Patents

Literature

246results about How to "Satisfy processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

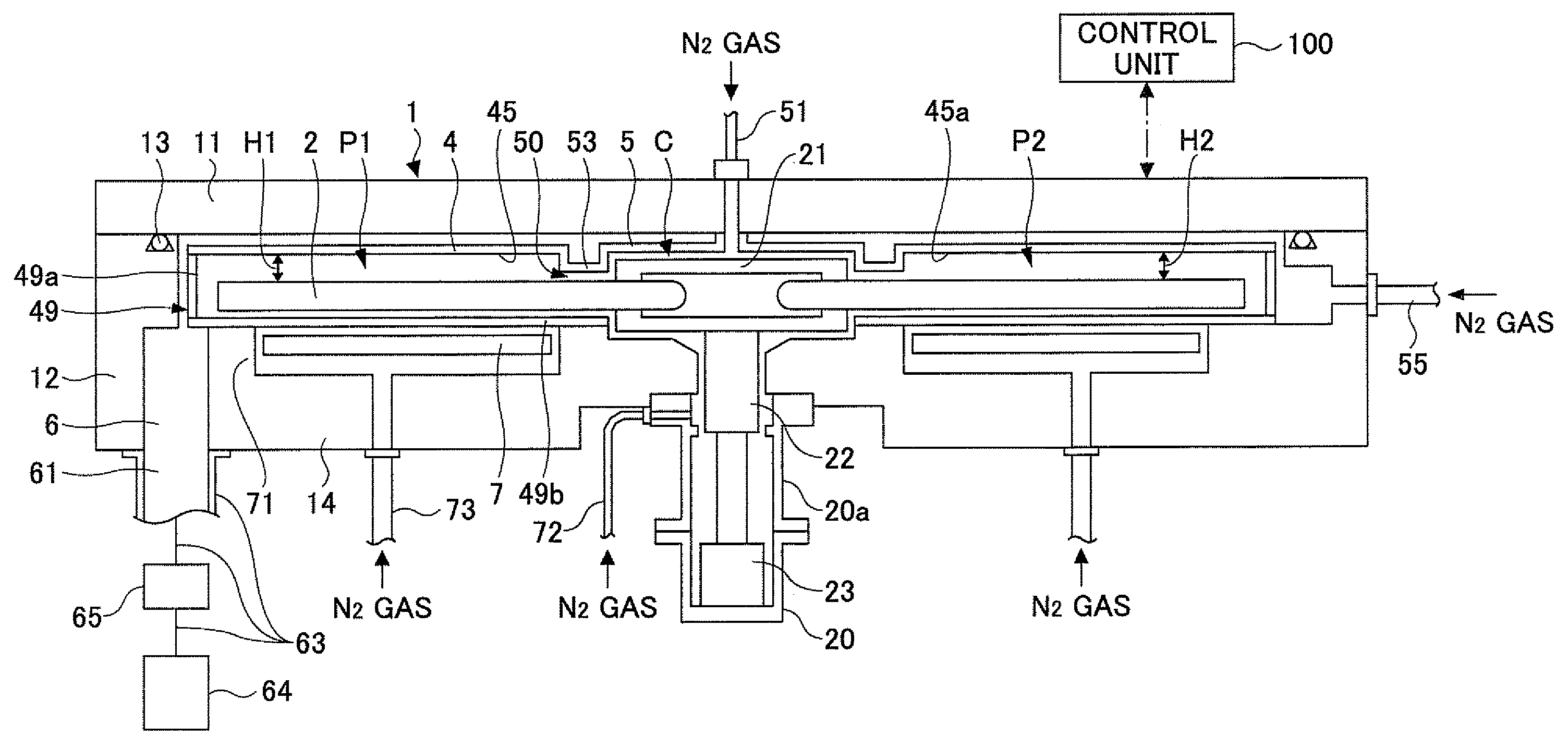

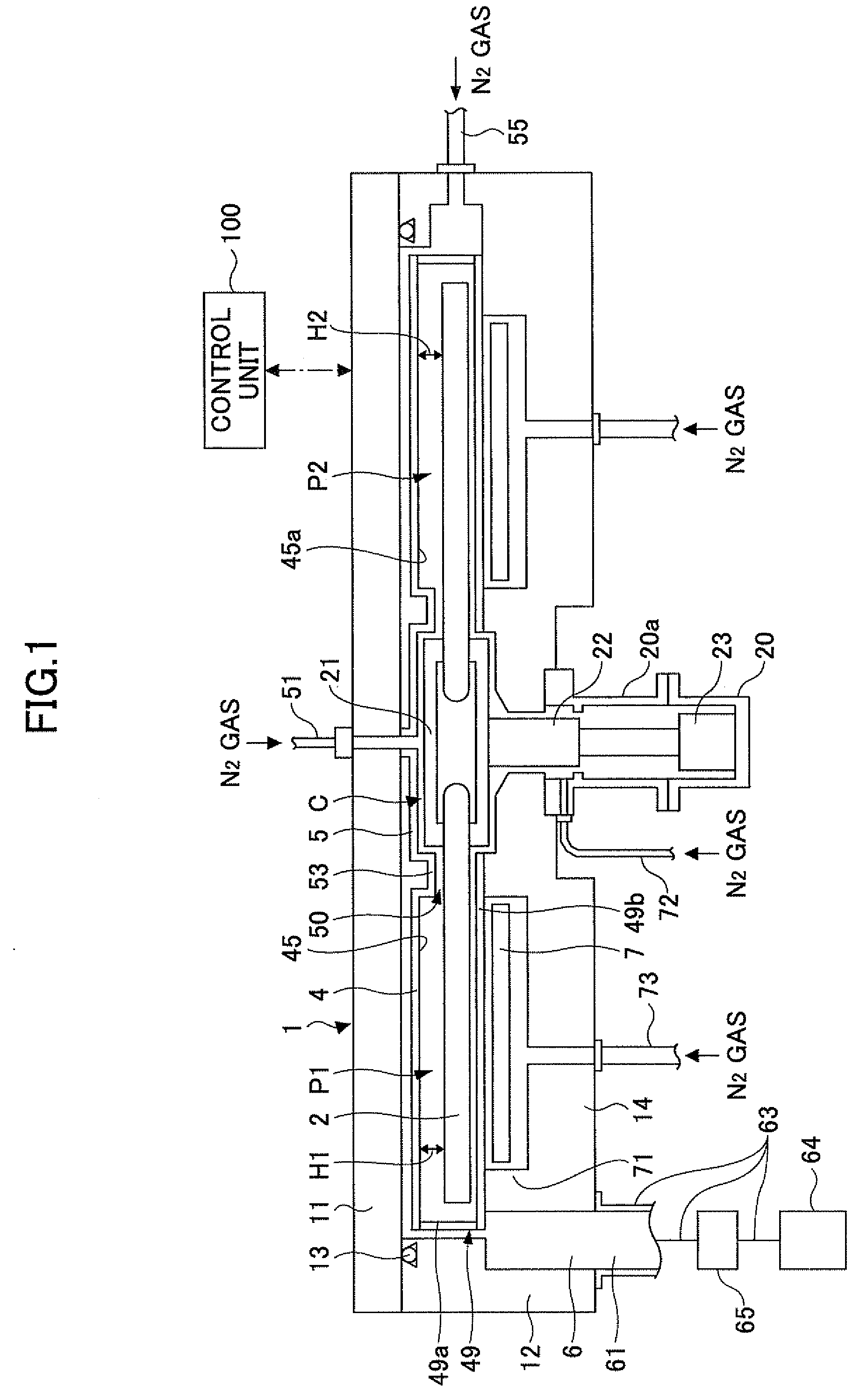

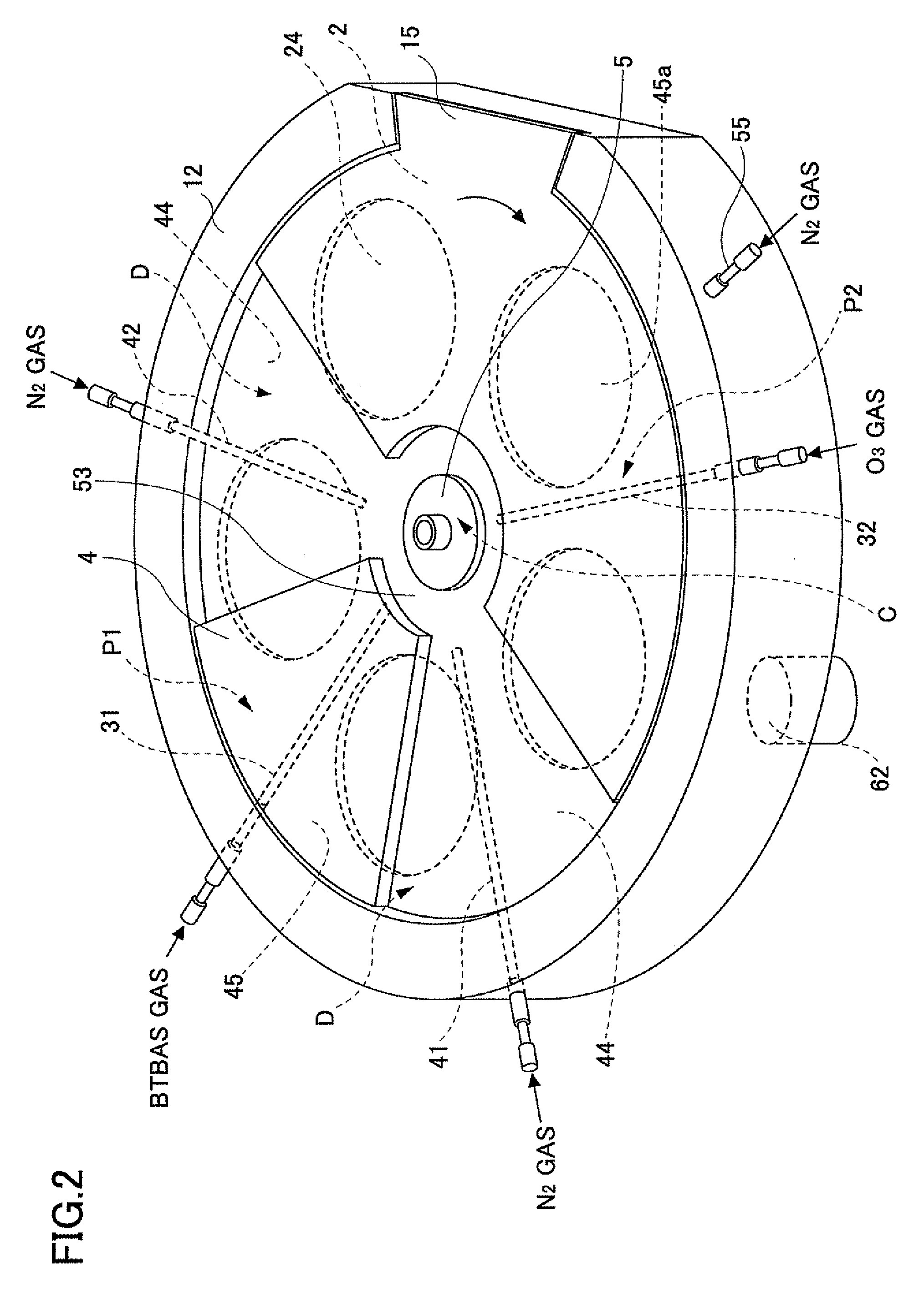

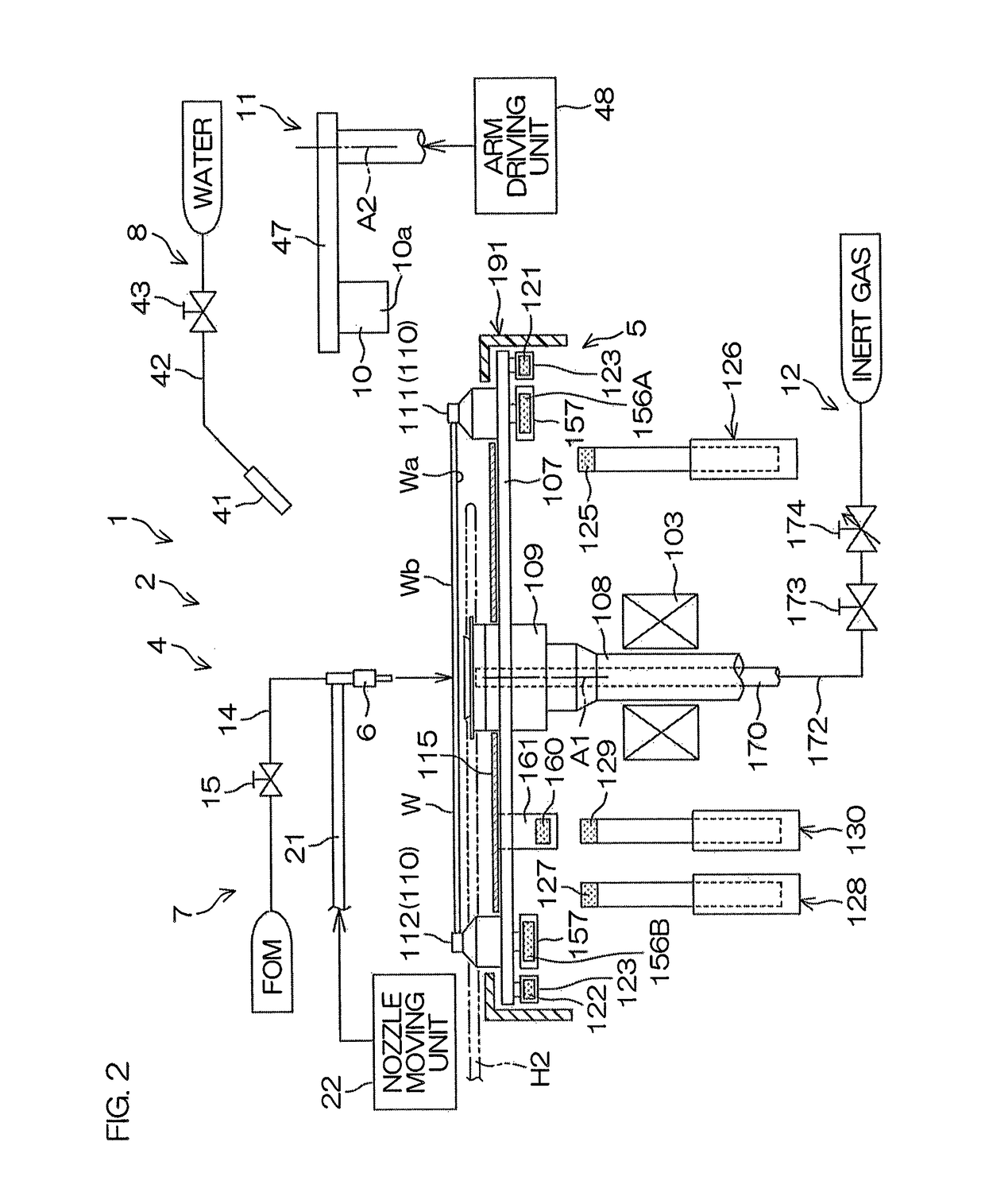

Film deposition apparatus, substrate processing apparatus, film deposition method, and storage medium

ActiveUS20100055316A1Improve throughputSatisfy processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas supplyVacuum chamber

A film deposition apparatus to form a thin film by supplying first and second reaction gases within a vacuum chamber includes a turntable, a protection top plate, first and second reaction gas supply parts extending from a circumferential edge towards a rotation center of the turntable, and a separation gas supply part provided therebetween. First and second spaces respectively include the first and second reaction gas supply parts and have heights H1 and H2. A third space includes the separation gas supply part and has a height H3 lower than H1 and H2. The film deposition apparatus further includes a vacuum chamber protection part which surrounds the turntable and the first, second and third spaces together with the protection top plate to protect the vacuum chamber from corrosion.

Owner:TOKYO ELECTRON LTD

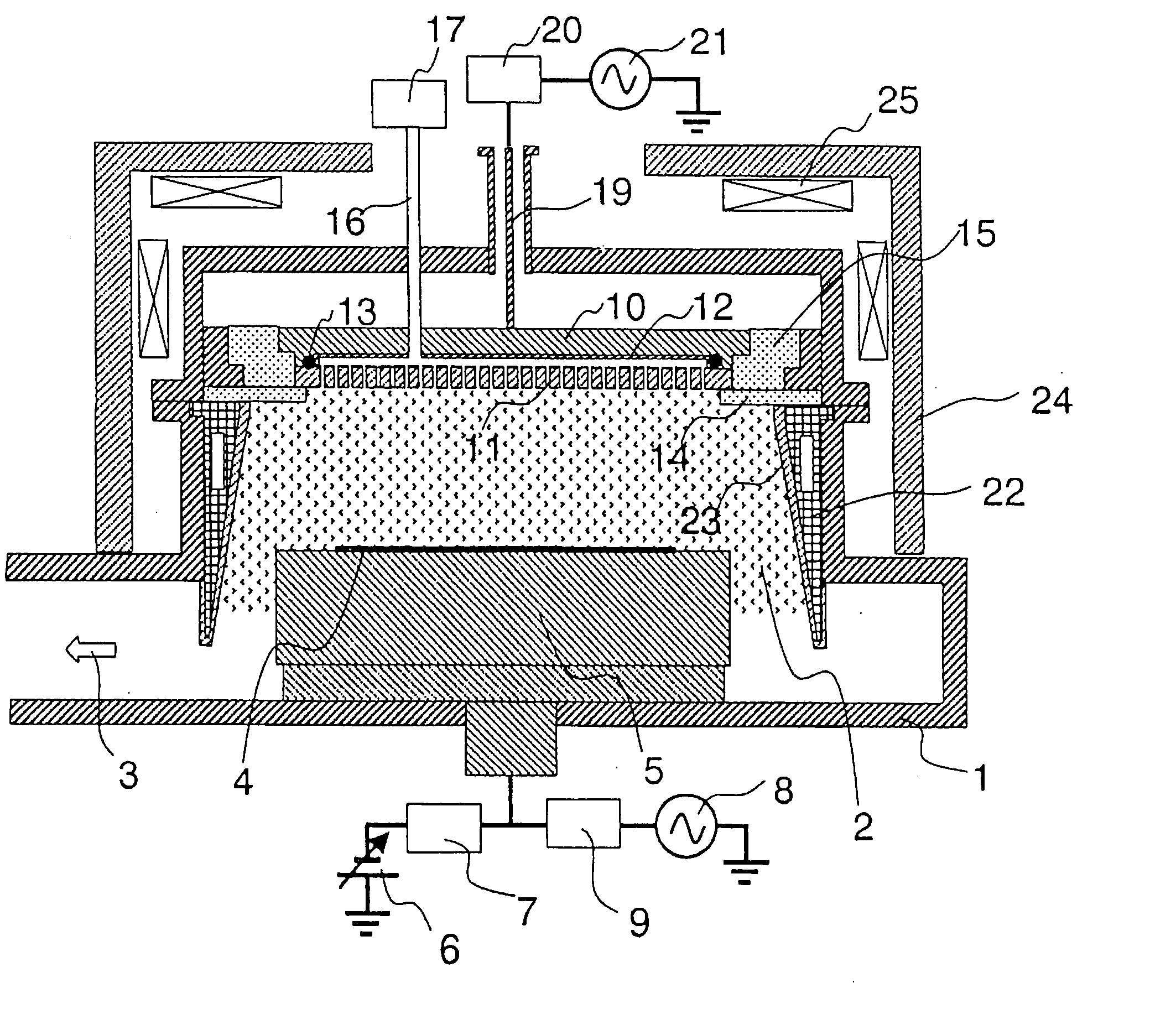

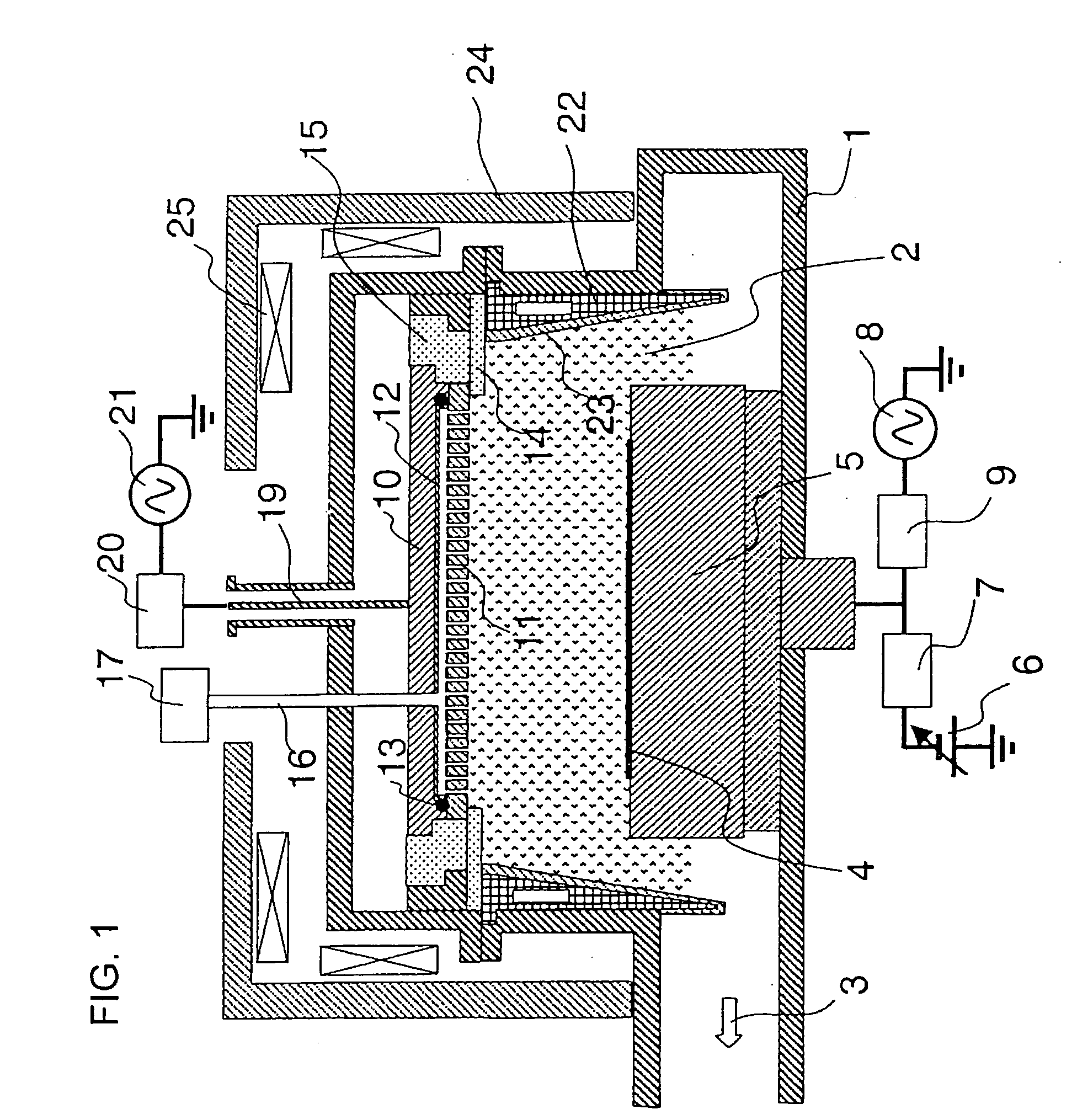

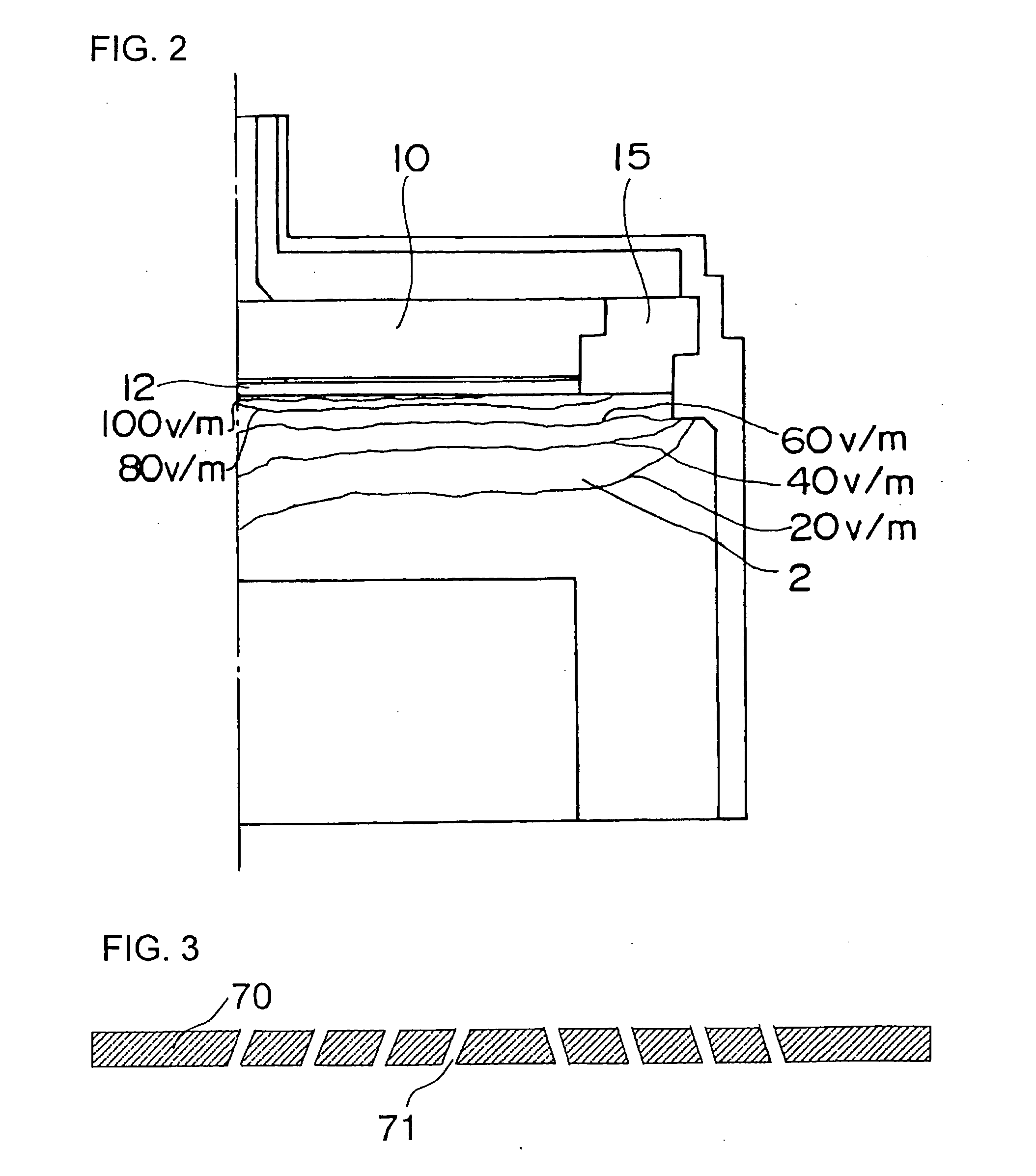

Plasma processing apparatus

ActiveUS20070044716A1Free from pollutionAvoid damageElectric discharge tubesChemical vapor deposition coatingTectorial membraneElectrical conductor

The invention provides a plasma processing apparatus aimed at suppressing the corrosion caused by reactive gas and heavy-metal contamination caused by plasma damage of components constituting the high-frequency electrode and gas supply unit. The plasma processing apparatus comprises a processing chamber 1 for subjecting a processing substrate 4 to plasma processing, gas supply means 17, 16 and 11 for feeding gas to the processing chamber 1, and an antenna electrode 10 for supplying high-frequency radiation for discharging the gas to generate plasma, wherein the gas supply means includes a gas shower plate 11 having gas discharge holes on the surface exposed to plasma, and a portion of or a whole surface of the conductor 10 exposed to gas constituting the antenna-electrode side of the gas supply means is subjected to ceramic spraying containing no heavy metal to form a protecting film 12.

