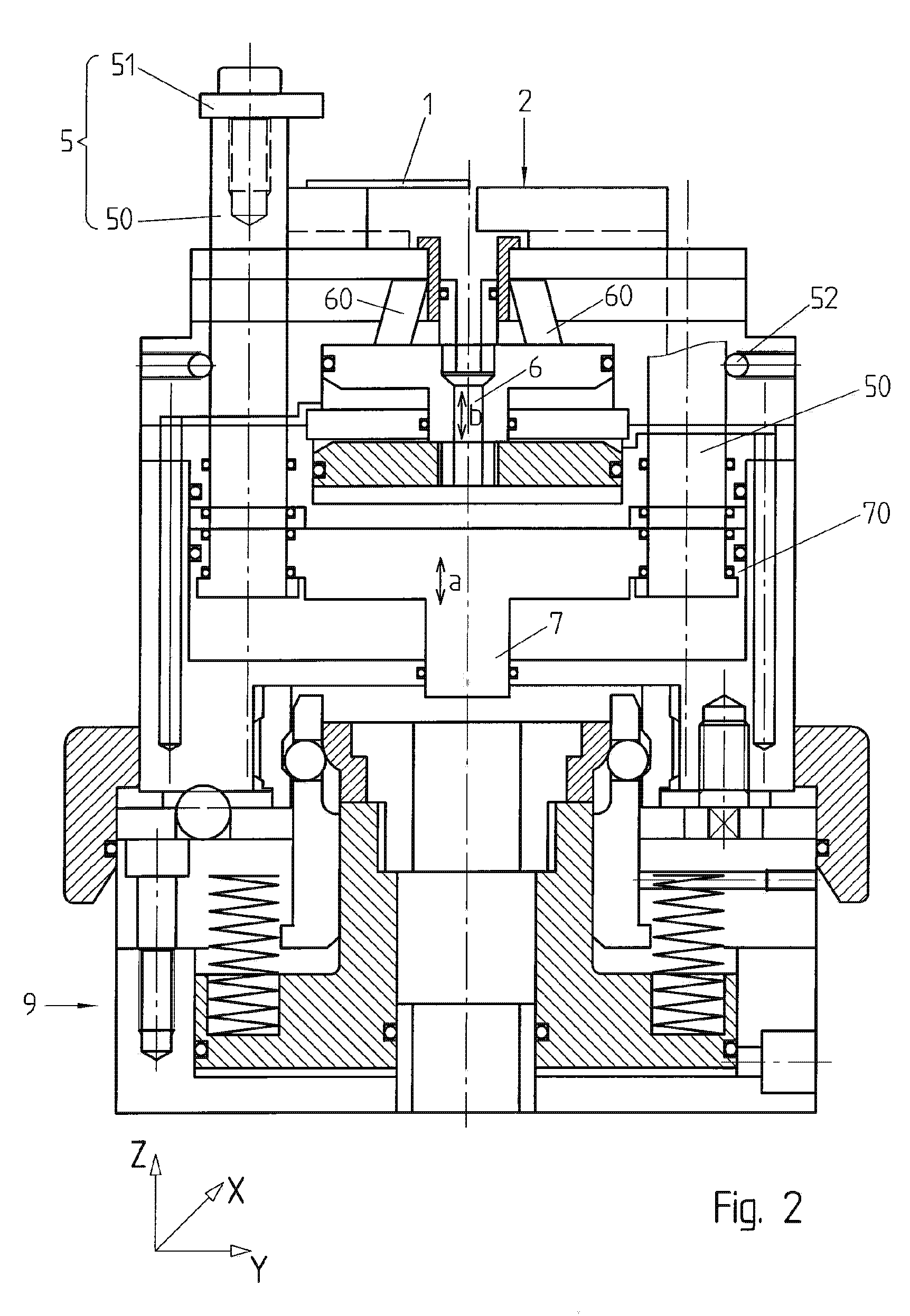

Automatic unlocking mechanism

InactiveCN106814593AAchieve initial positioningIntegrity guaranteedClock support devicesEngineeringMechanical engineering

The invention discloses an automatic unlocking mechanism. The automatic unlocking mechanism includes a supporting plate, cylinders, unlocking pull bars, pull bar fixing blocks, pressure plates, cylinder supports, positioning pins and carry tools, wherein each cylinder is fixed on each cylinder support; the cylinder supports are fixed on the supporting plate; the unlocking pull bars are fixed on the pull bar fixing blocks; the pull bar fixing blocks are fixed on the cylinders; the pressure plates are fixed on the supporting plate to block the unlocking pull bars to prevent tilting of the unlocking pull bars; the positioning pins are protruded upward from the supporting plate, and fix the carry tools to prevent the carry tools moving on the supporting plate; the back and forth motions of the cylinders drive the unlocking pull bars to move back and forth; the tail end of each unlocking pull bar is provided with a hook; and when the unlocking pull bars move back and forth, the hooks unlock the carry tools.

