Device for automatically fitting liners and treads of tires of electric vehicles or motorcycles

A motorcycle tire and bonding device technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of tire product quality and stability, high manual labor intensity, and low degree of automation. The effect of increasing the labor intensity of workers, improving production quality, and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

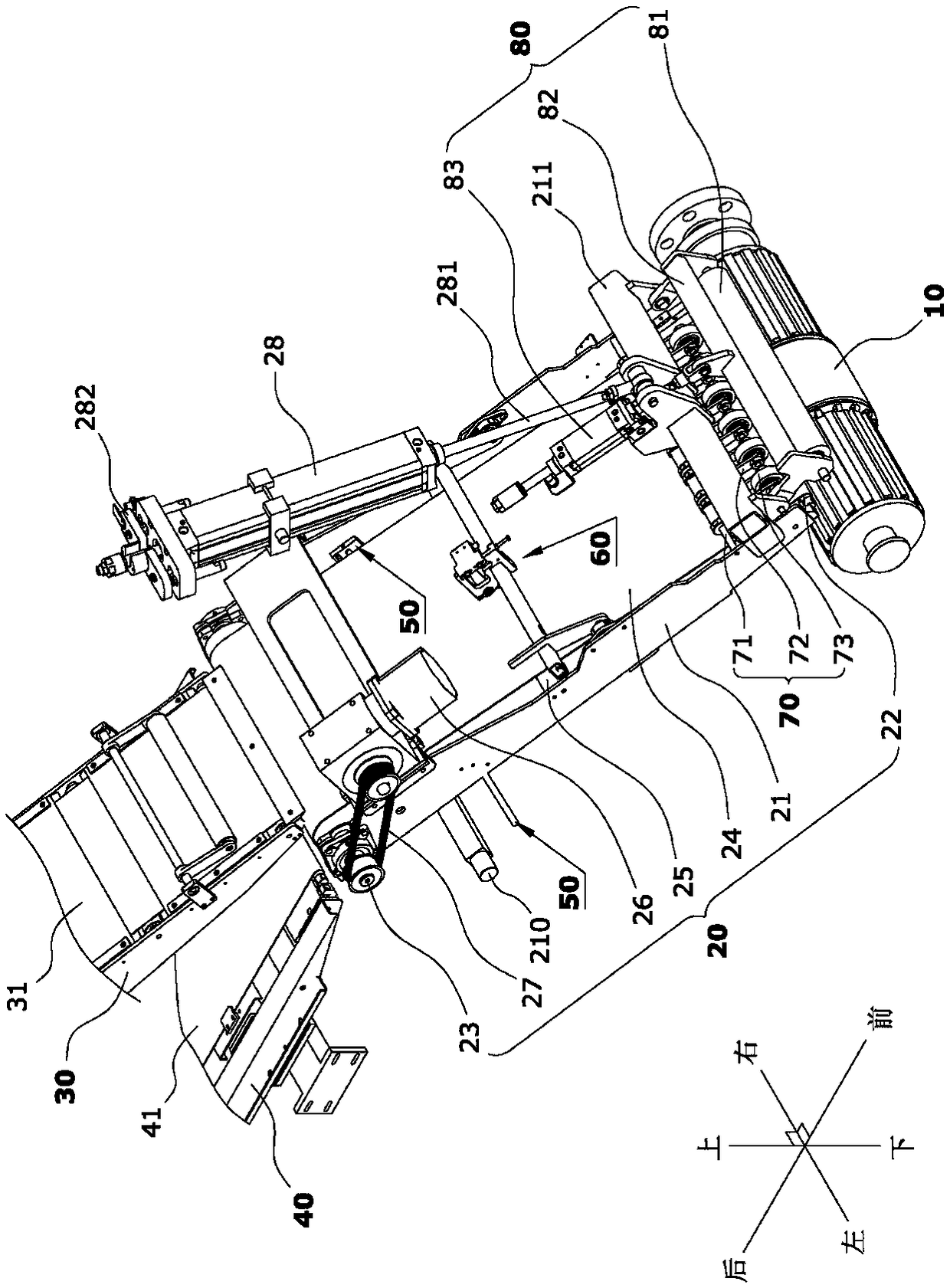