Owner:HITACHI HIGH-TECH CORP

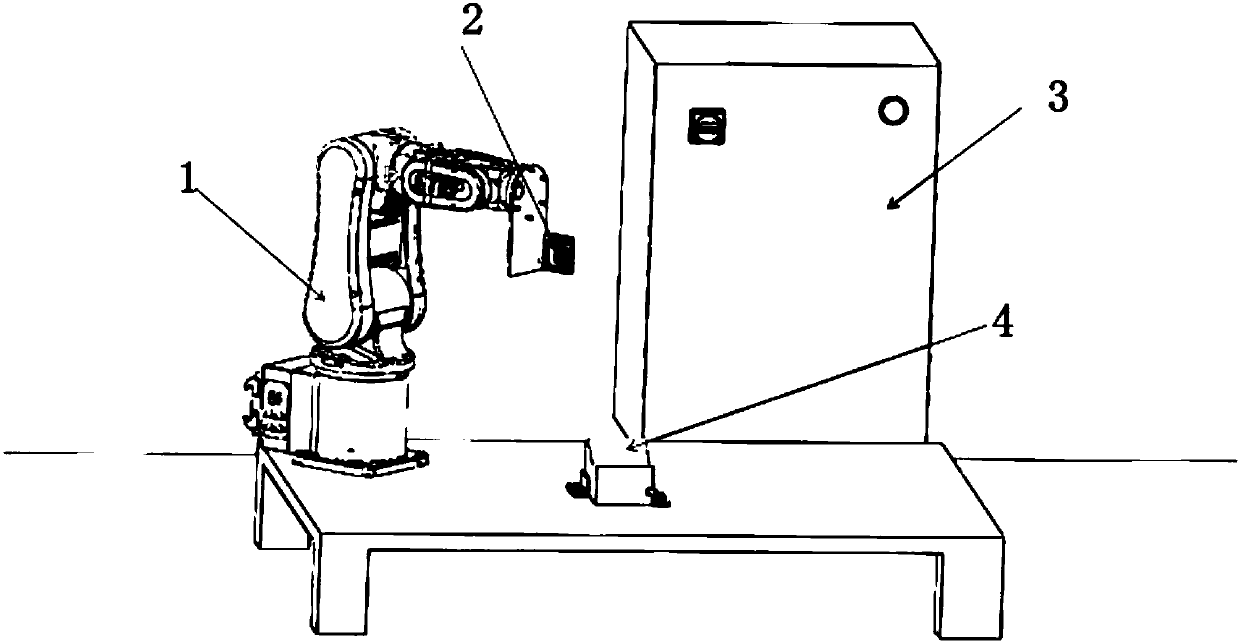

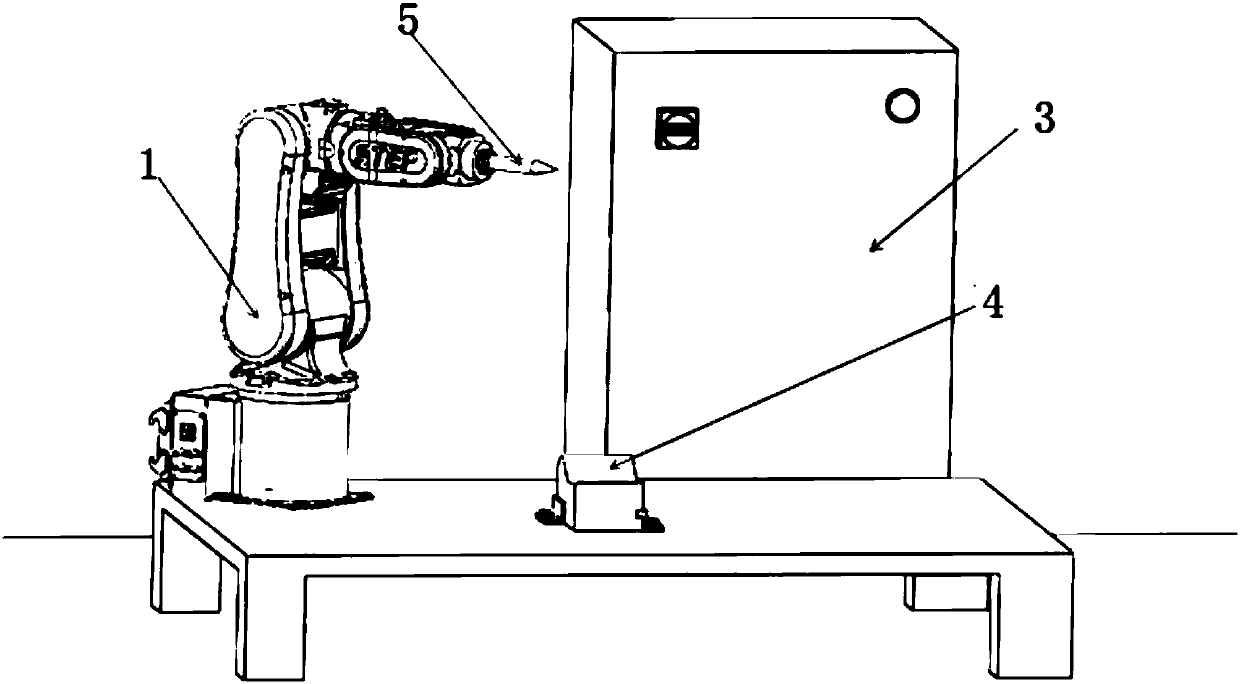

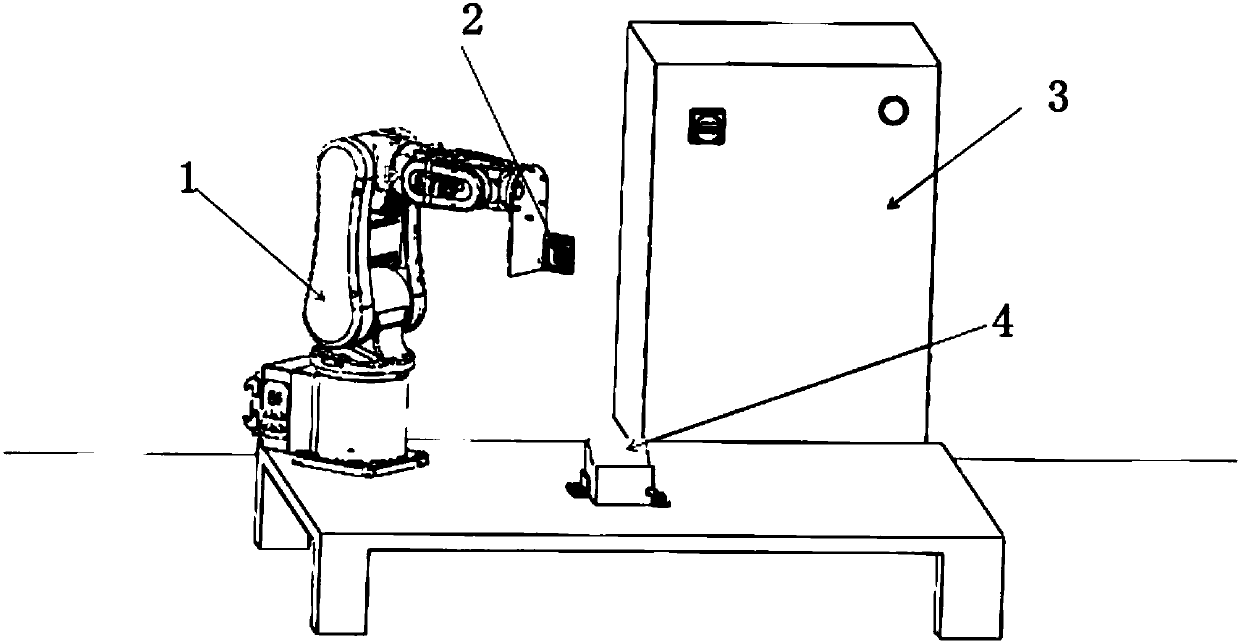

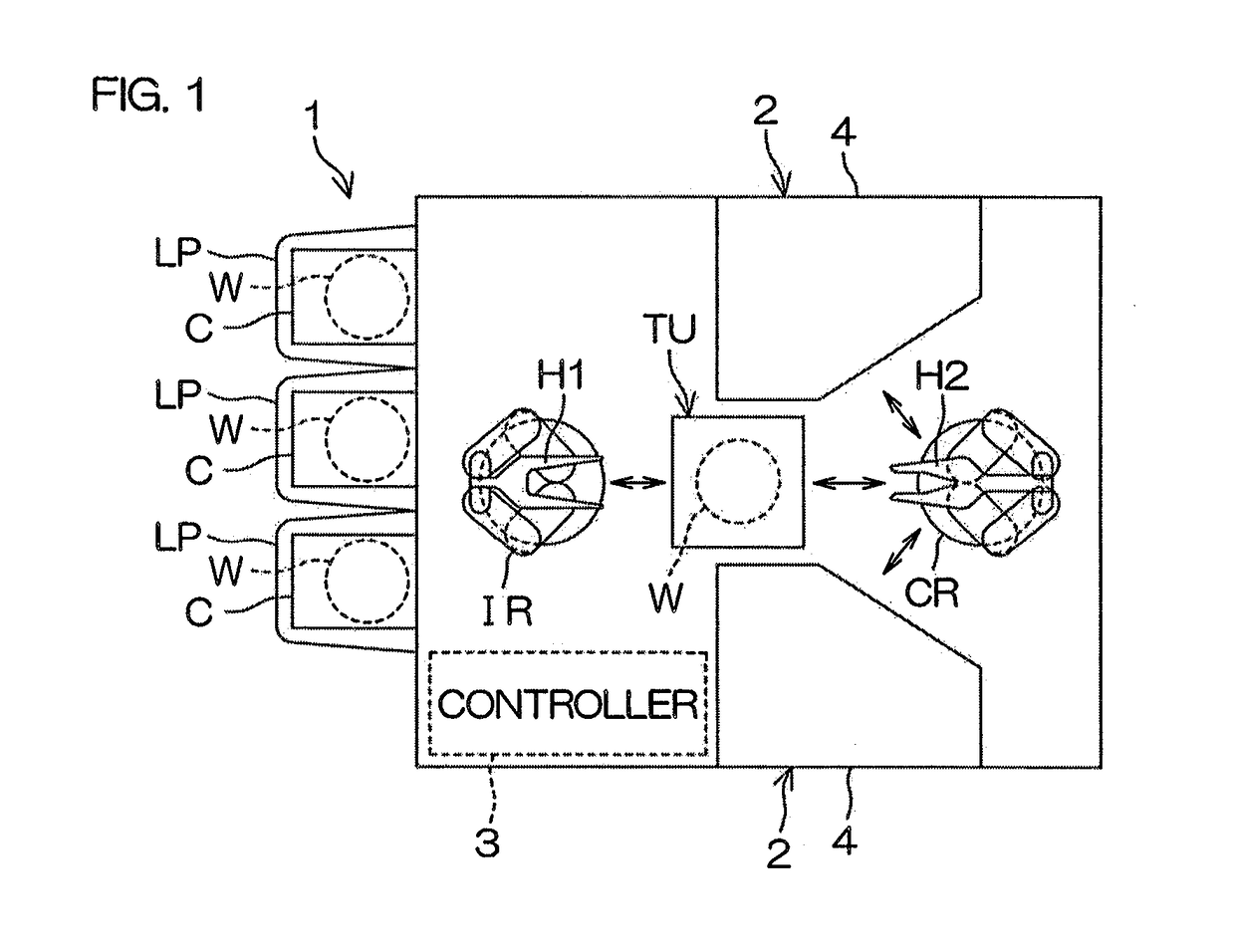

Three-dimensional point cloud real-time collecting device and robot polishing path planning method

PendingCN107127755ASatisfy processingHigh precisionProgramme-controlled manipulatorReal time acquisitionRobot control system

The invention discloses a three-dimensional point cloud real-time collecting device comprising a robot, a laser displacement sensor and a real-time robot control system. The laser displacement sensor is arranged at the tail end of the robot through the clamp. The real-time robot control system is connected with the robot and the laser displacement sensor through real-time industrial Ethernet bus and used for enabling reading of the laser displacement sensor to be synchronous with the pose of the robot, one-dimensional measurement is extended to three-dimensional measurement, and then the three-dimension point cloud of a workpiece is obtained through scanning. The invention further discloses a robot polishing path planning method based on the three-dimensional point cloud real-time collecting device. The pose of the robot during planning is planned based on the position information and normal information of the three-dimensional point cloud of the workpiece, the pose of the robot is corrected with a scanning path, and then the polishing path of the robot is formed. The three-dimensional point cloud real-time collecting device and the robot polishing path planning method based on the three-dimensional point cloud real-time collecting device are high in precision and have the advantages of having real-time performance and flexibility, the cost is low, and the requirement for machining of different workpieces can be met.

Owner:SOUTH CHINA UNIV OF TECH

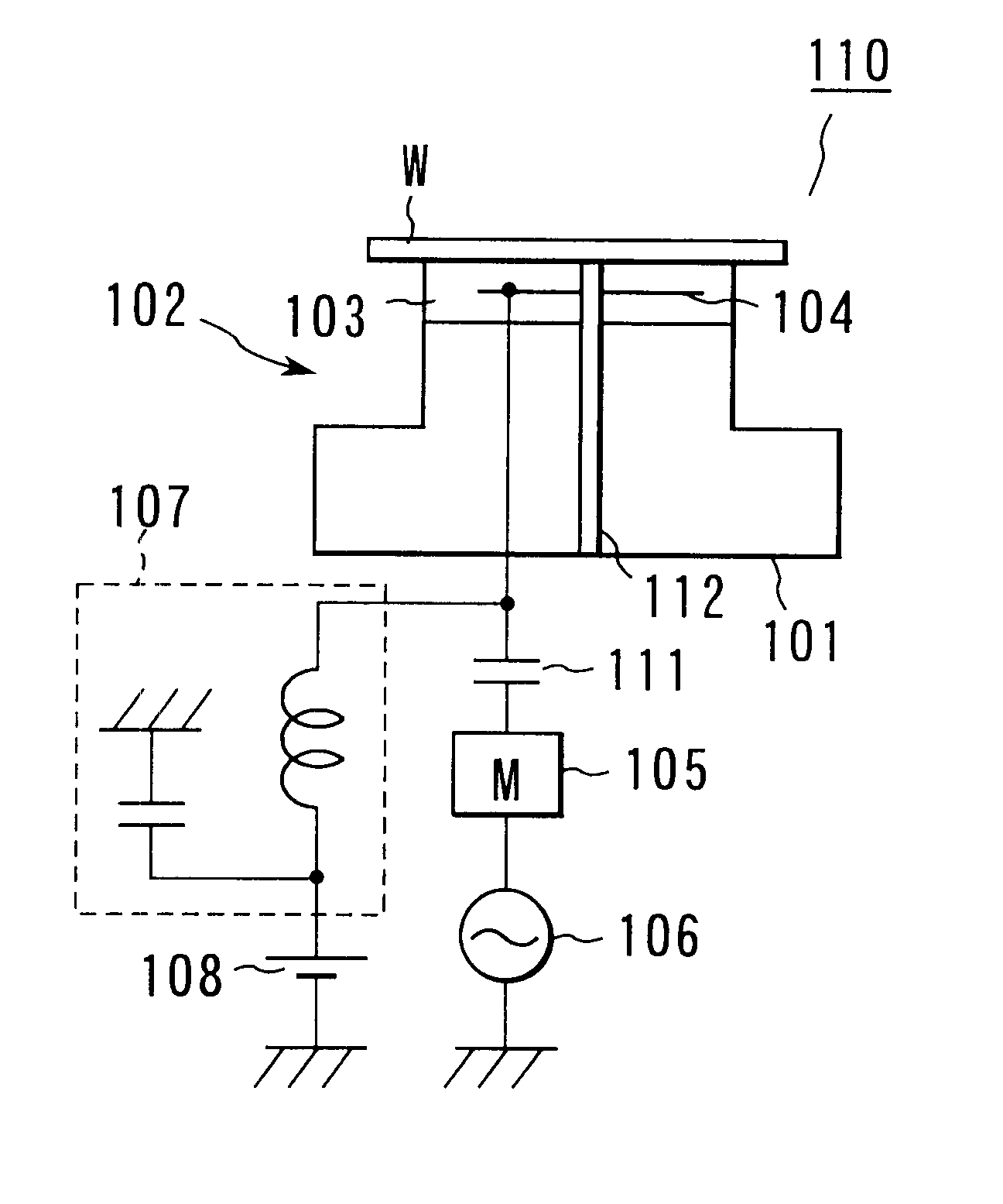

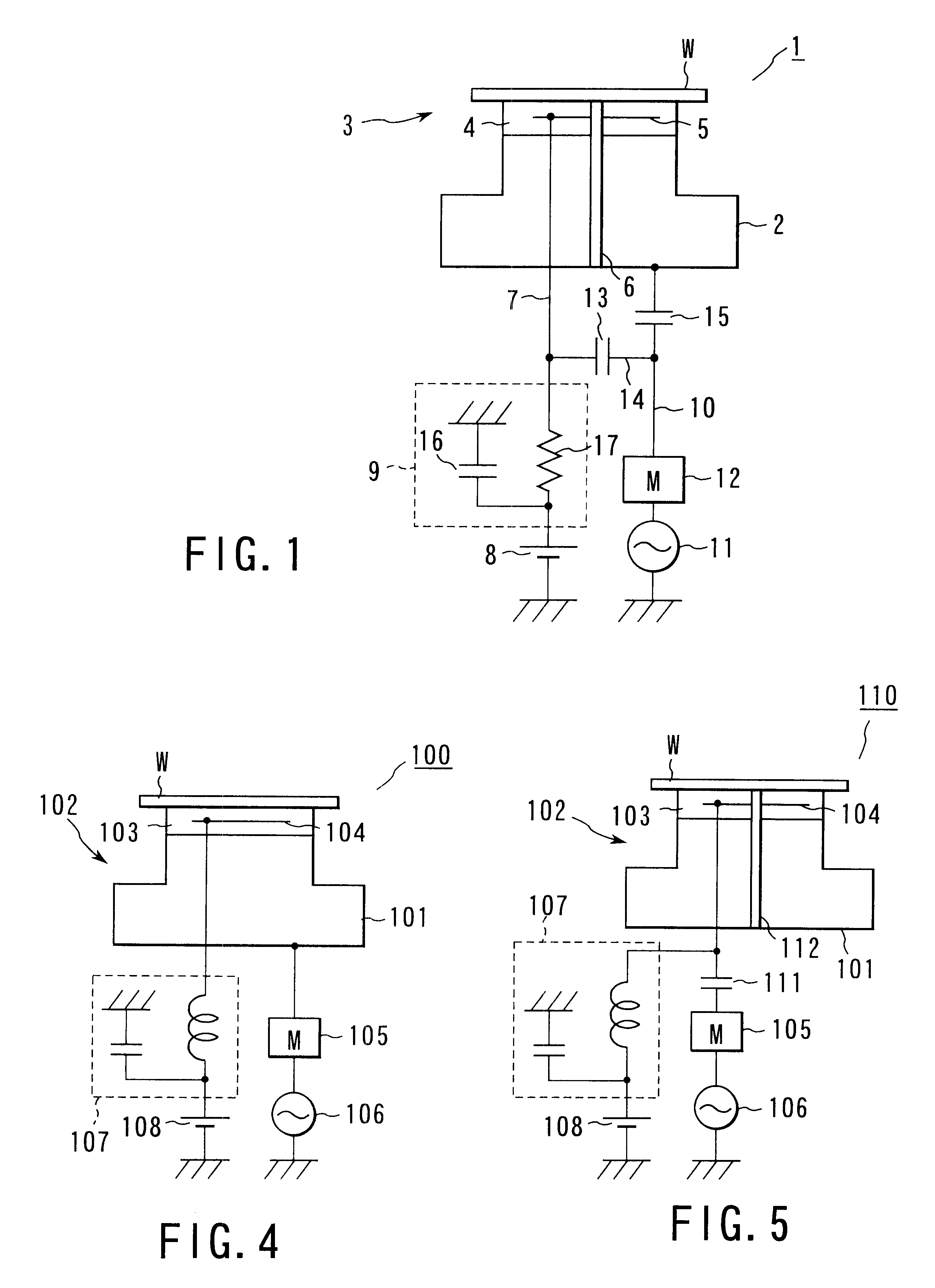

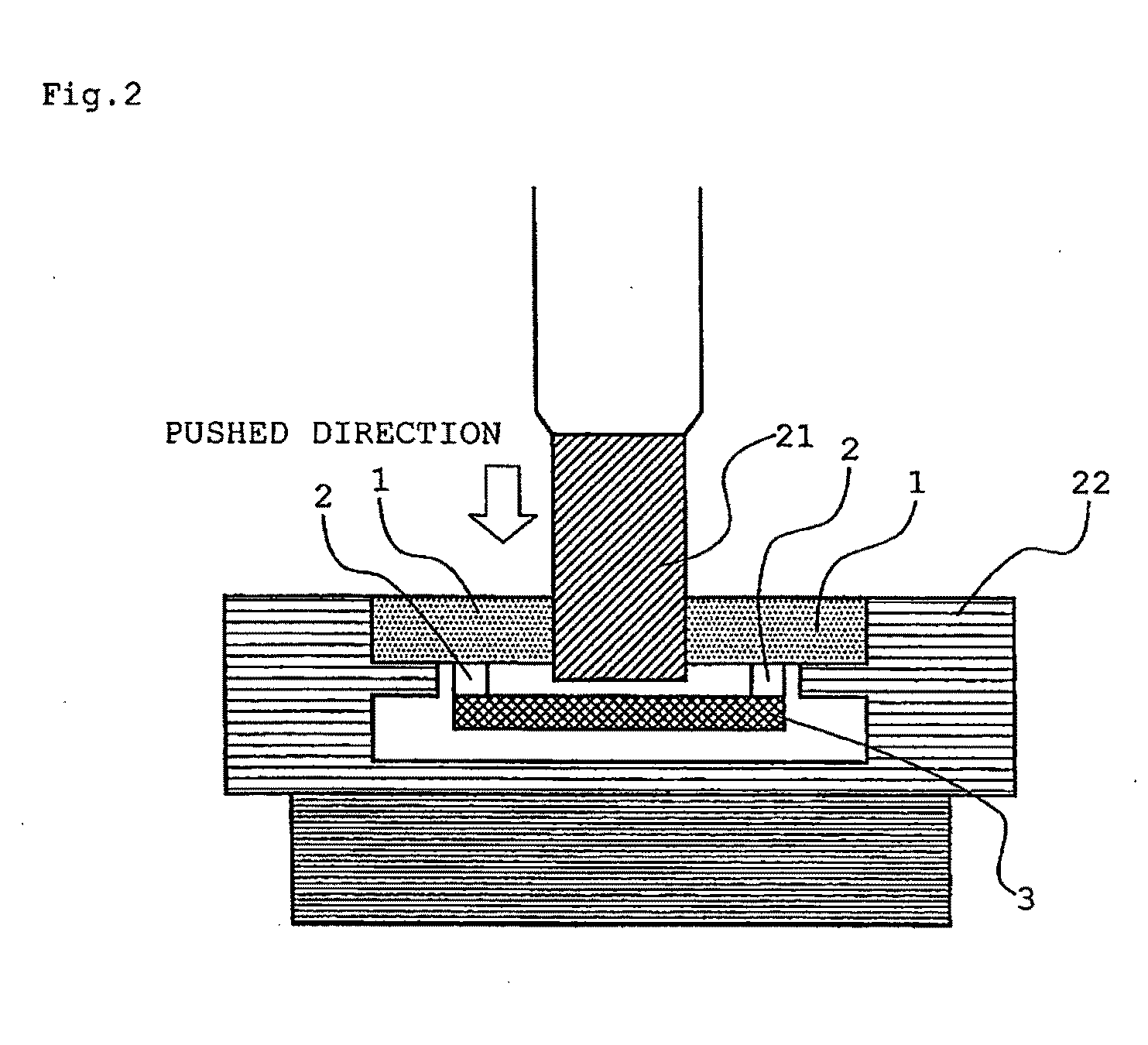

Plasma apparatus and lower electrode thereof

InactiveUS6492612B1Prevent abnormal dischargeSatisfy processingSemiconductor/solid-state device manufacturingArc welding apparatusConductive materialsDielectric layer

The present invention is constituted of a lower electrode structure (1) comprising a base table (2) formed of a conductive material, an electrostatic adsorption member (3) formed on the base table (2) and having a dielectric layer (4) on which the substrate to be mounted and within which an electrode (5) electrically isolated from the base table (2) is housed, first wiring (7) having an end connected to the electrode (3) of the electrostatic adsorption member, a direct-current source (8) connected to the other end of the first wiring (7), second wiring (10) having an end connected to the base table (2), a high frequency source (11) connected to the other end of the second wiring (10), a third wiring (14) for connecting the first wiring (7) and the second wiring (10), and a capacitor (13) formed on the third wiring (14). Plasma processing is performed by disposing the lower electrode structure (1) in the chamber (21).

Owner:TOKYO ELECTRON LTD

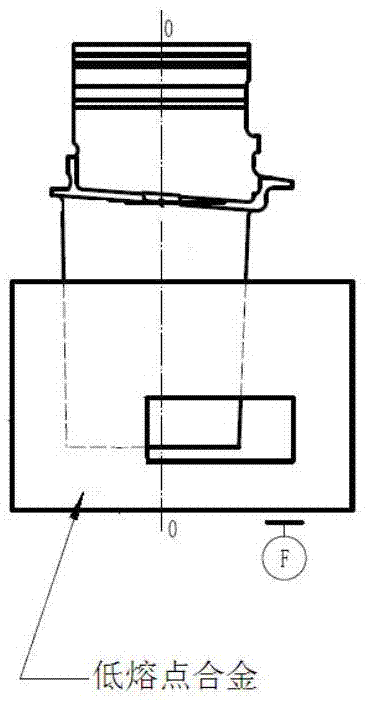

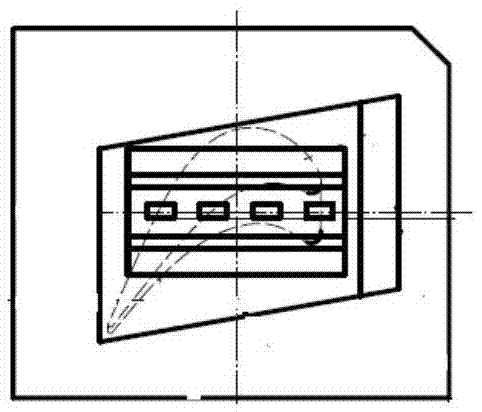

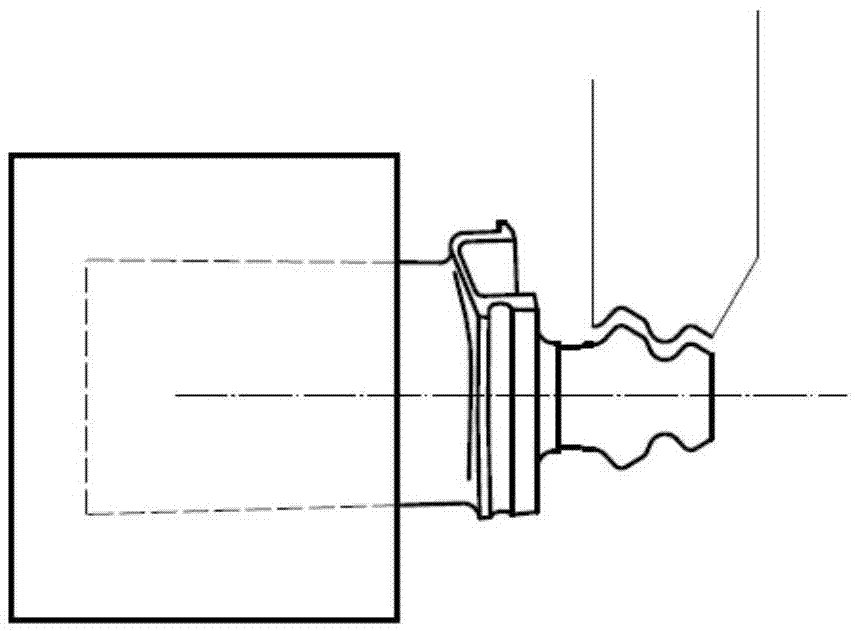

Machining method for turbine work blade

The invention discloses a machining method for a turbine work blade. The machining method for the turbine work blade aims to improve the production quality and production efficiency of the turbine blade and meet the machining and use requirements for the turbine work blade of an aero-engine. According to the technical scheme, the machining process comprises the steps of oil removing, precision positioning of the blade, wax filling, grinding of tenon teeth and the tooth exhaust side, wax removing, melting of low-melting-point alloy, pollutant removing, grinding of the bottoms of the tenon teeth, grinding of a marginal plate and the tooth air inlet lateral face, fluorescent inspection, comprehensive detection, machining of film holes, cleaning and storage. A five-axis numerical control creep feed grinder is adopted, the turbine work blade machining process with the advanced manufacturing technology is achieved, novelty, creativity and practicability are high, the process route is arranged reasonably, the production efficiency is high, the blade machining quality is high, the requirement for production of a large batch of turbine blades can be met, and the machining method can be widely used for machining turbine work blades of aero-engines.