Owner:SUZHOU RS TECH

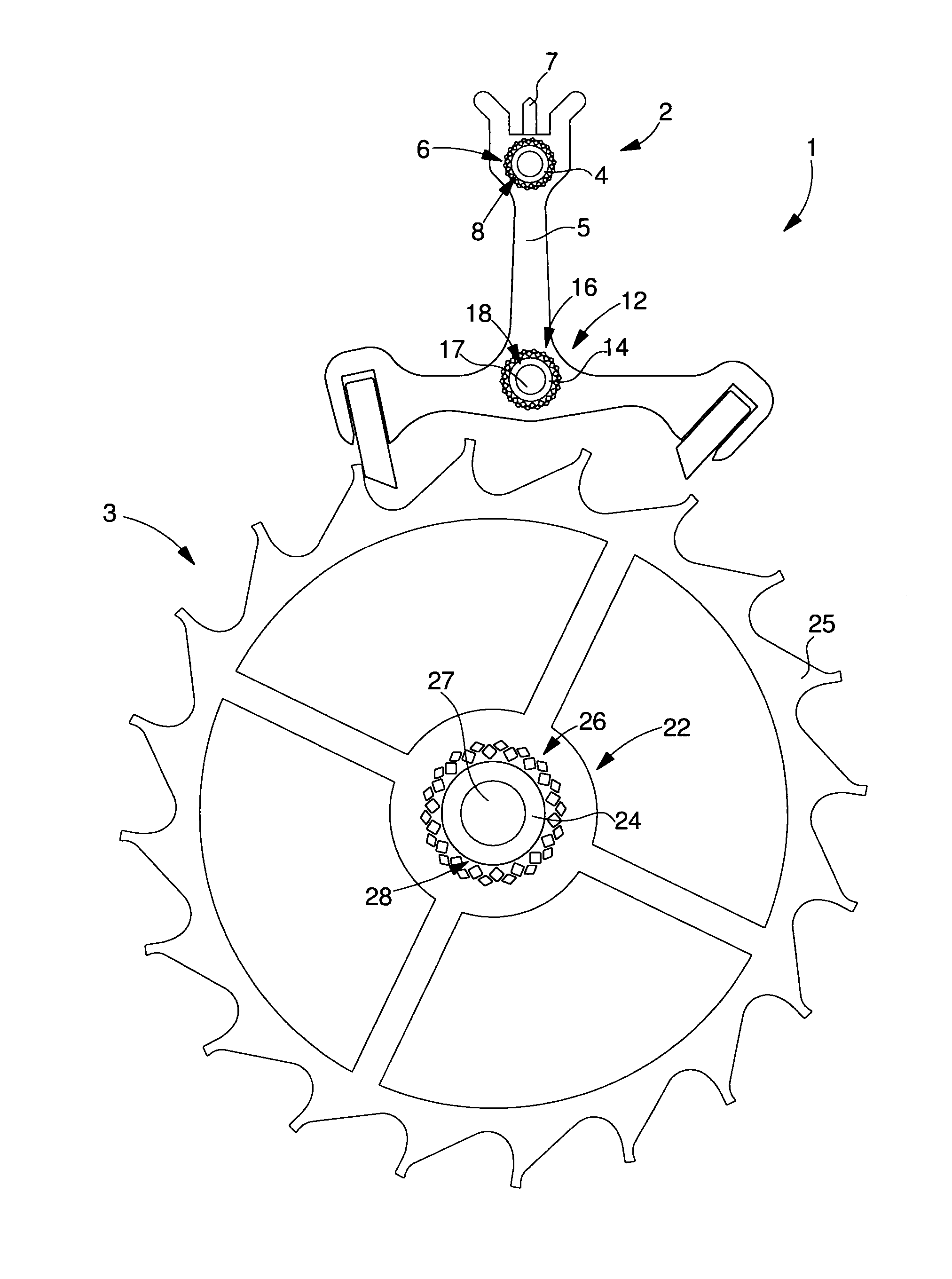

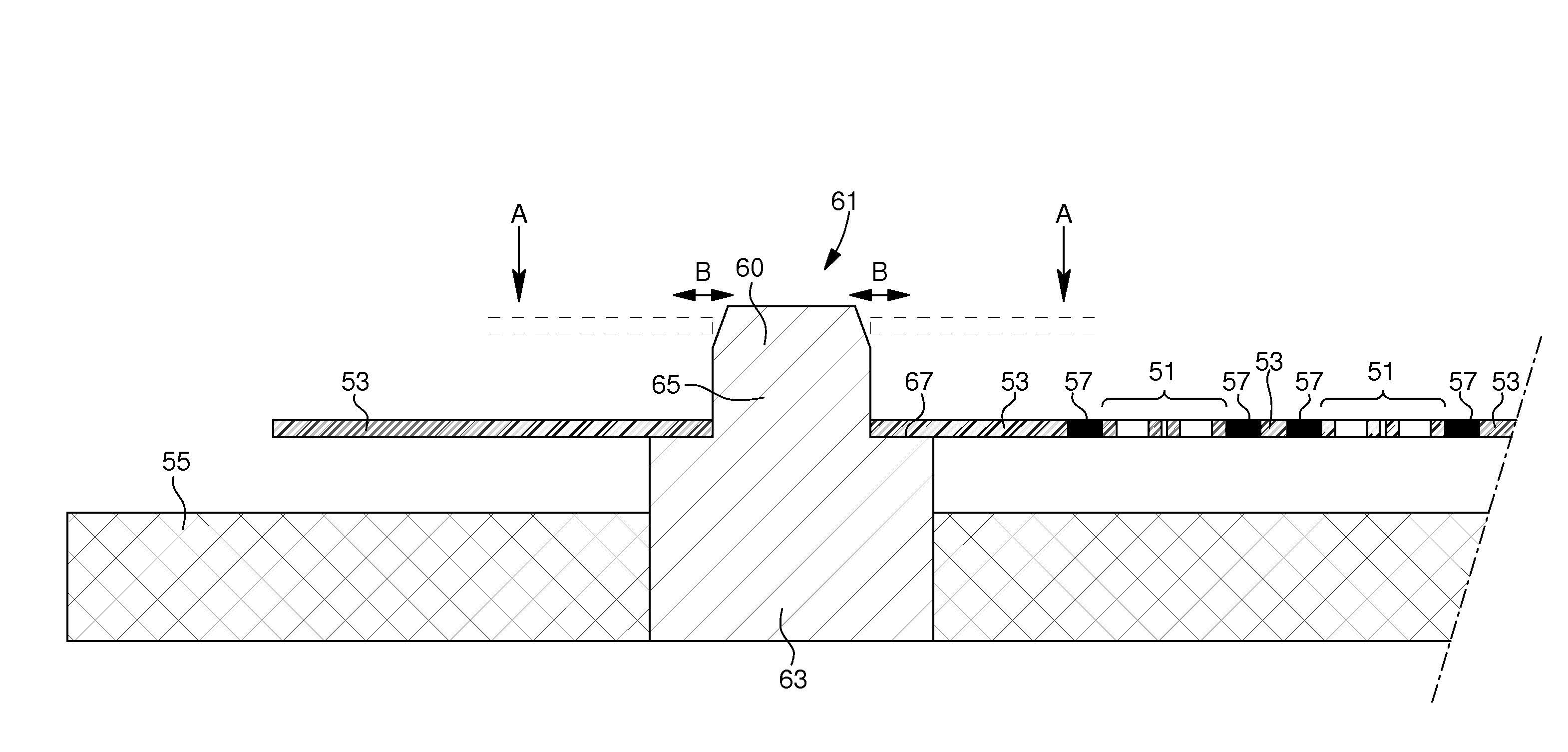

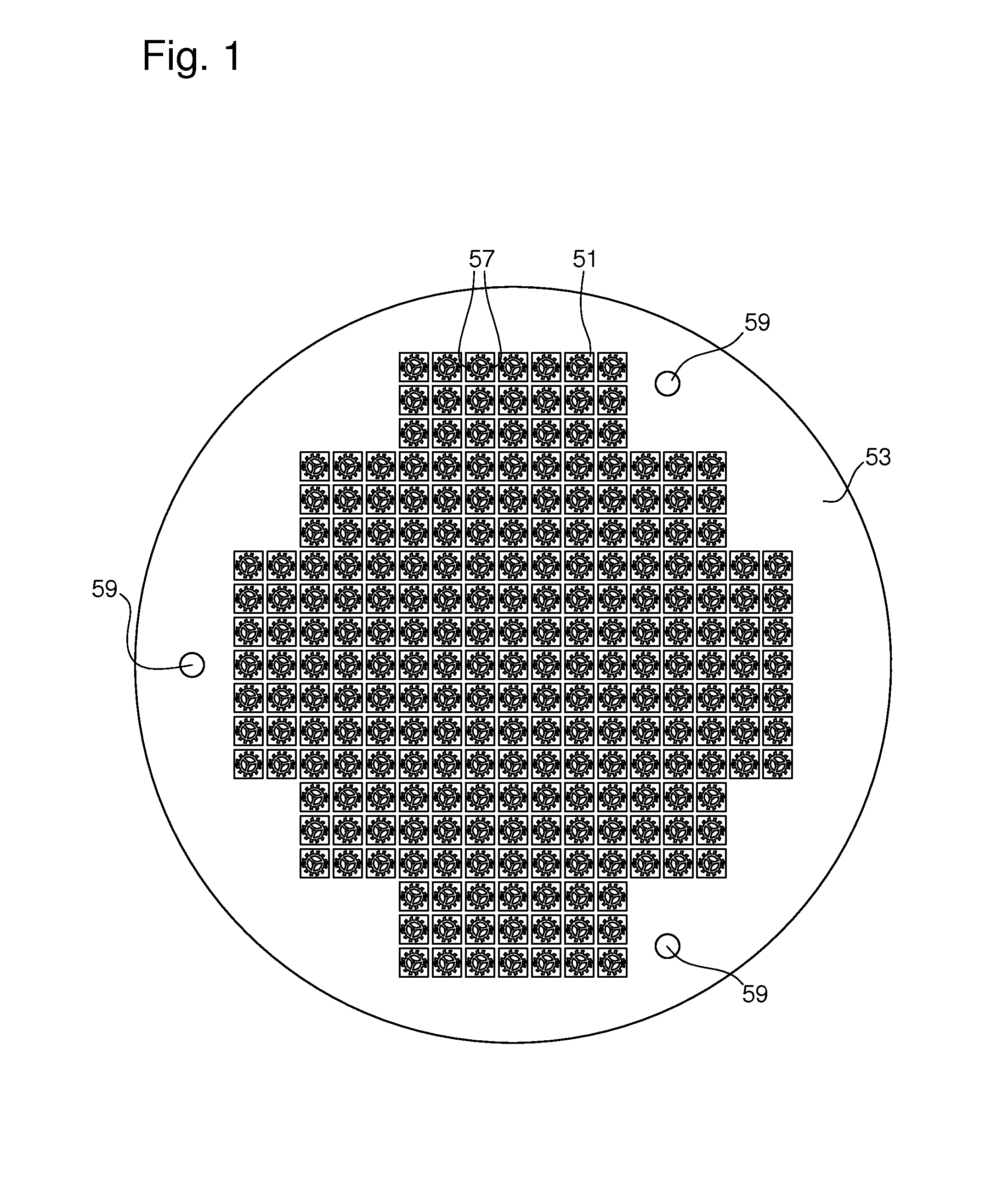

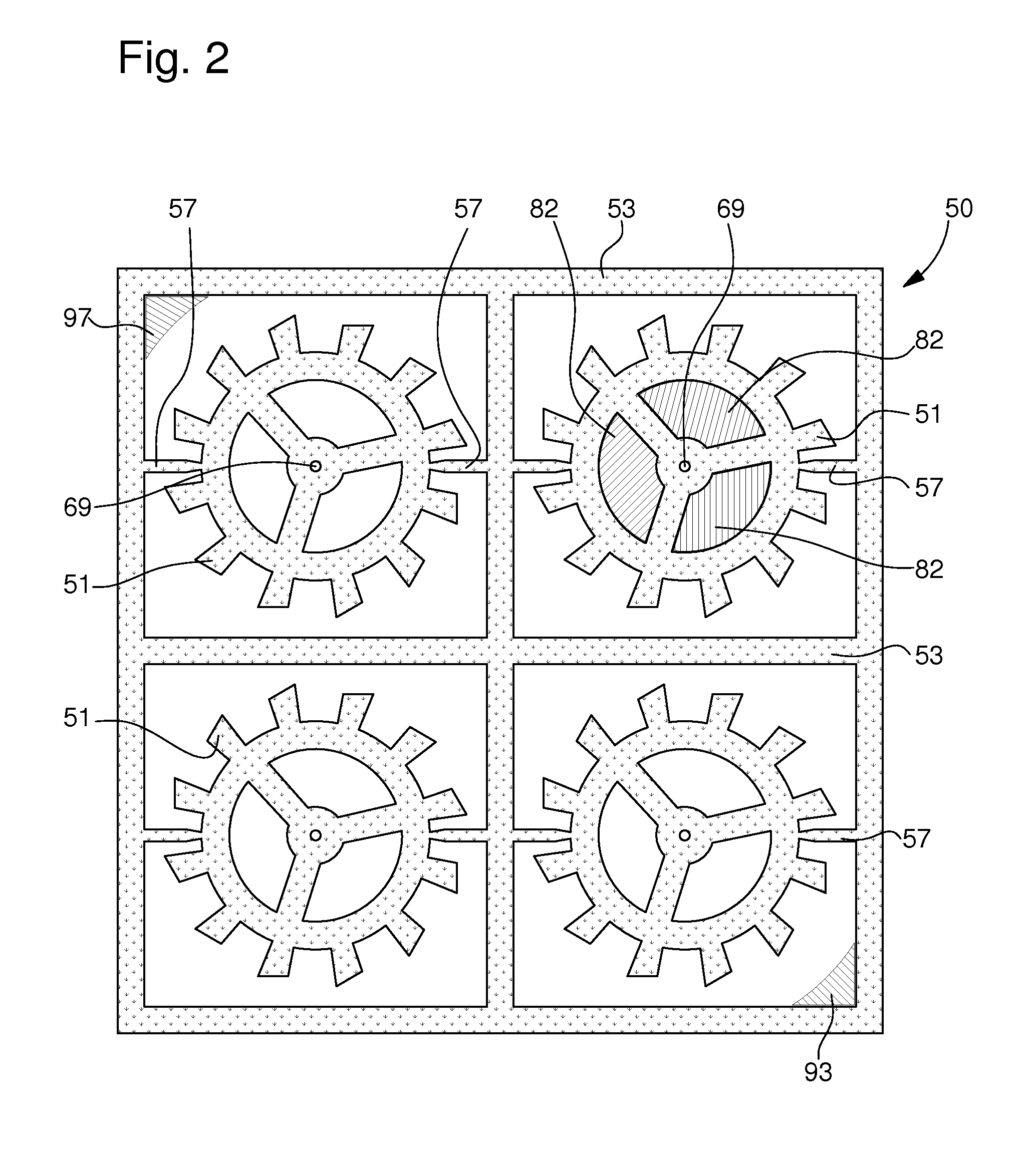

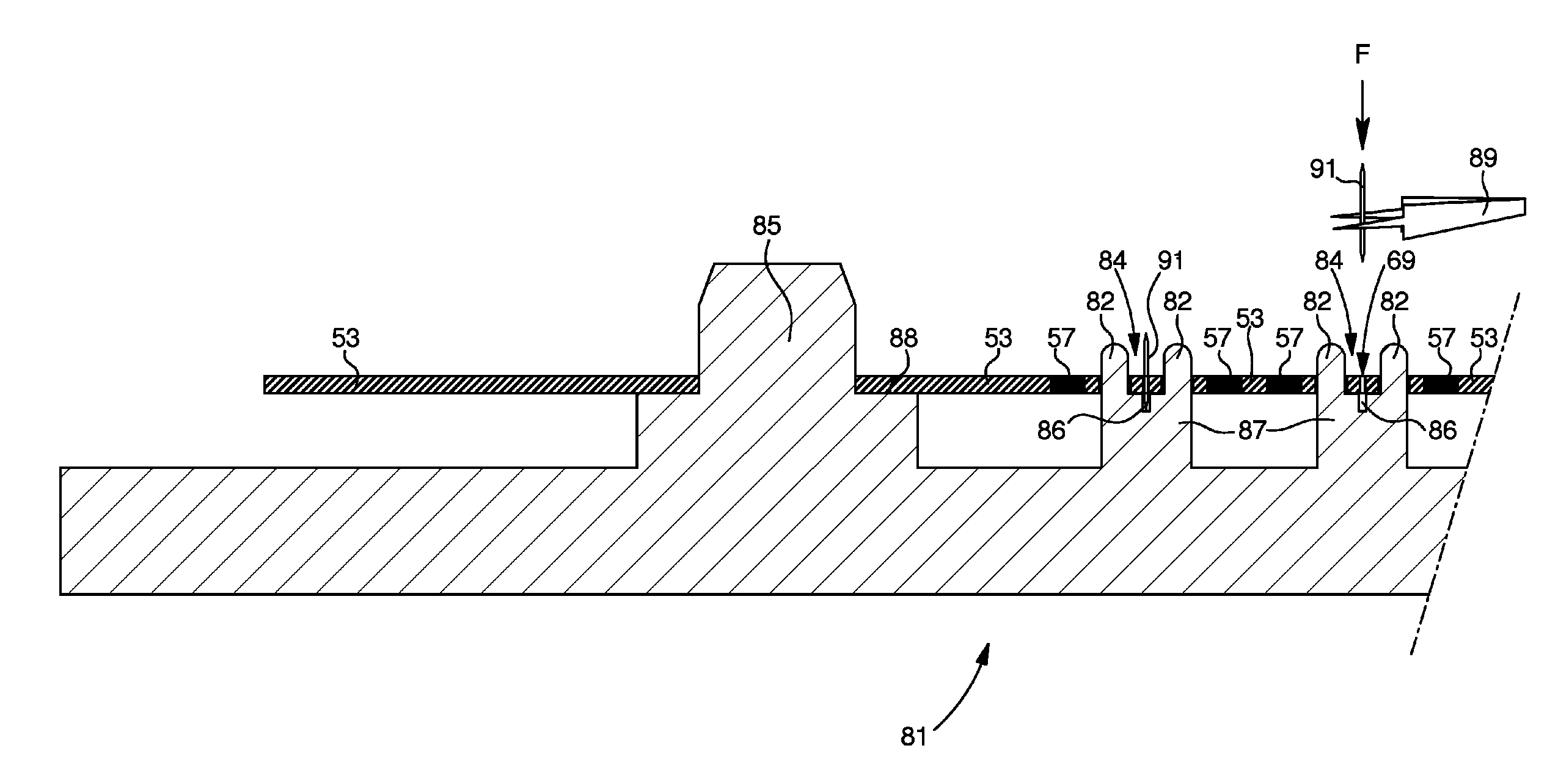

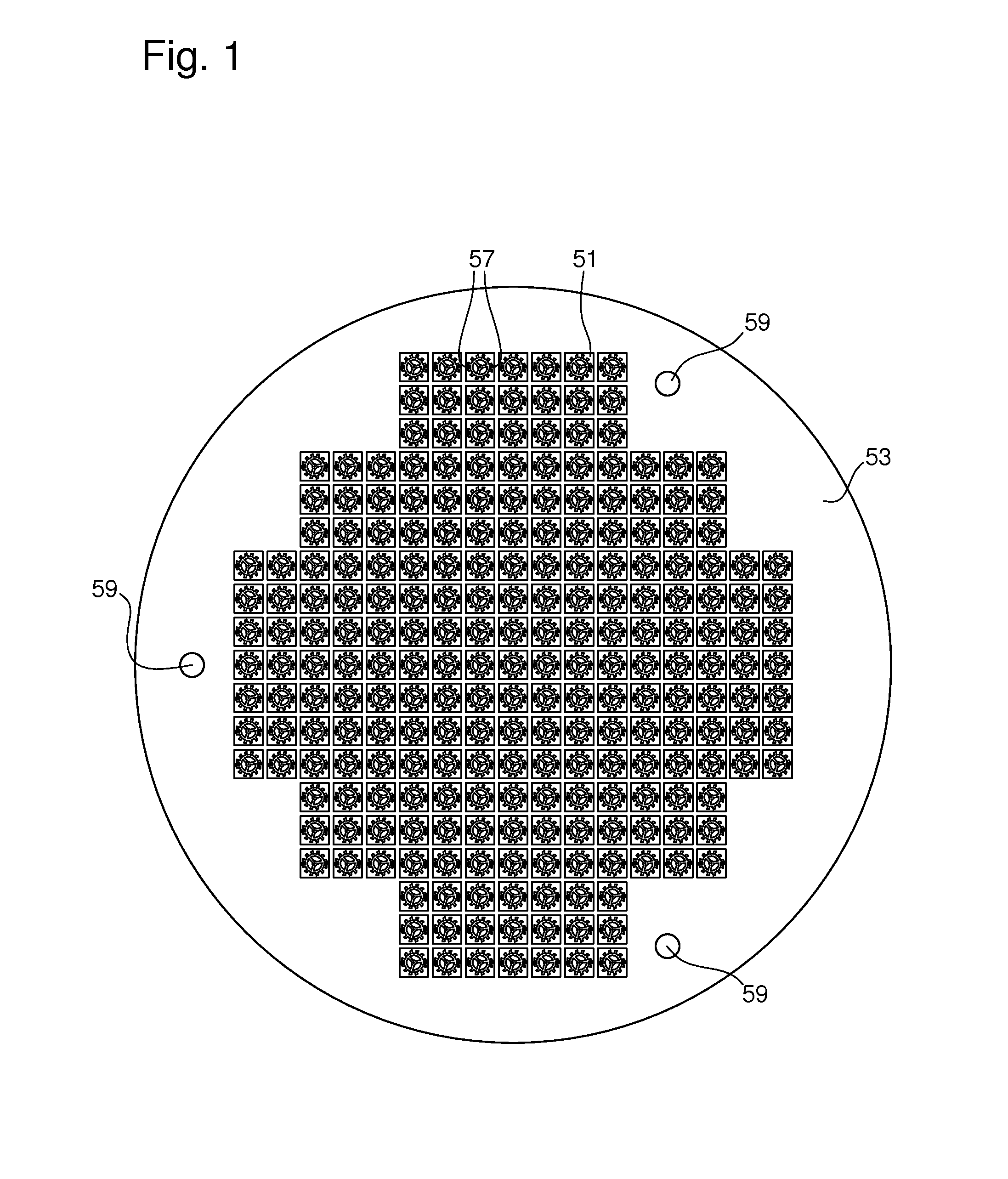

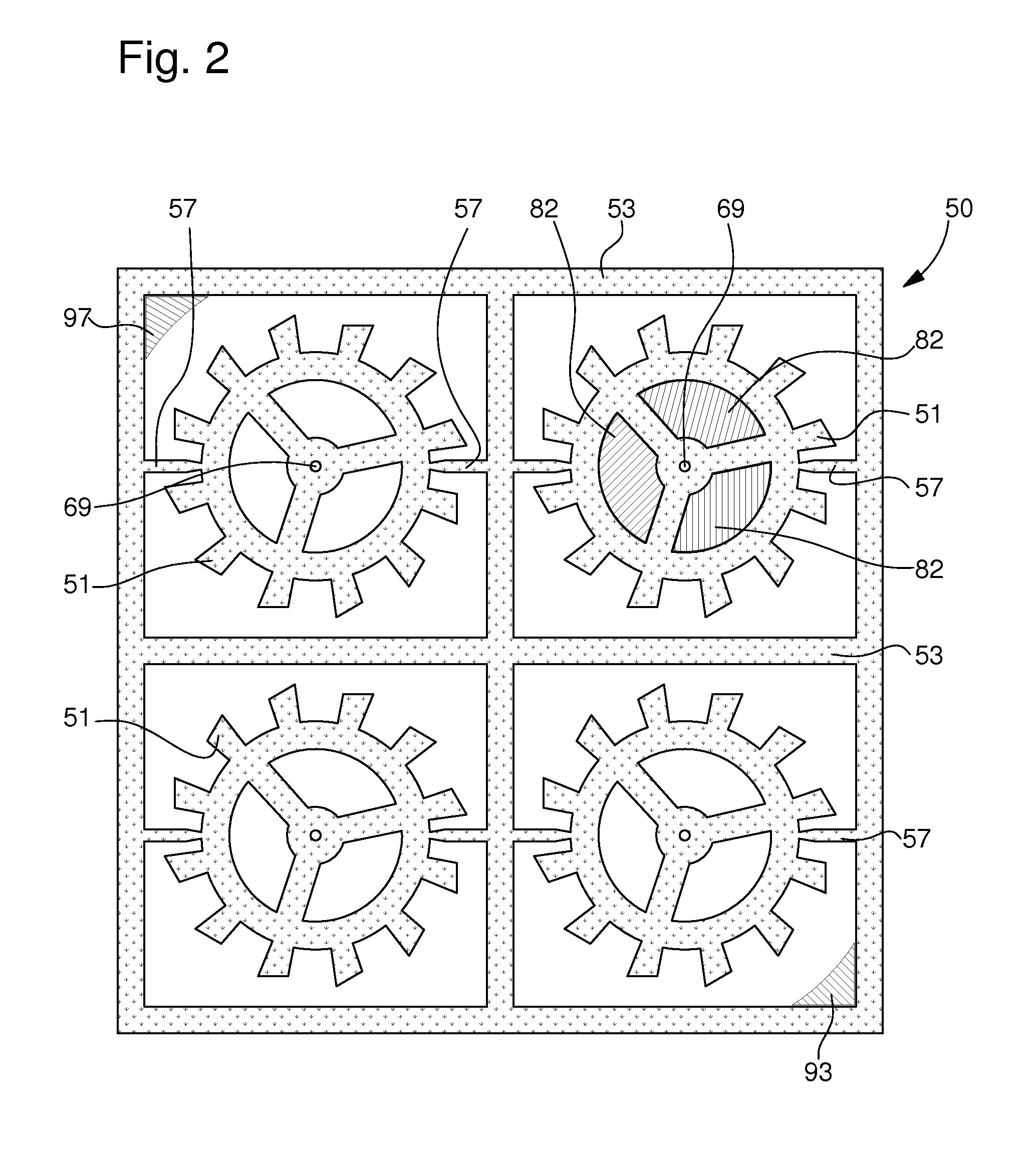

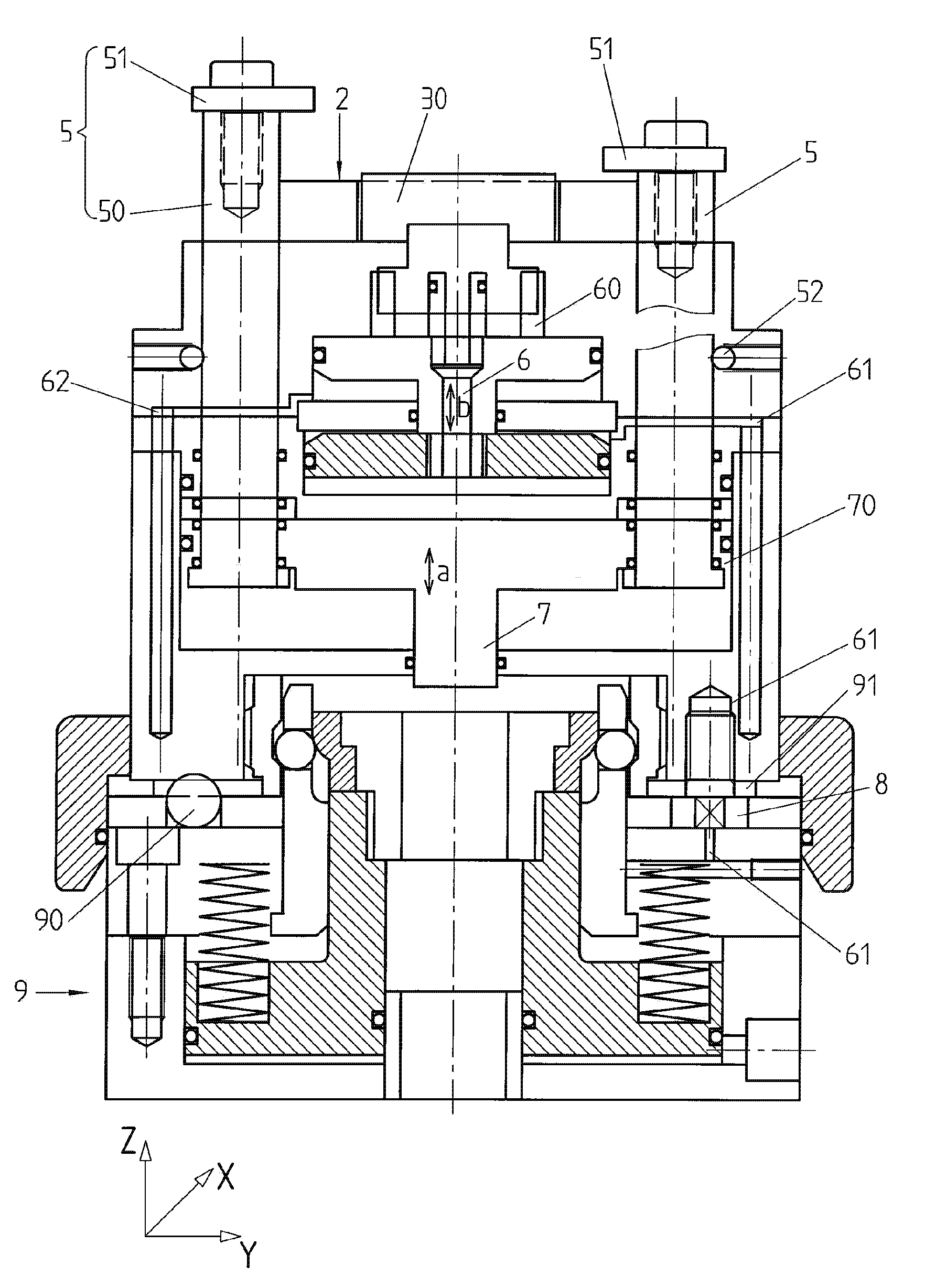

Method of manufacturing a micromechanical part

ActiveUS20100005659A1High quality manufacturingReduce processingGearworksEscapementsPhotolithographyElectrical and Electronics engineering

The invention relates to a method of manufacturing (1) a mechanical part (51) including the following steps:a) providing (3) a substrate (53) made of micro-machinable material;b) etching (5), with help of photolithography, a pattern (50) that includes said part through said entire substrate;According to the invention, the method further includes the following steps:c) assembling (13) a clip (91) on said part so that said part (51) is ready to be mounted without the portion made of micro-machinable material having to be touched;d) releasing (11) the part (51) from the substrate (53) so as to mount said part in a device such as a timepiece movement.The invention concerns the field of timepiece manufacture.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Collet without deformation of the fixation radius of the balance-spring and manufacturing method of the same

ActiveUS7213966B2Easy to operateEasy to controlFrequency stabilisation mechanismClock support devicesFriction torqueEngineering

Owner:NIVAROX FAR

Assembly of a part that has no plastic domain

The invention relates to an assembly of a part that has no plastic domain. A method of assembling a member (5, 15) made of a first material in a part (3) made of a second material having no plastic domain, includes forming the part (3) with an aperture (4), inserting a radially flared portion of the member (5, 15) into the aperture (4), without any stress, and elastically and plastically deforming the flared portion of the member in the aperture (4) by moving two tools (11, 13, 21) towards each other axially, respectively on the top and bottom parts of the flared portion, so as to exert a radial stress (B) against the wall of the part (3) surrounding the aperture (4), causing the elastic deformation of the part, to secure the assembly in a manner that is not destructive for said part. The member can be a timepiece.