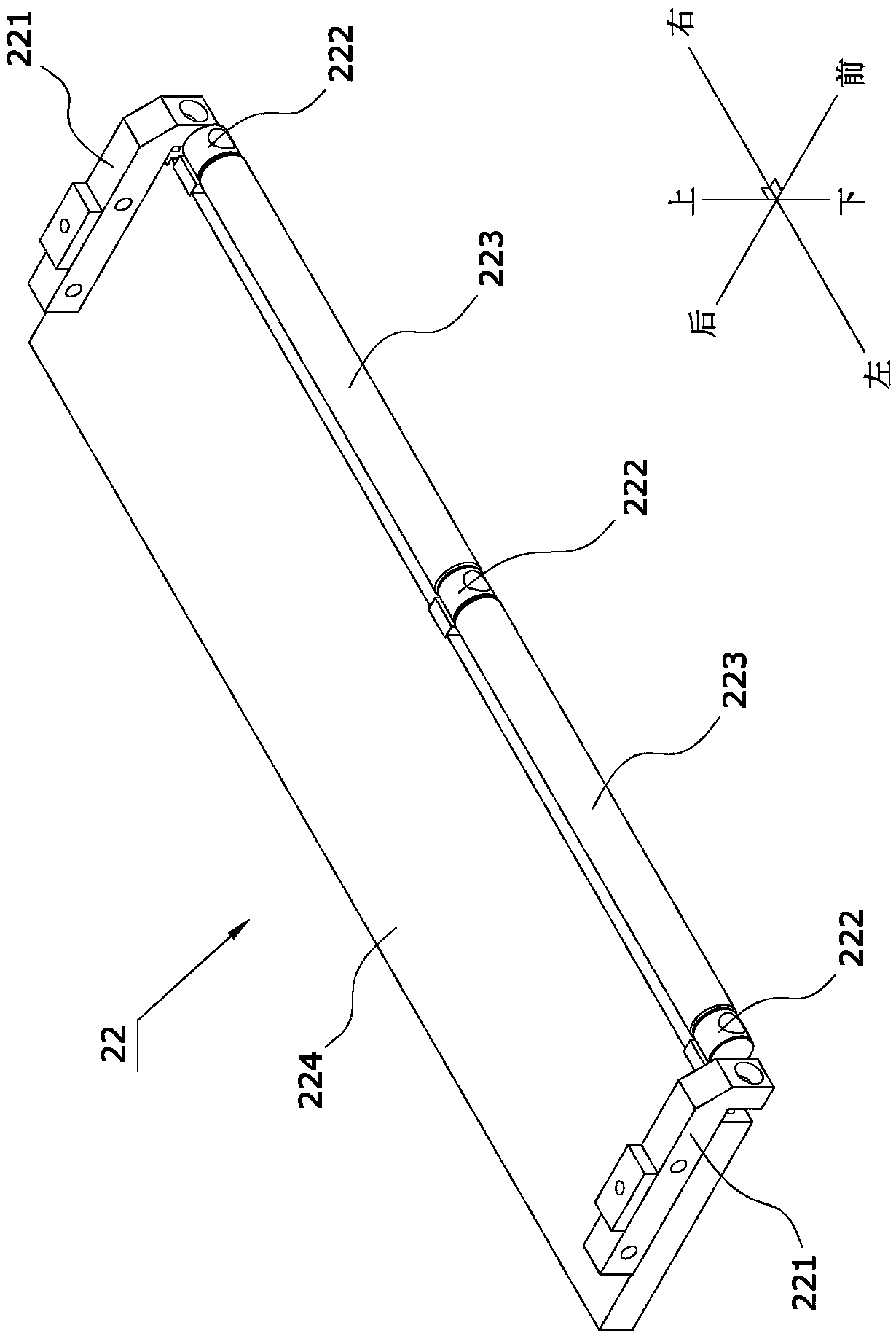

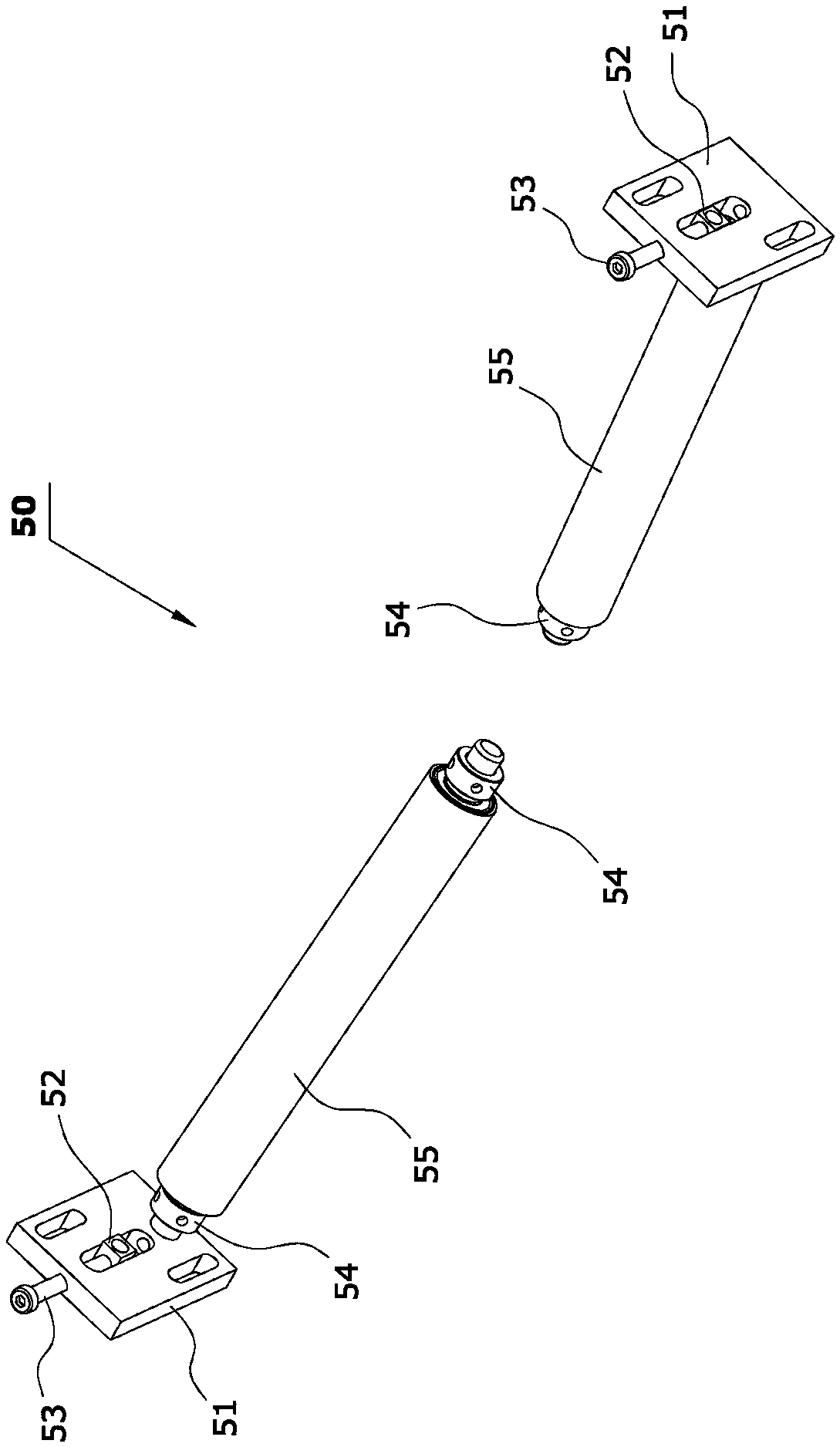

[0022] Such as figure 1 The shown automatic lamination device for inner liner and tread of a kind of electric vehicle or motorcycle tire includes a carcass drum 10, and a seesaw type material guide frame 20 is installed on the back and top of the carcass drum 10, and the material guide frame 20 rear side is fixed with a tread conveying frame 30 and a liner conveying frame 40 juxtaposed up and down, and the swinging material guide frame 20 can respectively guide the rubber material conveyed by the tread conveying frame 30 and the lining conveying frame 40 to the carcass Rolling and bonding on the drum 10; a deviation correction mechanism 50 that can guide the rubber material on it is installed under the rear part of the material guide frame 20, and a device that can detect the presence or absence of glue is installed in sequence from the middle of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com