Owner:AECC AVIATION POWER CO LTD

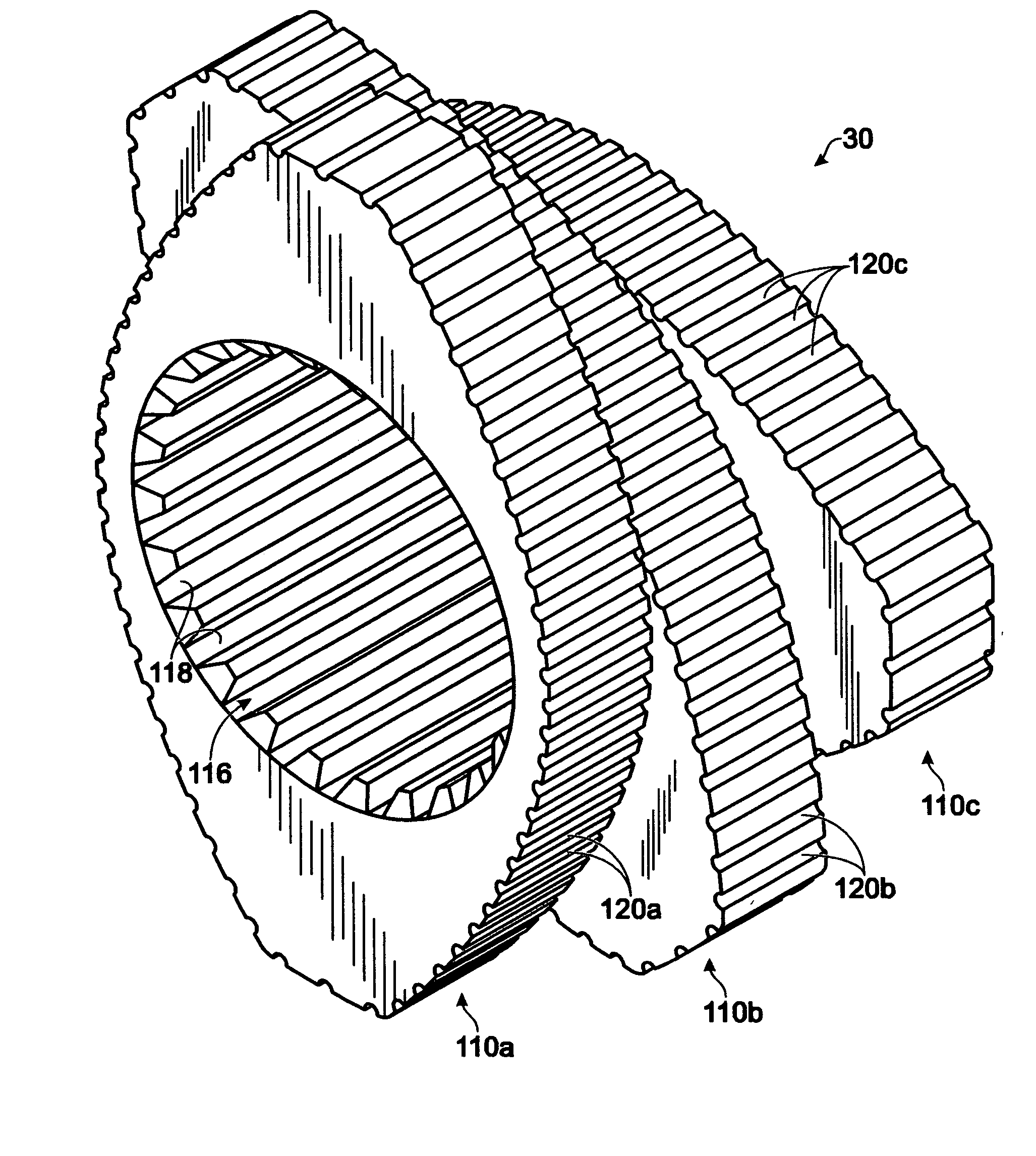

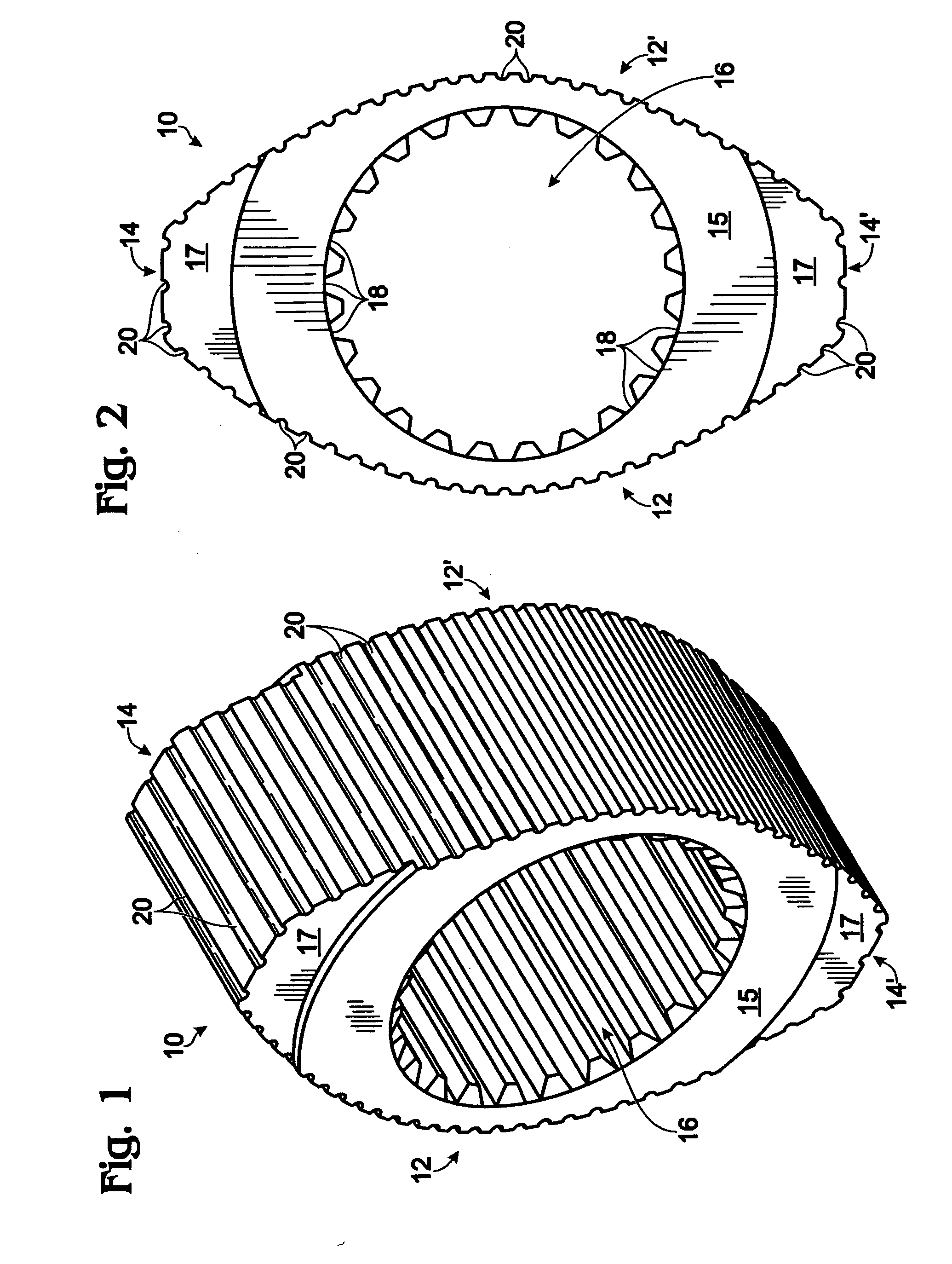

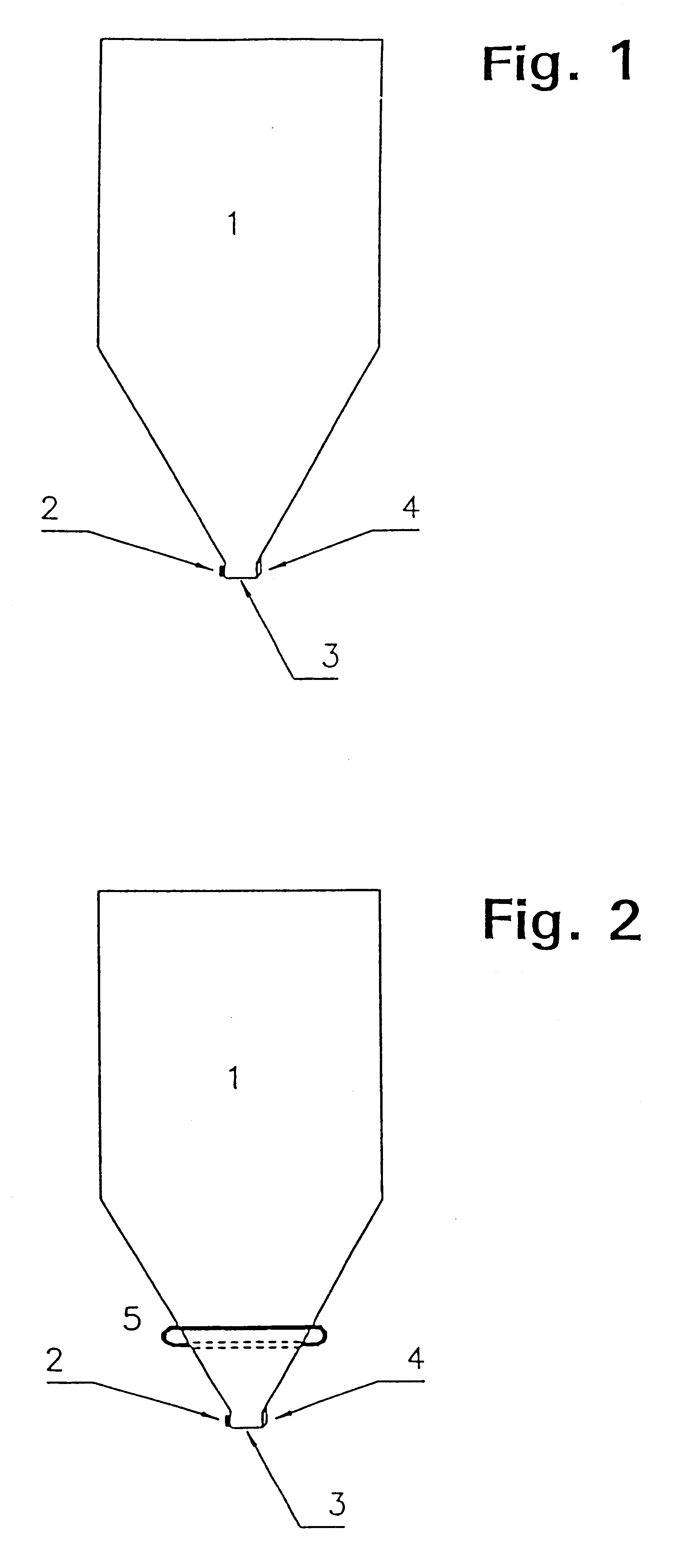

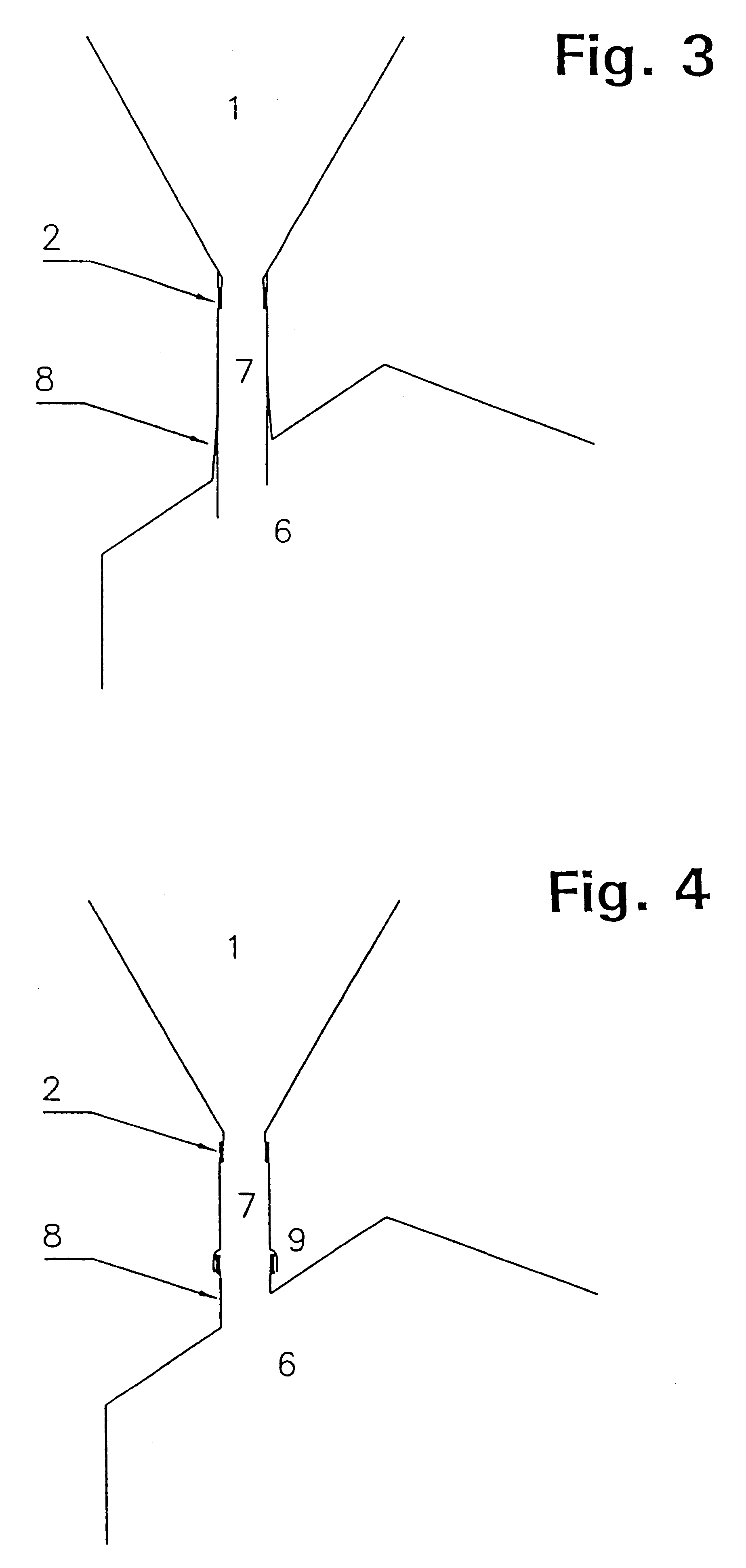

Serrated kneading disk and kneading block

InactiveUS20070177451A1None of process be satisfactorySatisfy processingRotary stirring mixersTransportation and packagingEllipseEngineering

A serrated kneading disk including a body having a perimeter that is an ellipse having truncated ends, the curved elliptical portions forming flanks and the truncated ends forming crests. The crests are curved to form the arc of a circle having a radius substantially the same as the radius of the bore of the extruder barrel with which the disk is to be used. The disk body has a cylindrical passageway extending through the middle thereof, the passageway having a configuration adapted to allow the kneading disks to be lockingly engaged on the shaft of an extruder screw. A plurality of grooves are formed in the flanks and crests. A serrated kneading block can be formed from a plurality of the serrated kneading disks, or formed as a single body having a plurality of lobes, each lobe being substantially identical to the serrated kneading disk.

Owner:BENJAMIN CRAIG A +1

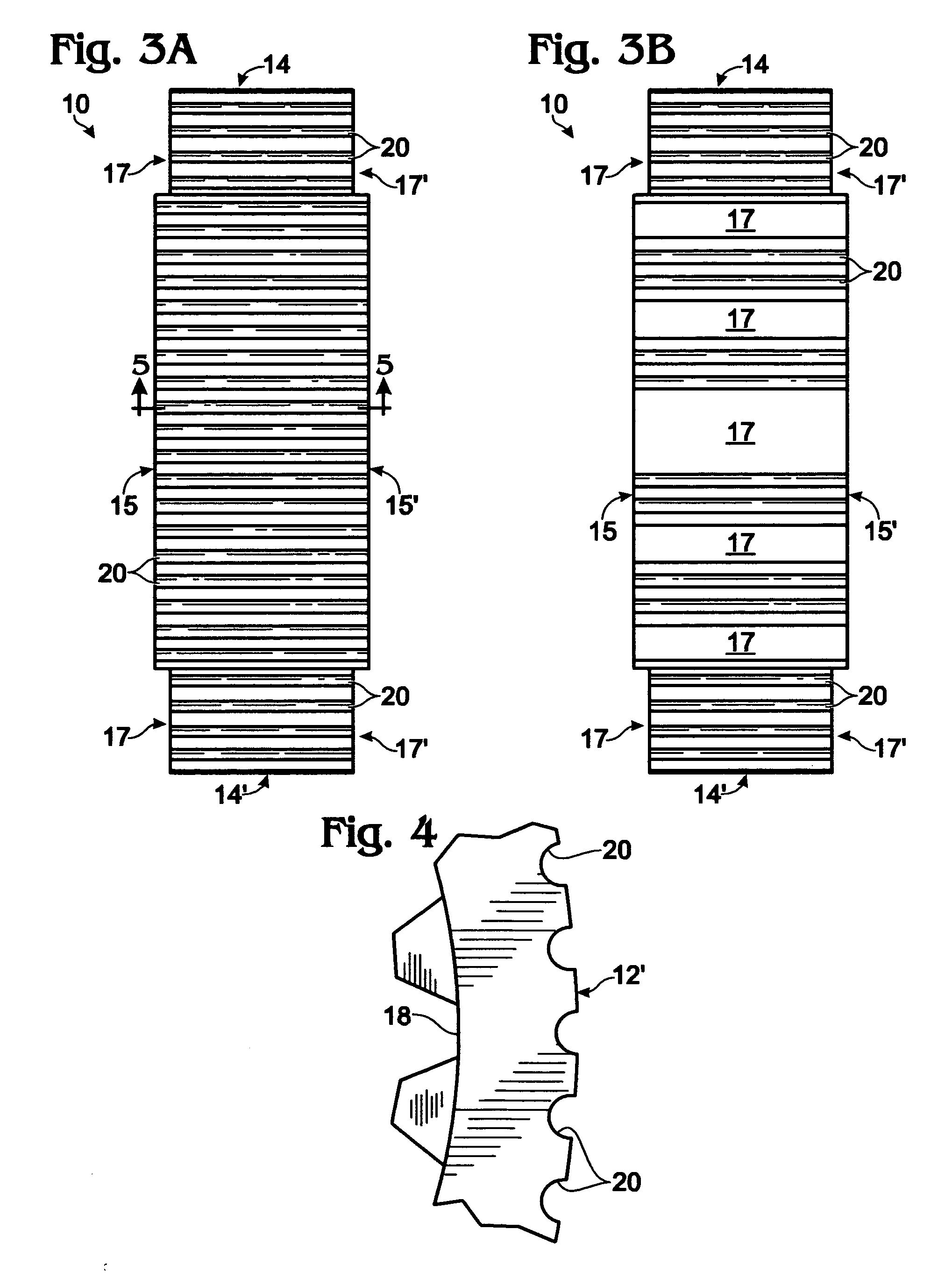

Faceted, tag-based approach for the design and composition of components and applications in component-based systems

InactiveUS20100095269A1Satisfy processingRequirement analysisSoftware reuseFacetSoftware requirements

A method, including: receiving a software requirement; and constructing a workflow template that can satisfy the software requirement, wherein the workflow template comprises a plurality of processing stages, wherein each processing stage includes at least one component class and each component class includes at least one component, and wherein an output of each processing stage is described by a processing goal pattern that is described by a set of tags and facets.

Owner:IBM CORP

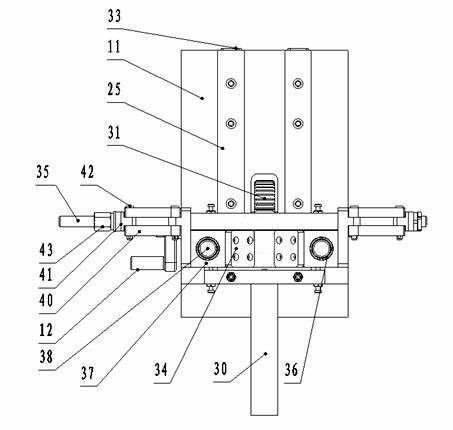

Multi-stage angle-variable machining tool

ActiveCN101890646ASimple structureReduce wastePositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a multi-stage angle-variable machining tool, which aims to provide an angle-variable swing angle workbench with the advantages of simple structure, easy operation and low cost, and the workbench not only can guarantee the machining quality of a multi-angle part, but also can aid ordinary numerical-control machining equipment to complete the task for machining the multi-angle part. The free ends of a swing angle workbench (1) are rotatablely connected to the step fitting surfaces of two step boss supporting seats (2) symmetrically arranged on the same surface of numerical control machines (6) by rotating shaft holes of fixed seats (3) fixedly connected to the surfaces of the numerical control machines (6), so that the swing angle workbench (1) can keep a required angle with the surfaces of the numerical control machines (6); and the bottoms of the step boss supporting seats (2) on both sides of the free ends of the symmetrical swing angle workbench (1) are also provided with a positioning key which can move only along the same key groove of the surface of the machine. The invention is applicable to be installed on the surface of a numerical control machine which can not perform swing angle machining, for machining slide blocks with various angles.