Owner:NIVAROX FAR SA

Assembly of a part that has no plastic domain

A method of assembling a member made of a first material in a part made of a second material having no plastic domain, includes forming the part with an aperture, inserting a radially flared portion of the member into the aperture, without any stress, and elastically and plastically deforming the flared portion of the member in the aperture by moving two tools towards each other axially, respectively on the top and bottom parts of the flared portion, so as to exert a radial stress against the wall of the part surrounding the aperture, causing the elastic deformation of the part, to secure the assembly in a manner that is not destructive for said part. The member can be a timepiece.

Owner:NIVAROX FAR

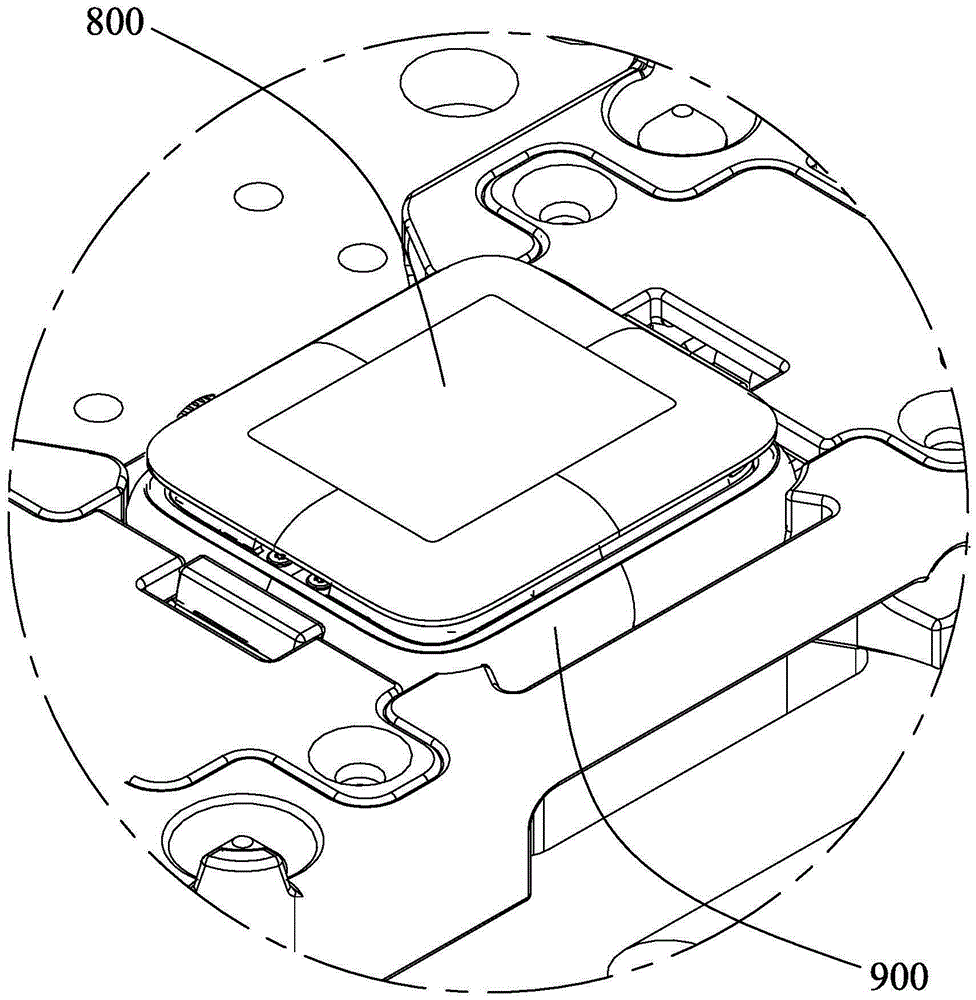

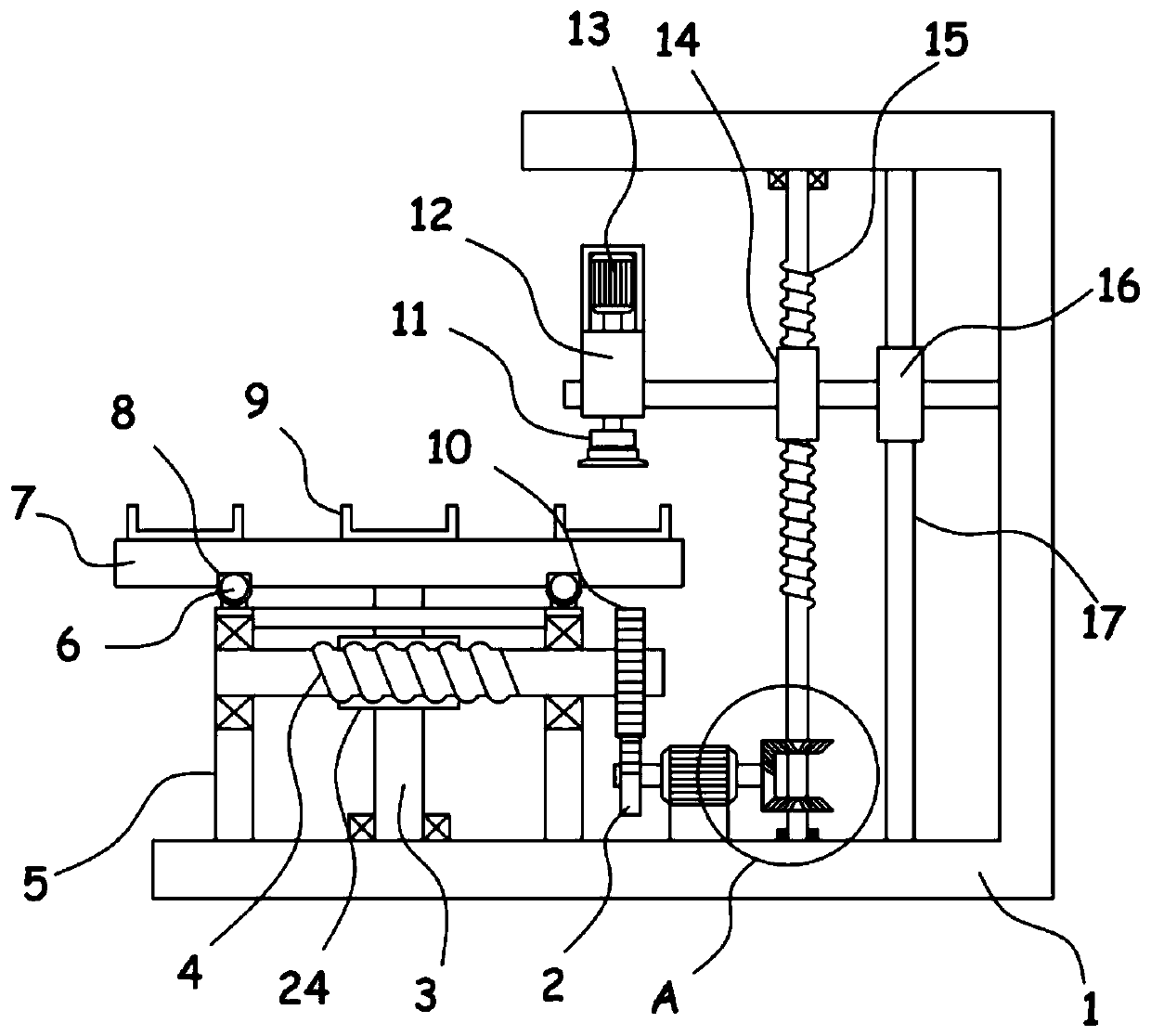

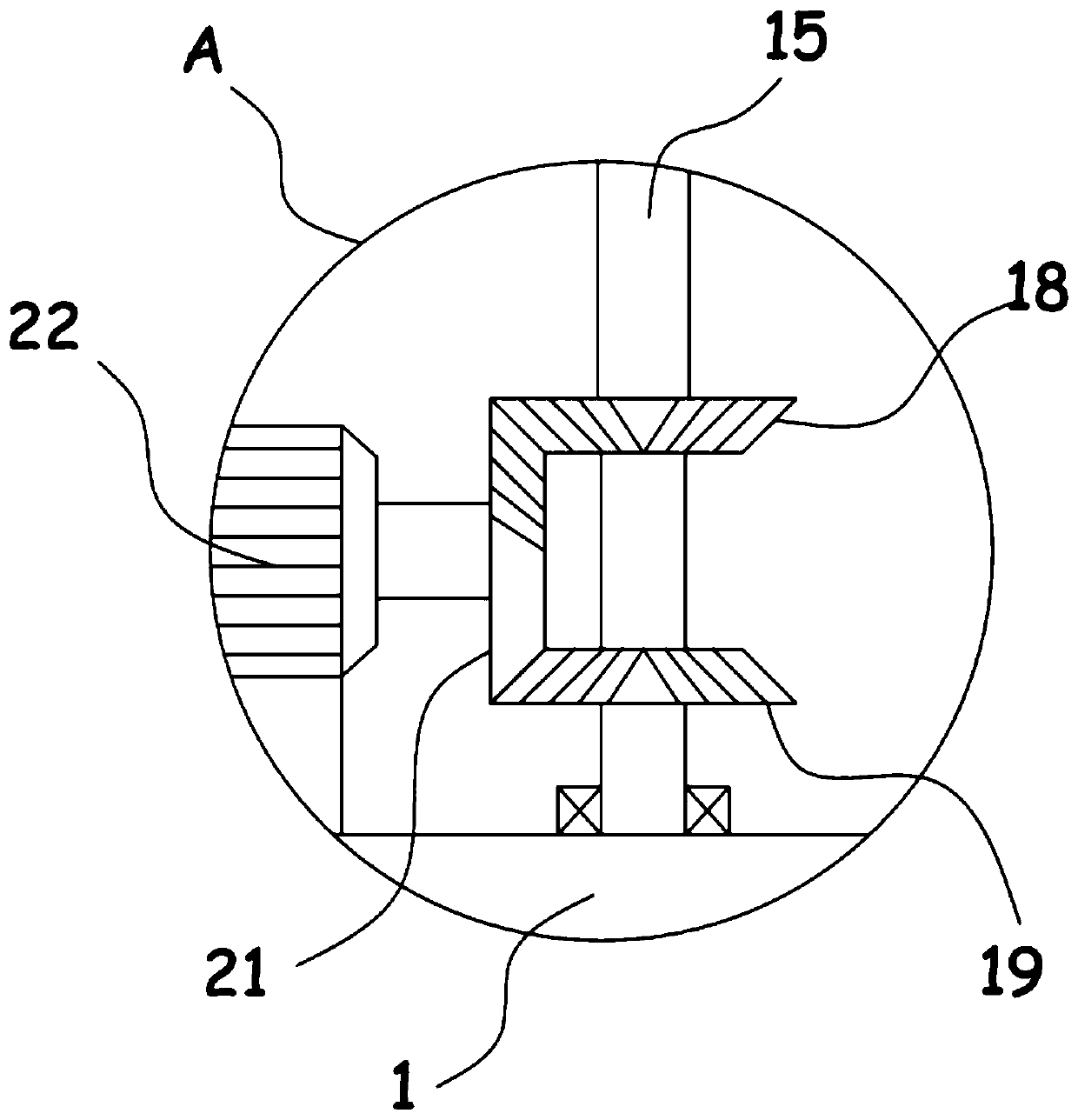

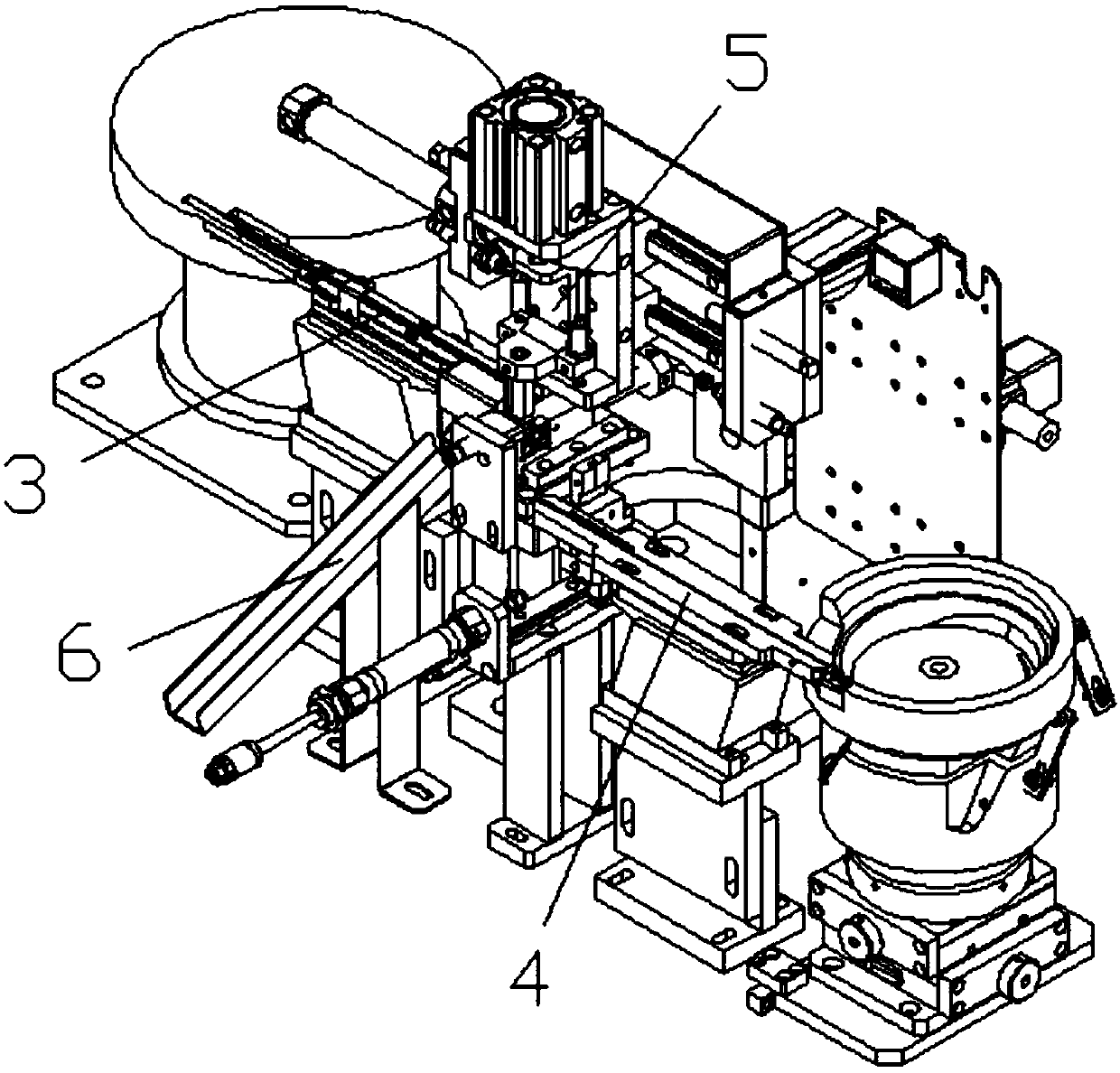

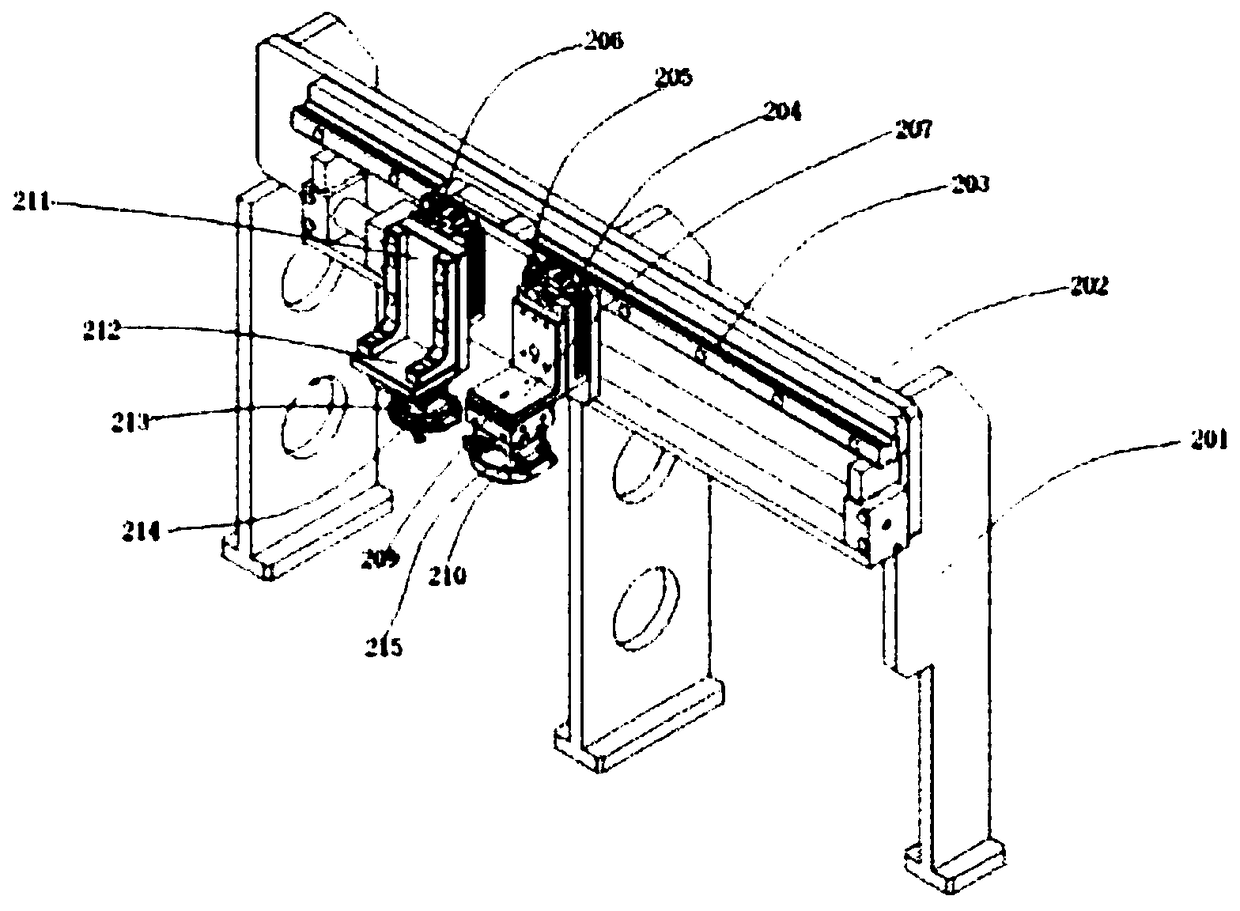

Automatic screwing and installing device for rear covers of electronic watches

ActiveCN110426944AImprove work efficiencyStable screwing operationClock support devicesFixed frameEngineering

The invention discloses an automatic screwing and installing device for rear covers of electronic watches, and relates to the technical field of installation of watches. The automatic screwing and installing device comprises a supporting frame, a fixed frame is fixed to the supporting frame, clamping bases for clamping the watches are uniformly distributed and fixed to a supporting turntable in the circumferential direction, a lead screw is in drive connection with the interior of the supporting frame through a forward and reverse rotation mechanism, a threaded casing pipe sleeves the lead screw through threads, and a screwing mechanism for screwing the rear covers of the watches is fixed to the threaded casing pipe. By means of the automatic screwing and installing device, the rear coversof the watches on the supporting turntable can be screwed and installed, the working efficiency of installing the watches is effectively improved, and the supporting turntable can conduct stepping-type rotation; through an electric suction cup which reciprocates up and down, the installing operation on the rear covers is high in automation