Material film circulating device for mobile phone glass film feeding machine

A recycling device and glass technology, applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve problems such as unsatisfactory bonding quality, affecting work efficiency, unfavorable processing and production, etc., to improve market competitiveness and simplify structure , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

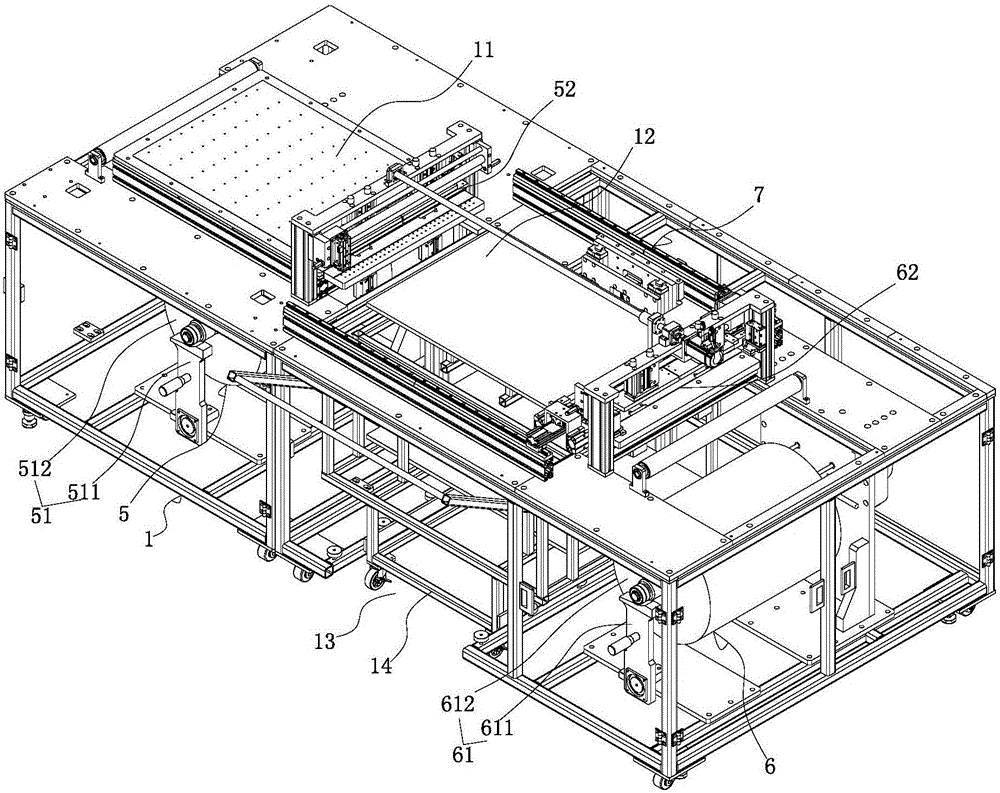

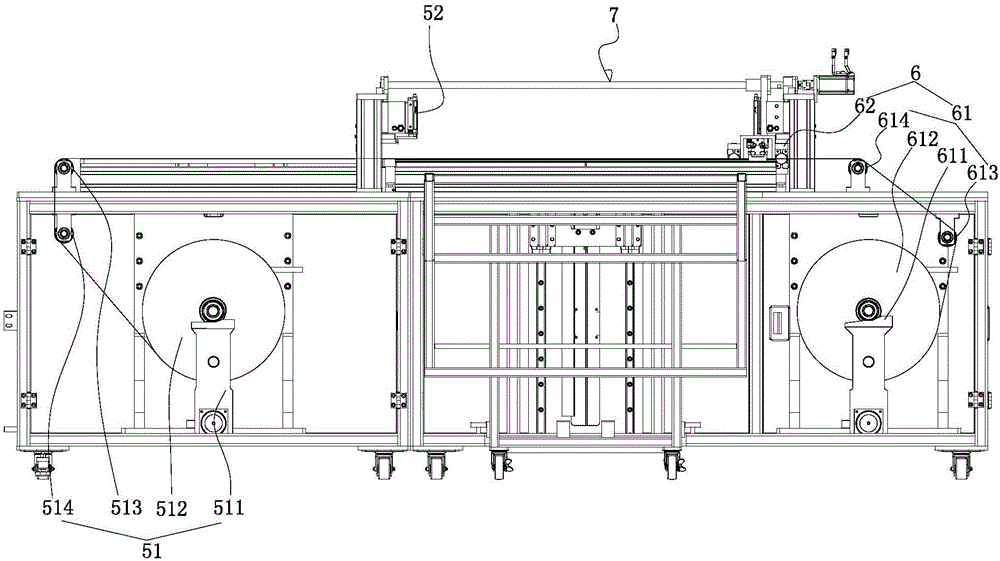

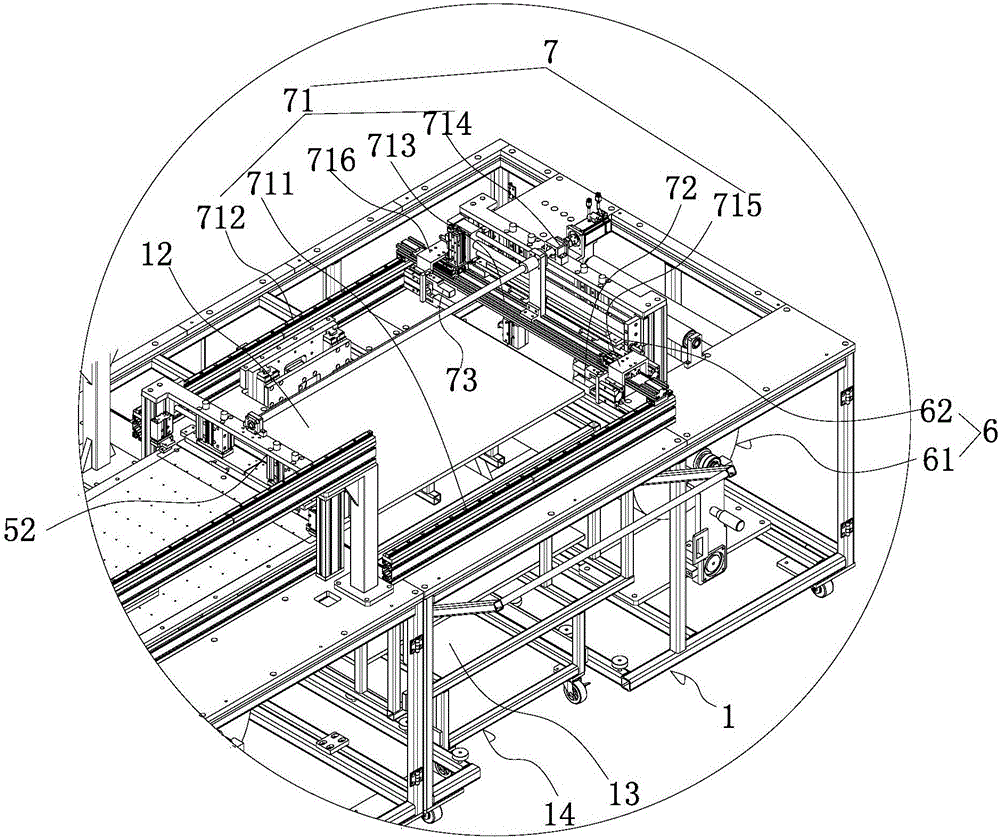

[0026] See Figure 1-4 As shown, it is a material film circulation device for a mobile phone glass seed film machine, which includes: a frame 1, a glass seed film vacuum platform 11 set on the frame 1, and a glass seed film receiving lifting platform 12, installed on the frame 1 on the glass carrier film feeding device 5, the glass attached film feeding device 6, and the glass double-mode pulling device 7.

[0027] The frame 1 is provided with a receiving space 13 below the glass seed film receiving lifting platform 12, and a seed film product receiving trolley 14 that can be pushed or pulled out is arranged in the receiving space 13, wherein the seed film The product receiving trolley 14 is provided with an inverted "convex"-shaped bearing space 141, and the outer side of the film product receiving trolley 14 is provided with an inclined push han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com