Owner:SICHUAN CHENGFEI INTEGRATION TECH

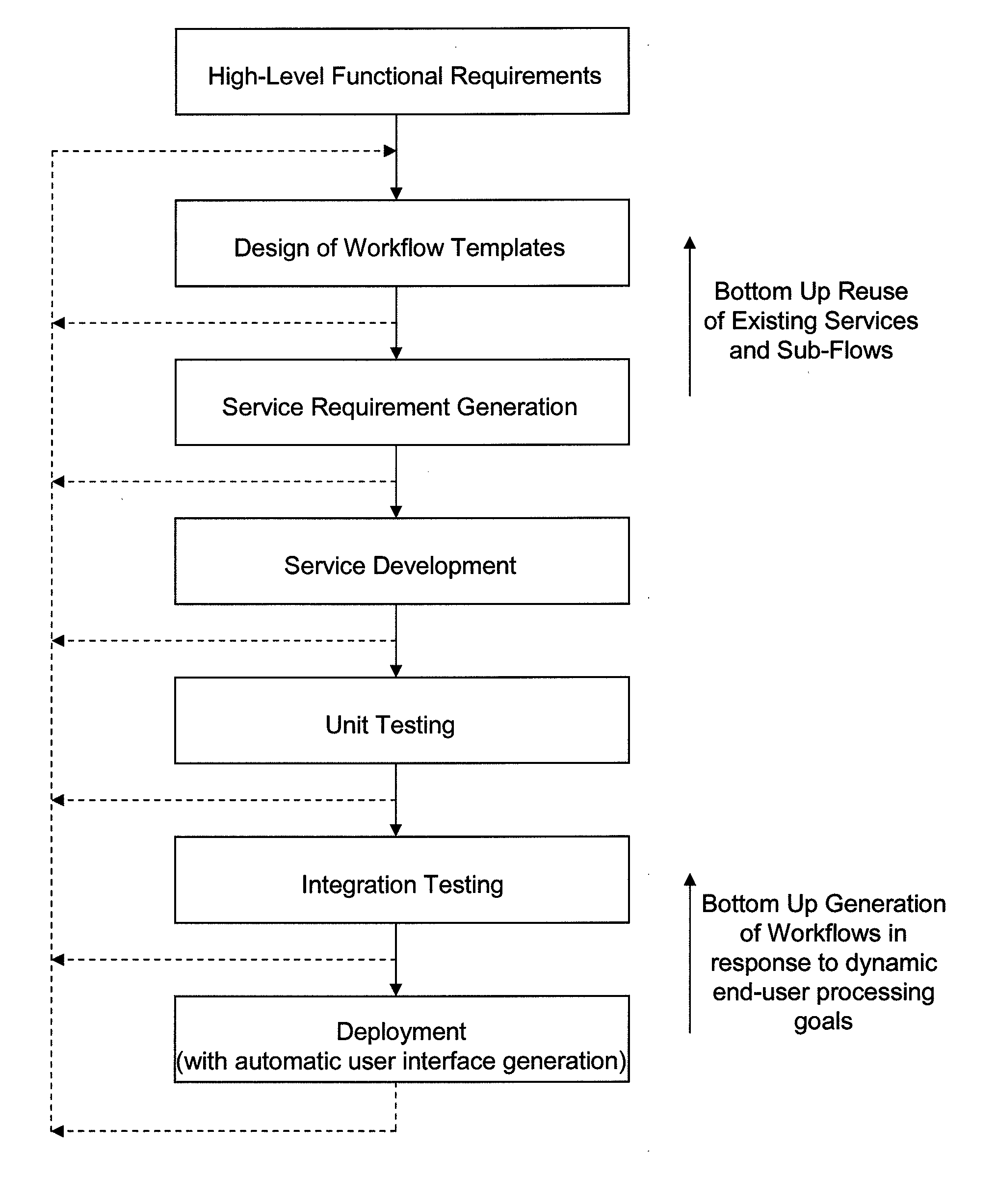

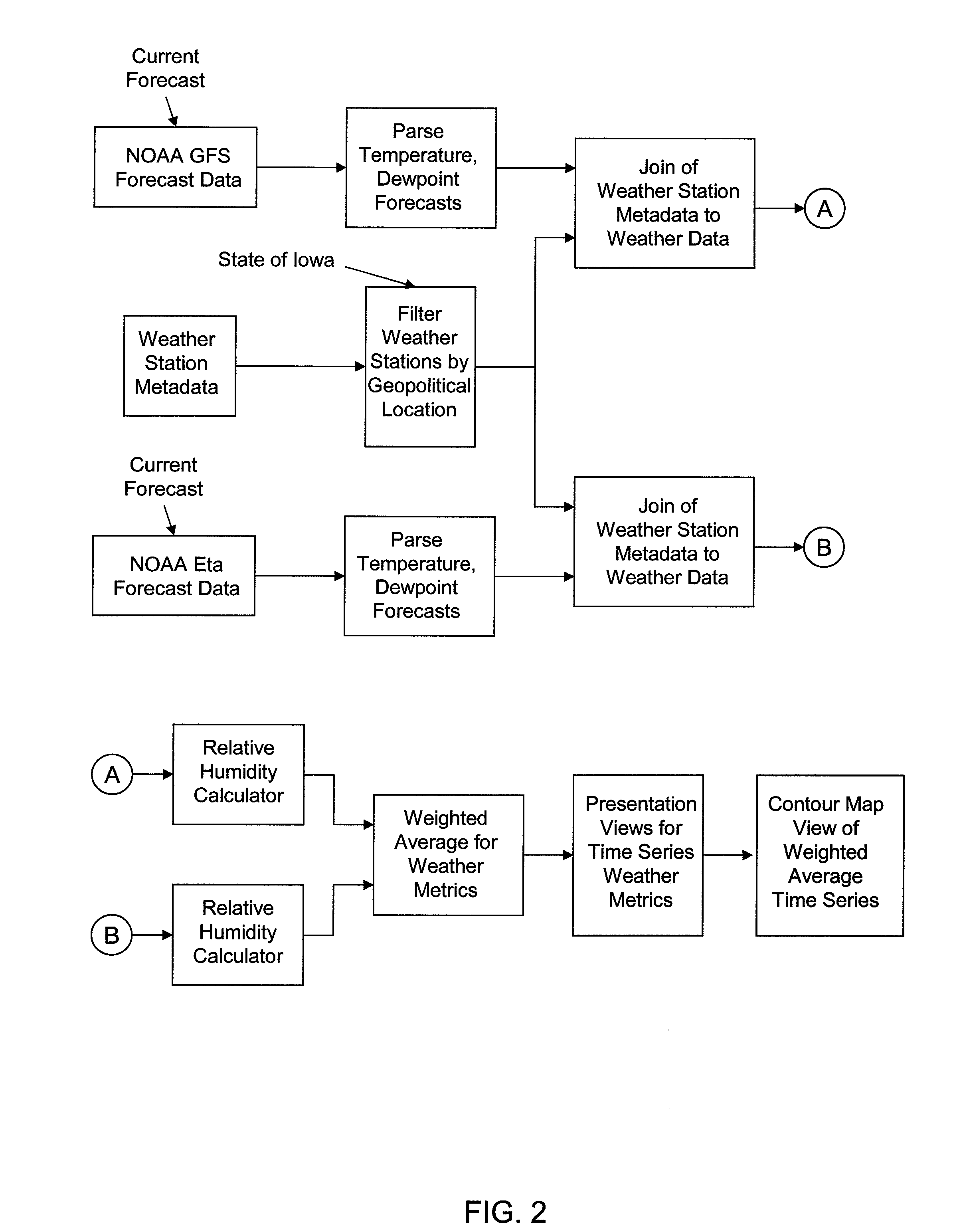

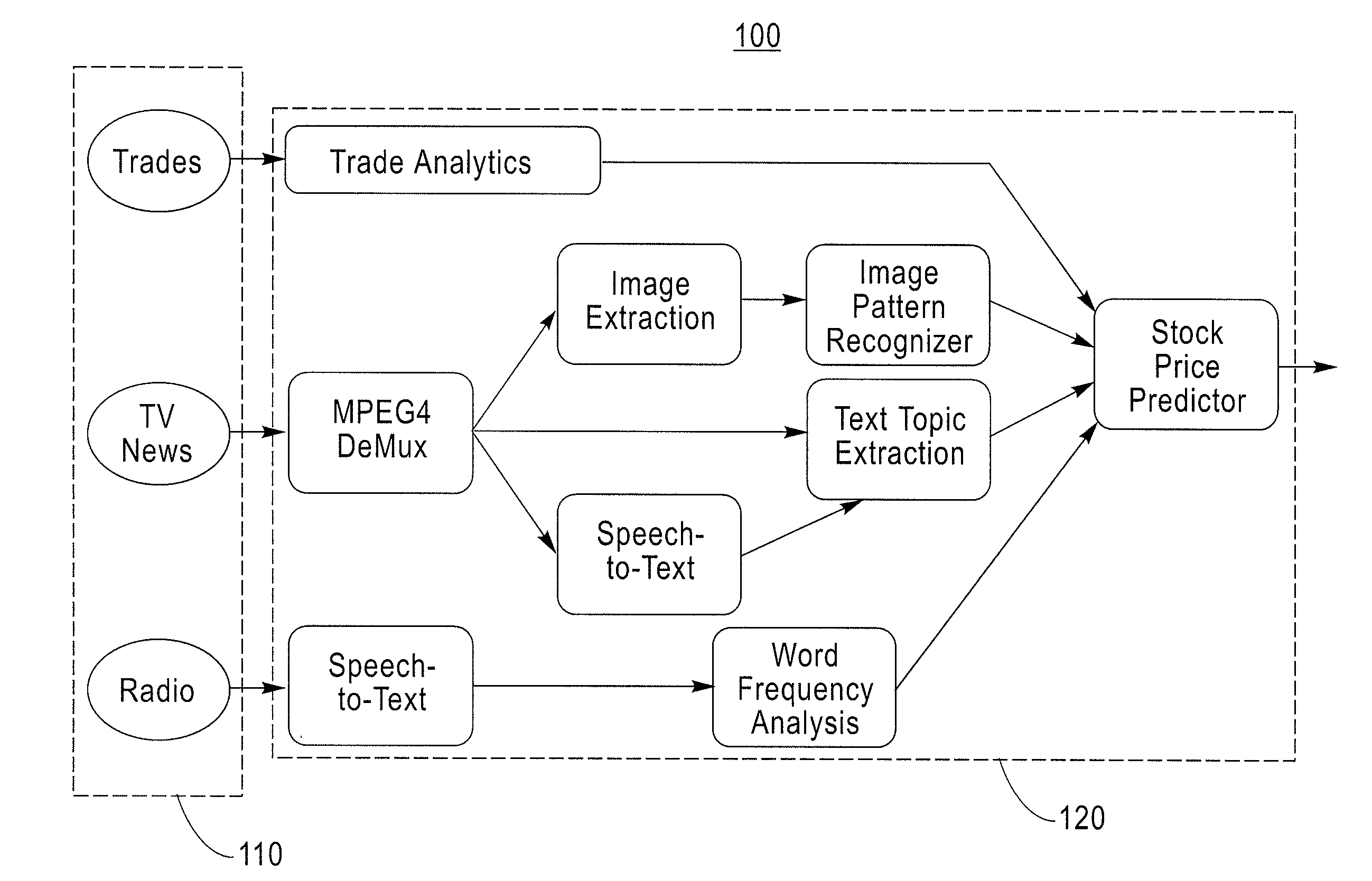

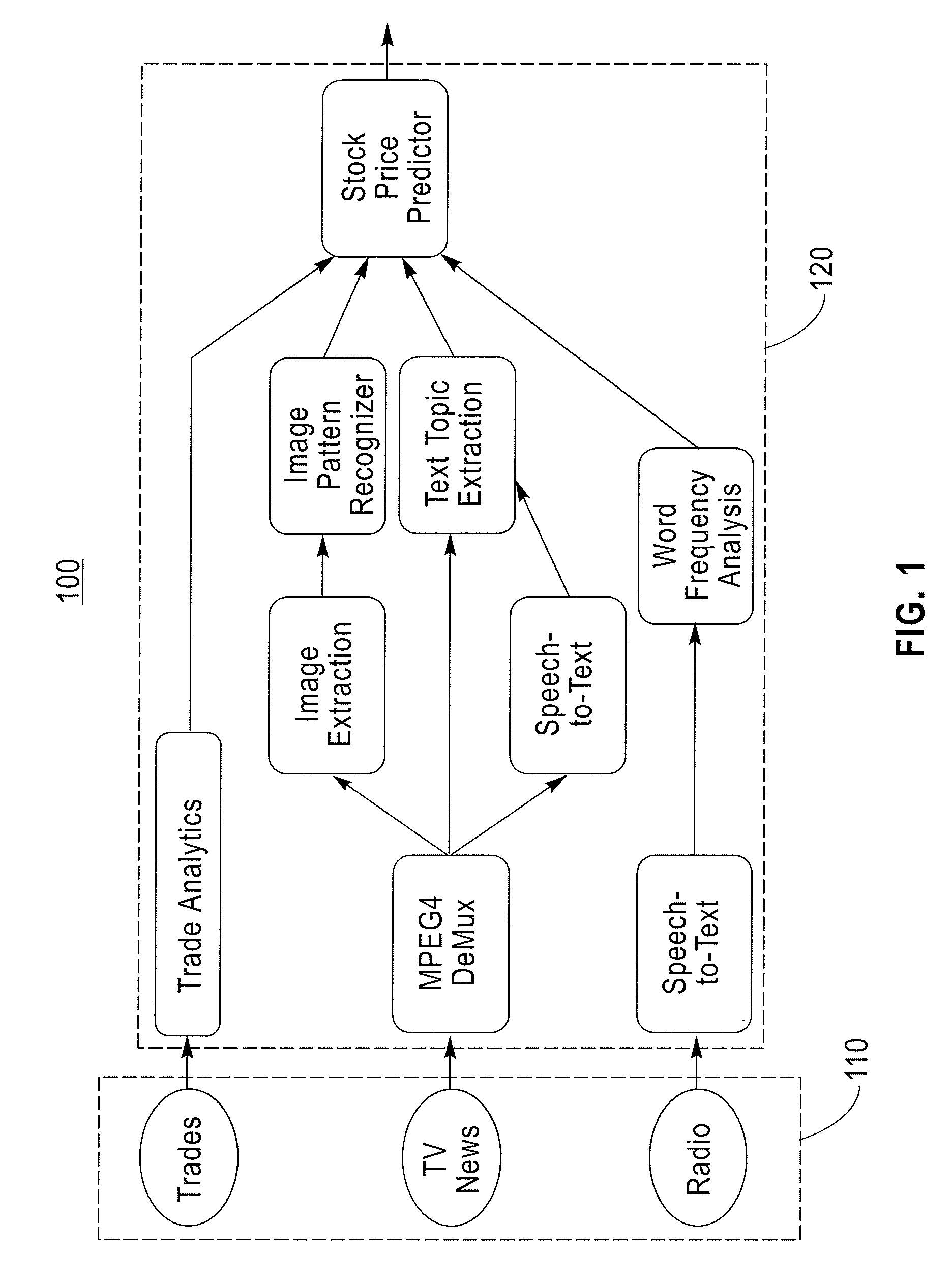

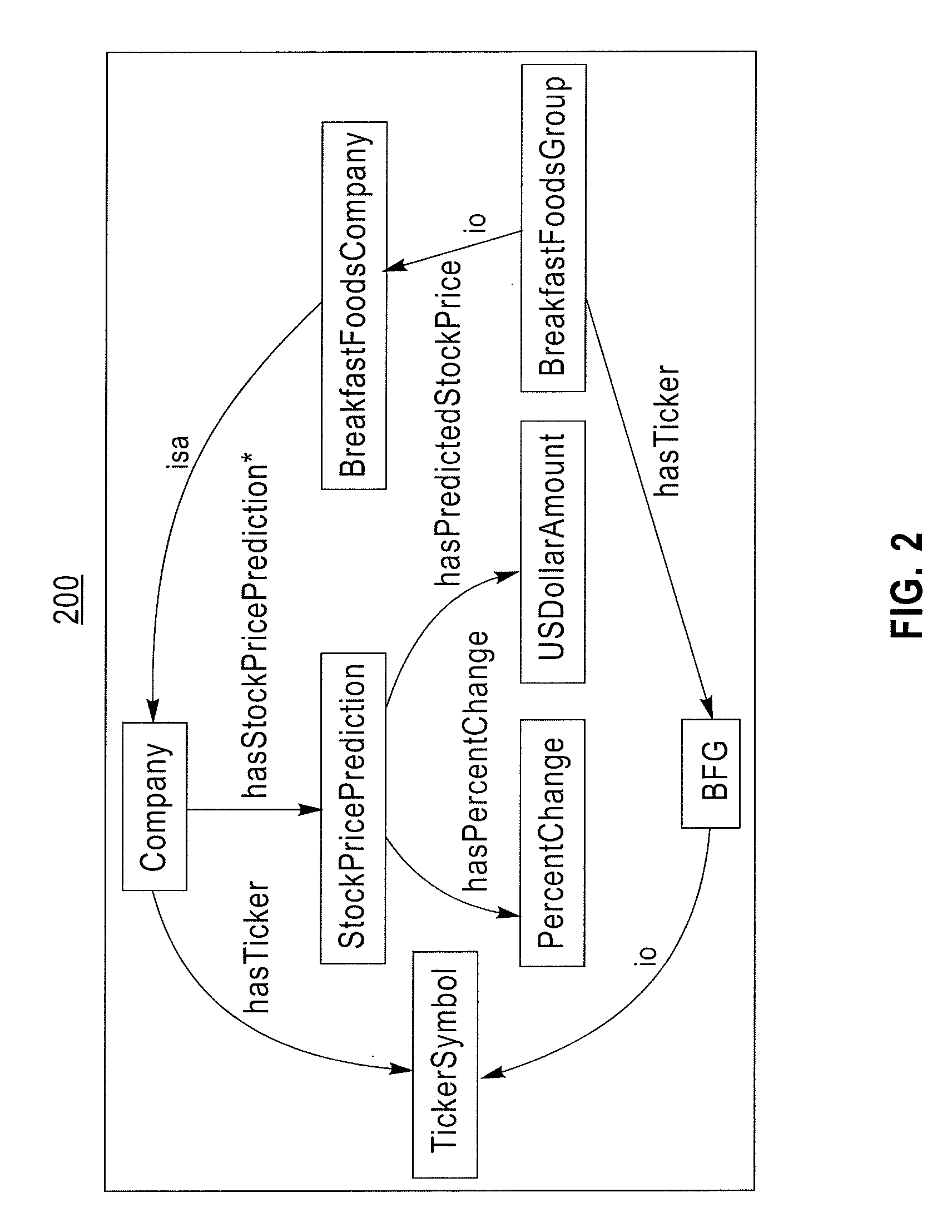

Method for declarative semantic expression of user intent to enable goal-driven information processing

InactiveUS20080243449A1Satisfy processingComputation using non-denominational number representationProgram controlInformation processingGraphics

A method for constructing a processing request so that an information processing application satisfying the processing request can be assembled, includes: inputting a processing request, wherein the processing request includes a goal that is represented by a graph pattern that semantically describes a desired processing outcome; and assembling a processing graph that includes at least one component that satisfies the desired processing outcome, wherein the processing graph is assembled by associating the graph pattern that semantically describes the desired processing outcome with a graph pattern that semantically describes an applicability condition of the at least one component or a graph pattern that semantically describes an inclusion effect of the at least one component.

Owner:IBM CORP

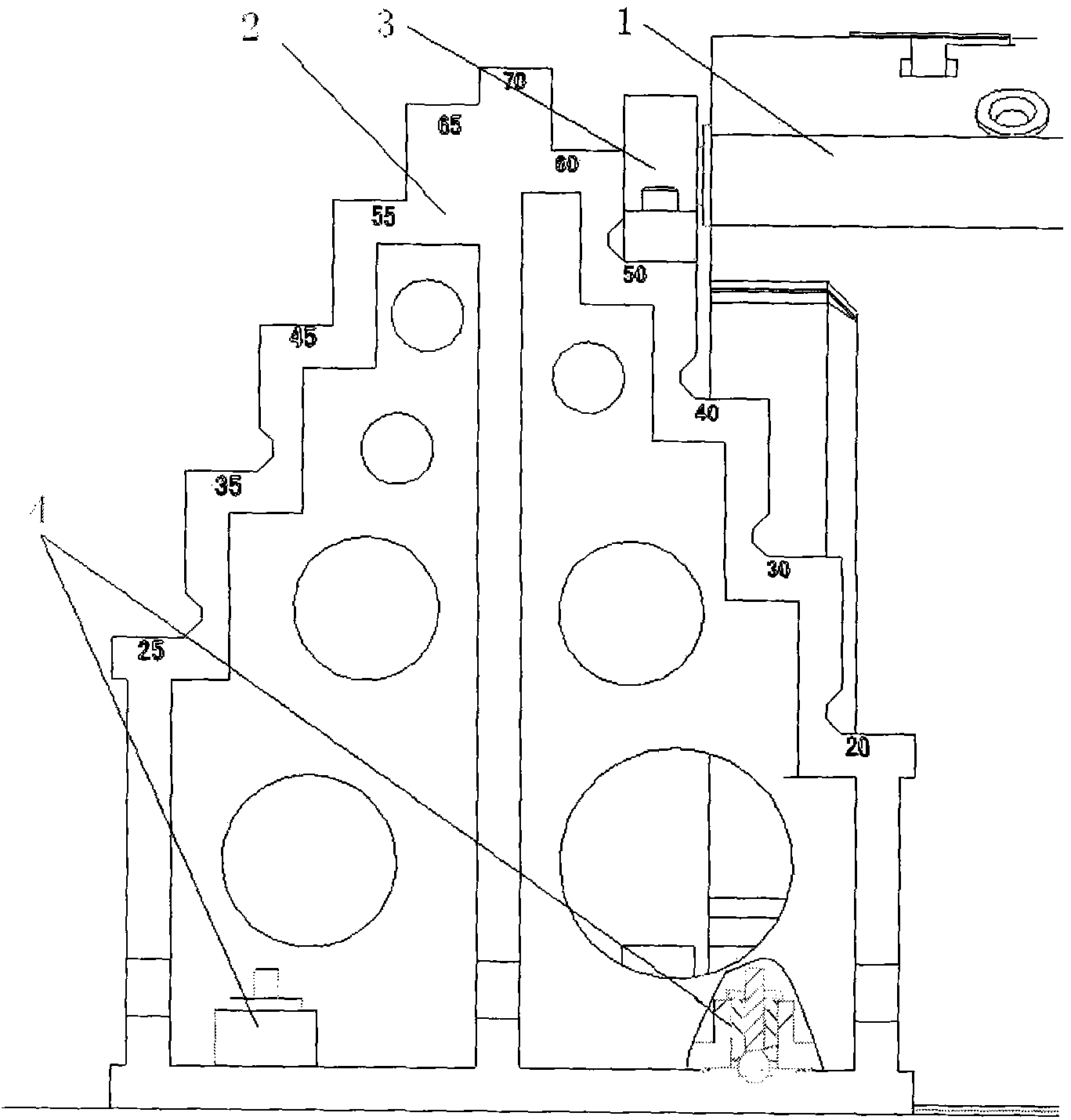

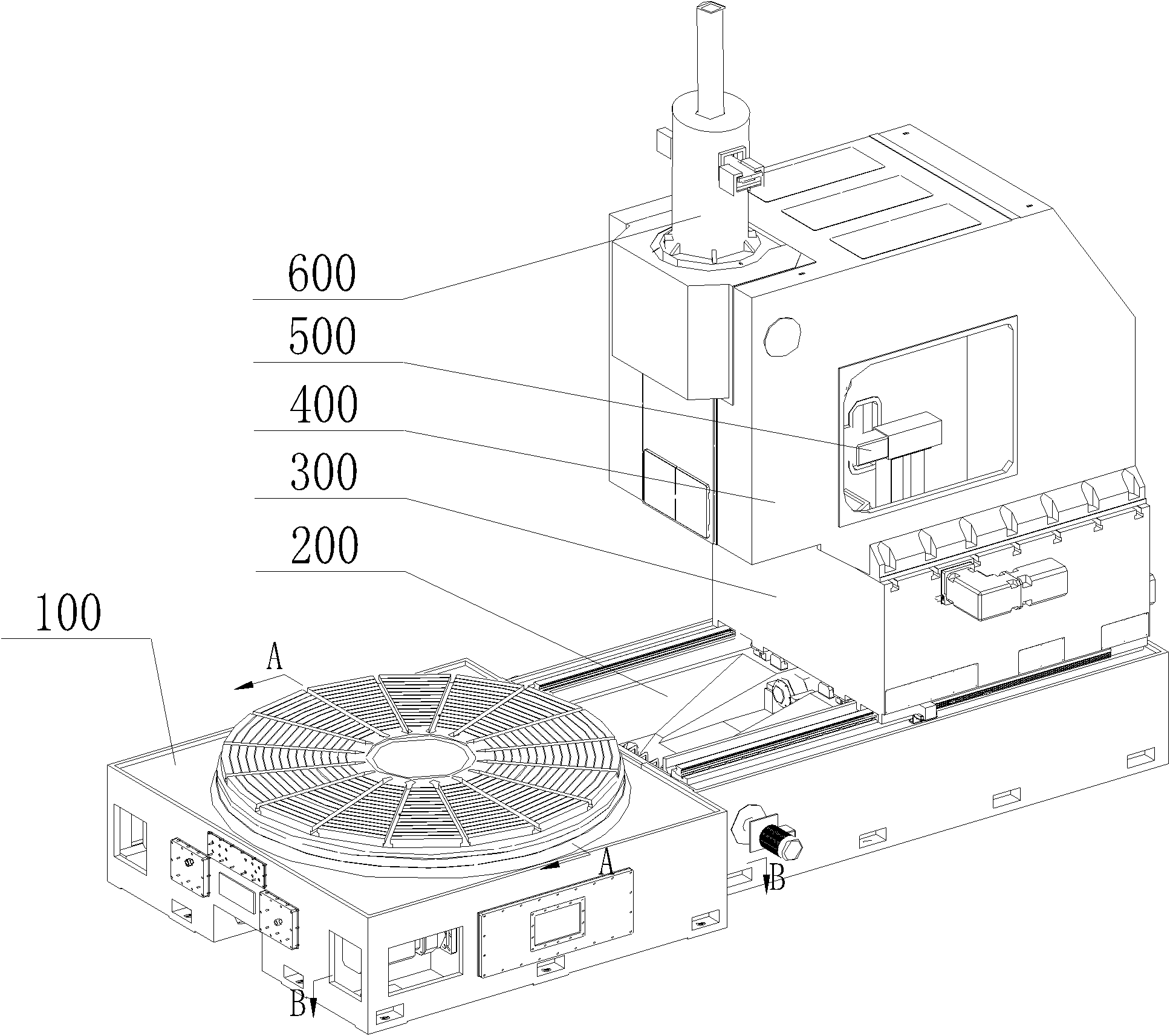

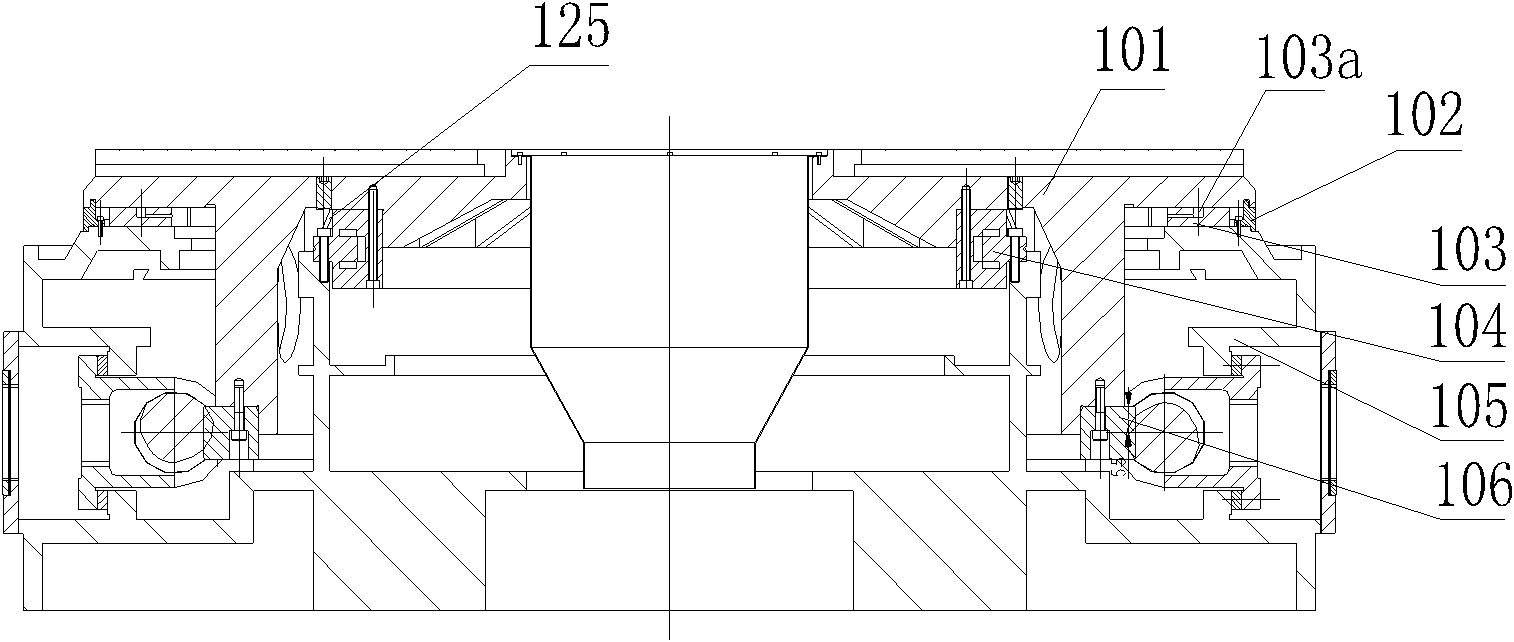

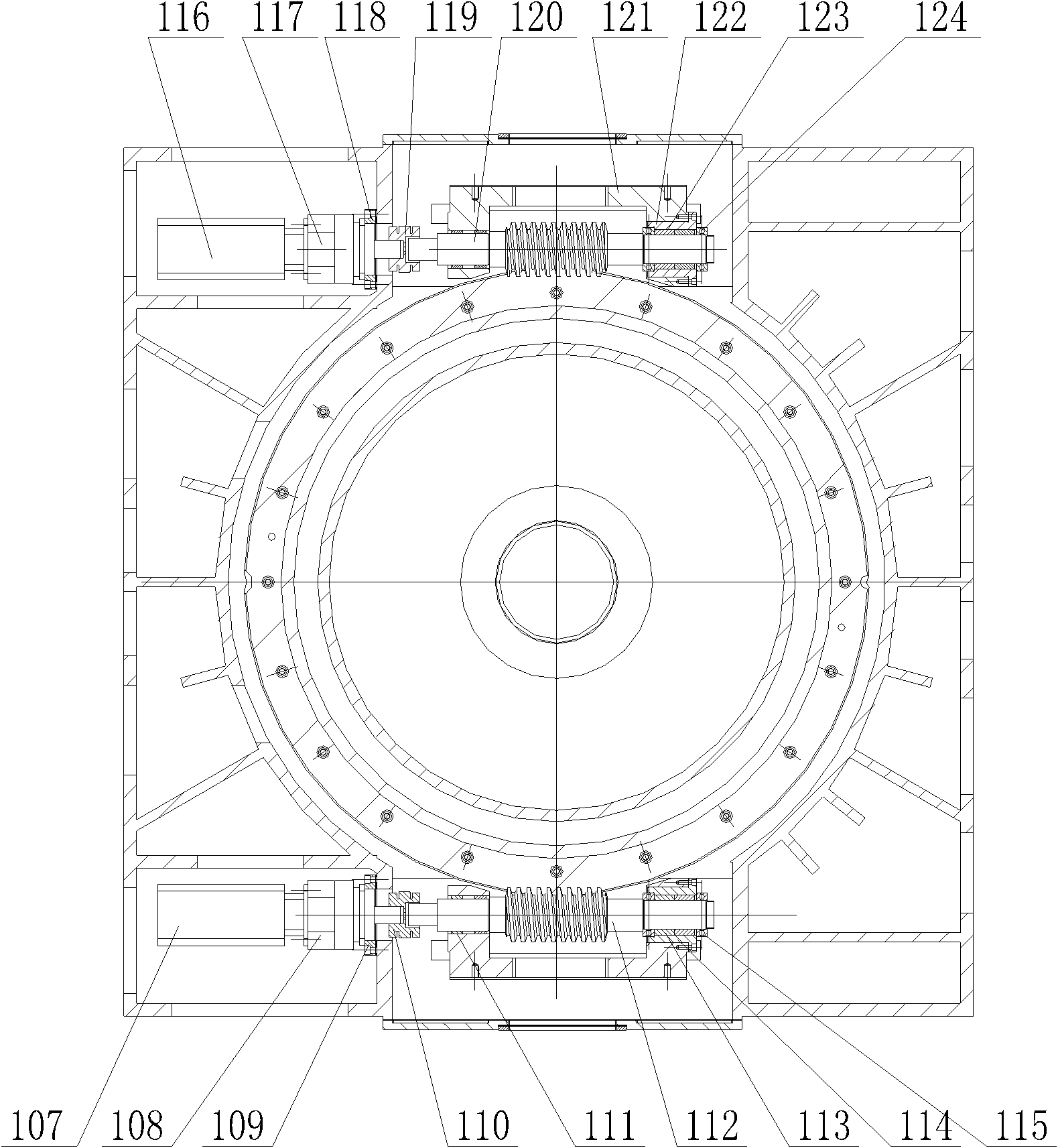

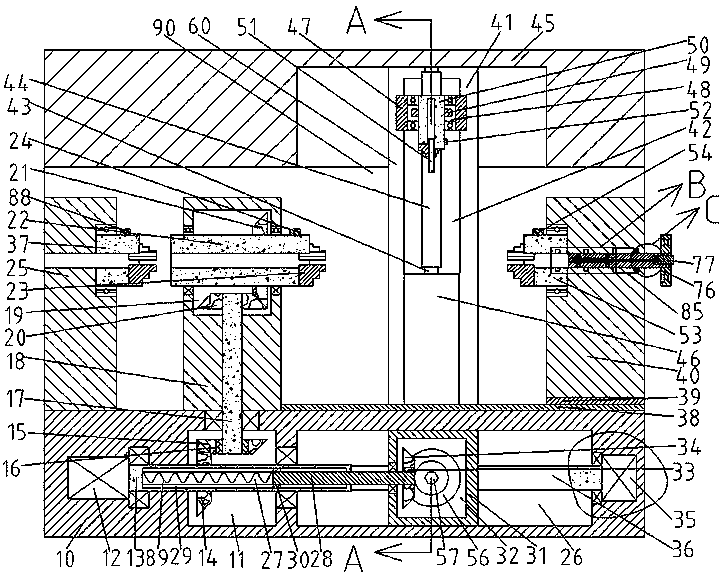

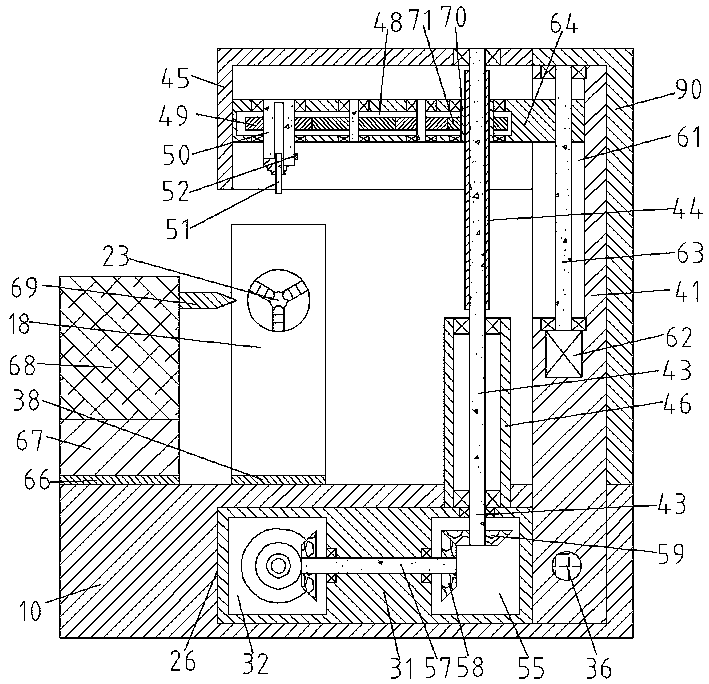

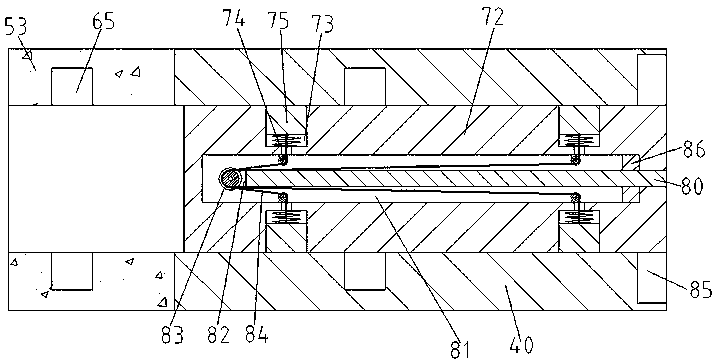

Full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting

ActiveCN102059402AIncrease cutting forceImprove accuracyGear-cutting machinesGear teethHydraulic cylinderCoupling

The invention relates to a full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting, comprising a rotary table, a shaper body assembly, an intermediate shaper body assembly, a stand column, a cutter relieving mechanism, a cutter rest mechanism, a numerical control system, a hydraulic system, a lubricating system and a cooling chip removing system. Serve motors are arranged on both sides of the rotary table and are connected with a worm gear motion pair through a shaft coupler to form a dual-driving mechanism of the rotary table; a cutter shaft of the cutter rest mechanism is driven by a hydraulic cylinder to do reciprocating motion; a motor base of the cutter rest mechanism is provided with a servo motor; and the cutter relieving mechanism is provided with camshafts of a conjugate dual cams to connect and drive the servo motor. The invention has the advantages that the gear shaper adopts the servo hydraulic cylinder to drive to provide reciprocating motion of the cutter shaft, adopts a torque motor to provide the rotary motion of the cutter shaft and adopts the servo motor to drive the cutter relieving mechanism to meet the processing requirement of large-scale precise gears; the rotary table bears heavy load and has high operation stability; the processing range, the stroke length and the cutting force are enlarged; the processing precision is high; and the processing flexibility adaptability is strong.

