Vision alignment platform

A visual alignment and platform technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of insufficient alignment accuracy, complex structure, and low film lamination efficiency, and achieve high alignment accuracy, improve lamination efficiency, The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

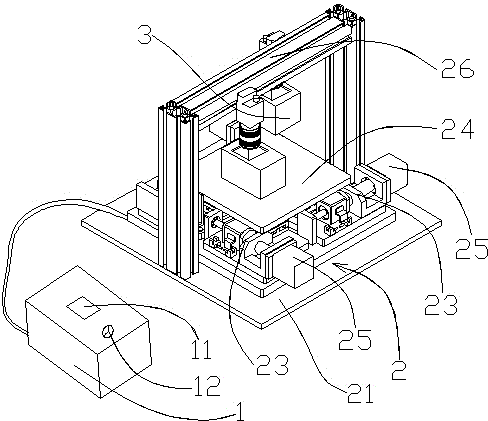

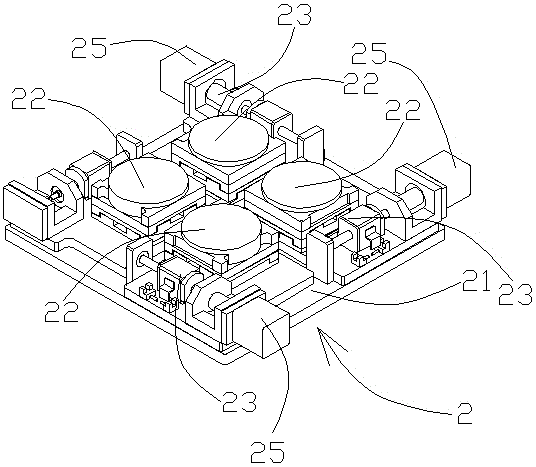

[0013] see figure 1 , a variety of visual alignment platforms, including a controller 1, an alignment mechanism 2 and a camera group 3, a display screen 11 is arranged on the controller 1, and analysis and calculation software is embedded in the controller 1, and the control The device 1 is in signal communication with the alignment mechanism 2 through a signal line, and the alignment mechanism 2 includes a base 21, four XYθ sliding tables 22, three adjusting screw rods 23 and a working platform 24, and the four XYθ sliding tables 22 are evenly distributed in the center of the base 21, and the three adjusting screw rods 23 are arranged on the outside of the XYθ slide table 22, and the three adjusting screw rods 23 are respectively driven by three external motors 25, so that The adjustment screw 23 drives the XYθ slide table 22 to move, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com