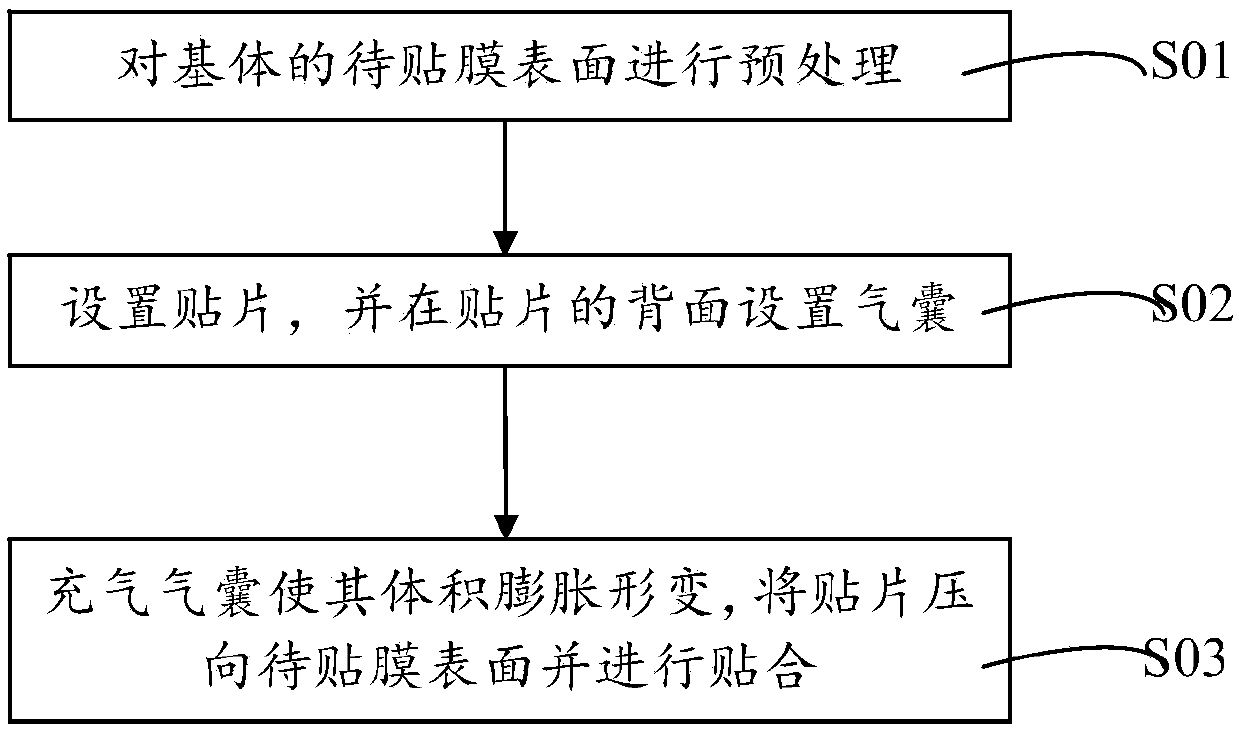

Film sticking method and equipment

A film sticking equipment and film sticking technology, applied in packaging and other directions, can solve problems such as poor bonding effect of curved surfaces, bubbles in bonding, and unsatisfactory quality, so as to avoid residual air bubbles, uniform force, and avoid uneven bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

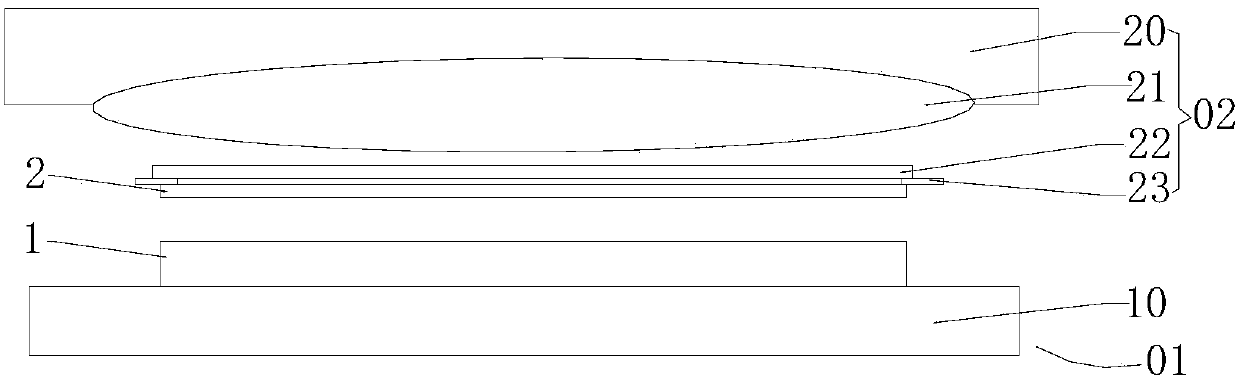

[0063] This embodiment provides a film sticking device and a film sticking method for a film sticking method. Wherein, the structure of the film sticking equipment is as follows: figure 2 As shown, it includes a base carrier module 01 and a film sticking module 02 . The base carrier module 01 includes a base carrier 10 for supporting a curved screen 1 provided with a surface to be pasted. The film sticking module 02 includes an airbag 21 and an airbag carrier 20 for loading the airbag 21. The volume of the airbag 21 expands and deforms as it is inflated, and the wall of the expanded and deformed airbag 21 is in contact with the airbag 21. The substrate 1 loaded by the substrate carrier 10 is in contact with the surface of the substrate 1 to be laminated.

[0064] In this embodiment, the method of attaching the film to the curved screen 1 is as follows:

[0065] (1) After cleaning the surface of the curved screen 1 to be pasted, place it on the carrier module 01, and make t...

Embodiment 2

[0068] This embodiment provides a film sticking device and a film sticking method for a film sticking method. Wherein, the structure of the film sticking equipment is as follows: figure 2 As shown, it includes a base carrier module 01 and a film sticking module 02 . The base carrier module 01 includes a base carrier 10 for supporting a curved screen 1 provided with a surface to be pasted. The film sticking module 02 includes an airbag 21 and an airbag carrier 20 for loading the airbag 21. The volume of the airbag 21 expands and deforms as it is inflated, and the wall of the expanded and deformed airbag 21 is in contact with the airbag 21. The substrate 1 loaded by the substrate carrier 10 is in contact with the surface of the substrate 1 to be laminated. The film sticking module 02 also includes a movable baffle 22 and a fixing frame 23 for fixing the curved screen protective film, the fixing frame 23 is arranged between the airbag 21 and the base carrier 10, and the movabl...

Embodiment 3

[0073] This embodiment provides a film sticking device and a film sticking method for a film sticking method. Wherein, the structure of the film sticking equipment and the sticking method are the same as those in Example 2, except that the curved screen 1 is a flat screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com