Owner:通用技术集团天津第一机床有限公司

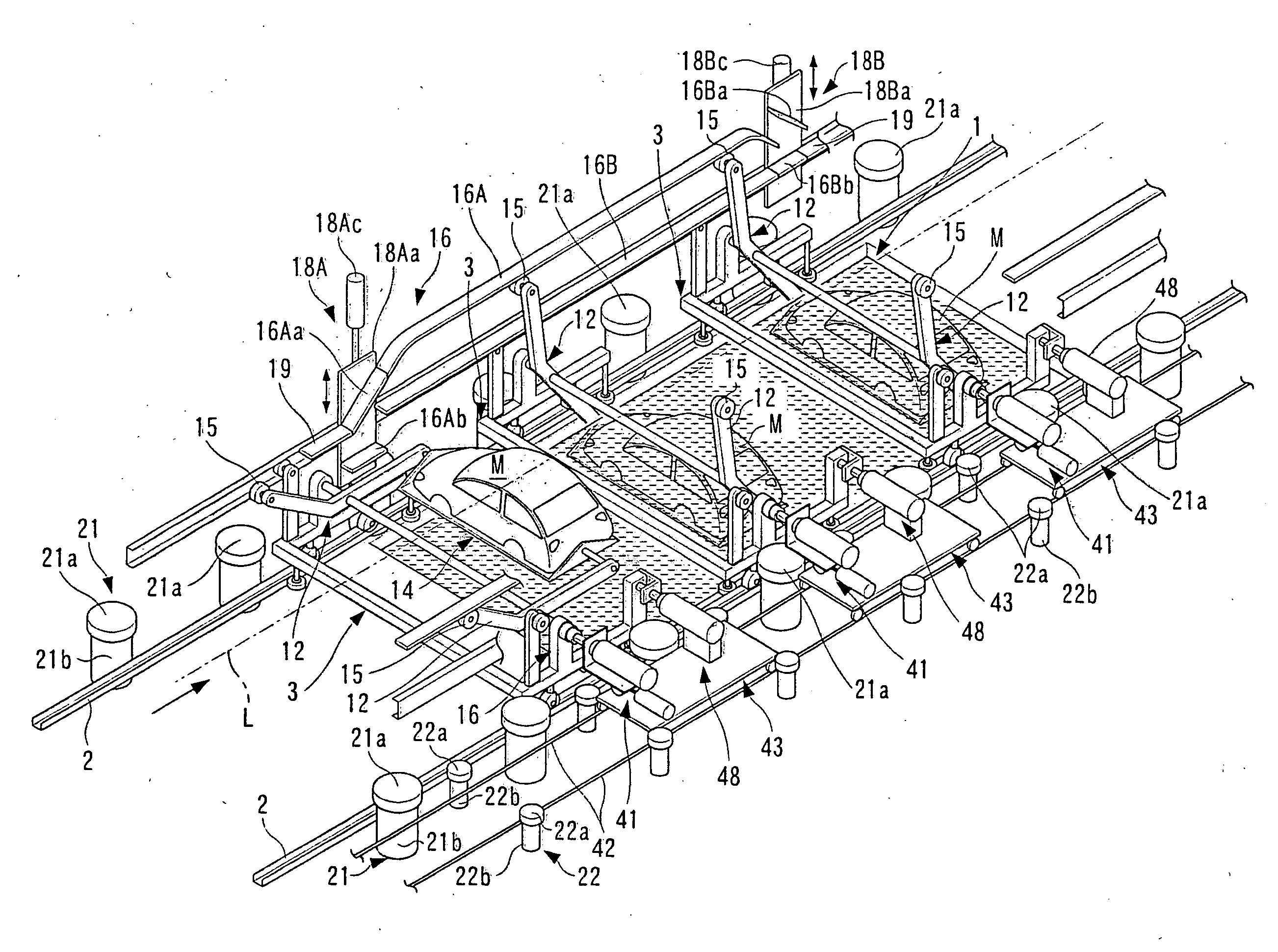

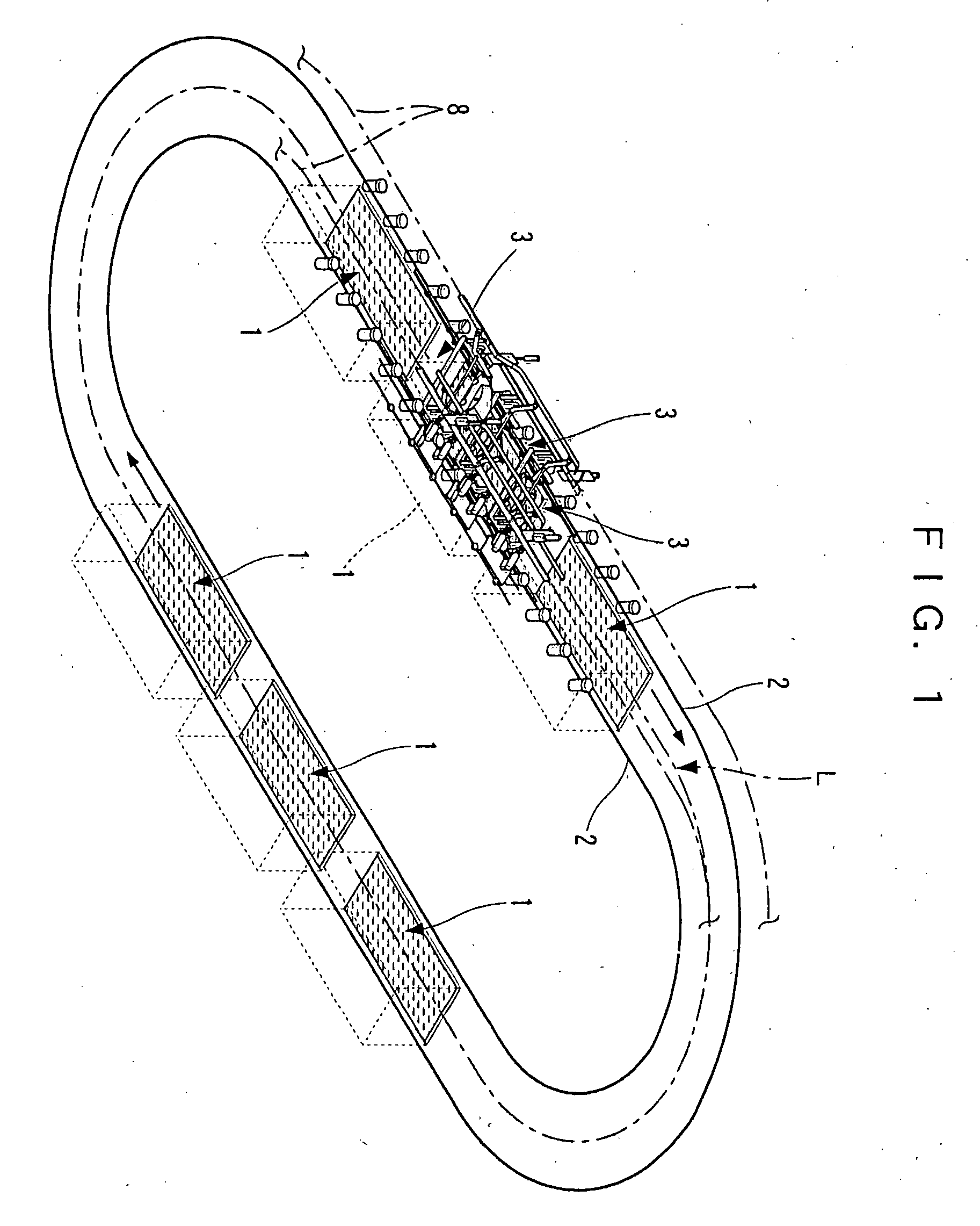

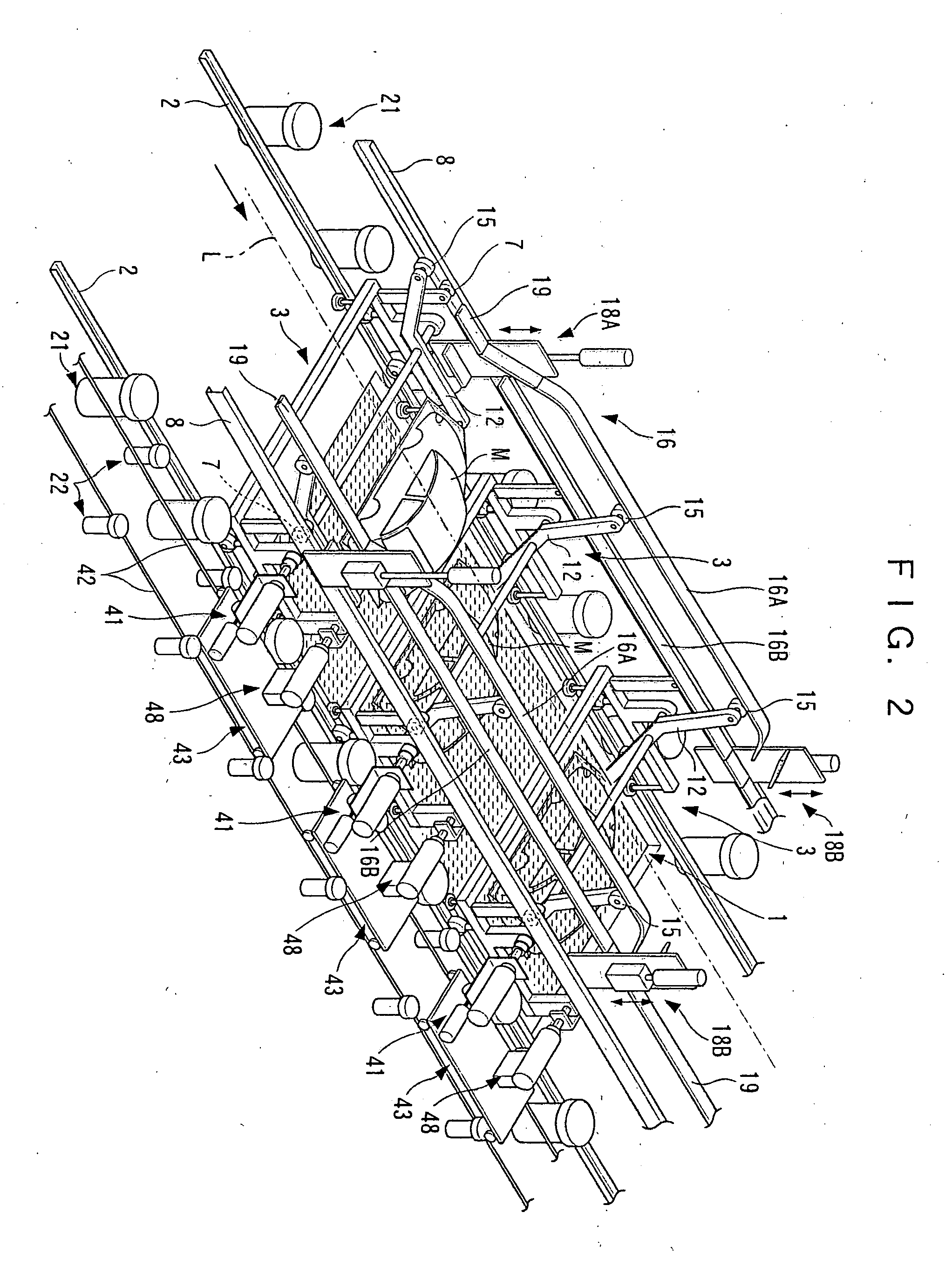

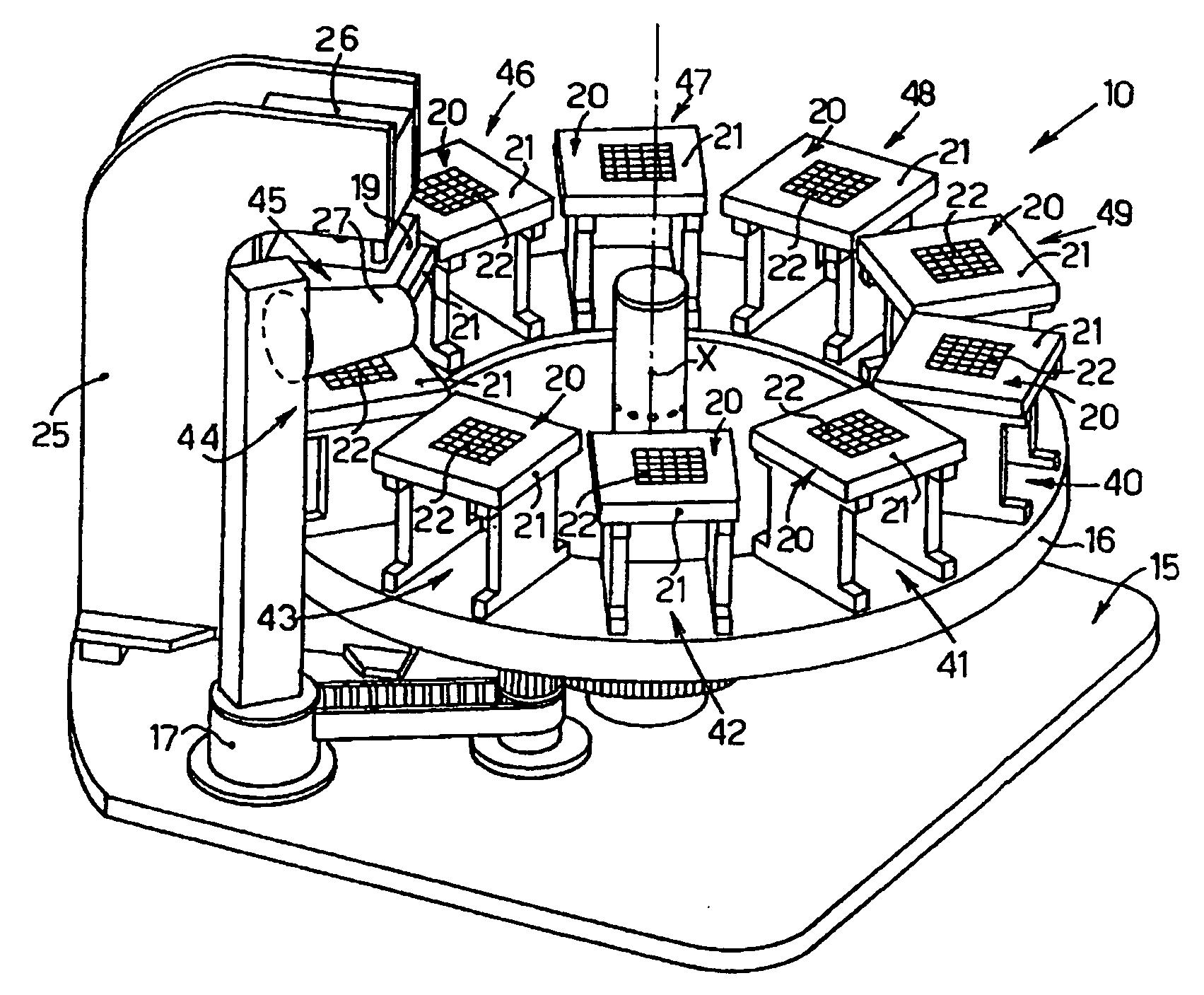

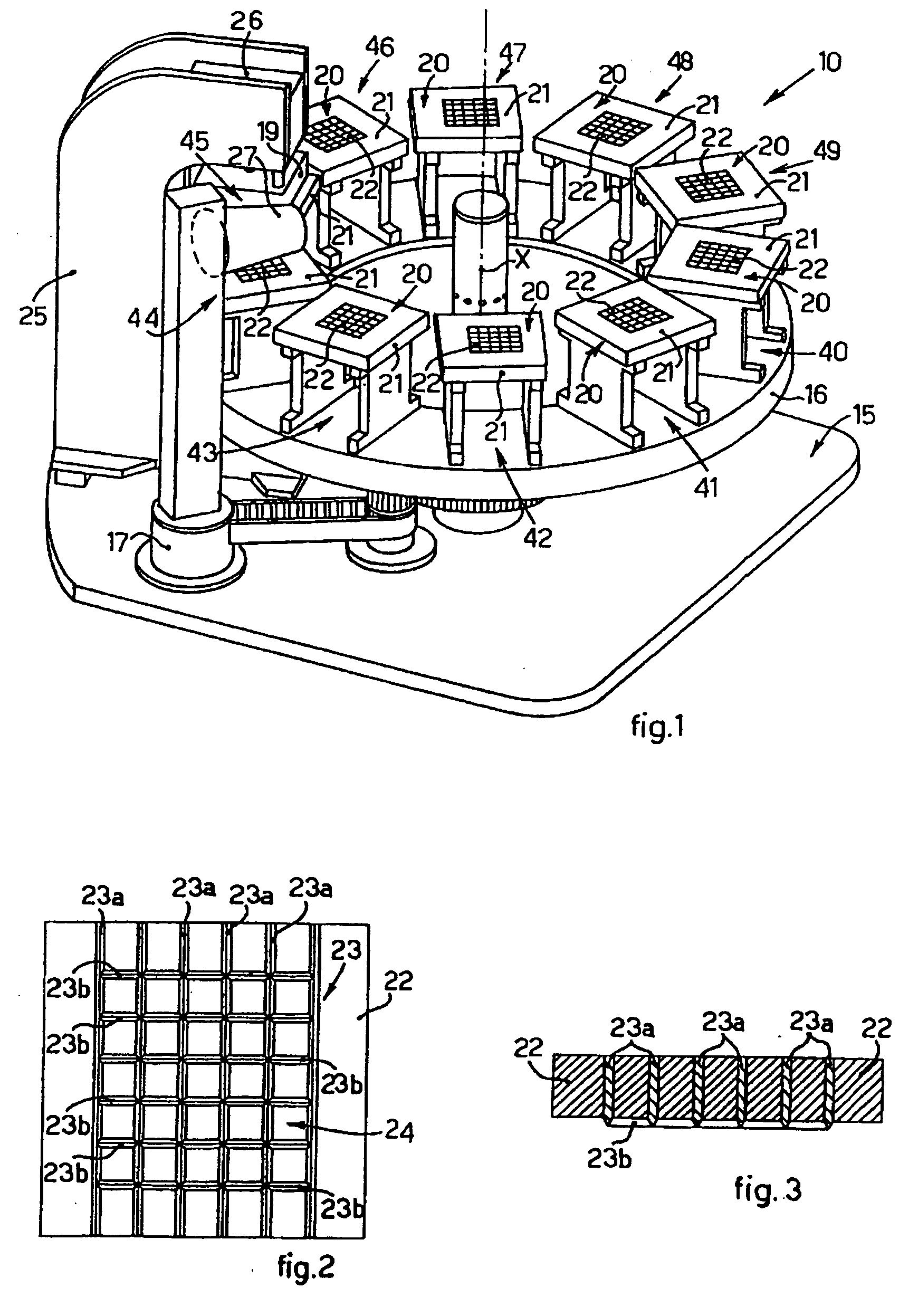

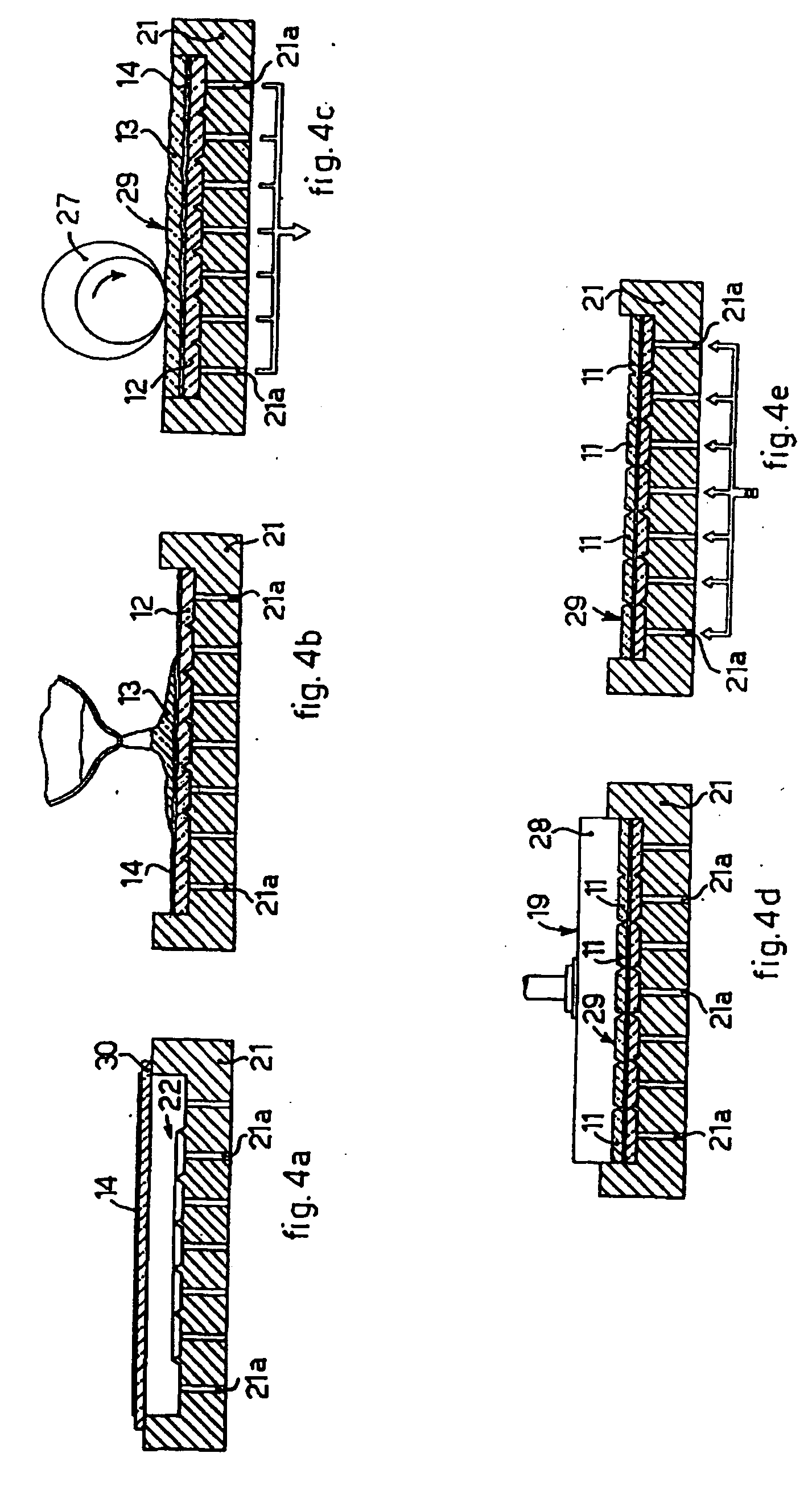

Conveyance method and apparatus for processing step

InactiveUS20040149542A1Satisfy processingLiquid surface applicatorsElectric lighting sourcesLiquid tankEngineering

An operating arm (12) supported on a movable body (3) is operated to move downwards, and a supporting body (14) located on the front end section of the operating arm (12) is rotated about an axis in the lateral direction of a processing line (L), whereby a conveyance object (M) supported on the supporting body (14) is immersed in a processing liquid in a processing liquid tank (1) and processed by the same. Furthermore, the conveyance object (M) is removed from the processing liquid, during which operation the supporting member (14) is rotated in accordance with the shape of the conveyance object (M), thereby controlling the angle of the conveyance object (M) upon introduction into the processing liquid, the angle of the conveyance object (M) during immersion in the processing liquid, and the angle of the conveyance object (M) upon removal from the processing liquid.

Owner:DAIFUKU CO LTD

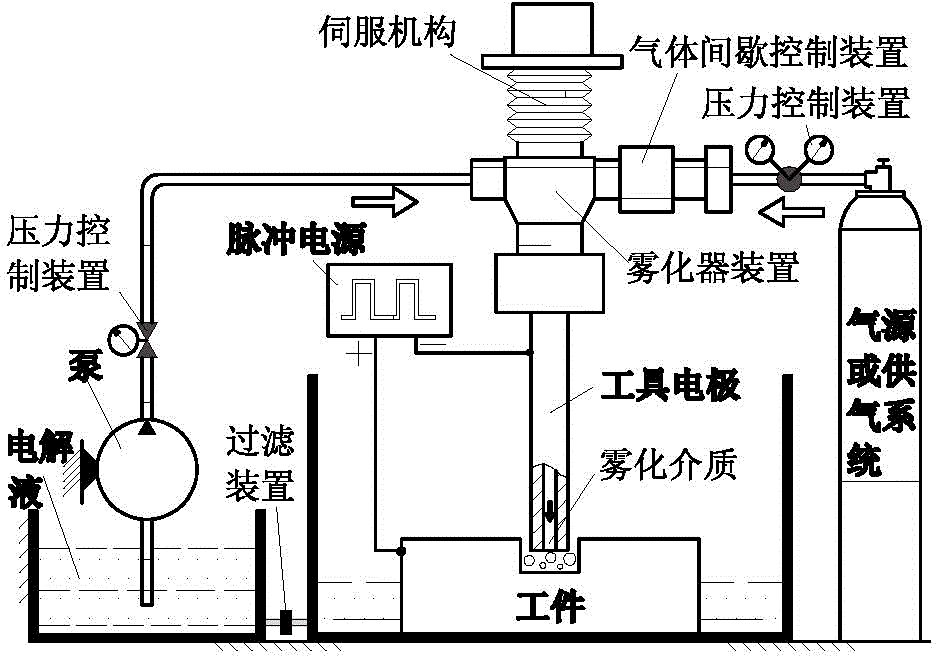

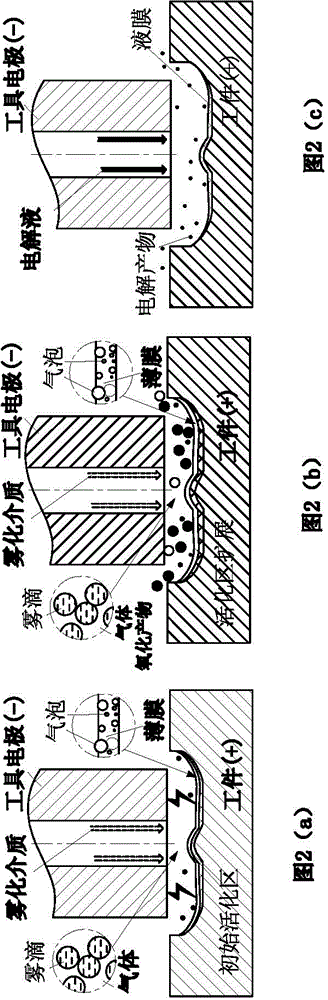

Conductivity adjustable atomizing medium electric spark discharge ablation and electrolytic combined machining method

The invention provides a conductivity adjustable atomizing medium electric spark discharge ablation and electrolytic combined machining method which is characterized in that during the electric spark induced ablation machining, an insulated working medium used by electric spark discharge is replaced by electrolyte and forms an atomizing medium with an inflammable (combustion-supporting) gas such as oxygen to be sprayed into the machining area, the aim of controlling the conductivity of the atomizing medium is achieved by adjusting the proportion of the gas and the electrolyte during the machining, and a machining manner of mainly taking discharge induced ablation machining, or discharge induced ablation and electrolytic machining, or electrolytic machining can be realized at different stages of the whole machining process based on the machining needs or stage requirements, and the machining improves the machining efficiency through ablation, or takes the machining efficiency and surface quality into account, or removes a surface degenerating layer. The aims of initial high efficiency machining based on machining needs during the whole machining process and degenerating layer reduction or removal at the end are achieved. The machining manner can be applied to milling of conductive materials and machining of deep blind holes.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

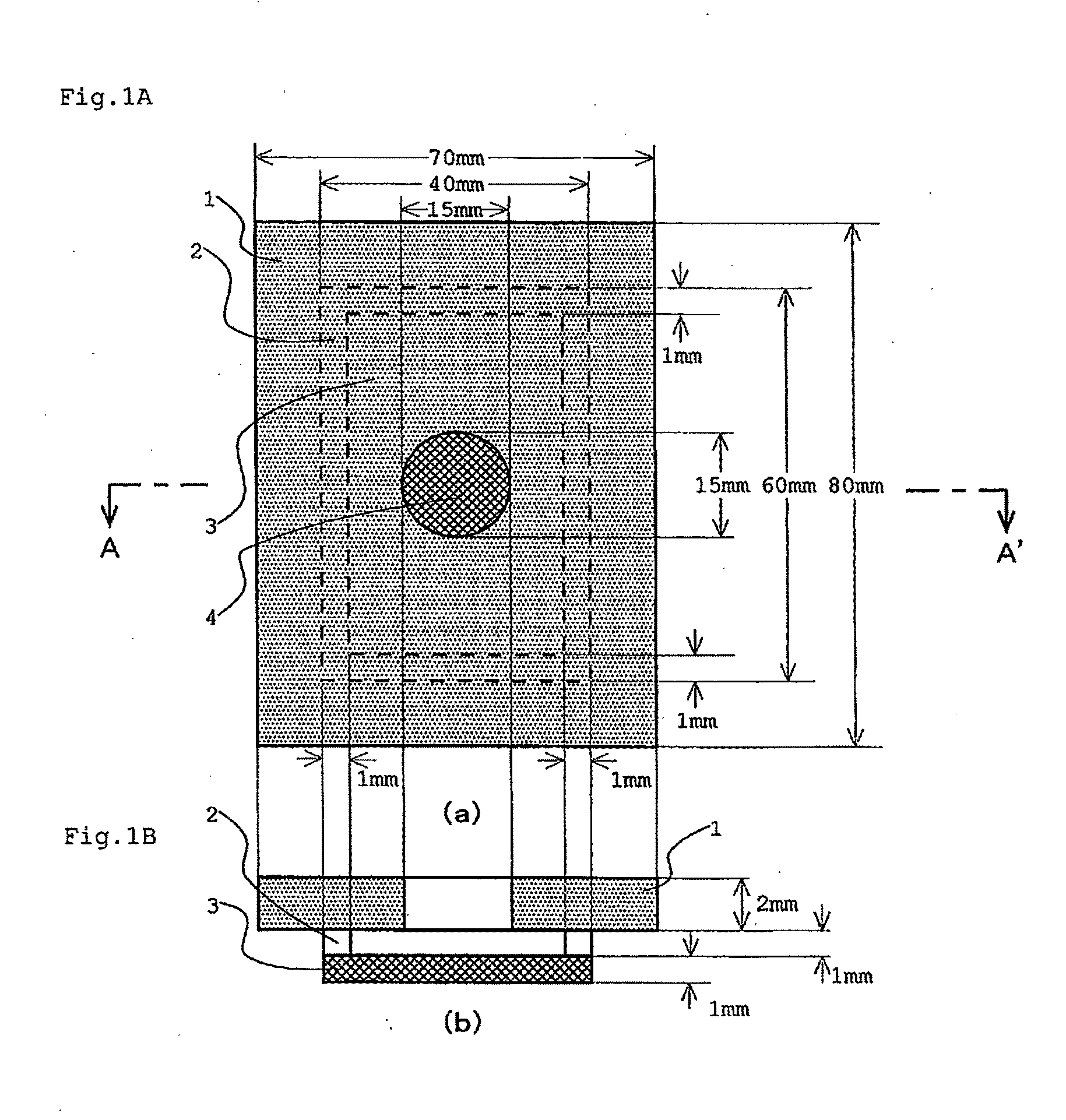

Double-faced pressure-sensitive adhesive tape

ActiveUS20100143685A1Improve waterproof performanceSatisfy processingFilm/foil adhesivesSynthetic resin layered productsAdhesive beltEngineering

Disclosed is a double-faced pressure-sensitive adhesive tape which includes a foam substrate, one pressure-sensitive adhesive layer arranged on or above one side of the substrate, and another pressure-sensitive adhesive layer arranged on or above the other side of the substrate. The adhesive tape has a total thickness of 250 μm or less. The adhesive tape is thin but highly waterproof (sealable against water). The adhesive tape preferably has a tensile strength of 0.5 to 20 MPa for further superior processability.