degree, and the time and labor are saved in the process of installing the watches; through the arrangement of the screwing mechanism, the operation of screwing the rear covers of the watches is very stable, and in the screwing process, an axial fan rotatesto achieve air flow in a transmission pipe, and has a great heat dissipation effect on a servo motor.

Owner:SHANDONG KAER ELECTRIC

Method of manufacturing a micromechanical part

ActiveUS8354032B2High quality manufacturingReduce processingGearworksEscapementsMicromachiningsMechanical engineering

A method of manufacturing a mechanical part includes providing a substrate of micro-machinable material; etching, using photolithography, a pattern that includes said part through said entire substrate; assembling a clip on said part so that said part is ready to be mounted without the portion made of micro-machinable material having to be touched by a tool other than the clip; releasing the part from the substrate so as to mount said part in a device such as a timepiece movement.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

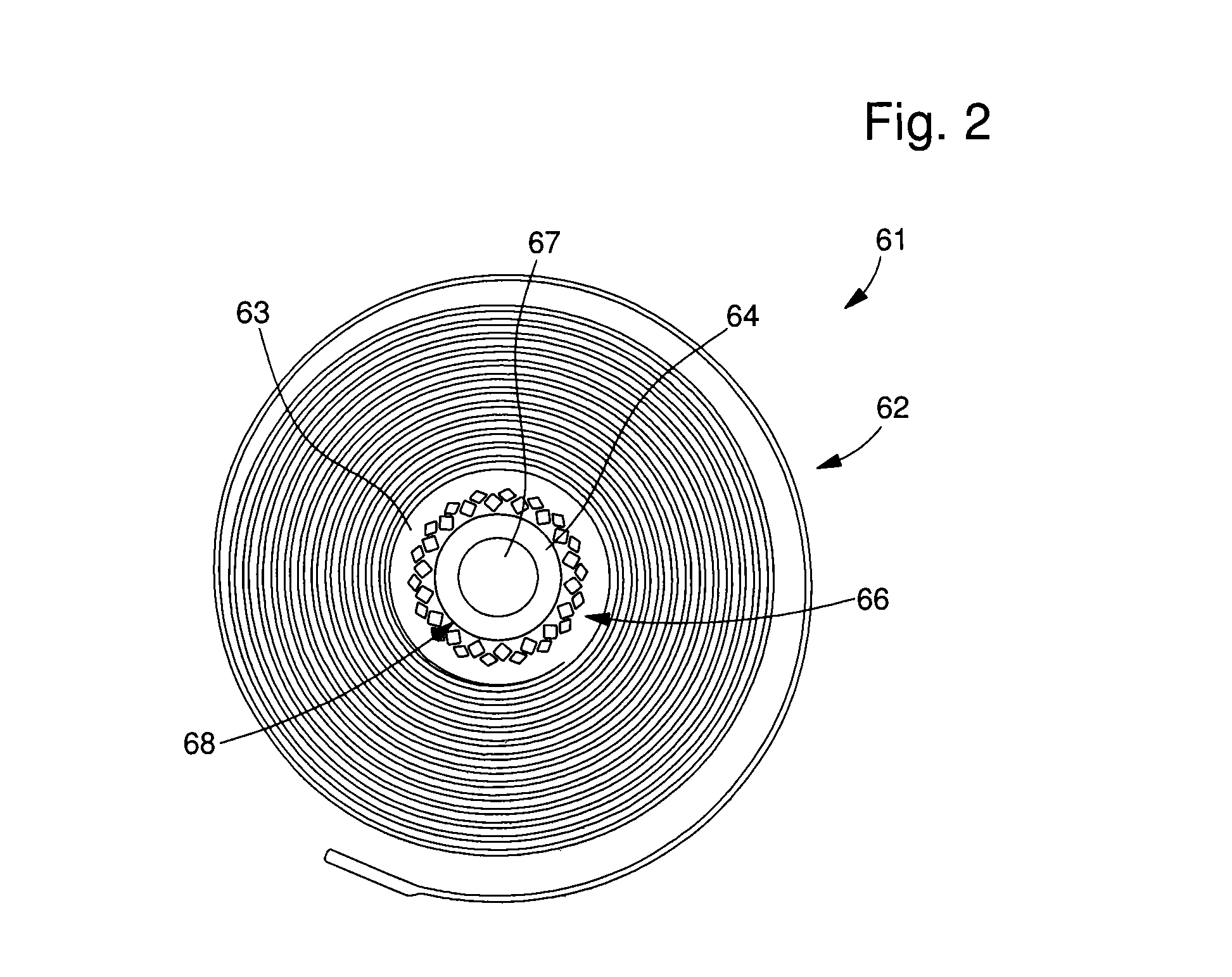

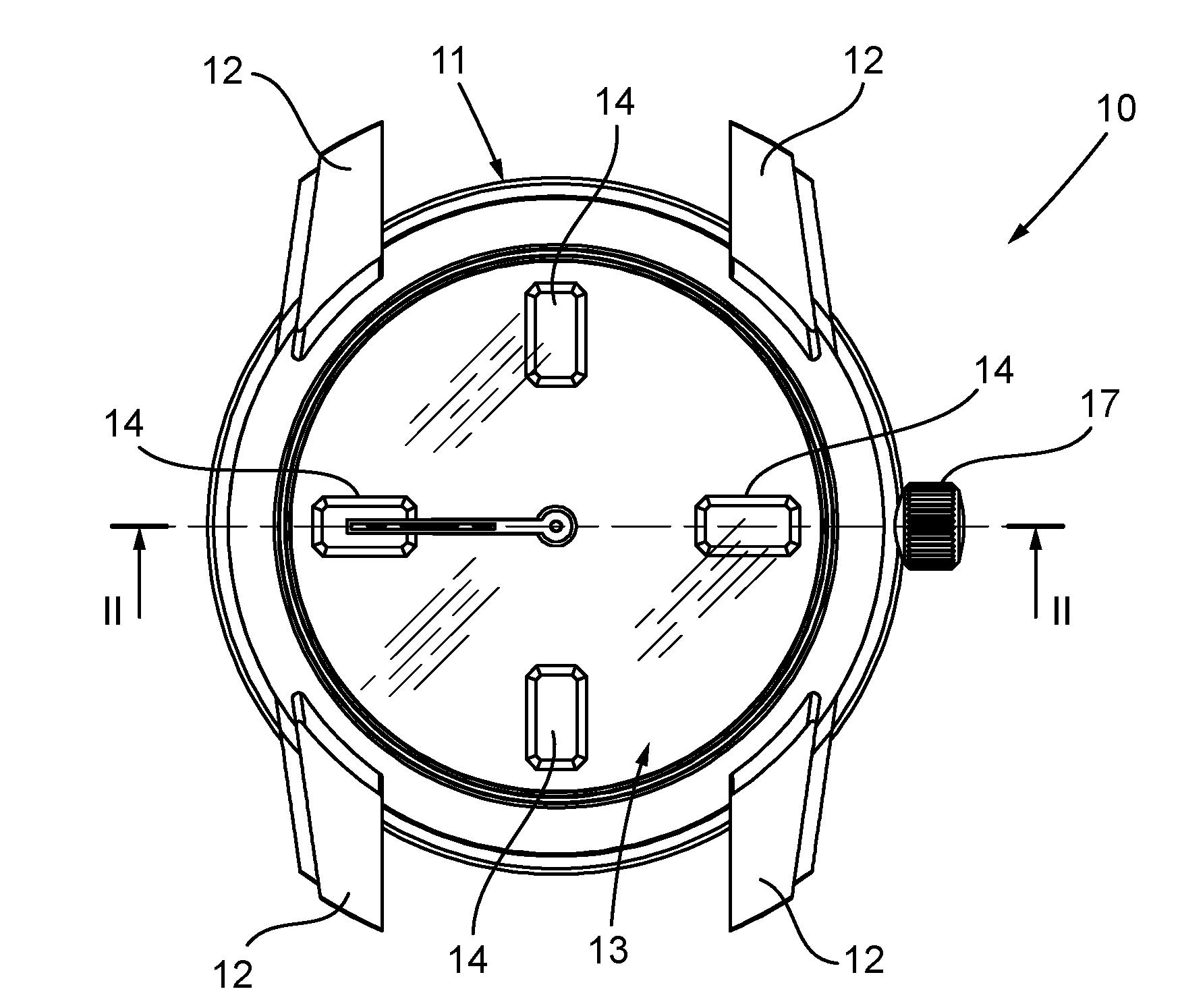

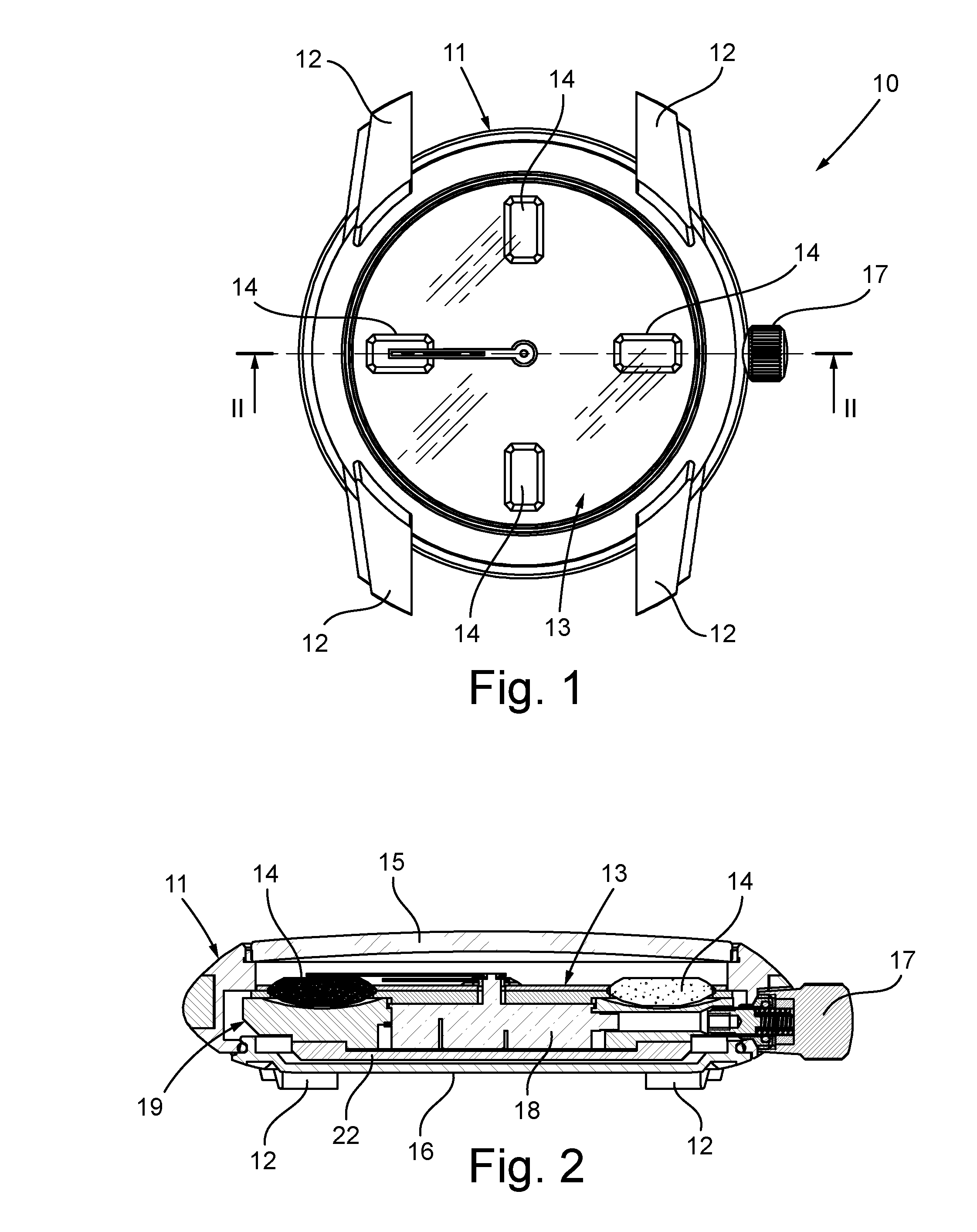

System for fastening gems to a watch dial and a watch provided with such a system for fastening gems

ActiveUS20160139566A1Simple and cost-effective can be madeEasy to disassembleVisual indicationClock support devicesEngineeringMechanical engineering

In order to make a system for fastening gems to a watch dial, the dial is made of an upper plate-shaped element and of a lower plate-shaped element facing each other, the upper plate-shaped element being provided with openings for housing the gems in a visible manner and the lower plate-shaped element being provided with openings at the openings of the upper element and having the same size as these latter. Each of the openings mutually facing by pairs extends across the thickness of the respective plate-shaped element with an own peripheral edge inclined so that each opening narrows, within the section of the respective plate-shaped element, going from the surface of the plate-shaped element facing the other plate-shaped element towards the opposite surface thereof for forming a seat for housing and retaining a gem between the two elements.

