Automatic screwing and installing device for rear covers of electronic watches

An electronic watch and installation device technology, applied in clocks, clocks, clock support devices, etc., can solve the problems of low degree of automation and low installation efficiency of the back cover of the watch, and achieve high degree of automation, stable screwing operation, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

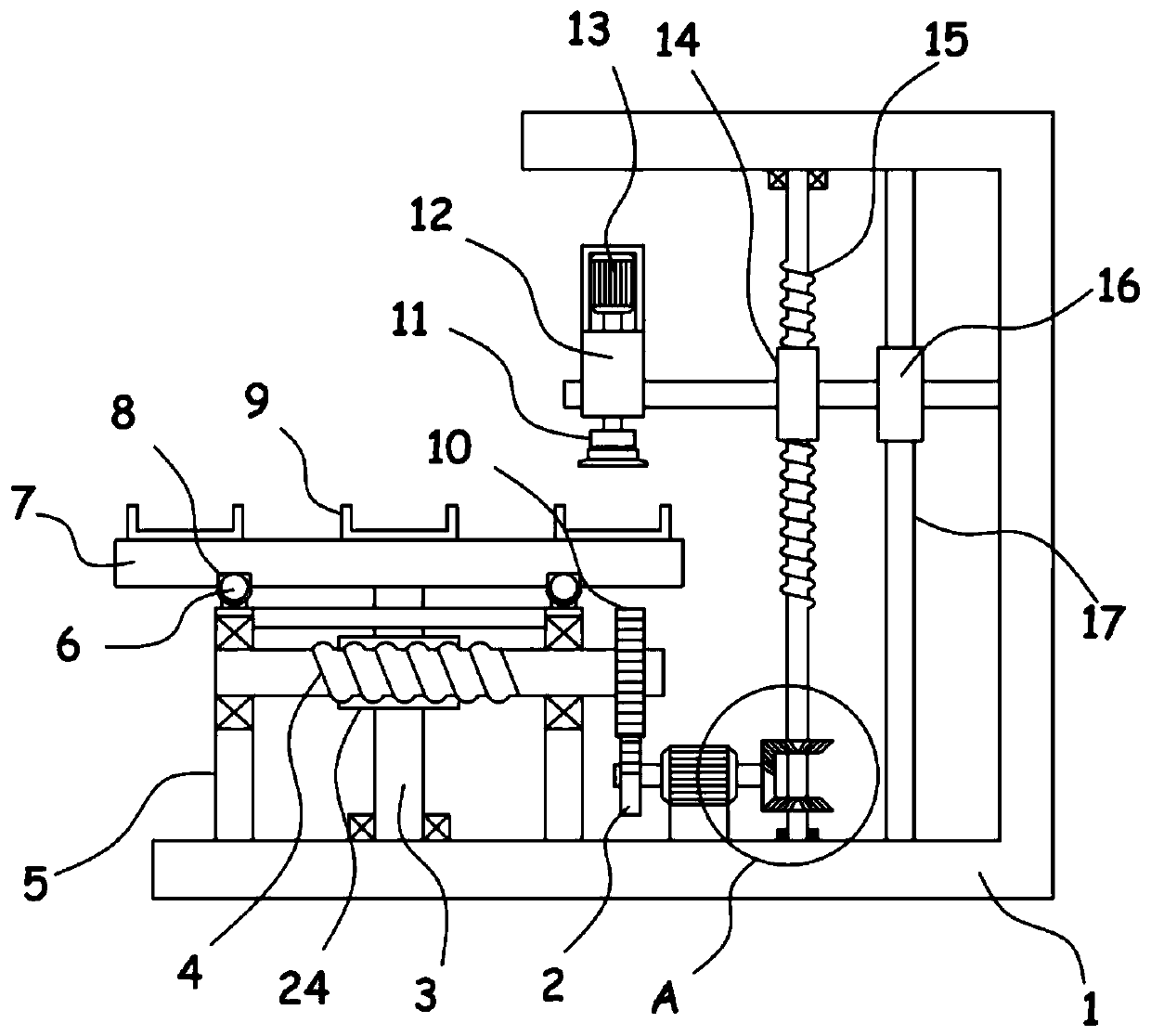

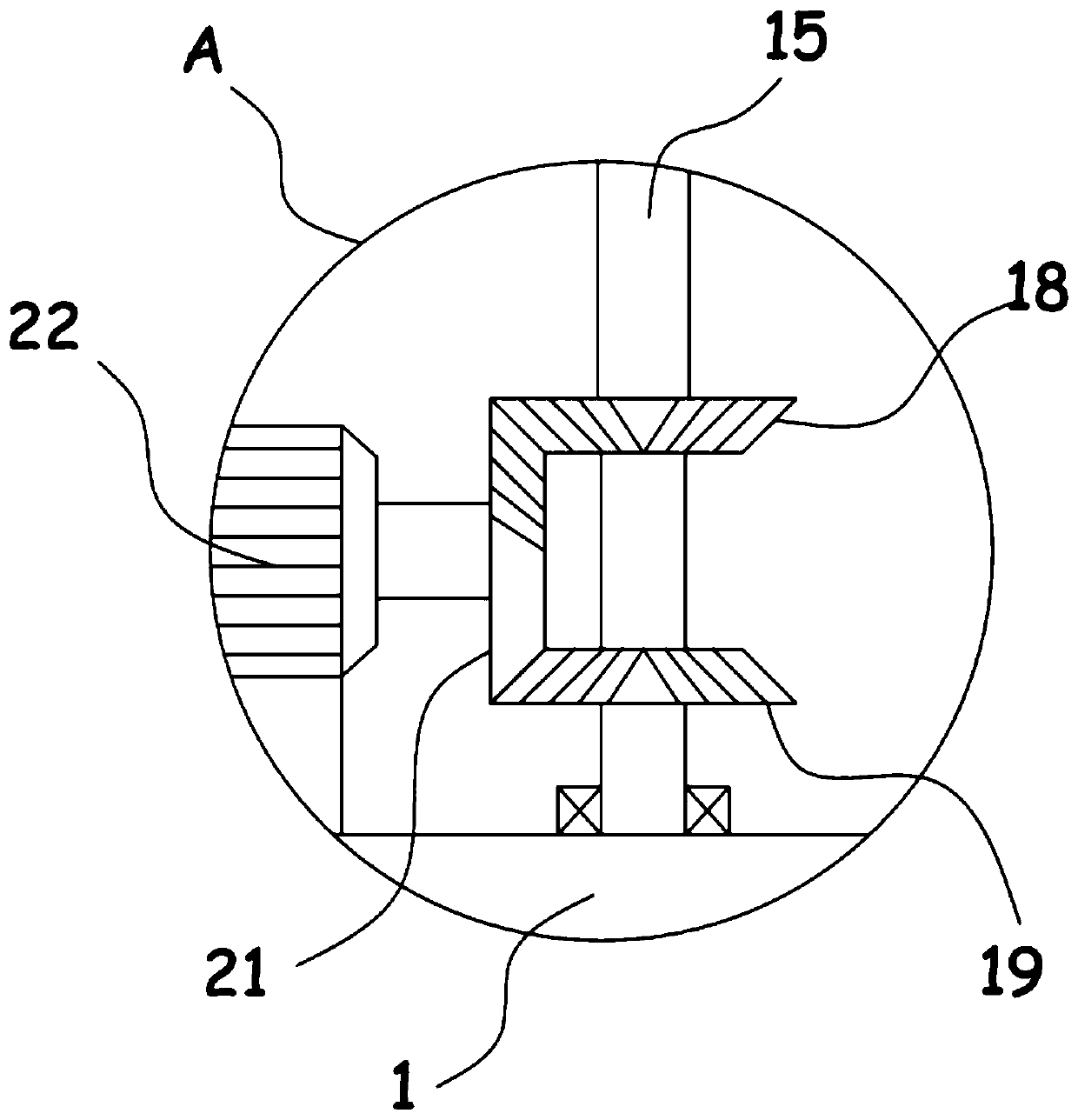

[0026] see Figure 1-6 , an automatic screwing and installation device for the back cover of an electronic watch, comprising a support frame 1, on which a fixing frame 5 is fixed, the support frame 1 is provided with a biaxial motor 22, and the biaxial motor 22 is driven and connected by a stepping mechanism to rotate The support turntable 7 is installed on the fixing frame 5, and the support turntable 7 is uniformly distributed and fixed with the clamping bases 9 for holding the watch. The upper thread is sleeved with a threaded sleeve 14 , and a screwing mechanism for screwing the back cover of the watch is fixed on the threaded sleeve 14 .

[0027] The device clamps and fixes the electronic watch through a plurality of clamping sockets 9 provided. When the clamping socket 9 rotates to the bottom of the screwing mechanism, the screwing mechanism moves down to screw and install the back cover of the watch.

[0028] Specifically, the screwing mechanism is vertically correspon...