Owner:NITTO DENKO CORP

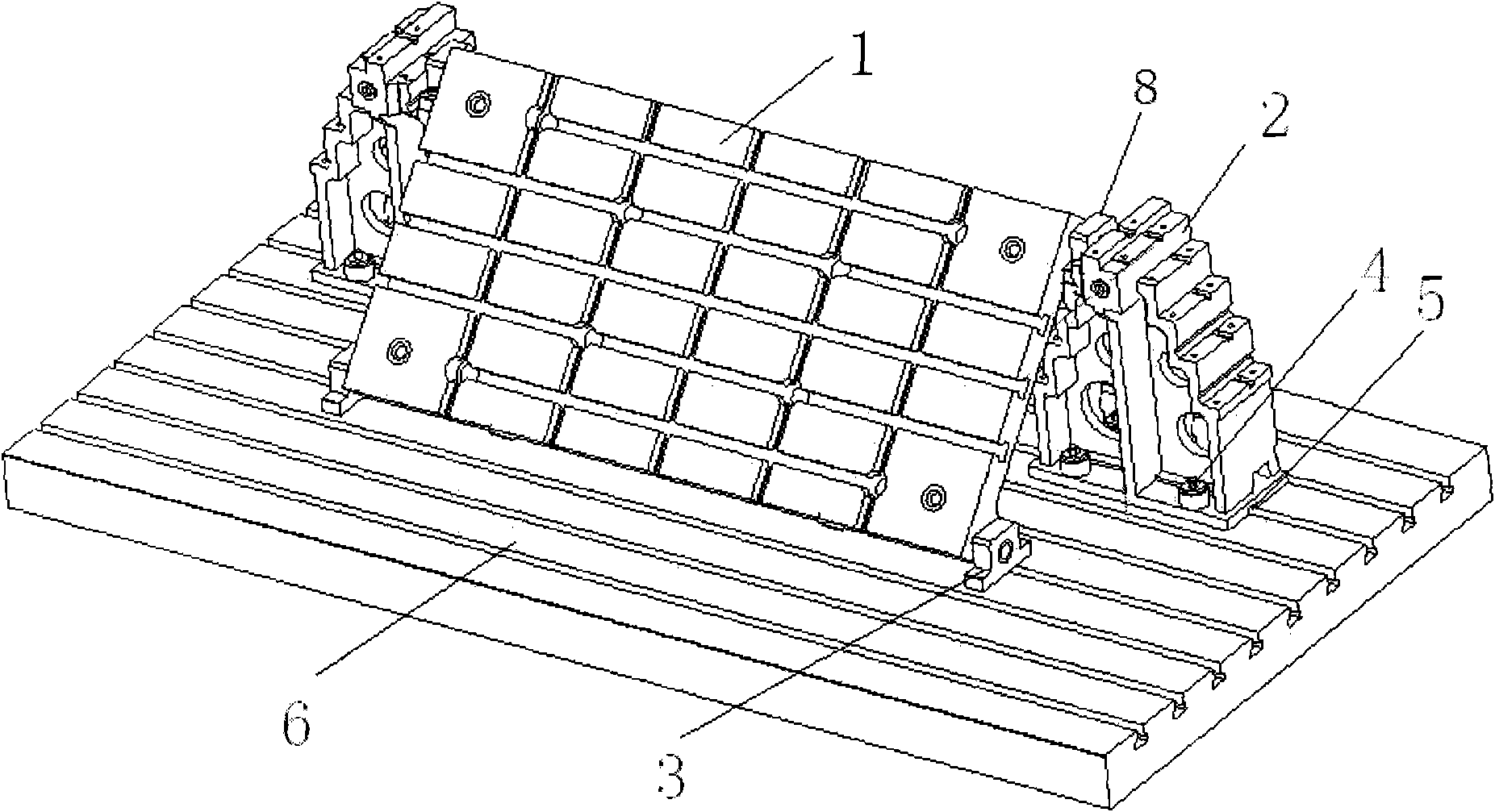

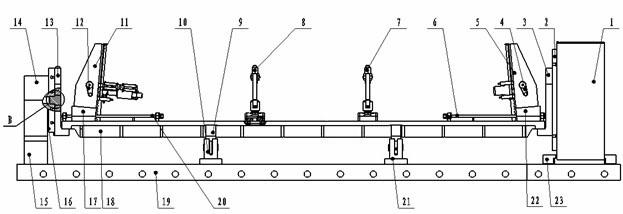

Universal fixture for processing plate spring inclined hole of heavy-duty automobile front axle

ActiveCN102672495AGuarantee the uniformity of the benchmarkSatisfy processingPrecision positioning equipmentPositioning apparatusHeavy dutySurface plate

The invention discloses a universal fixture for processing a plate spring inclined hole of a heavy-duty automobile front axle. The universal fixture comprises a substrate, a left graduated disk assembly and a right graduated disk assembly respectively arranged on the left end and the right end of the substrate, and a cross beam surface plate with two ends being respectively connected with a left graduated disk and a right graduated disk. The universal fixture is characterized in that a left positioning seat assembly is matched and connected onto the left end part of the cross beam surface plate; and a right positioning seat assembly is matched and connected onto the right end part of the cross beam surface plate. The universal fixture can ensure each part to be standard and universal, and not only can meet the requirement of processing of workpieces with different heights and different lengths, but also can meet the requirement of processing of plate spring holes of workpieces with different included angles.

Owner:重庆大江车桥有限责任公司

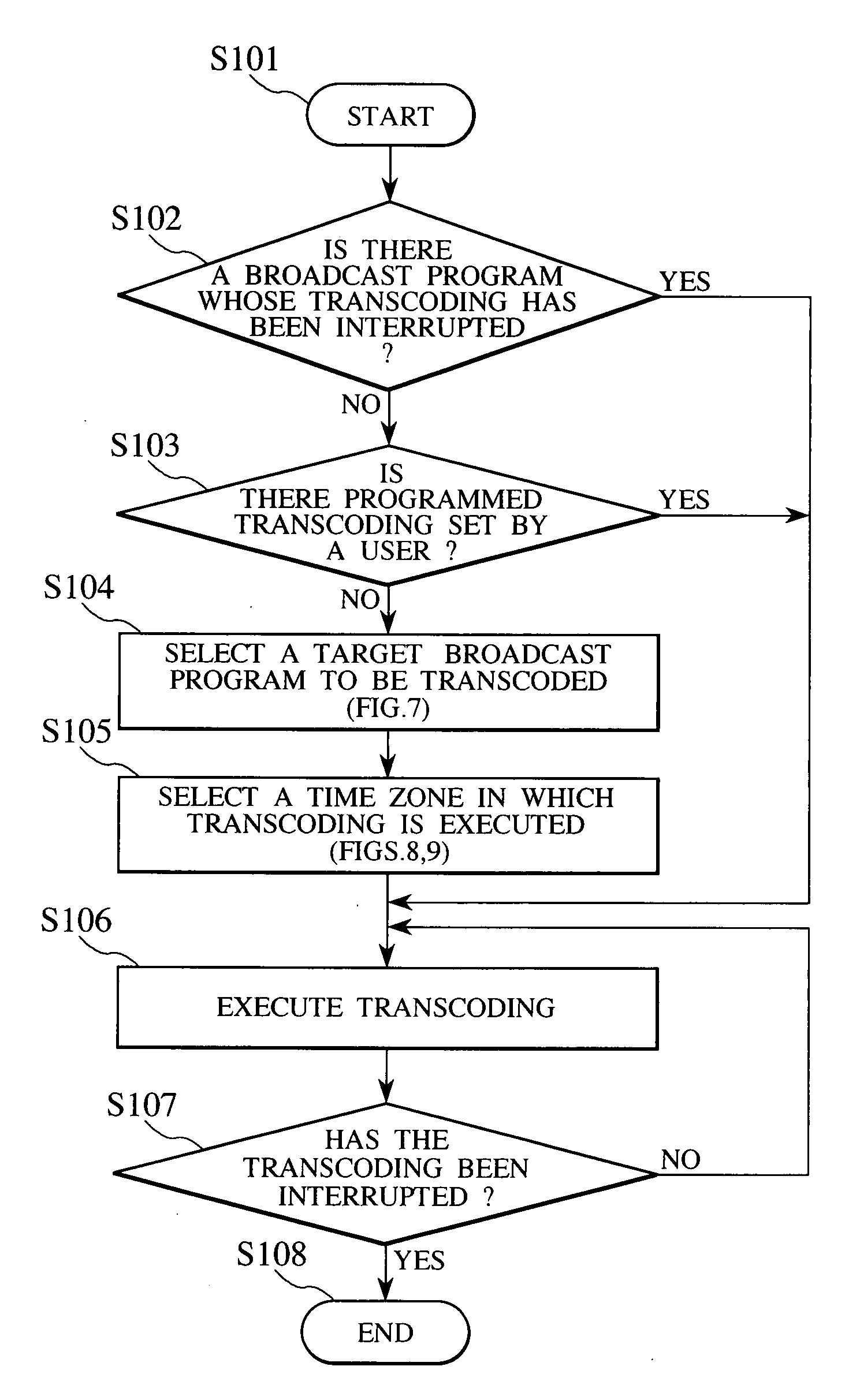

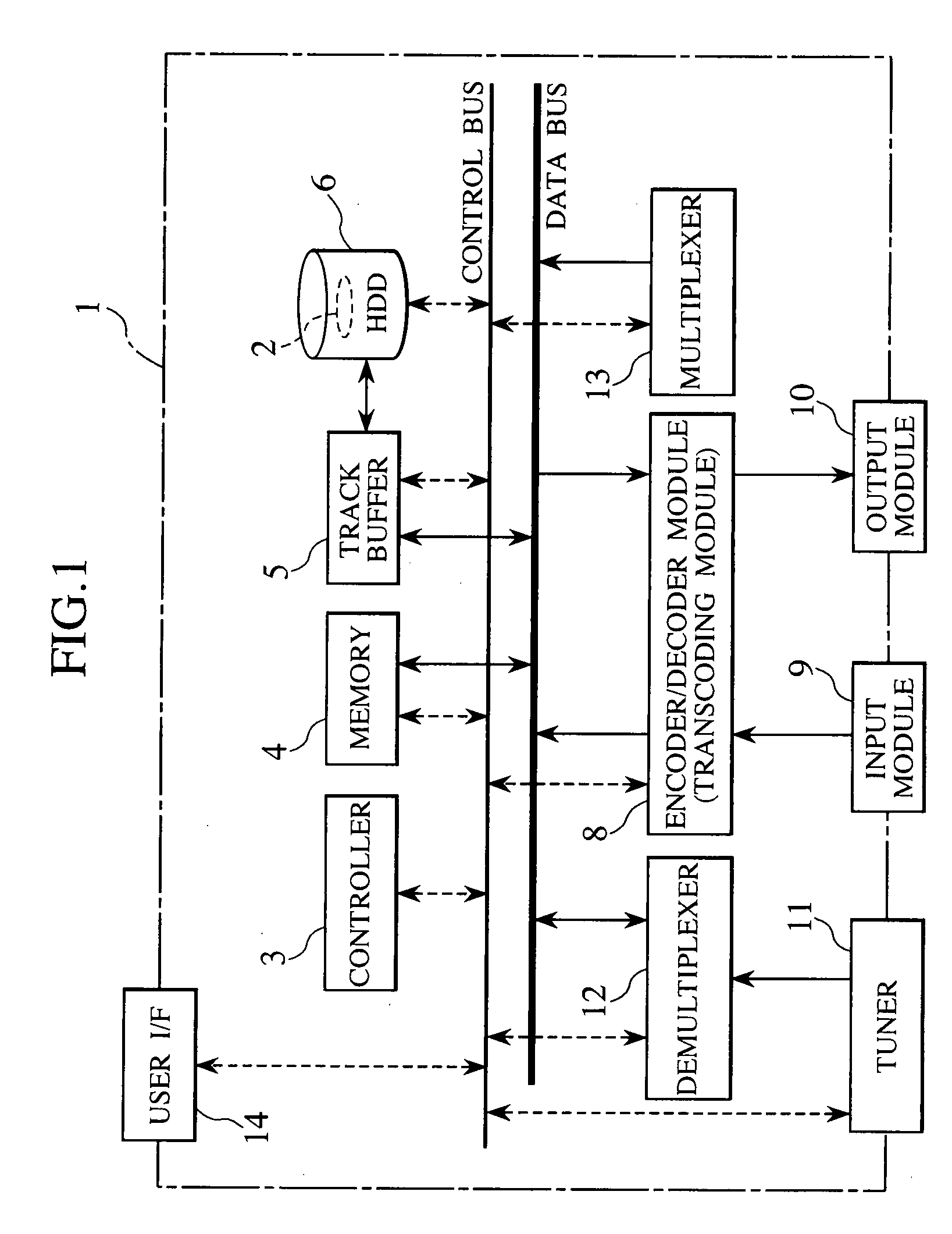

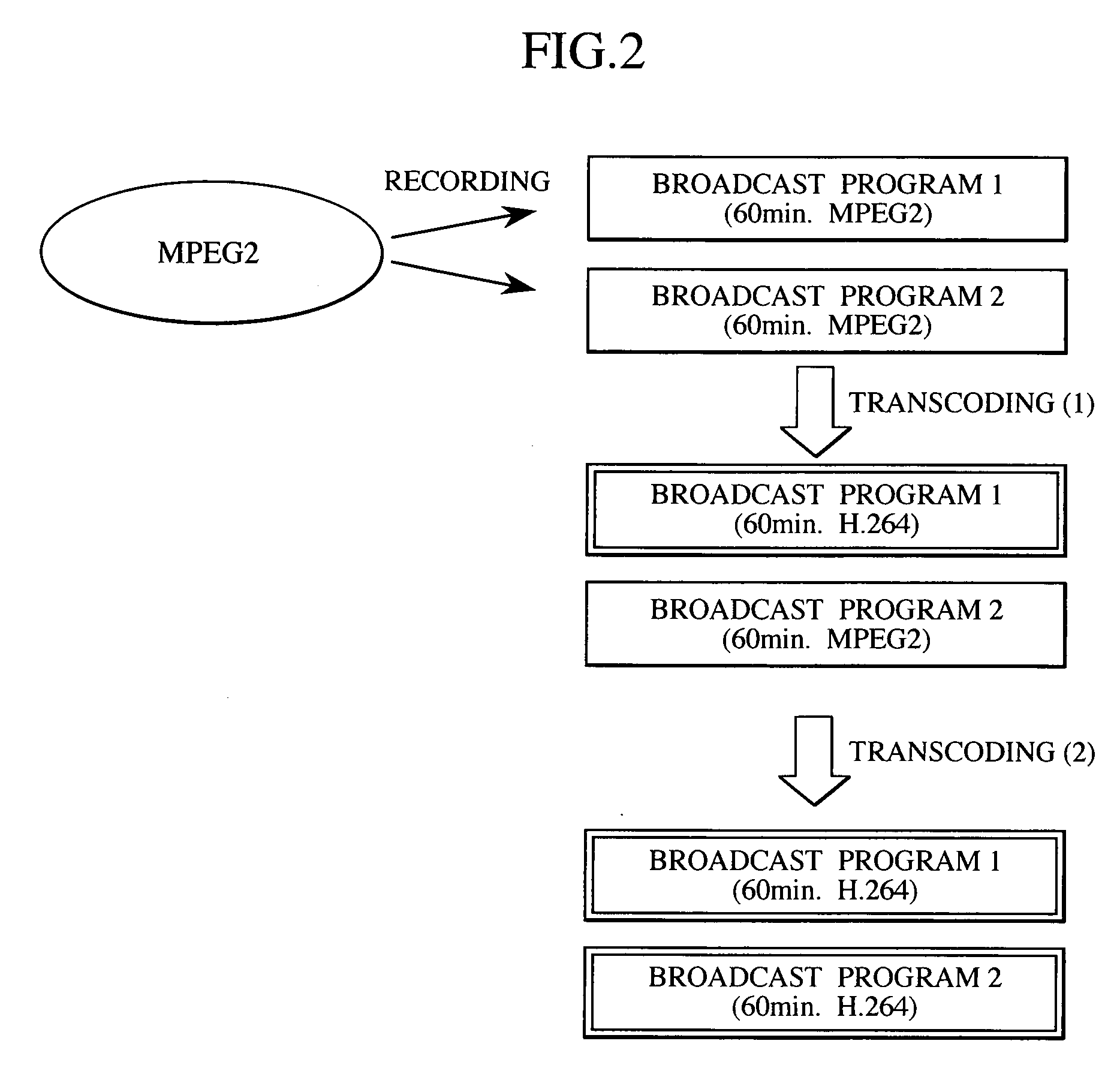

Data recording and reproducing apparatus

ActiveUS20080019666A1Satisfy processingTelevision system detailsColor television detailsTime scheduleTime segment

A recording and reproducing module records a signal (broadcast program) based on a first compression method to a recording medium, and during a period of time during which recording is not performed, reproduces the signal based on the first compression method, which has been recorded to the recording medium. Then, a transcoding module transcodes the signal based on the first compression method to a signal based on a second compression method. The signal based on the second compression method, whose transcoding has been completed, is recorded to the recording medium; and the signal based on the first compression method is erased from the recording medium. The controller refers to recording history information and sets a schedule including a target broadcast program to be transcoded and a time zone in which the target broadcast program is transcoded.

Owner:MAXELL HLDG LTD

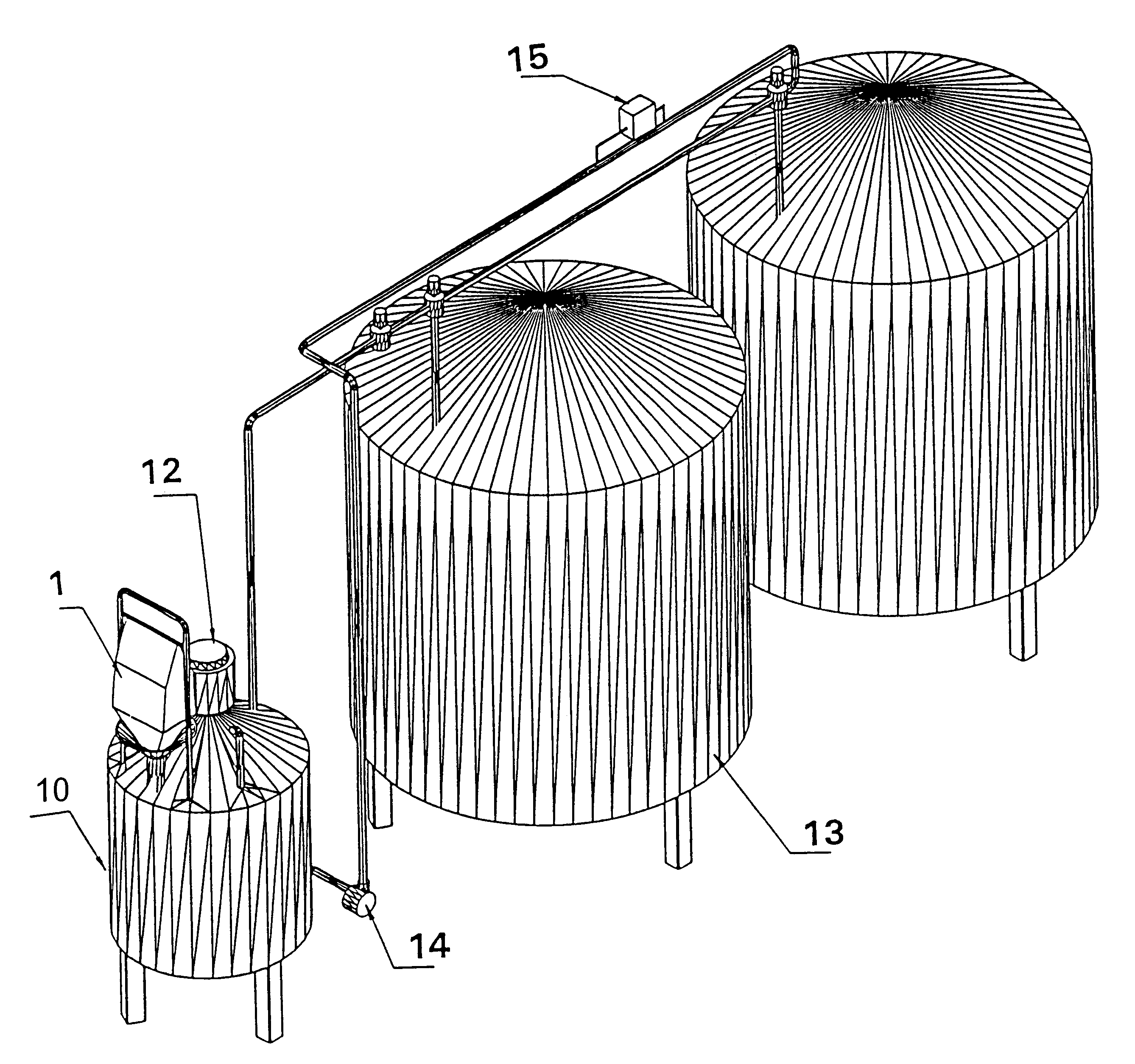

Dairy starter culture delivery system and method thereof

InactiveUS6335040B1Retain activityRetain viabilityMilk preparationCheese manufactureProduction lineEngineering

A delivery system for introduction of a starter culture directly into a dairy process line, comprising a sealed enclosure having outlet means for connecting the enclosure to the process line, the sealed enclosure containing the starter culture and / or milk clotting enzyme. The system can be used to introduce a dairy starter culture directly into a closed dairy process line without risk of contamination.

Owner:CHR HANSEN AS

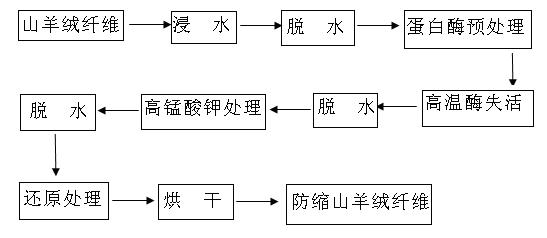

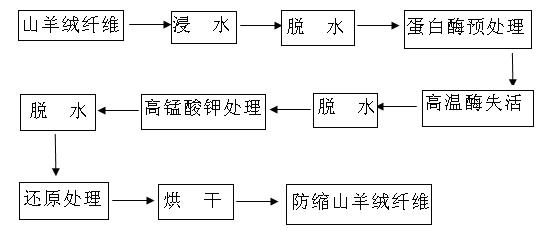

Shrink-proof treatment method for cashmere fibres

InactiveCN101929078ASatisfy processingDoes not affect colorBiochemical fibre treatmentAnimal fibresFiberWater baths

The invention discloses a shrink-proof treatment method for cashmere fibres. The method comprises the following steps of: soaking the cashmere fibres in water for 5 to 20 minutes and dehydrating the cashmere fibres; putting the cashmere fibres in 2 to 8 mass percent solution of proteinase, treating the cashmere fibres at the temperature of between 30 and 60 DEG C for 0.3 to 1 hour, and keeping the pH value between 7 and 10; placing the cashmere fibres in a water bath at the temperature of between 70 and 90 DEG C, treating the cashmere fibres for 5 to 20 minutes, and dehydrating the cashmere fibres with a centrifuge; placing the cashmere fibres in 2 to 15 mass percent solution of potassium permanganate, treating the cashmere fibres at the temperature of between 30 and 60 DEG C for 0.5 to 1 hour, keeping the pH value between 1 and 6, and dehydrating the cashmere fibres with the centrifuge; and placing the cashmere fibres in reduction treatment solution, treating the cashmere fibres at the temperature of between 30 and 60 DEG C for 10 to 20 minutes, and drying the cashmere fibres to obtain the shrink-proof cashmere fibres. The shrink-proof treatment method of the invention is applied to the occasion of mainly adopting fibre dyeing in the production of cashmere knit fabrics and woven fabrics. The cashmere fibres are subjected to shrink-proof treatment and are dyed according to production requirements, but the colours of the fibrics are not affected and the fibres subjected to shrink-proof treatment can meet the processing requirement of knit fabrics, braided fabrics and woven fabrics.