Owner:DOLCE & GABBANA

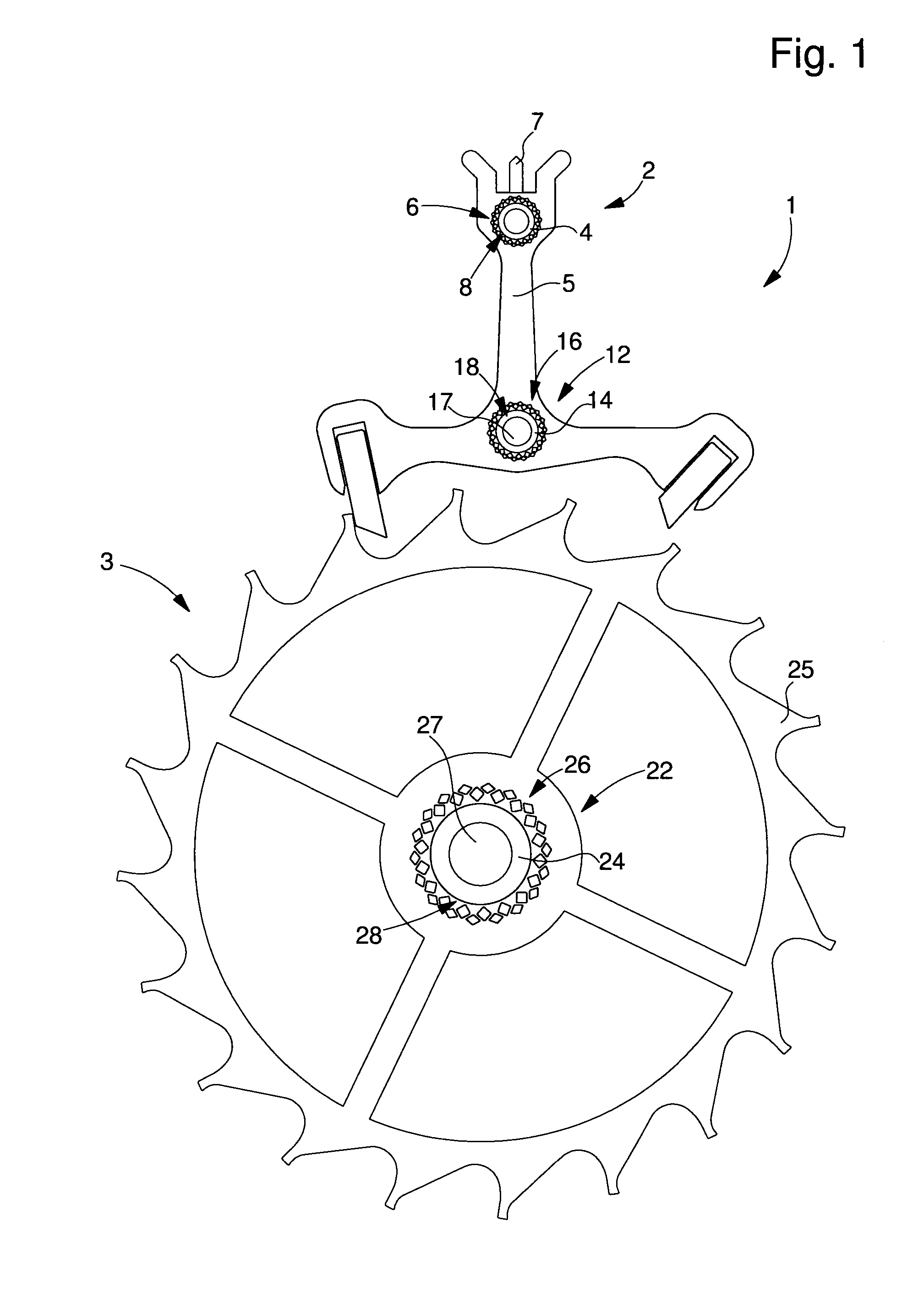

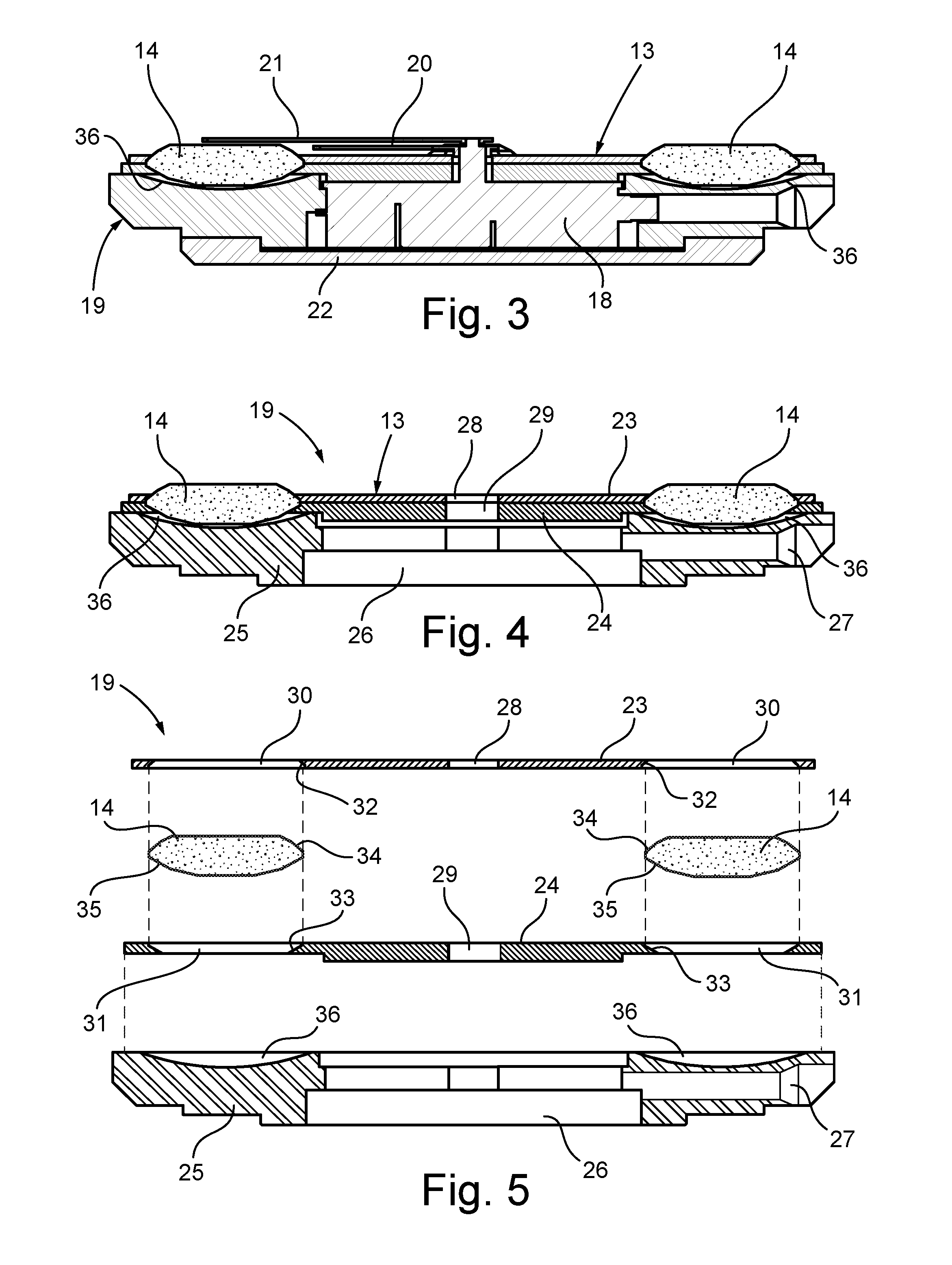

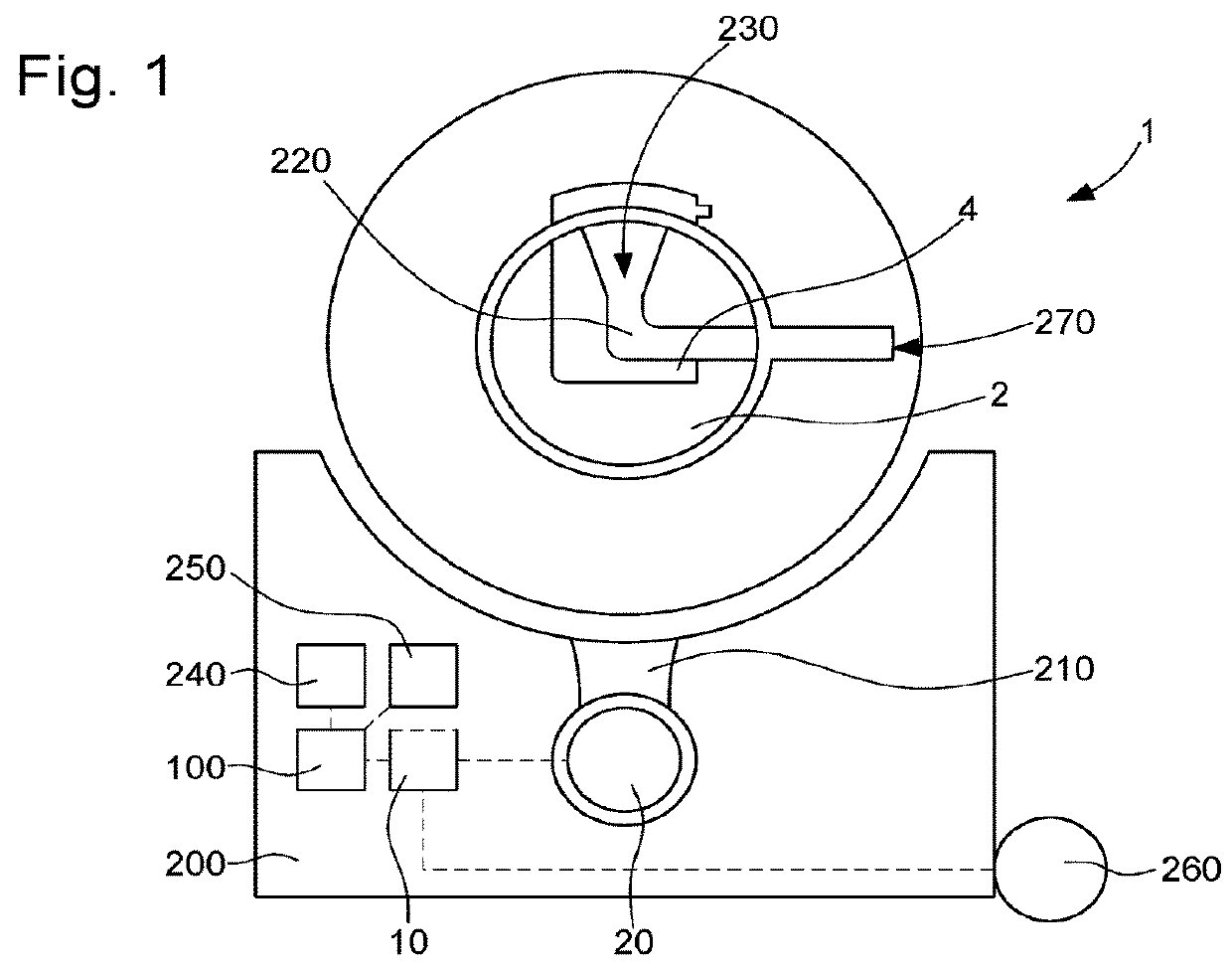

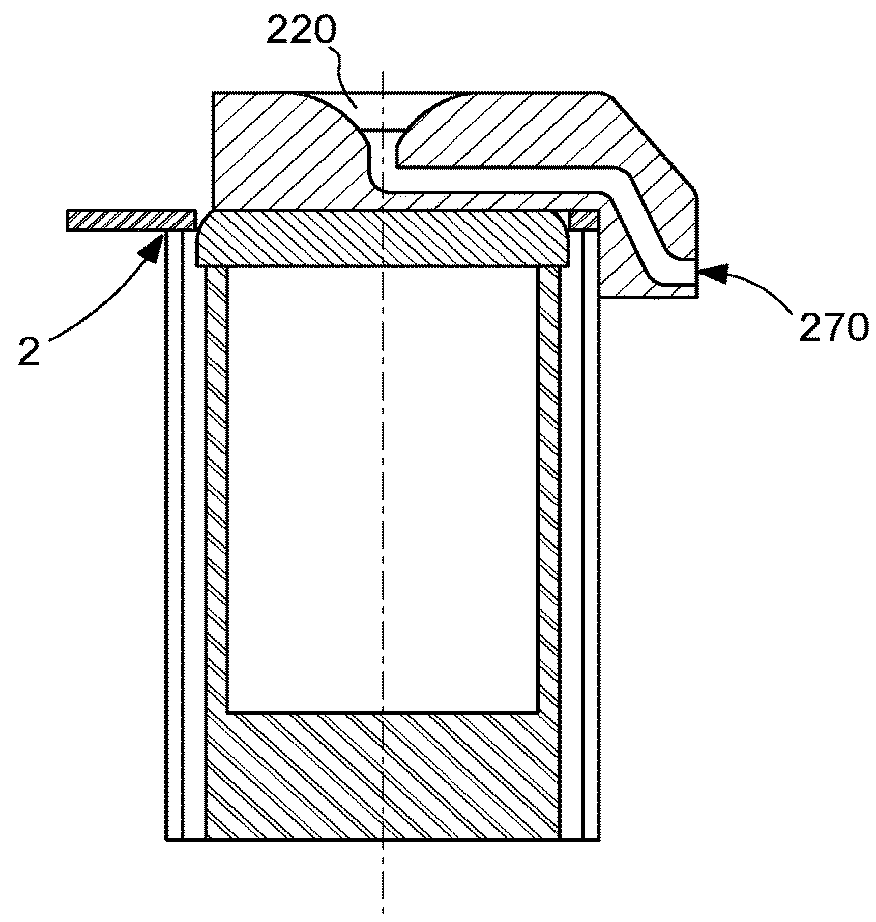

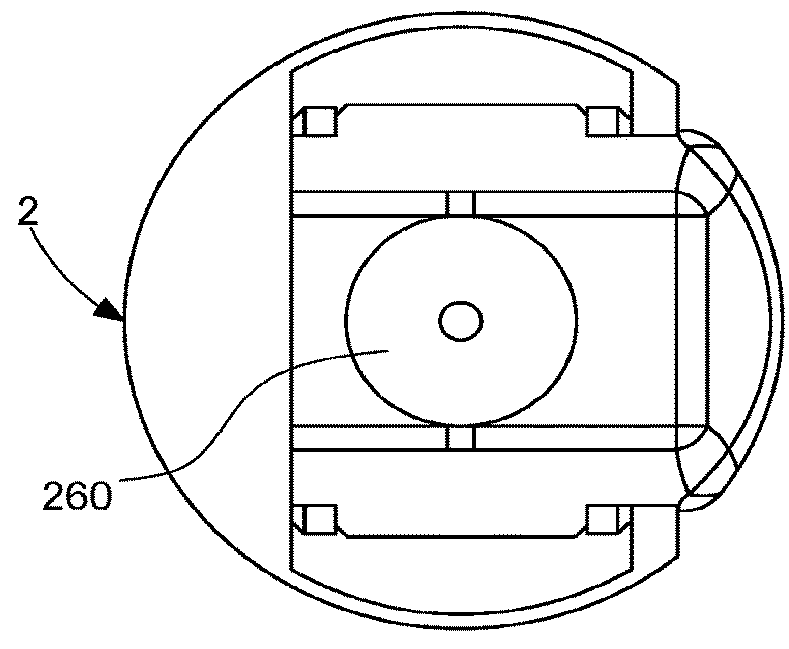

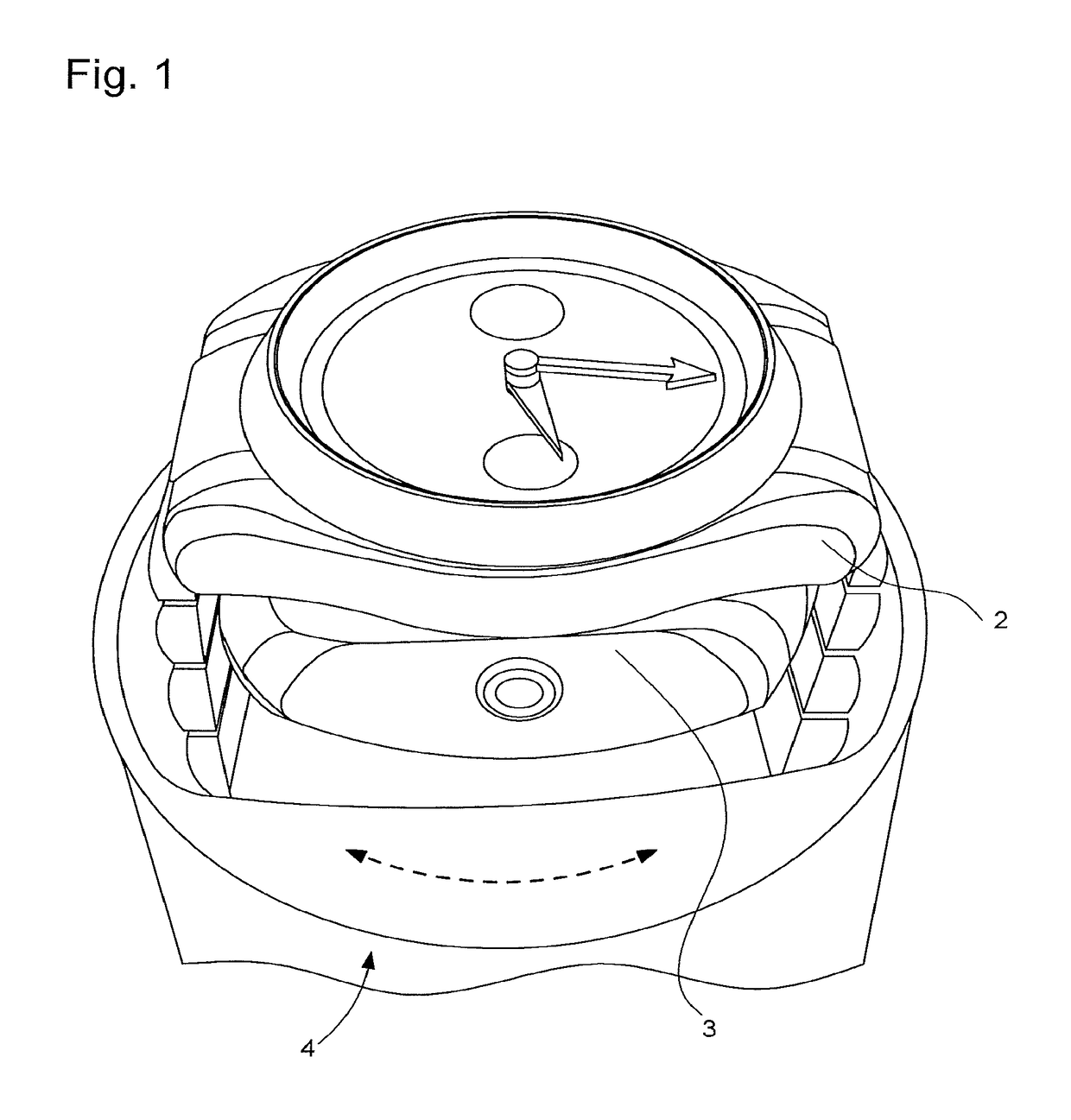

Intelligent device for winding watches

The invention relates to a watch winding device, with a motor driving a winding operation, means for acoustic measurement of the oscillator of a watch in the winding position, control means analysingthe signals transmitted by the measuring means and comparing them to desired values that can be parameterized to regulate the operation of the motor by starting this motor when the operating amplitudeof the oscillator is less than a minimum value, and by stopping this motor when the working amplitude is higher than a maximum value, these acoustic measuring means are fixed in a base behind an sensing opening of the acoustic sensor means, the device includes an acoustic duct which places a receiving port, located inside a chamber for housing a watch, in communication with a transmitting port movable by the motor facing this sensing opening.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

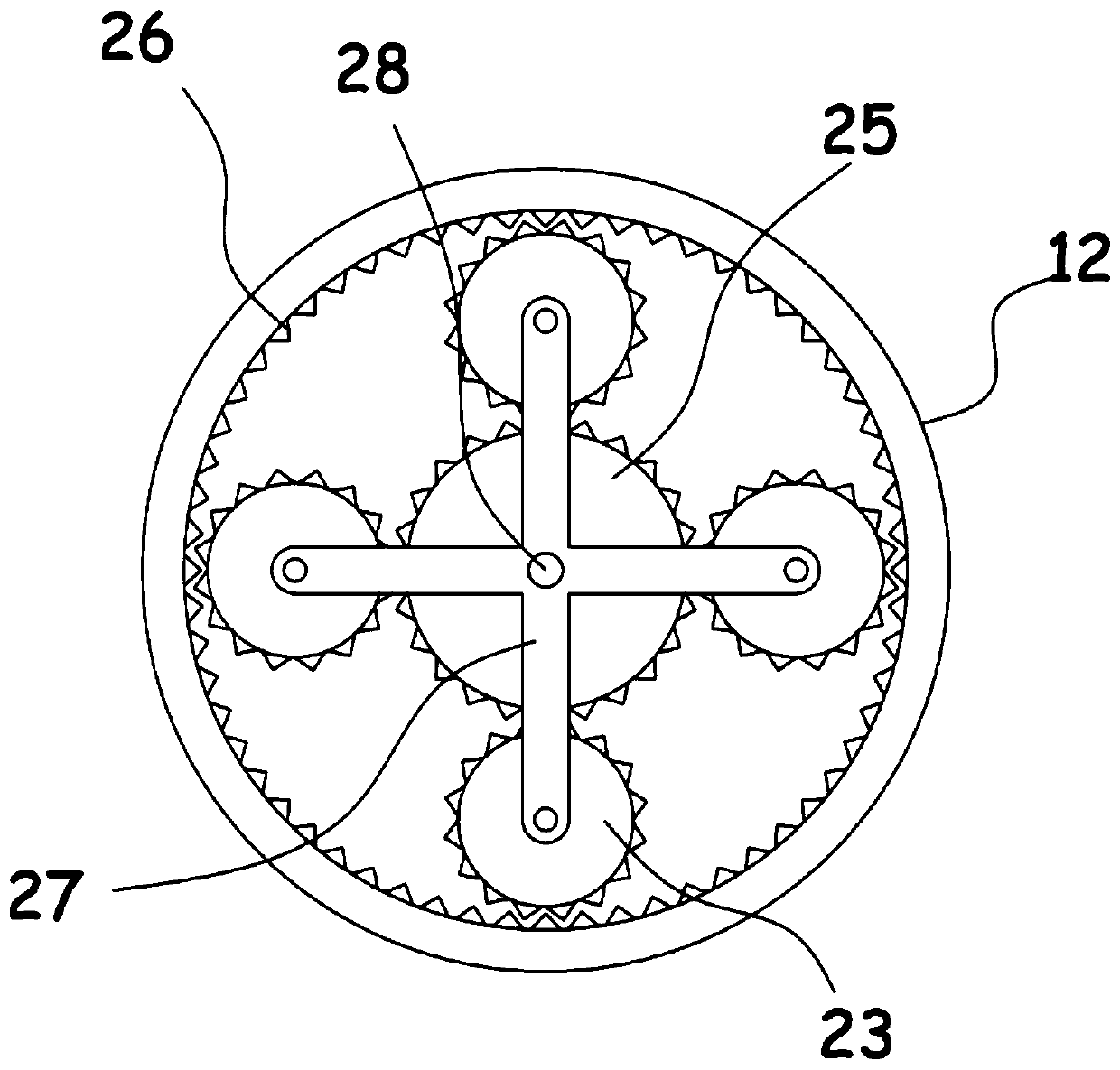

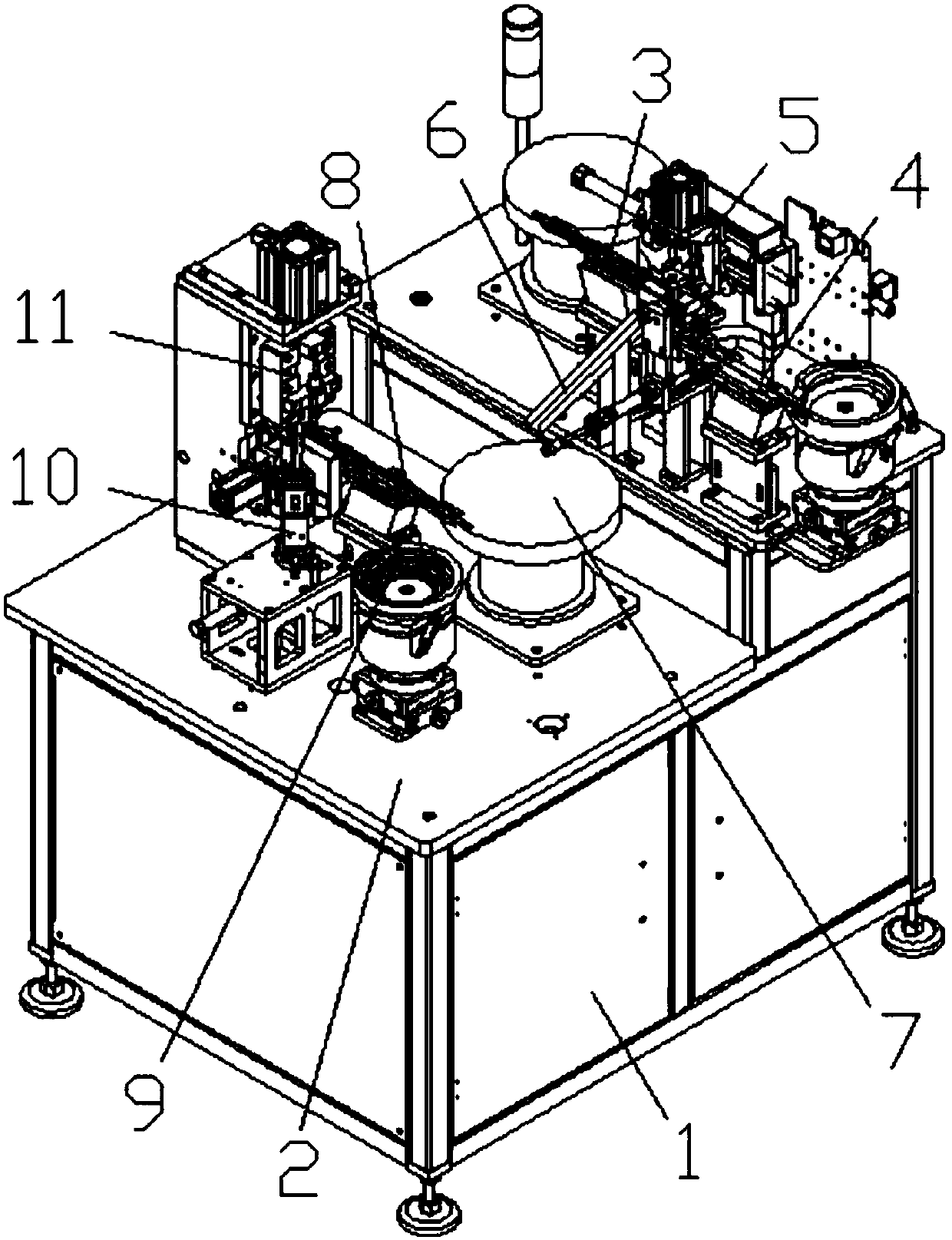

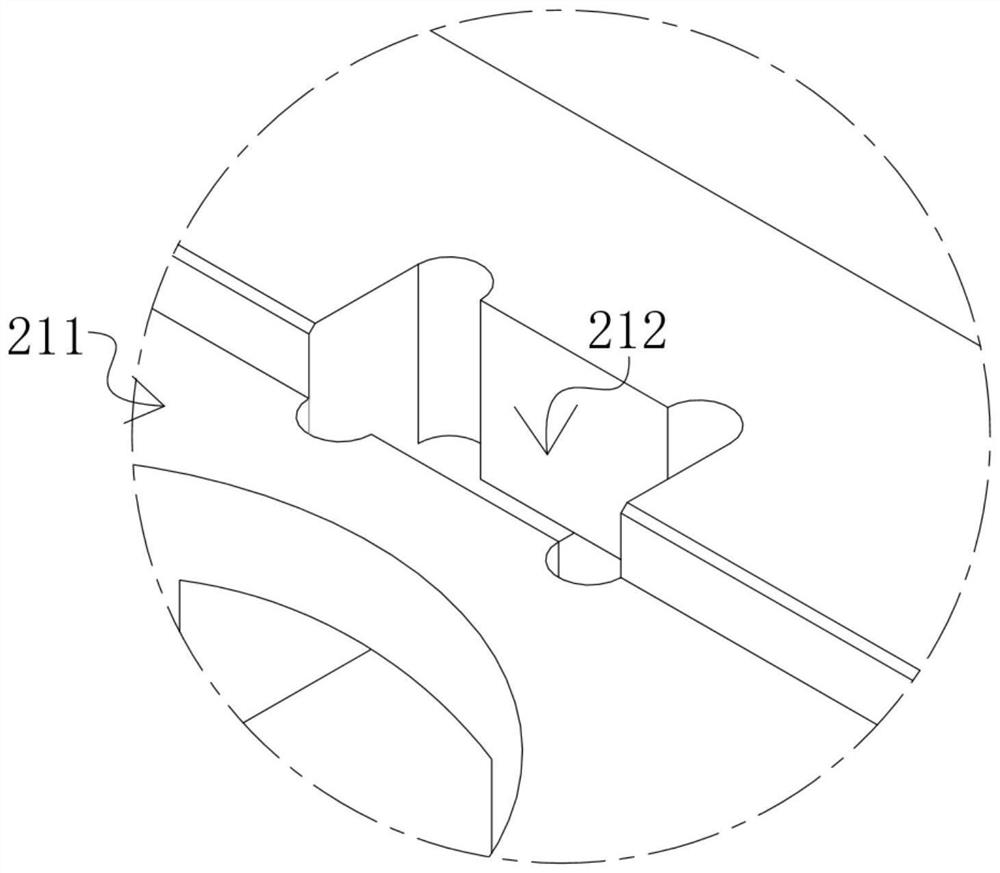

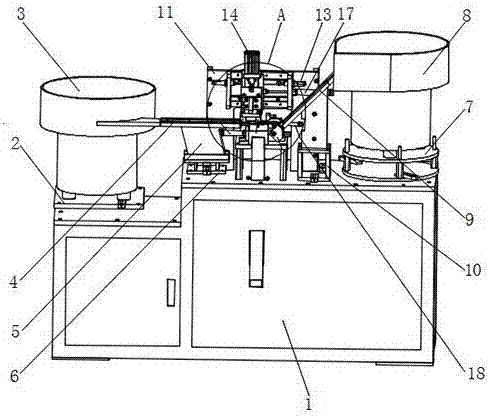

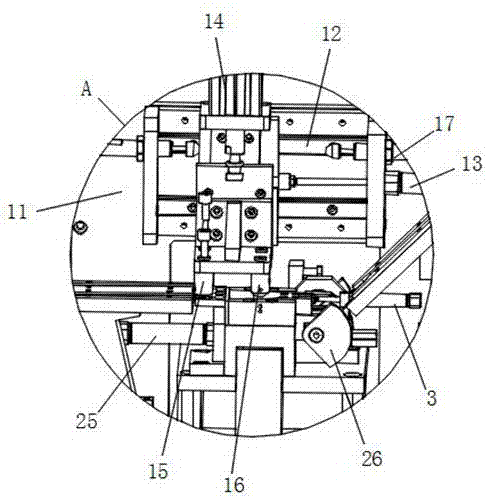

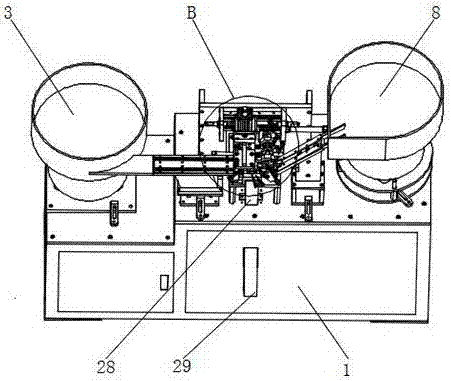

Clock and watch accessory assembling machine

InactiveCN107589658AImprove yield rateImprove assembly efficiencyClock support devicesWork in processIndustrial engineering

The invention relates to a clock and watch accessory assembling machine, which is characterized in that a rack is provided with a fork piece feeding device and a fork piece receiving movable device which are matched with each other, the lateral part of the fork piece receiving movable device is provided with a semi-finished product blanking groove in a matched manner, the upper