Embodiment 2

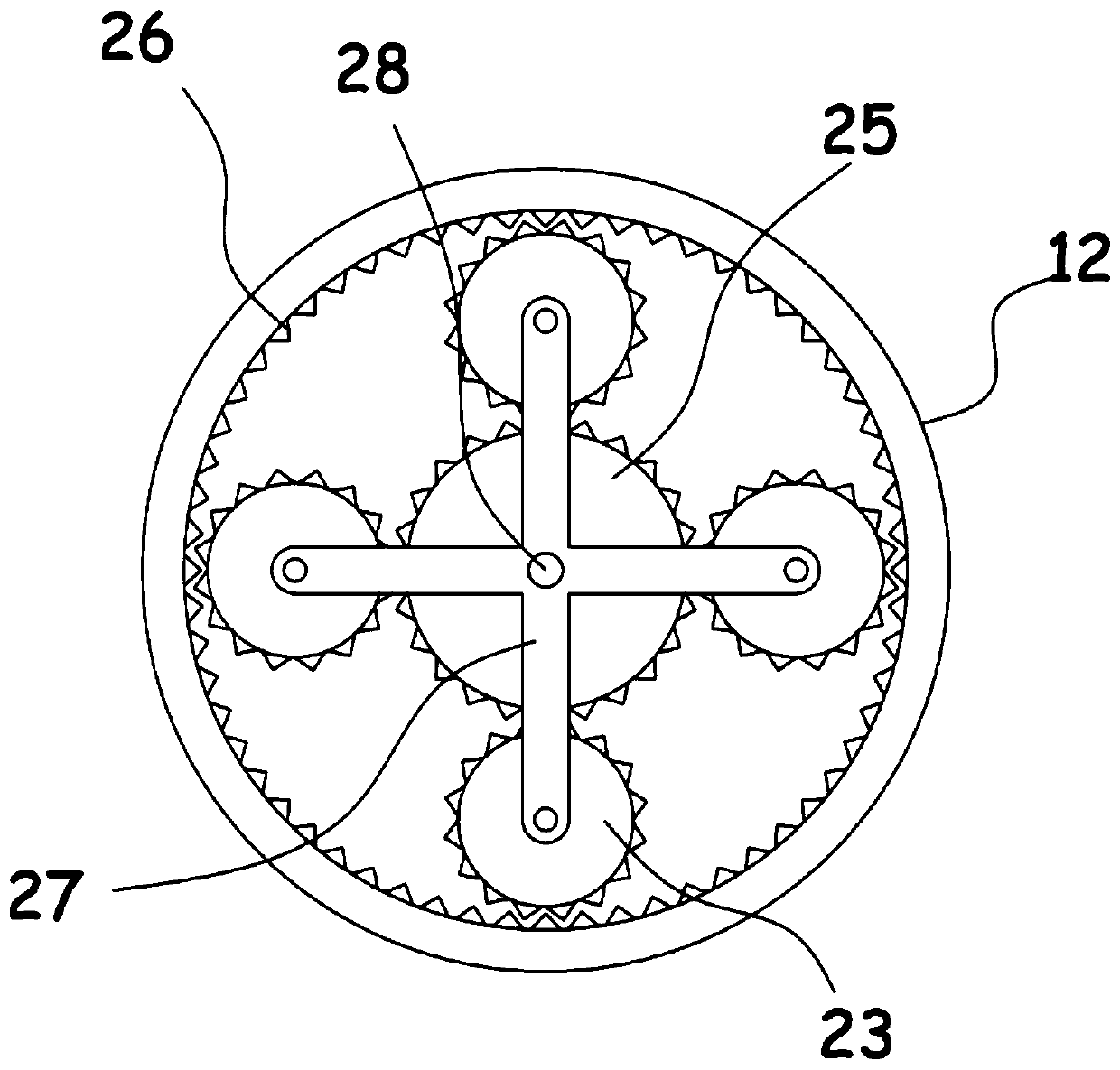

[0032] In order to improve the screwing effect of the screwing mechanism in the device on the back cover, on the basis of Embodiment 1, in addition, the device is also provided with a stepping mechanism, which includes an incomplete gear 2 driven by a biaxial motor 22, The incomplete gear 2 is meshed with a transmission gear 10, the transmission gear 10 is coaxially fixed with a worm 4, the worm 4 is meshed with a worm wheel 24, and the worm wheel 24 is coaxially fixed with a steering wheel that is fixed to the bottom center of the support turntable 7 axis 3.

[0033] The biaxial motor 22 can drive the incomplete gear 2, and the incomplete gear 2 drives the transmission gear 10 to rotate intermittently. At this time, the worm 4 drives the worm gear 24 meshing with it to rotate intermittently, and the worm gear 24 drives the support turntable 7 to rotate through the steering shaft 3. The clamping seat 9 on the support turntable 7 can be rotated stepwise to the bottom of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com