Owner:XI'AN POLYTECHNIC UNIVERSITY

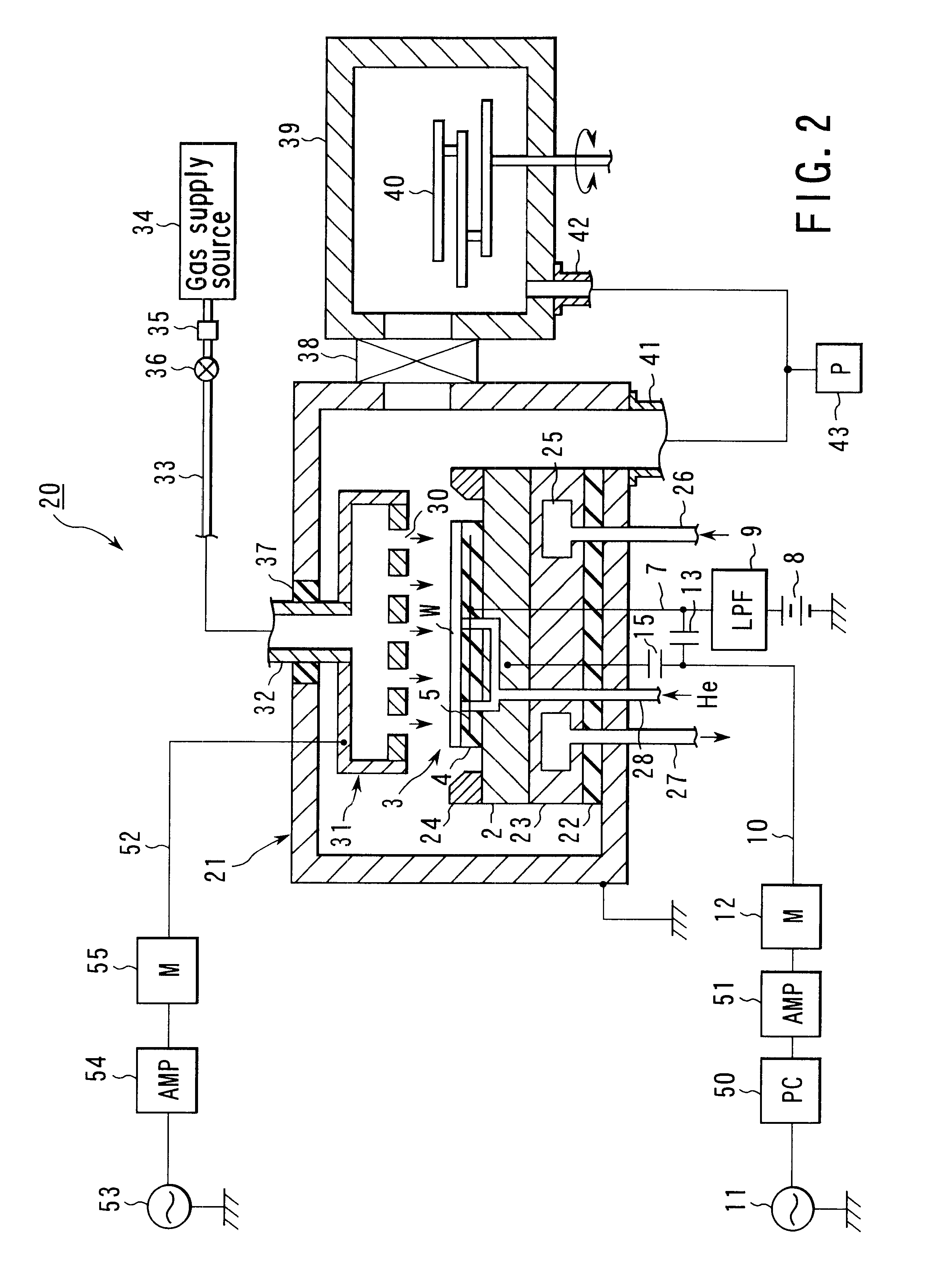

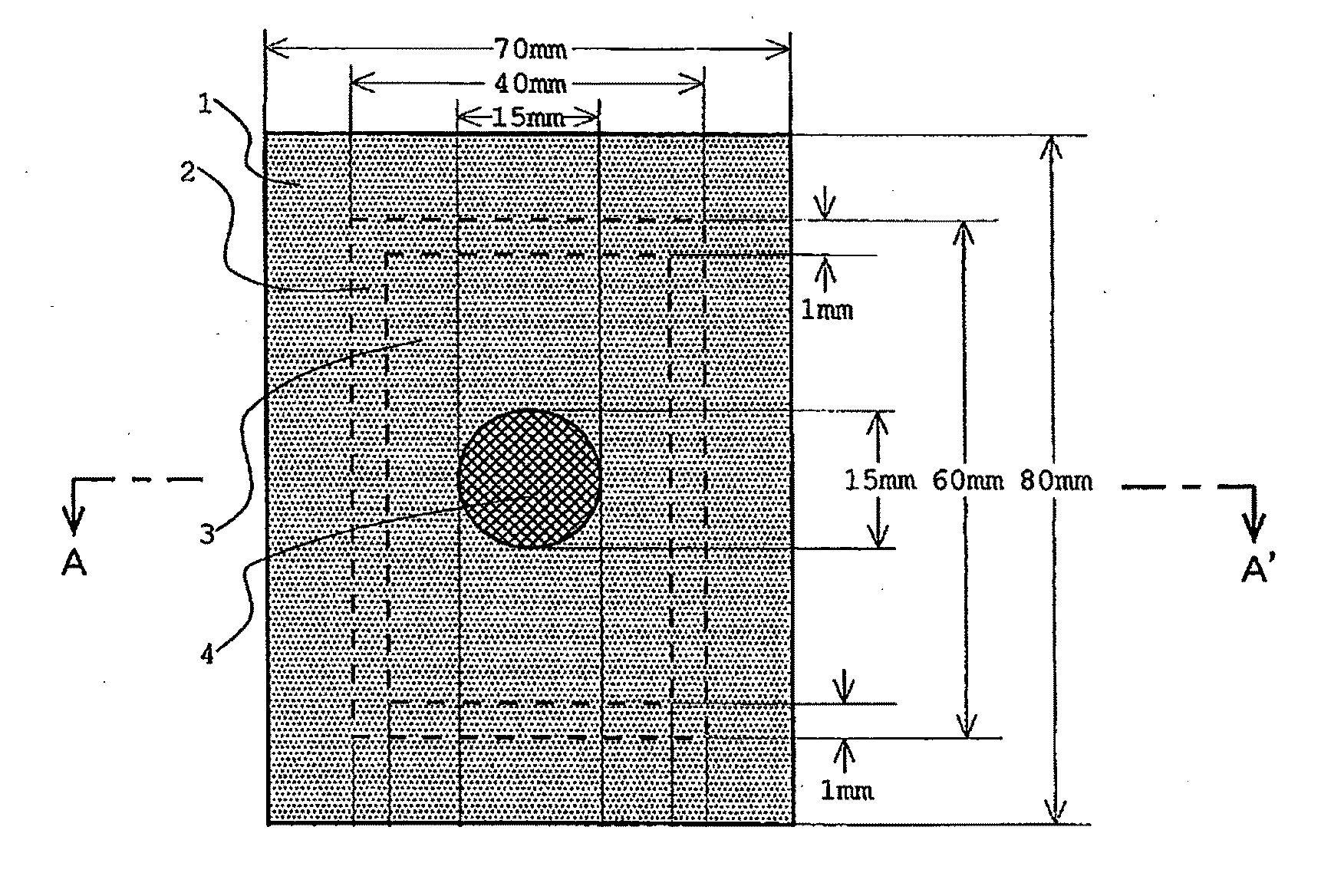

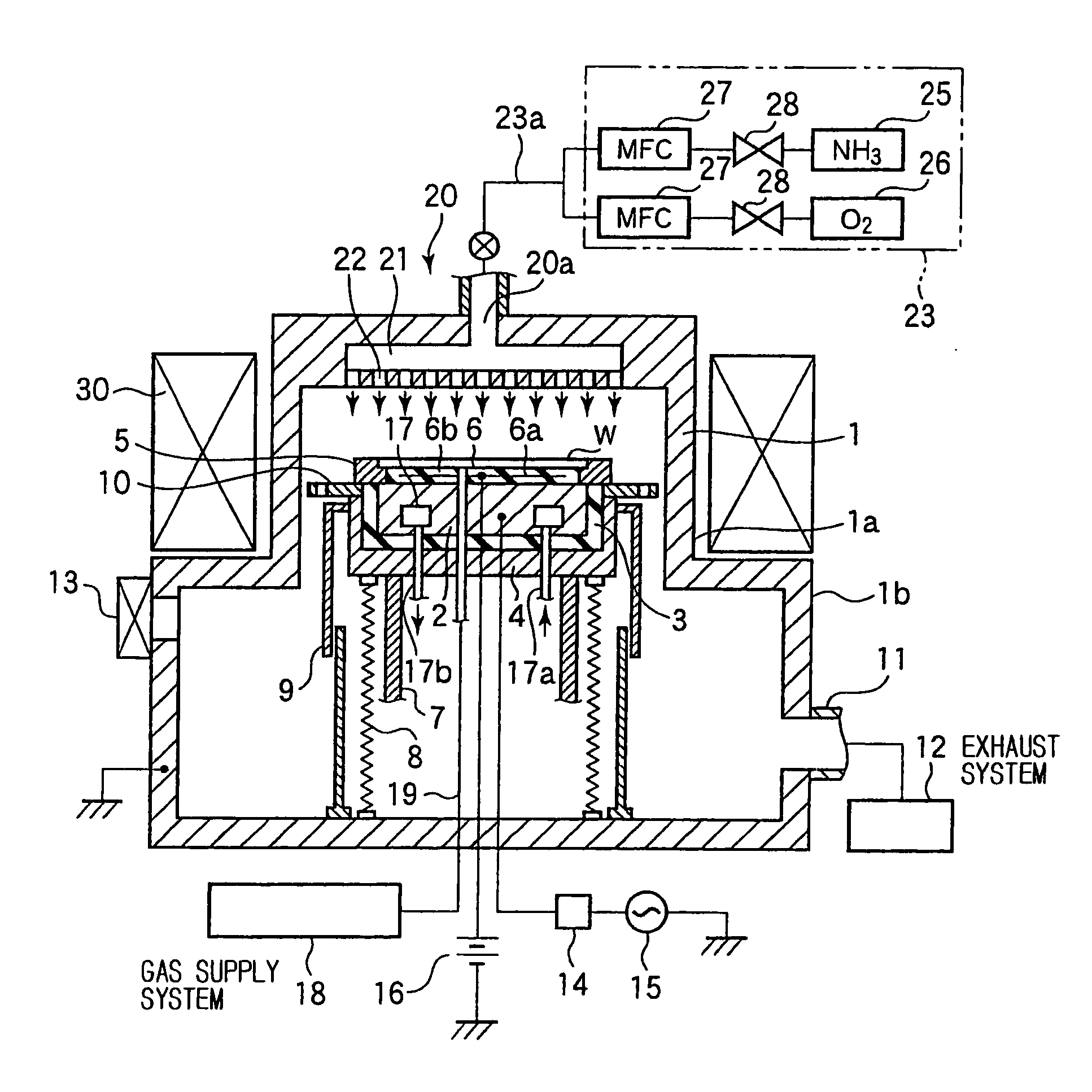

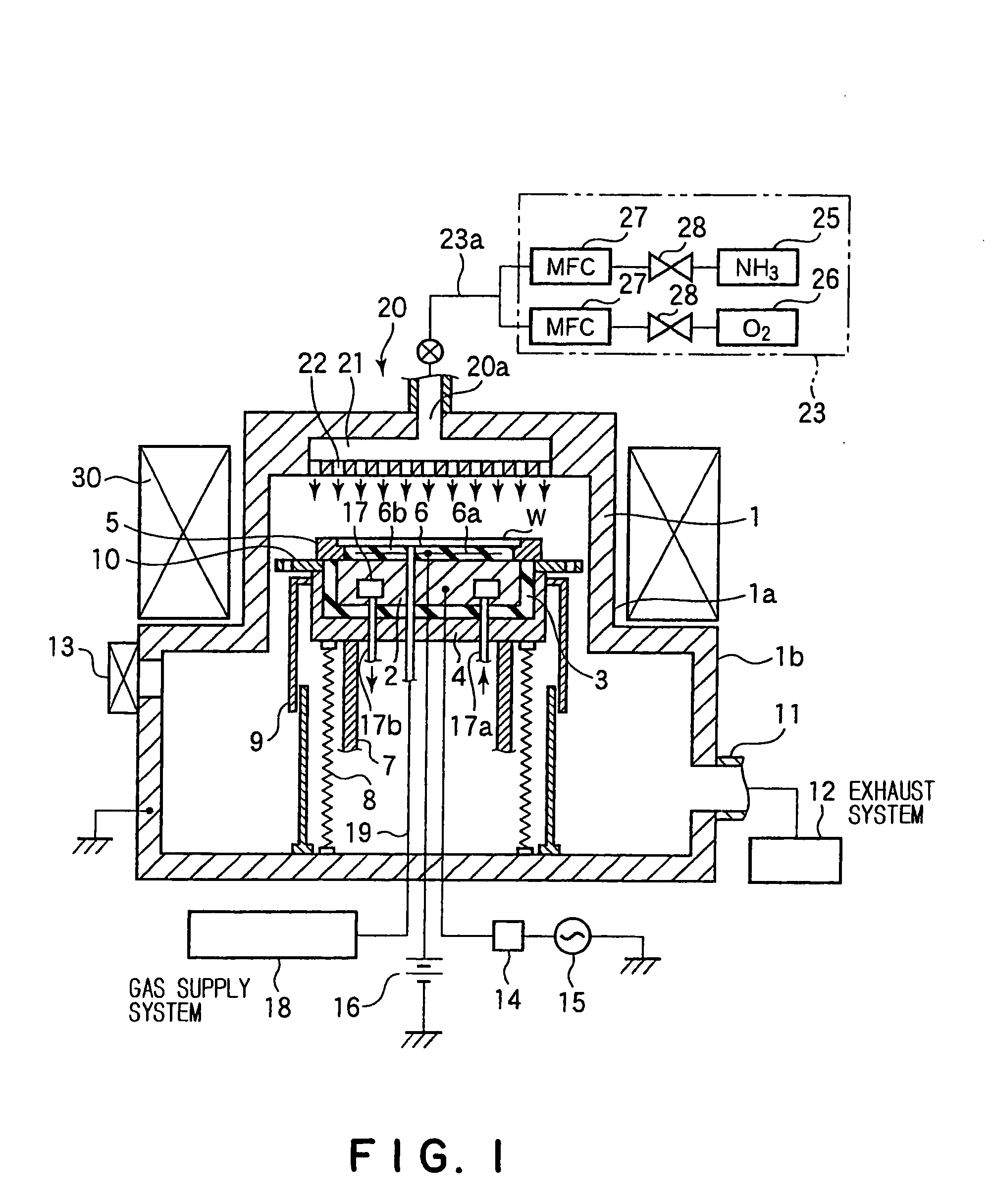

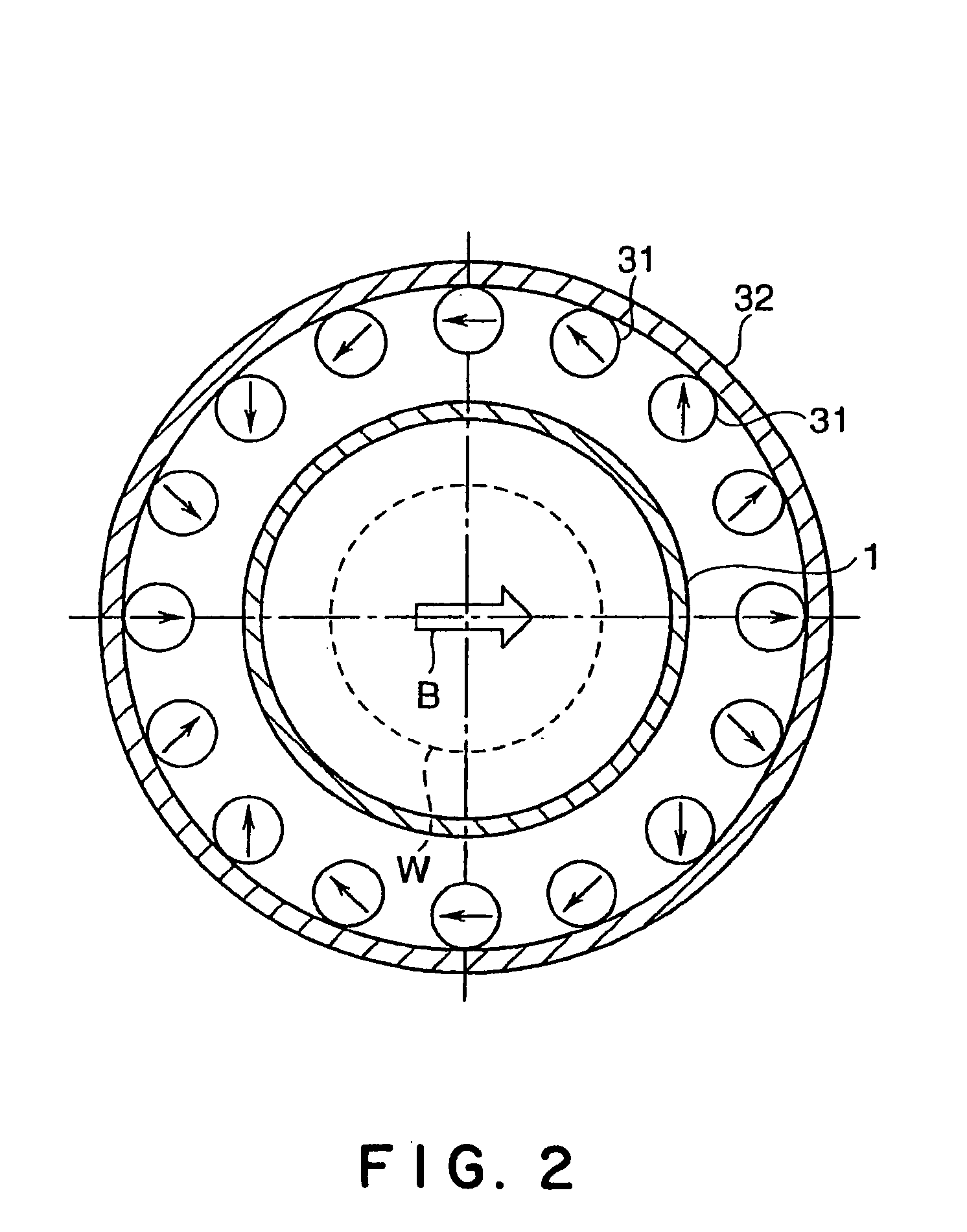

Etching method

ActiveUS20050085077A1Increase etch rateHigh in-plane uniformitySemiconductor/solid-state device manufacturingIn planeOrganic film

An etching method etches an organic film by using an inorganic film as a mask at a high etch rate, in a satisfactory etch profile in a satisfactory in-plane uniformity without causing the inorganic film to peel off. An organic film formed on a workpiece is etched by using an inorganic film as a mask with a plasma produced by discharging an etching gas in a processing vessel (1). The etching method uses a mixed gas containing NH3 gas and O2 gas for etching the organic film when the organic film is to be etched in a pattern having an opening ratio of 40% or above. The etching method uses NH3 gas as an etching gas for etching the organic film when the organic film is to be etched in a pattern having an opening ratio below 40%.

Owner:TOKYO ELECTRON LTD +1

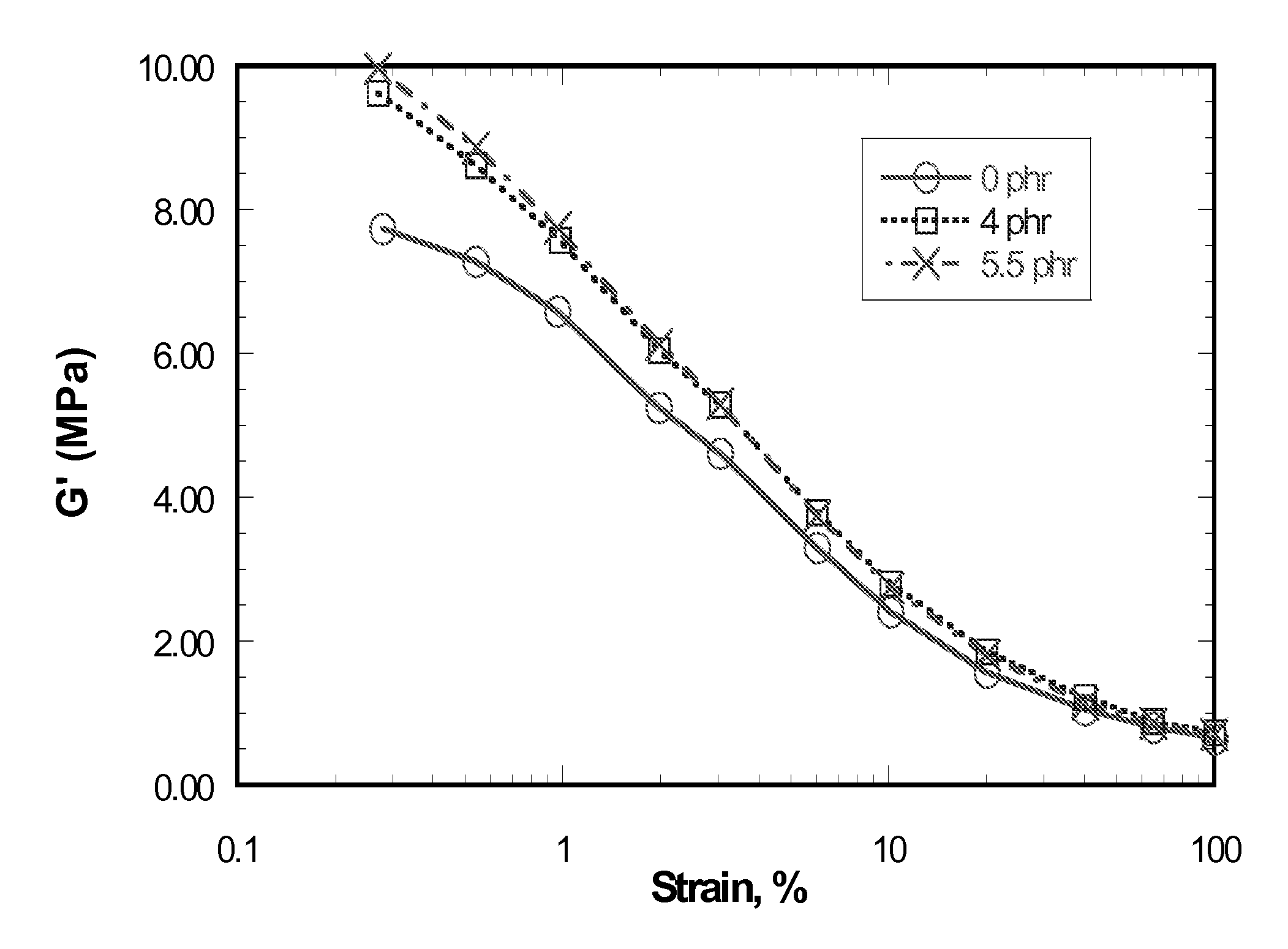

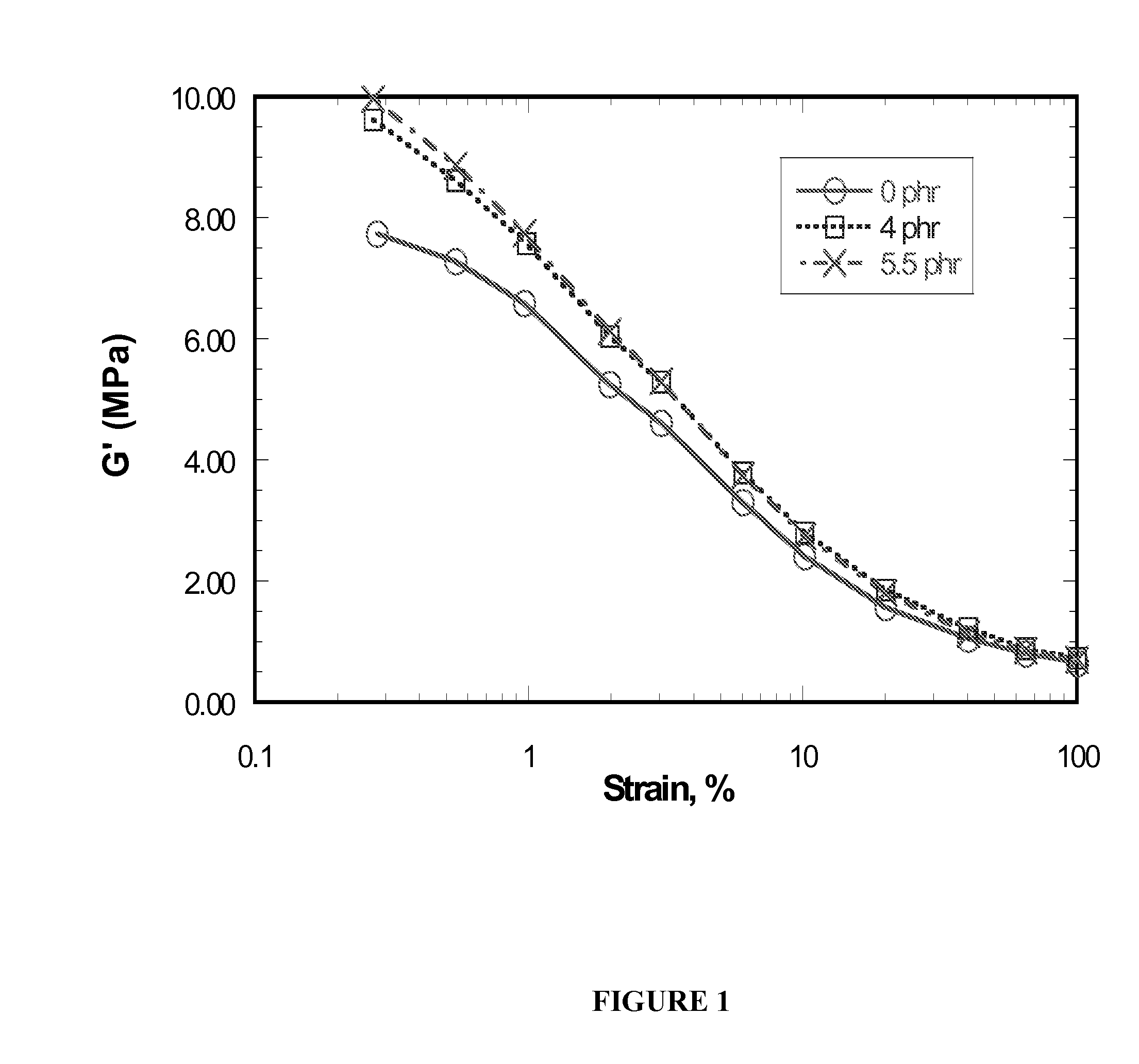

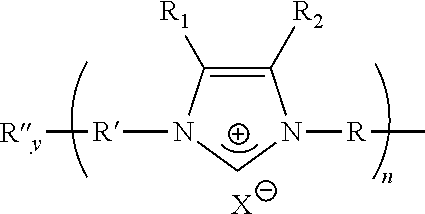

Polymerized (substituted imidazolium) for improved handling properties in silica-reinforced rubber compounds

InactiveUS20100004359A1Good physical propertiesSatisfy processingCosmetic preparationsToilet preparationsHysteresisPolymer science

It has been discovered that the use of a silica dispersing aid, a polymerized (substituted imidazolium) (PSI), in vulcanizable rubber compositions, provides an increase in the compound modulus and satisfactory processing of silica-containing rubber compounds, especially for tire components, without sacrificing other beneficial rubber properties or increasing hysteresis.

Owner:BRIDGESTONE CORP

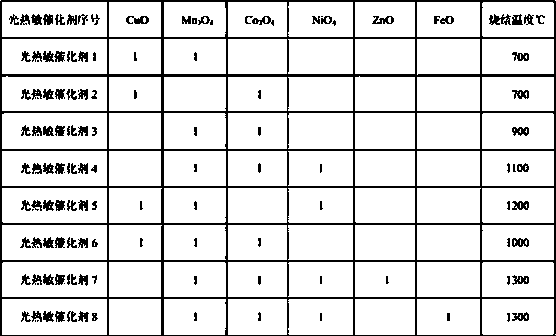

Photo-thermal cooperatively controllably degradable high-molecular composite mater batch and preparation method thereof

InactiveCN103642109AMaintain basic physical and chemical propertiesSatisfy processingPtru catalystMetallurgy

The invention discloses a photo-thermal cooperatively controllably degradable high-molecular composite mater batch and a preparation method thereof. The master batch comprises the components in parts by weight: 0.5-4 parts of a photo-thermal sensitive catalyst, 80-95 parts of a high-molecular material, 0.1-2 parts of an anti-oxidant and 0.025-0.2 part of a coupling agent. The preparation method comprises: mixing metal oxides, grinding finely and performing high-temperature sintering to obtain the photo-thermal sensitive catalyst; performing surface activation on the photo-thermal sensitive catalyst by employing the coupling agent; and then beforehand mixing with the anti-oxidant and the high-molecular material, then performing extrusion by a double screw extruder, cooling and granulating to obtain the master batch. The master batch provided by the invention is capable of regulating the degradation induction period and expanding the application scope by adding the master batch into synthetic high molecules according to different ratios.

Owner:SOUTHWEAT UNIV OF SCI & TECH

UV gravure RFID printing ink and preparation method thereof

The invention discloses UV gravure RFID printing ink and a preparation method thereof; the UV gravure RFID printing ink comprises, by weight:10-30 parts of petroleum resin, 10-30 parts of acrylic acid prepolymer, 0.1-1 part of a polymerization inhibitor, 5-12 parts of a photoinitiator, 5-10 parts of pigment, 1-5 parts of a dispersant, and 20-50 parts of acrylic acid monomers. The UV gravure RFID printing ink of the invention has the following beneficial effects: the printing ink is suitable for gravure press and flexo-graphic machines, is instantly dried by an ultraviolet lamp, which greatly increases the working efficiency. After dried, the printing ink can resist strong acid etching; the concentration of the etching acid can be adjusted at will; the etching solution temperature can be increased; the etching time can be increased; and thus processing of various RFID labels can be met. After drying and etching, the printing ink is easy to be washed by alkalis, and a 3% NaOH solution can remove the ink within 5-20 seconds. The line surface is effectively maintained to be clean and free of printing ink residues, and thus the final product quality is ensured.