part is provided with a pressing shaft device matched with a fork shaft taking sleeve of a fork shaft feeding device on the rack in a matched manner, the semi-finished product blanking groove is connected with a semi-finished product vibration plate, the semi-finished product vibration plate is connected with a semi-finished product receiving movable device through a semi-finished product feeding groove, the upper part of the semi-finished product receiving movable device is provided with a fork pin taking device and a pressing pin device in a matched manner, the fork pin taking device (10) is matched with a fork pin feeding device. According to the invention, a fork piece and a fork shaft are assembled into a semi-finished product through matching the fork piece receiving movable device with the shaft pressing device capable of movably taking a shaft, and then the semi-finished product and the fork pin are assembled into a finished product through matching the semi-finished product receiving movable device with the fork pin taking device and the pressing pin pressing device, so that the assembling efficiency is greatly improved, and the yield of the assembled finished products is improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Watch rear shell locating assembly device and processing technology thereof

ActiveCN109001968ARealize automatic photo detectionIncrease temperatureClock support devicesIndustrial engineeringEngineering

The invention discloses a watch rear shell locating assembly device. The watch rear shell locating assembly device comprises a workbench and a workbench turntable component; a loading component, a grabbing component, an alignment component and a CCD component are arranged on the edge of the turntable component; automatic photographing detection of the CCD is realized; then, precise locating assembly is carried out; the device temperature is high; the installation precision is high; the product production efficiency is high; and the quality is good.

