An efficient vacuum plane film laminating machine and a film laminating method

A vacuum laminating machine and plane technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of low product qualification rate, waste of PVC film, low work efficiency, etc., to ensure product quality, The effect of saving power consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

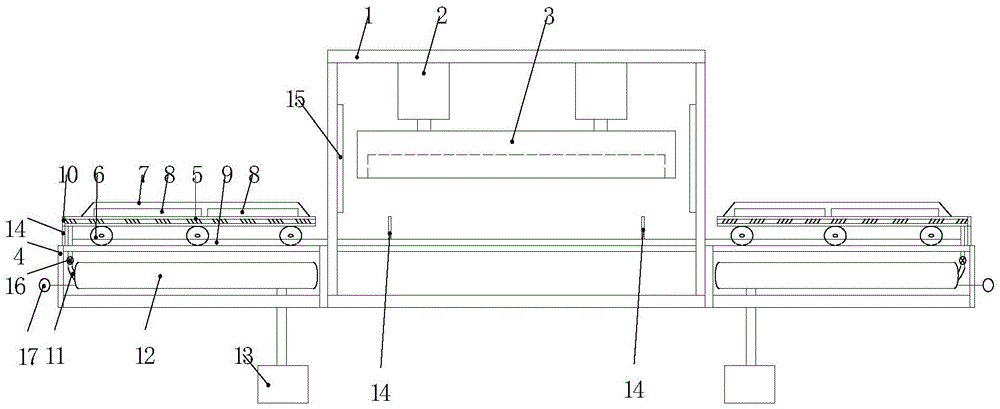

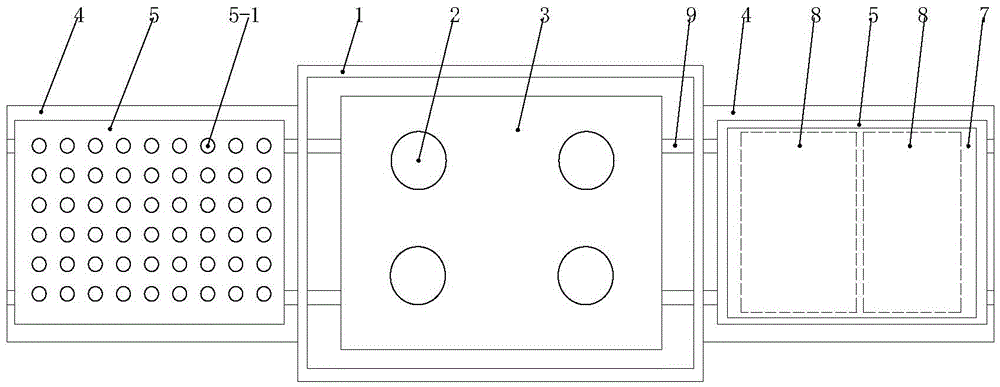

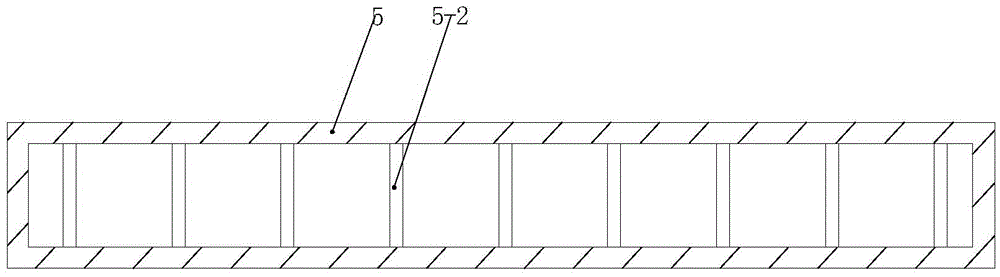

[0025] Embodiment 1 Plane High Efficiency Vacuum Laminating Machine

[0026] Such as Figure 1-Figure 3 As shown, the planar high-efficiency vacuum laminating machine consists of a frame 1, a cylinder 2, a heating box 3, a workbench 4, a planar worktable 5 that can form a vacuum, a transmission device 6, a guide rail 9, a vacuum device, and a travel switch I14 , Travel switch II10, travel switch III15, manual ball valve 16, vacuum pressure gauge 17 and control system.

[0027] In this embodiment, four air cylinders 2 are provided, and the air cylinders 2 are installed on the frame 1, and the air cylinders 2 drive the heating box 3 to move.

[0028] In this embodiment, two sets of planar workbenches 5 capable of forming a vacuum are provided, and the two sets of planar workbenches 5 are symmetrically installed on both sides of the frame 1 to satisfy alternate lamination and heating, save time and improve work efficiency.

[0029] A heating box 3 is provided for constant tempe...

Embodiment 2

[0035] Embodiment 2 A kind of planar vacuum coating method

[0036] In this embodiment, the door panel is used as a workpiece, and a PVC film is pasted on it as an example to further illustrate the planar vacuum laminating method. Using the planar high-efficiency vacuum laminating machine of Embodiment 1, the method is as follows:

[0037] 1) Put the door panel 8 that has been polished and sprayed with plastic absorbing plastic on the flat workbench 5, cover it with a PVC film 7 that is 3 cm larger than the periphery of the door panel, and pave it flat.

[0038] 2) Turn on the manual ball valve 6 and the vacuum pump 13, and vacuumize the flat workbench through the negative pressure chamber 12, and the PVC film is completely absorbed and covered on the door panel due to the negative pressure.

[0039] 3) The control system controls the transmission device 6 to drive the plane workbench 5 to move toward the heating box 3. When the travel switch II on the plane workbench contacts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com