Owner:徐州佳联农业发展有限公司

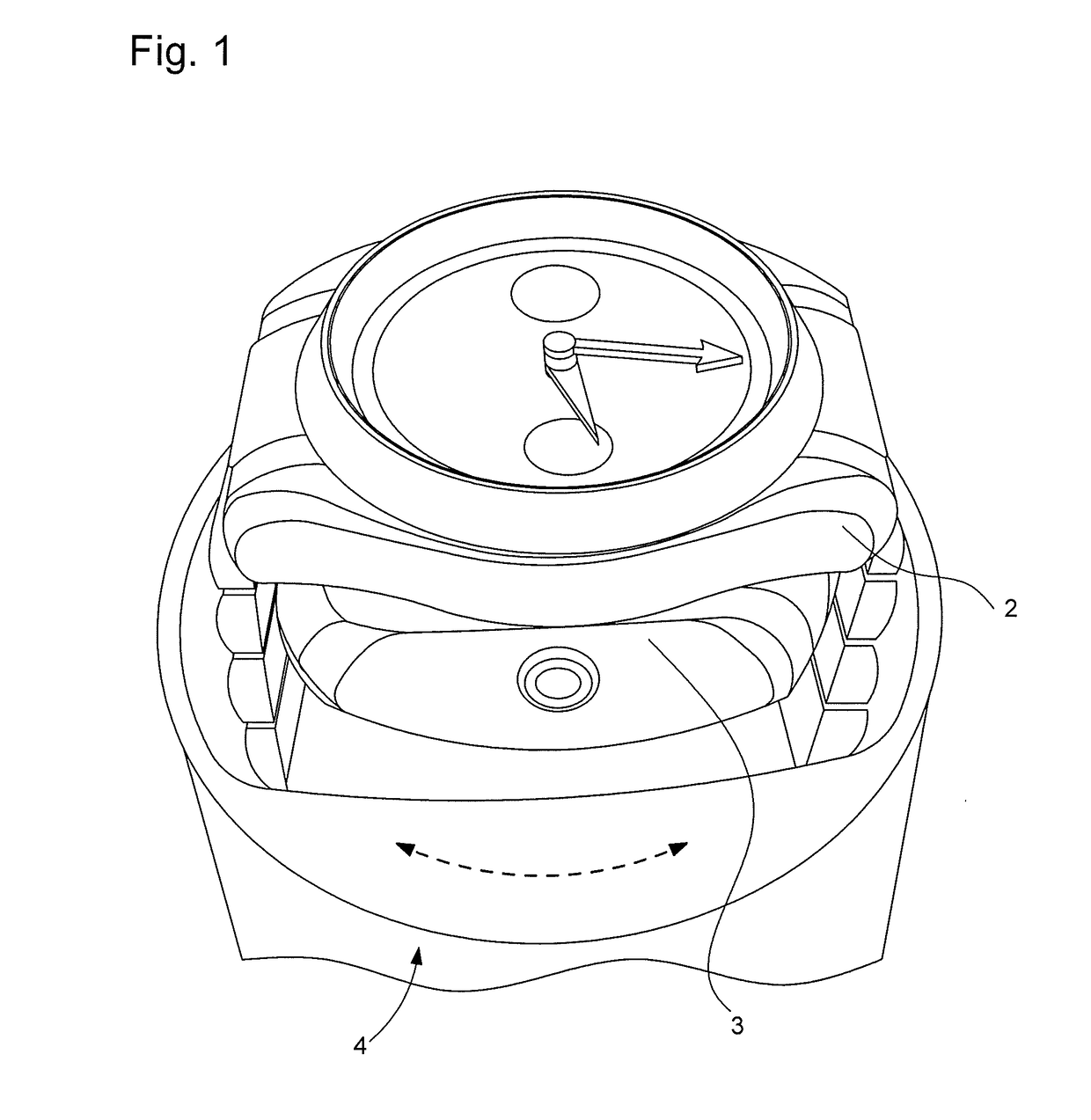

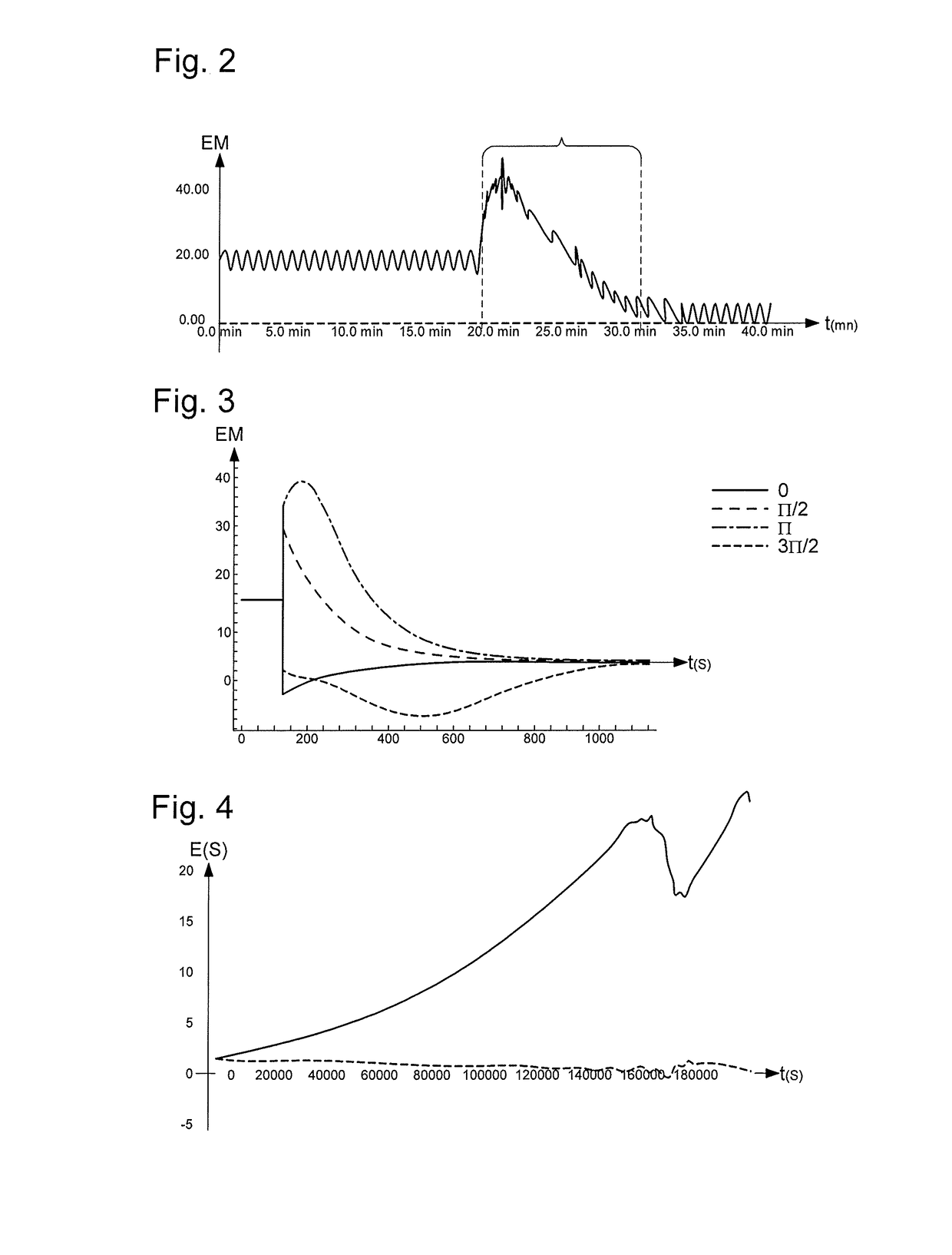

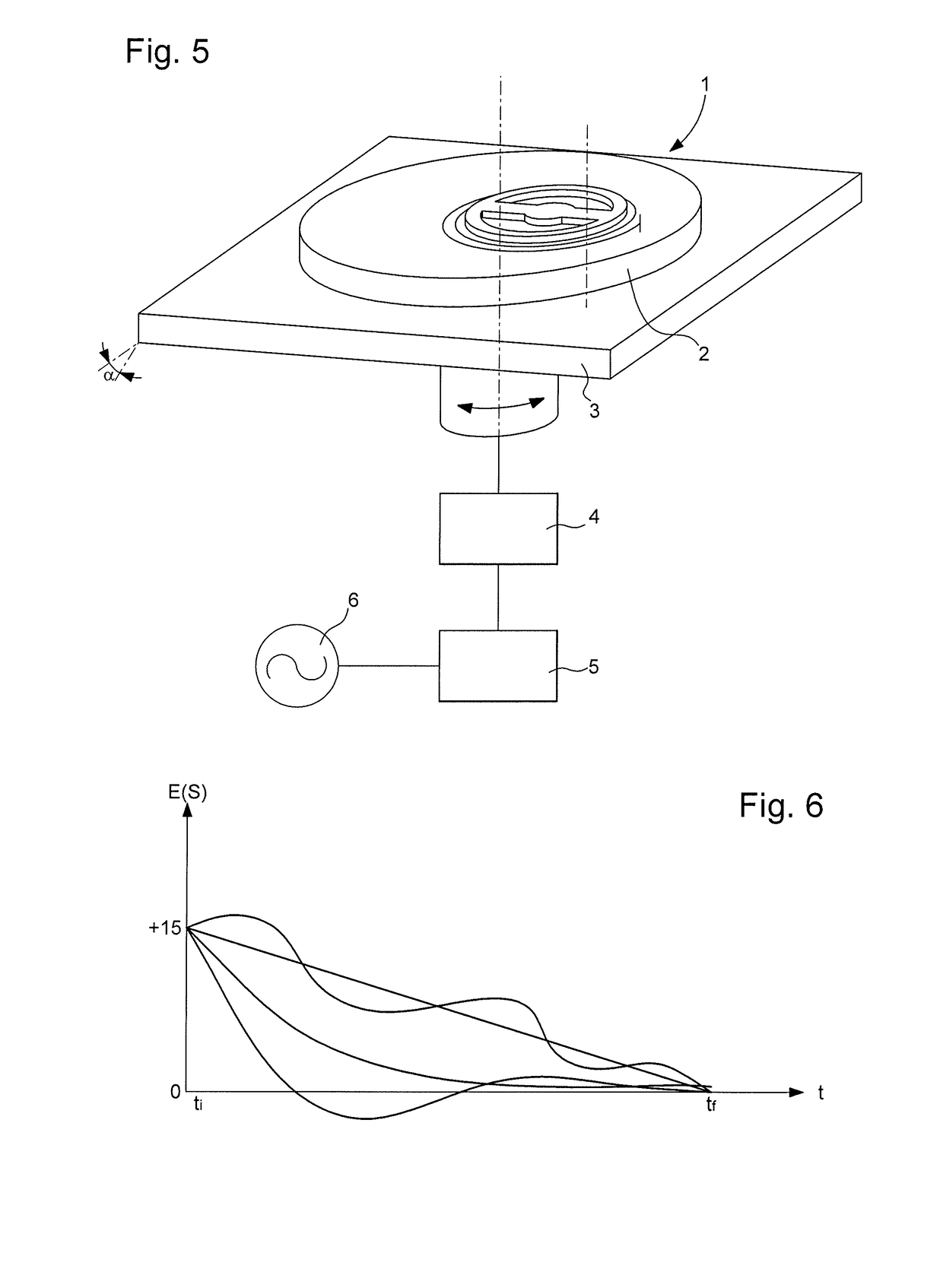

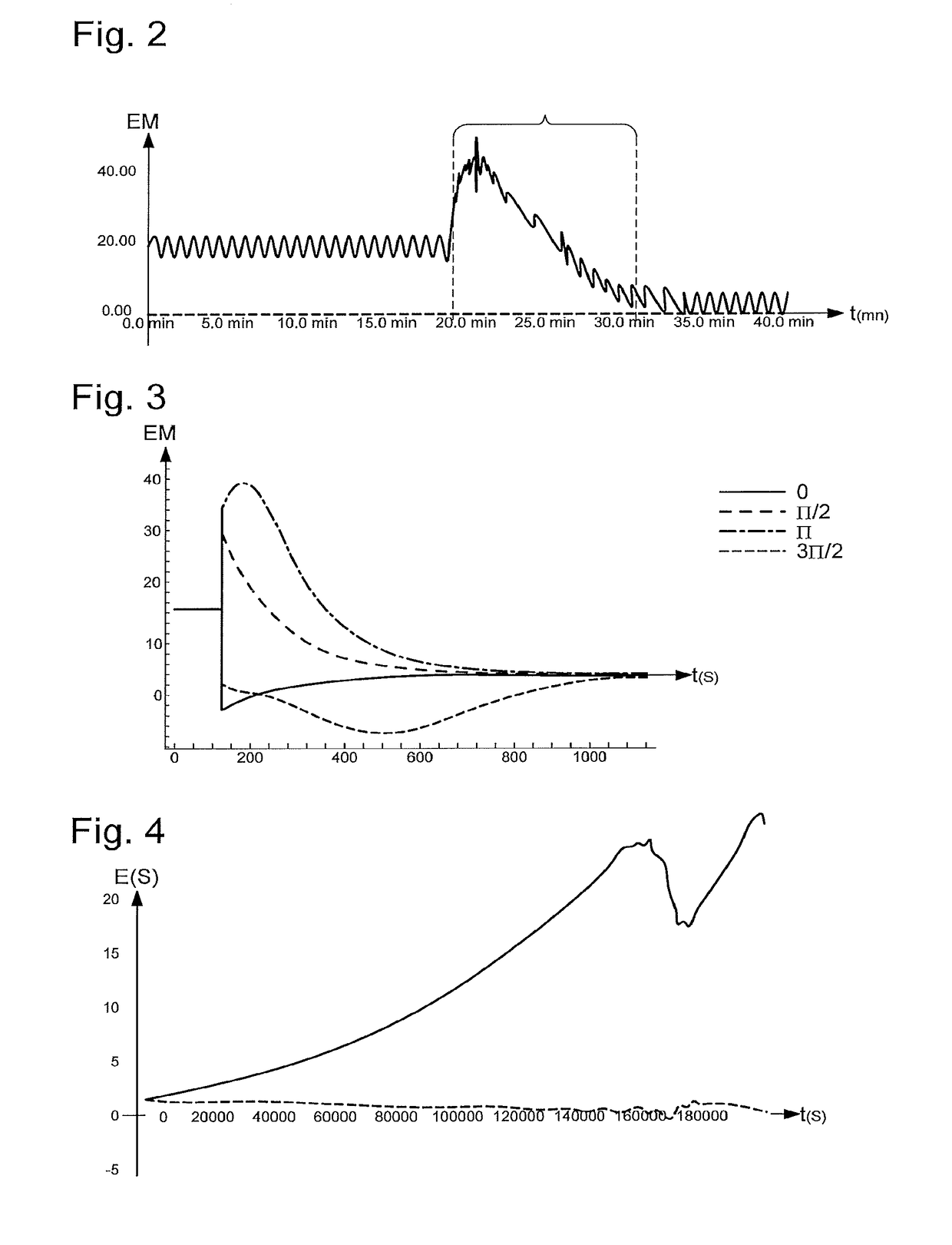

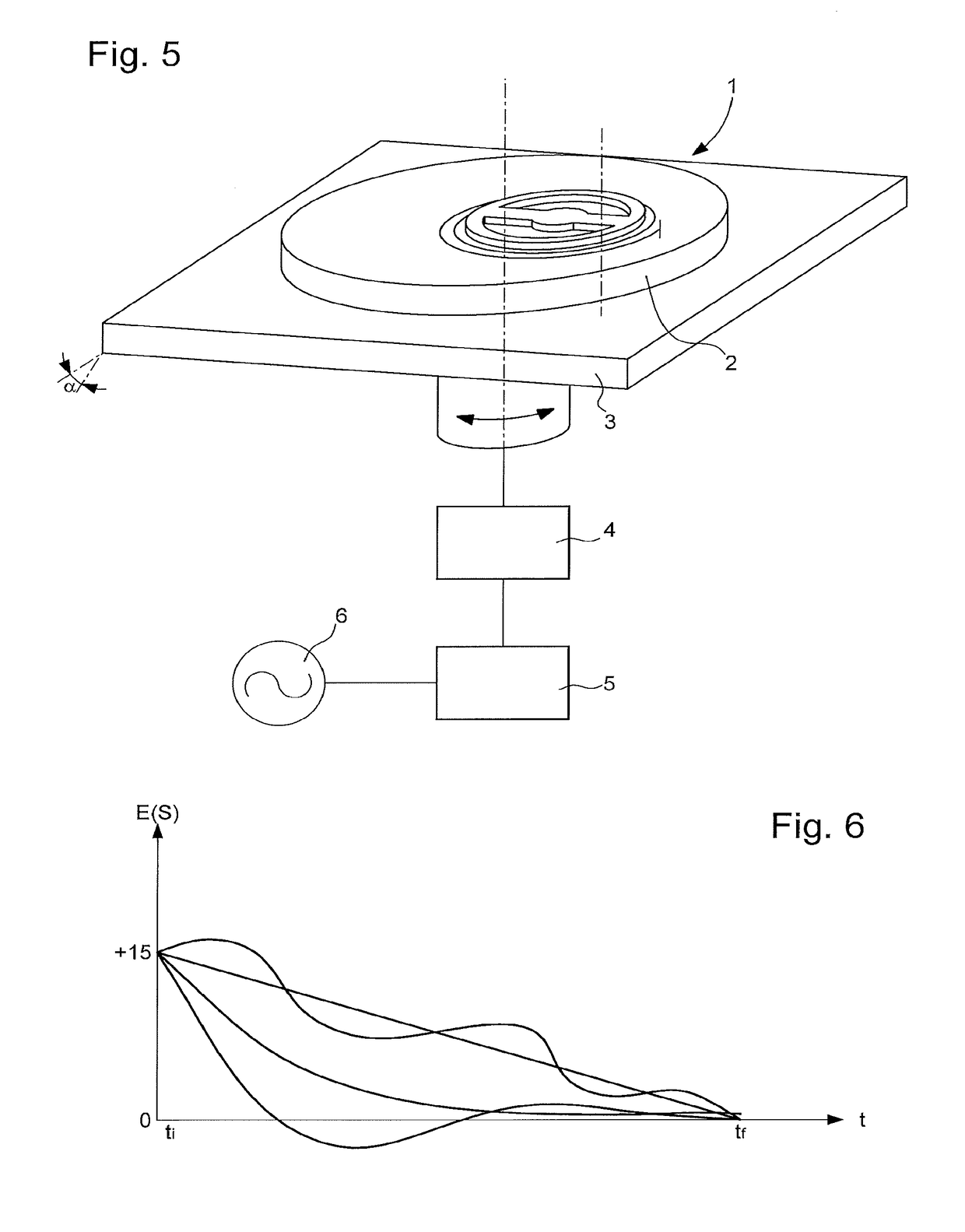

Device and method for adjusting the rate of a watch

ActiveUS20180341226A1Easy to controlFrequency setting mechanismMaster clocksMaster oscillatorNominal frequency

A method for adjusting the rate of a watch with an oscillator arranged to generate oscillation at a nominal frequency N0, with a servo-system including a master oscillator arranged to generate excitation oscillation at an excitation frequency NE, which is approximately equal to, or equal to the nominal frequency N0, or to an integer multiple of this nominal frequency N0, the watch is subjected to excitation oscillation or to a modulated motion, generated by the master oscillator, during a transition phase after which the oscillator of the watch is stabilised at excitation frequency NE, and there is incorporated in the servo-system a winder for mechanical or automatic watches, arranged to move a support on which such a watch is fixed.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Crown for watches and a tool for attaching a screw-in tube for the crown arrangement on a watch case

Owner:DAMASKO

Smart watch winding device

ActiveUS20180181075A1Simple and inexpensive and compact meanSolve the power is smallElectric windingNormal windingMotor driveElectric machine

Watch winding device, with a motor driving a winding operation, means for acoustic measurement of the oscillator of a watch in the winding position, control means analysing the signals transmitted by the measuring means and comparing them to desired values that can be parameterized to regulate the operation of the motor by starting this motor when the operating amplitude of the oscillator is less than a minimum value, and by stopping this motor when the working amplitude is higher than a maximum value, these acoustic measuring means are fixed in a base behind an sensing opening of the acoustic sensor means, the device includes an acoustic duct which places a receiving port, located inside a chamber for housing a watch, in communication with a transmitting port movable by the motor facing this sensing opening.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Assembly of a part that has no plastic domain

Owner:ETA SA MFG HORLOGERE SUISSE

Part holding device

InactiveUS20080106017A1Pin efficiently machined partClock support devicesPositioning apparatusEngineeringFlange

Owner:YERLY MICHEL

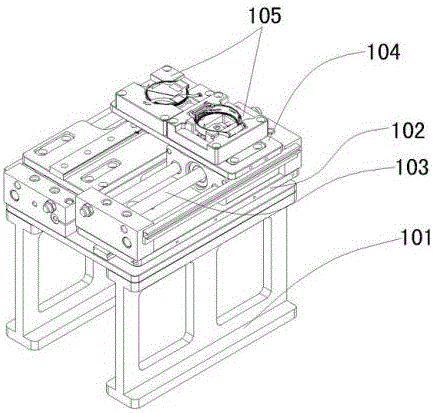

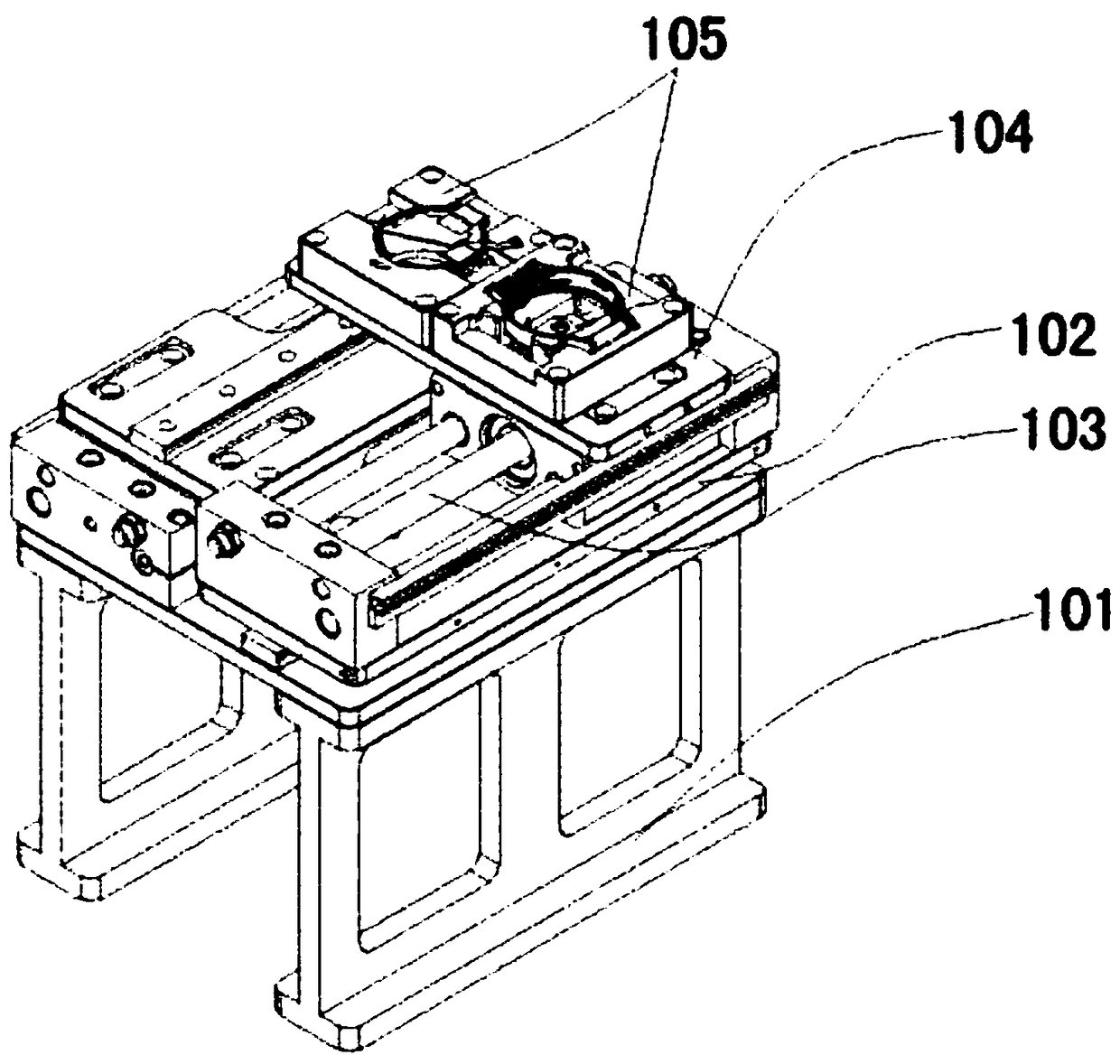

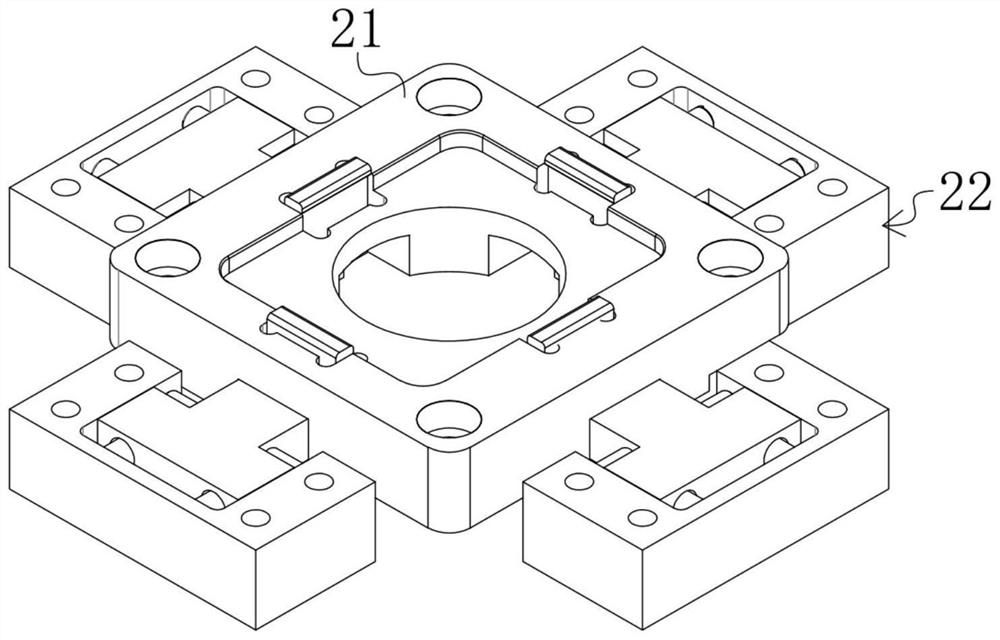

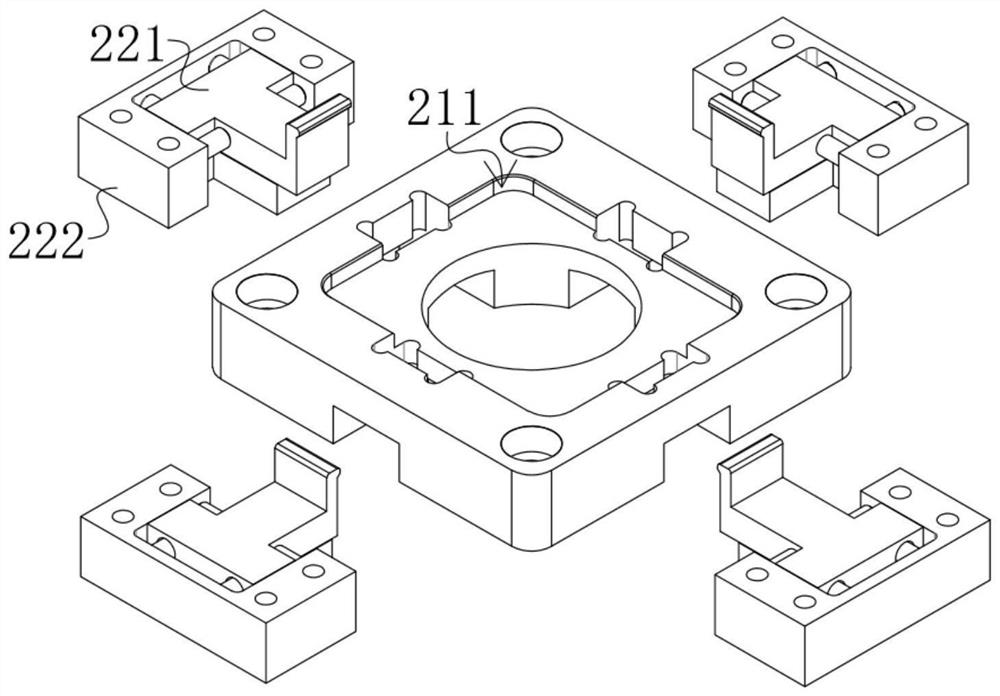

Watch dial plate clamp mechanism and carrier device comprising same

InactiveCN111708270AAchieve fixationEasy to useClock support devicesEngineeringMechanical engineering

The invention provides a watch dial plate clamp mechanism comprising a clamp assembly which comprises a clamp assembly, and the clamp assembly comprises a clamp substrate and a clamping jaw module; amaterial bearing groove used for containing a dial plate is arranged at the upper surface of the clamp substrate; the clamping jaw module comprises clamping jaws, the clamping jaw module is arranged at the side surface close to the material bearing groove, the clamping jaws are bent to form clamping parts used for fixing a dial plate, and the clamping jaws are at least arranged on three side facesof the dial plate; the clamping jaws are driven by acting force to move towards the dial plate in the material bearing groove, so that the clamping parts on the clamping jaws make contact with the dial plate, the clamping jaws clamp the dial plate, the dial plate is rapidly fixed, the material taking or discharging efficiency is improved, and the clamp mechanism is convenient to use, simple in structure and convenient to maintain.

Owner:BOZHON PRECISION IND TECH CO LTD

Quartz clock movement second shaft automatic assembling machine

ActiveCN107255916AImprove qualityIncrease production capacityClock support devicesEngineeringAssembly machine

A quartz clock movement second shaft automatic assembling machine disclosed by the present invention comprises a host rack body, a vibrating disc regulation pedestal is arranged at the left side of the upper end of the host rack body, and a second wheel sheet plastic component vibrating disc is arranged at the upper end of the vibrating disc regulation pedestal. A second wheel sheet direct vibration material channel is arranged at the right end of the second wheel sheet plastic component vibrating disc, a second wheel sheet direct vibration material channel fixing rack is arranged at the lower end of the middle part of the second wheel sheet direct vibration material channel, and a height regulation pedestal is arranged at the lower end of the second wheel sheet direct vibration material channel fixing rack. According to the present invention, a sucker is moved left and right to suck a second wheel sheet and a second shaft to thereby press in and assemble. For the assembly high capacity, a left-right structure is adopted, so that the yield is improved substantially. At present, one machine can substitute for the daily yield of 4-5 workers, the quality is improved, one person can check more than 4-5 devices, the assembly precision and the capacity are high, the performance is stable, the assembled parts are stored automatically, the quality is good, the assembled products are uniform, and the yield of the quartz clock movement second shaft automatic assembling machine is more than 2-3 times of the yield of an assembling machine in the market.

Owner:福建德丰智能装备有限公司

Device and method for adjusting the rate and correcting the state of display of a watch

ActiveUS20180341225A1Easy to controlFrequency stabilisation mechanismFrequency setting mechanismMaster oscillatorCorrection method

Method for adjusting the rate of a basic oscillator of a watch arranged to oscillate at a nominal frequency N0, with a master oscillator generating an excitation frequency NE approximately equal to an integer multiple of this nominal frequency N0, the master oscillator subjecting the watch to excitation or a modulated motion during a transition phase after which the basic oscillator is stabilised at the excitation frequency NE, and a state of display correction method with a winder for mechanical or automatic watches, moving a support carrying the watch and comprising a state of display correction oscillator, having a lower variation of rate value than the initial variation of rate value DI of this basic oscillator, and oscillating at a correction frequency NC to impose oscillation or a motion on the watch, during a state of display correction phase whose duration is adjusted to exactly correct a state of display error measured at the initial moment of actuation.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Protection of a timepiece component made of micromachinable material

Timepiece sub-assembly comprising a component made of micromachinable material comprising an attachment area with a peripheral contact surface, and a shell element deformable between two shapes, one contracted and one expanded, arranged to hold the attachment area inside a housing with at least one degree of freedom, and which comprises a complementary contact surface arranged, in its contracted shape, to exert a clamping force on the contact surface and to securely immobilise the attachment area in all directions, the shell element comprising a first element and a second element that are movable with respect to each other in its expanded shape, each comprising a complementary contact surface, and comprising clamping means for holding the first and second elements clamped together in its contracted shape.

Owner:NIVAROX FAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com