Owner:杭华油墨股份有限公司

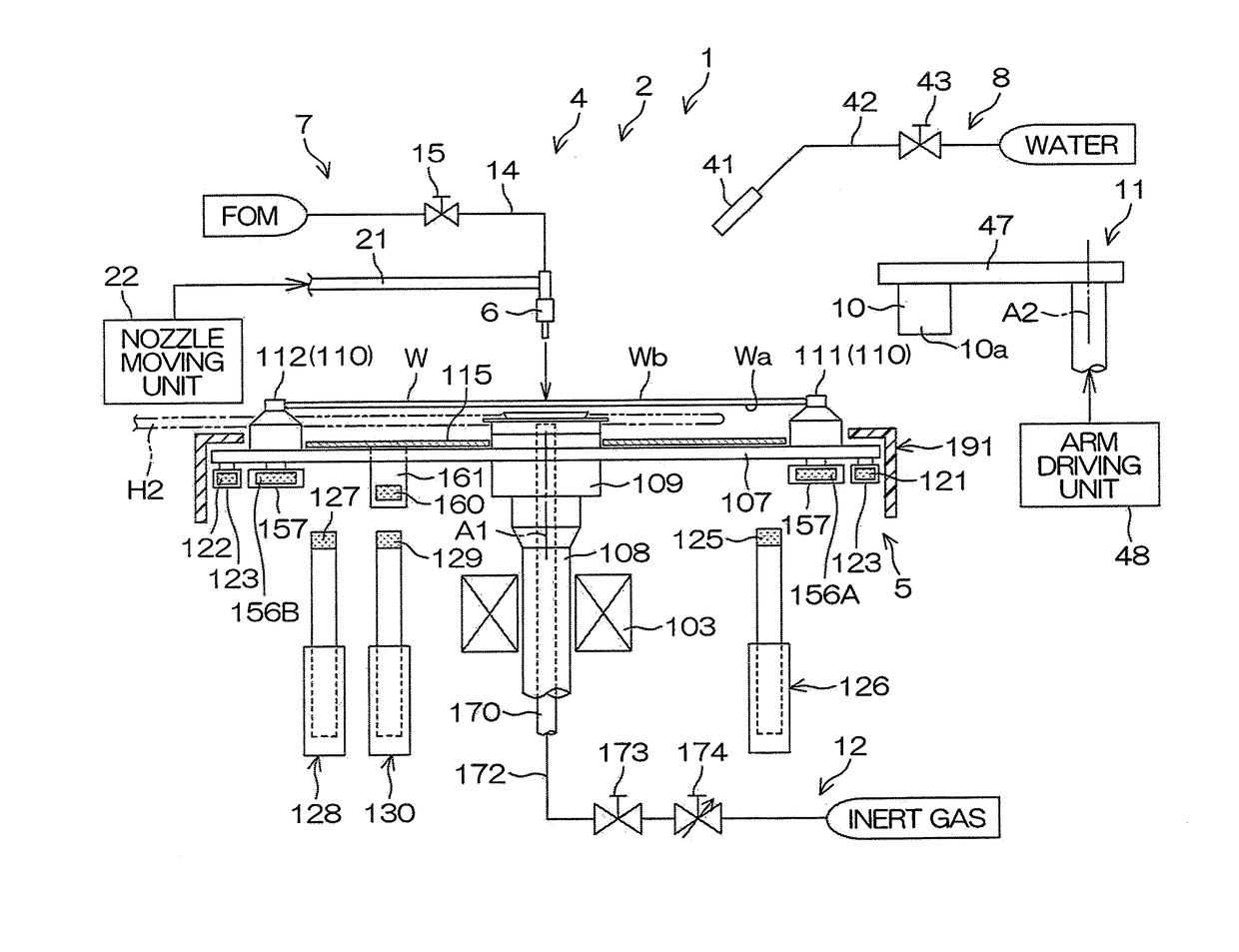

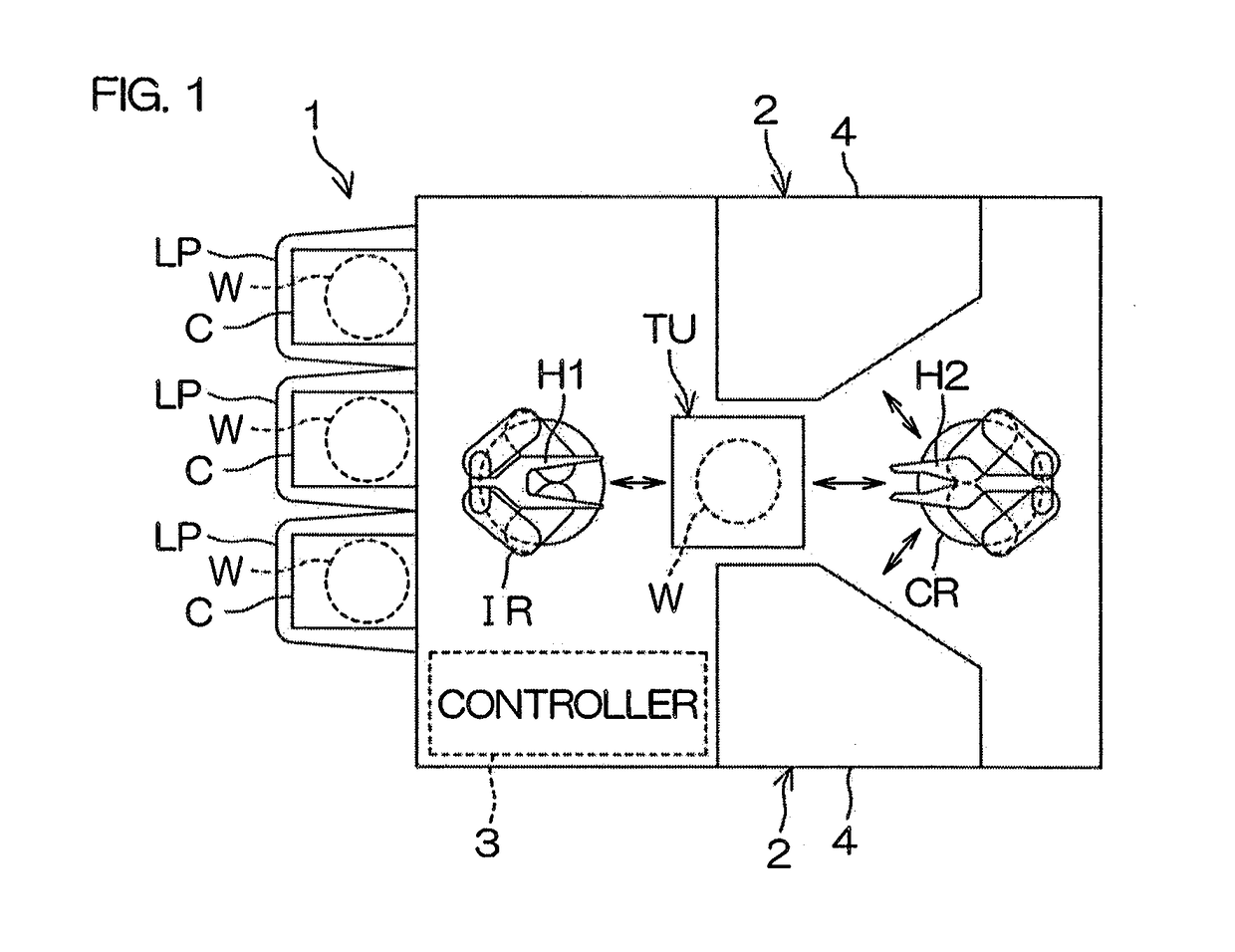

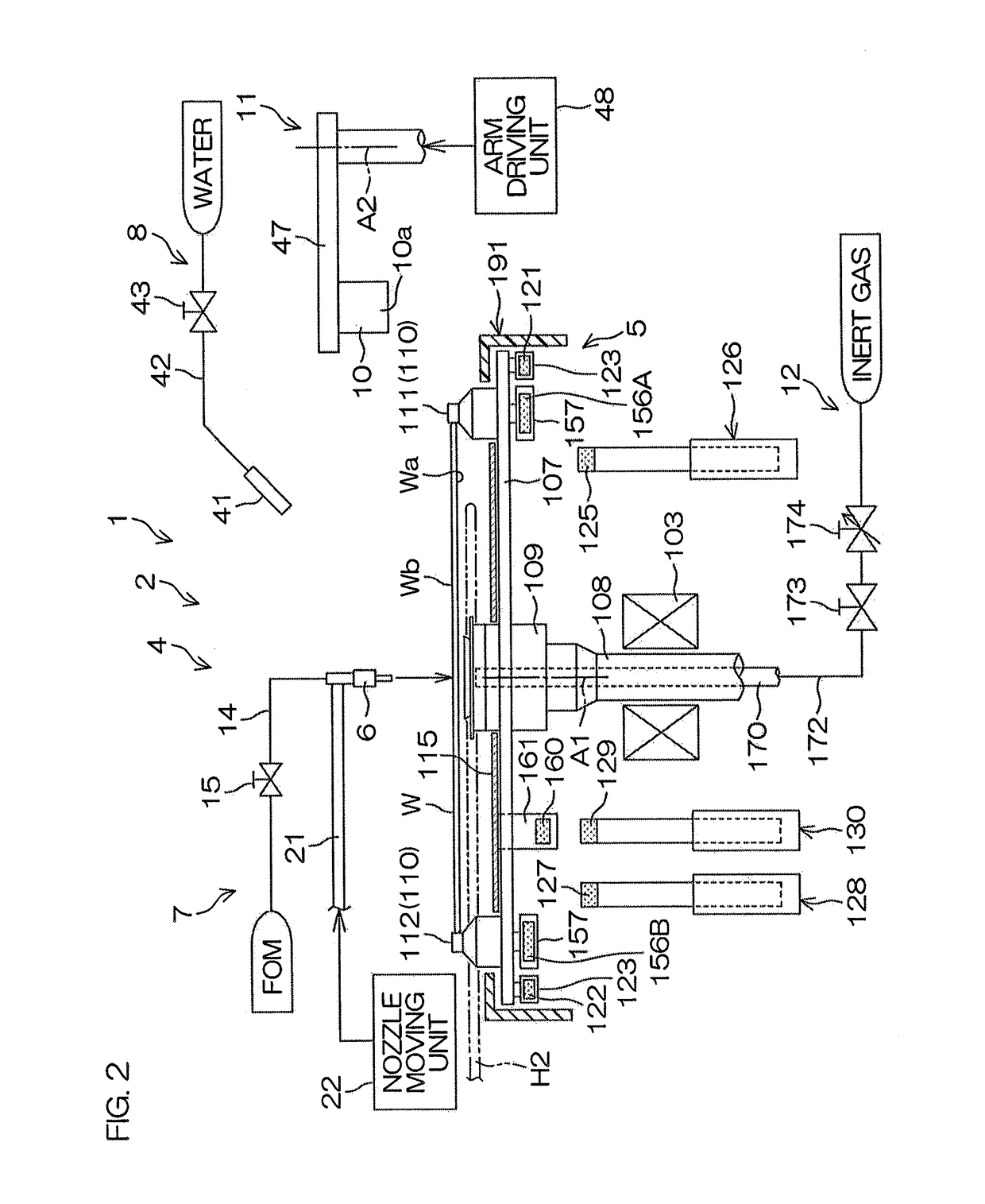

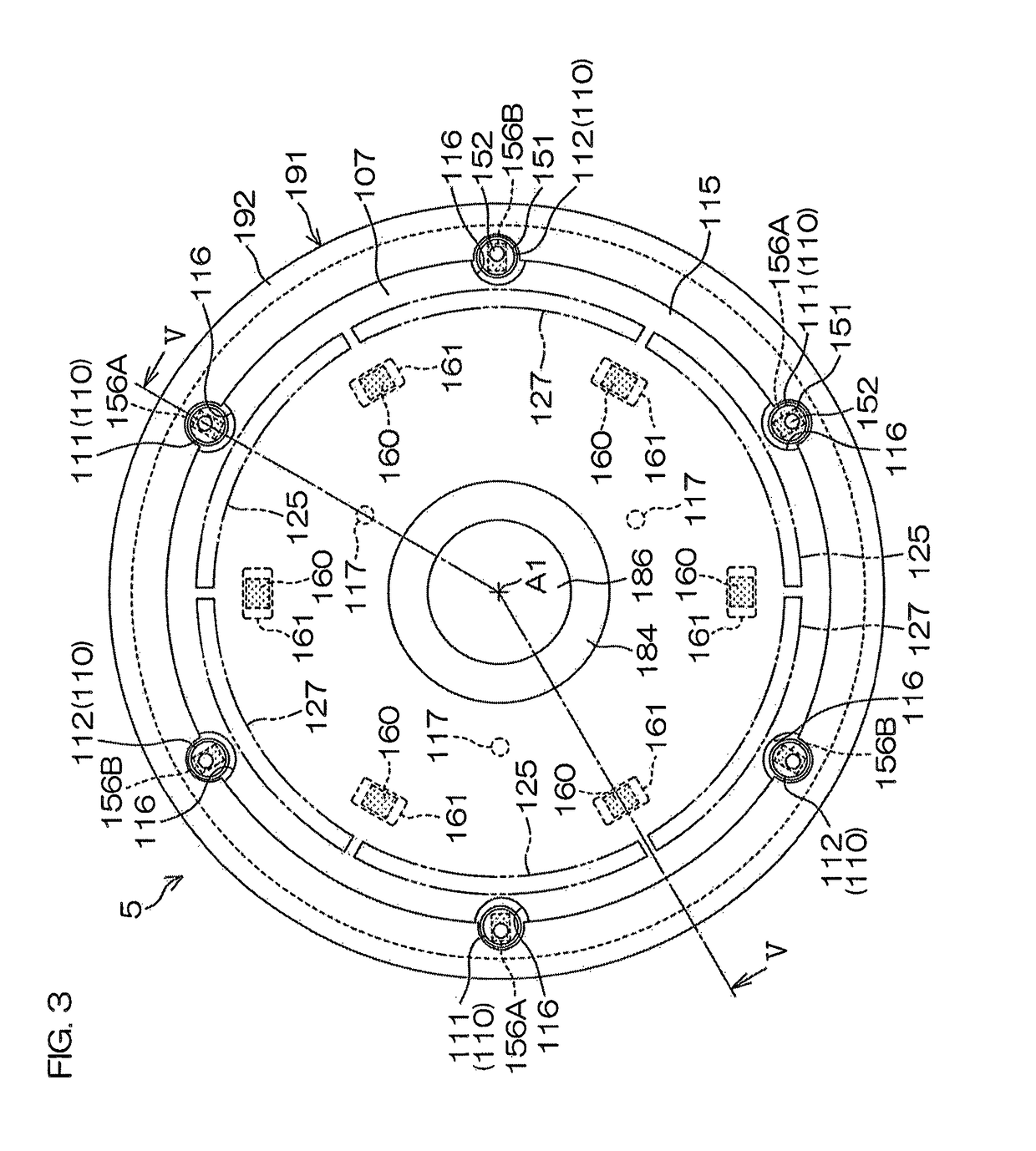

Substrate holding/rotating device, substrate processing apparatus including the same, and substrate processing method

ActiveUS20170092532A1Satisfy processingEasy positioningSemiconductor/solid-state device manufacturingFlexible article cleaningMagnetic polesEngineering

A substrate holding / rotating device includes an urging unit, urging support portions of movable pins to either an open position or a hold position, first and second driving magnets, mounted in correspondence to respective movable pins of respective first and second movable pin groups and having mutually opposite magnetic pole directions, a first moving magnet, for urging the support portions of the first movable pin group to the other of either the open position or the hold position, and a second moving magnet, for urging the support portions of the second movable pin group to the other of either the open position or the hold position.

Owner:DAINIPPON SCREEN MTG CO LTD

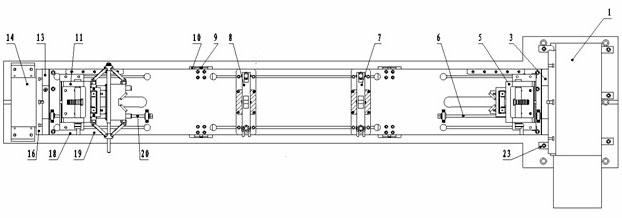

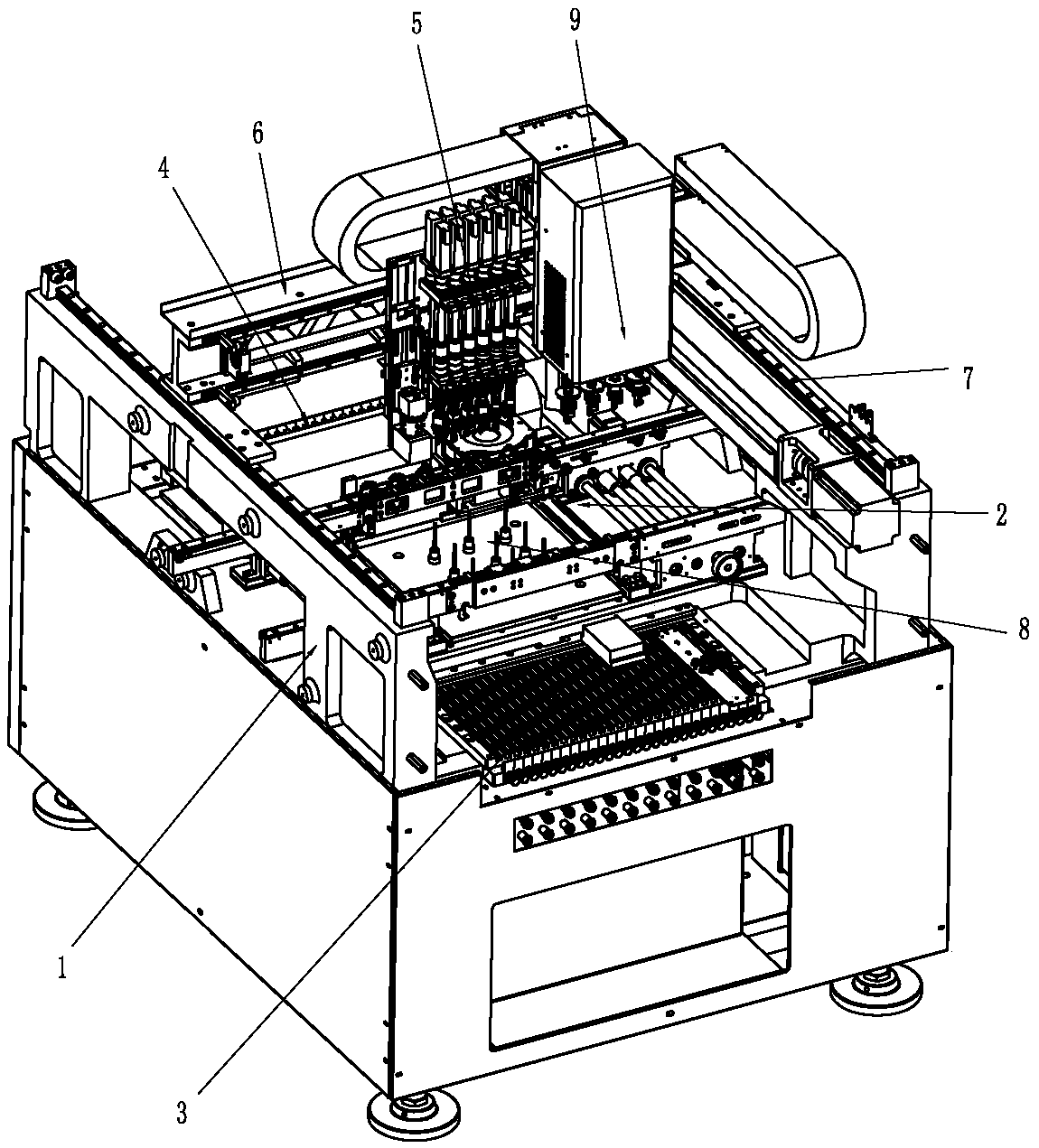

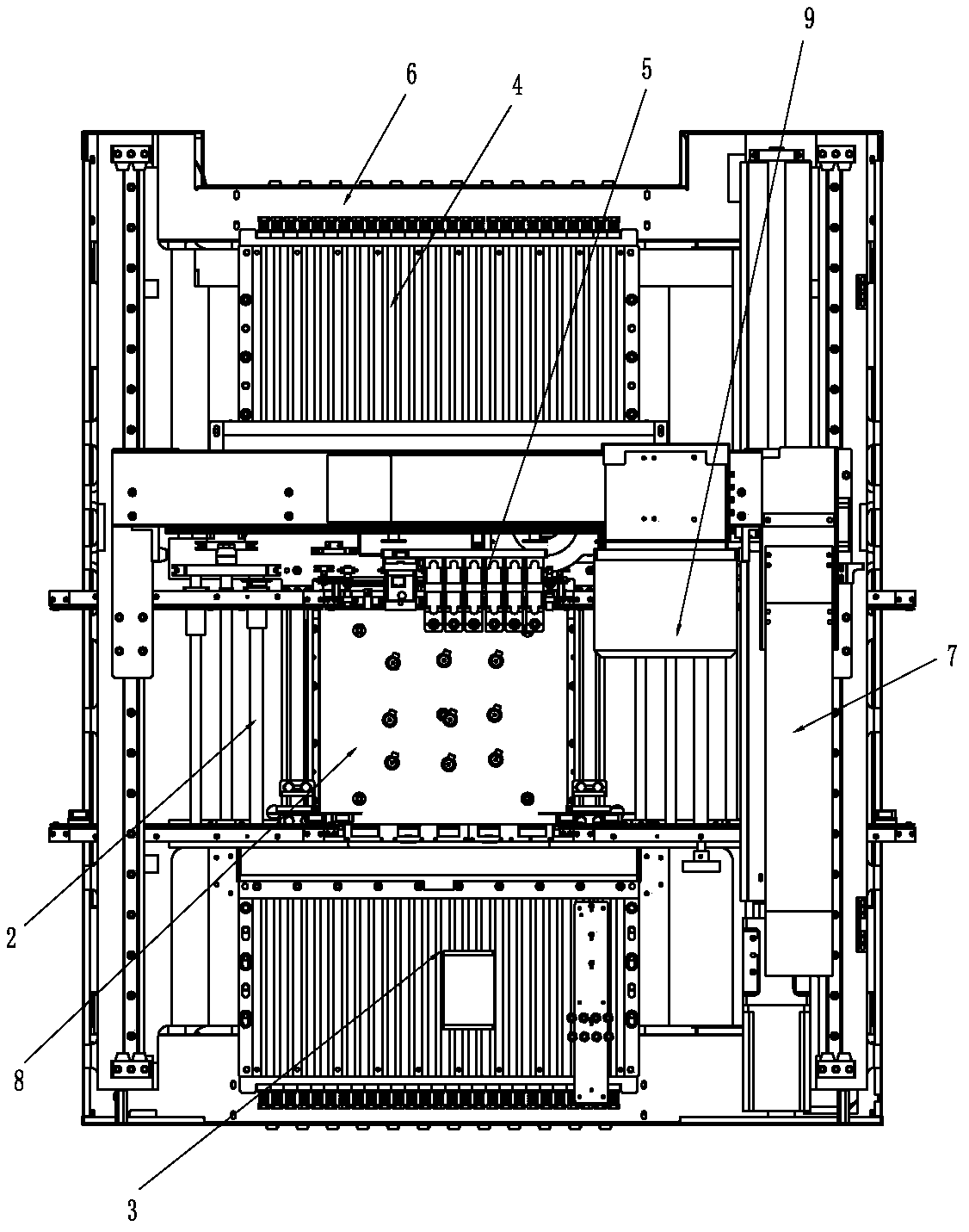

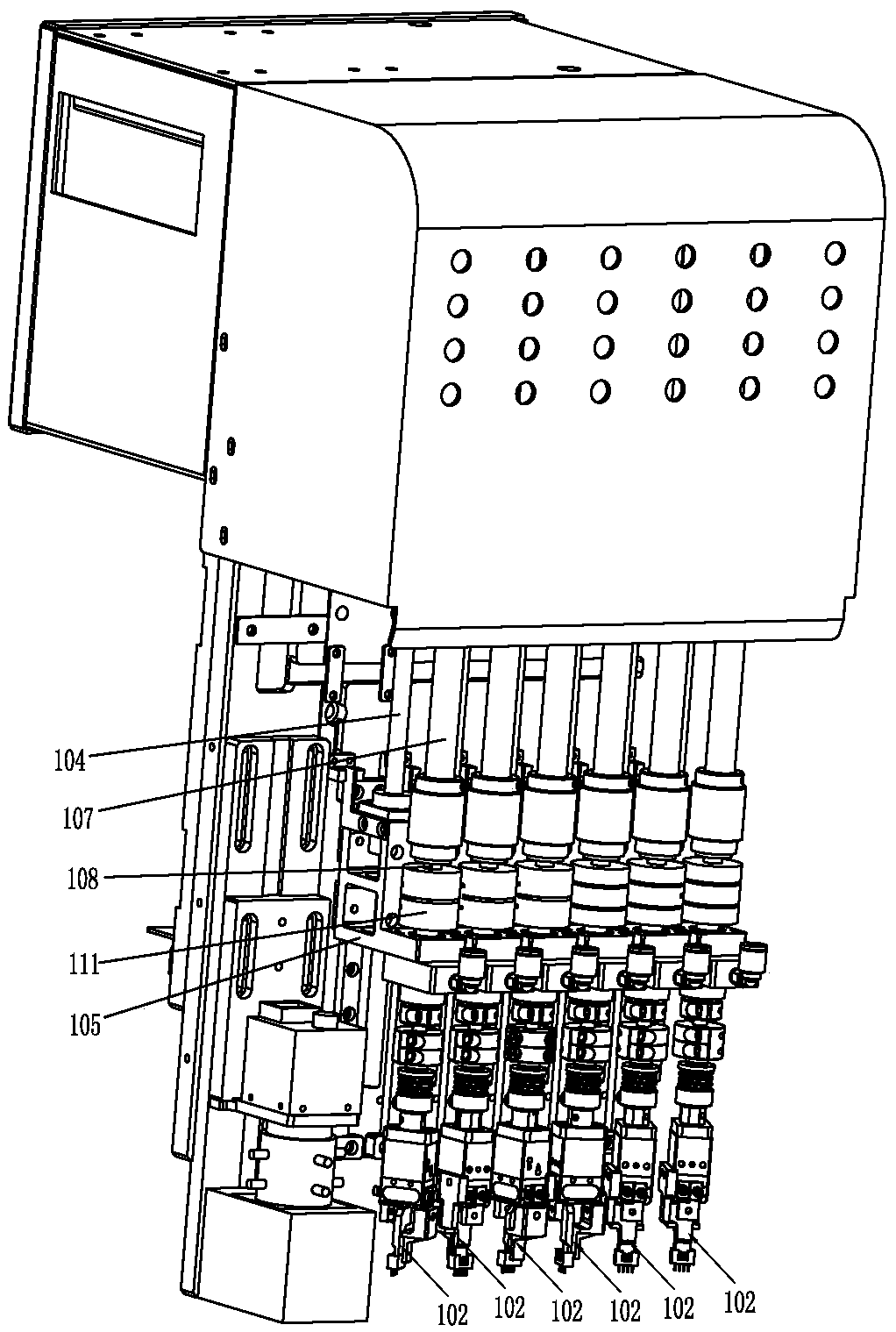

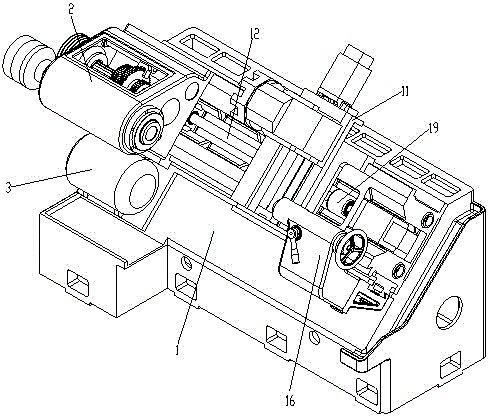

Efficient and accurate automatic component insertion machine

PendingCN109462976AHigh running precisionPrecise positioningElectrical componentsEngineeringInsertion - action

The invention discloses an efficient and accurate automatic component insertion machine. The component insertion machine comprises a rack assembly, and a PCB conveying track, a feeding device, a discharging device and a component insertion machine head which are arranged on the rack assembly; the feeding device and the discharging device are arranged on the two sides of the PCB conveying track respectively; the component insertion machine head is movably arranged above the PCB conveying track; the PCB conveying track comprises a fixed track assembly and a movable track assembly which are arranged oppositely; an adjustable conveying track is formed between the fixed track assembly and the movable track assembly, and can be applied to the component insertion machining of PCBs with various width specifications, so that the universality of equipment is improved; the component insertion machine head comprises a machine head base and a plurality of component insertion mechanical arms mountedon the machine head base; each component insertion mechanical arm is independently connected with a driving assembly; and each driving assembly comprises a lifting motor, a lifting screw rod, a sliding seat, a rotary motor, a spline shaft sleeve and a spline shaft. Therefore, the running precision of the automatic component insertion machine is higher, the precision of a component insertion action is higher, and the action is quicker and more efficient.

Owner:东莞市南部佳永电子有限公司

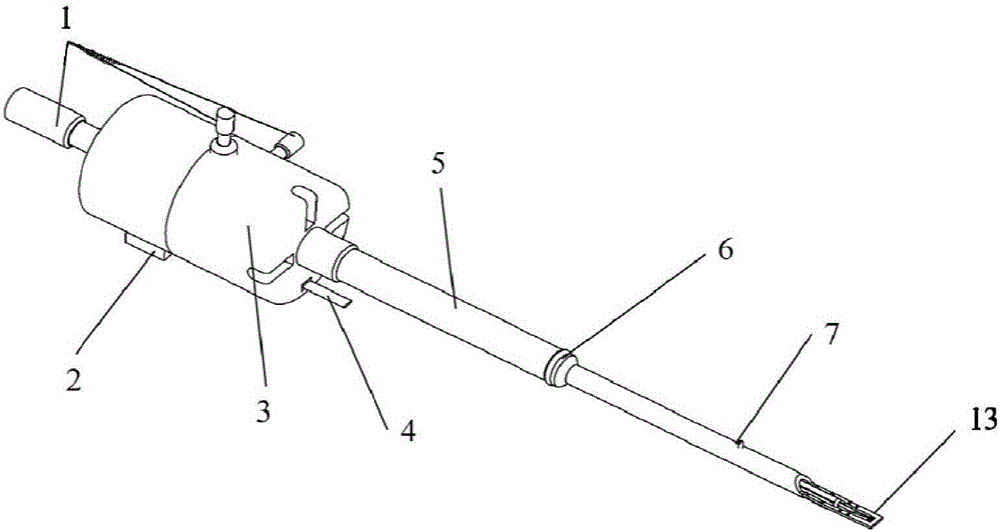

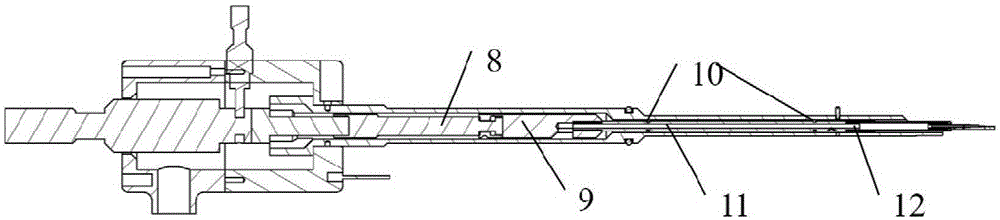

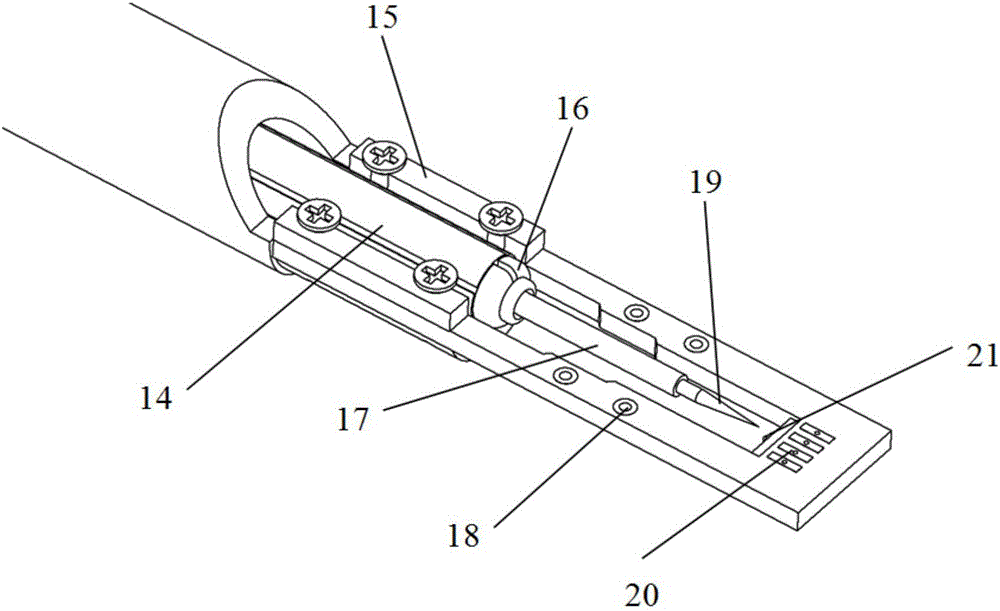

Scalable force and electric field transmission electron microscope in situ sample rod

InactiveCN106057618AReduce difficultyReduce the difficulty of operationElectric discharge tubesElectricityConventional transmission electron microscope

The invention provides a scalable force and electric field transmission electron microscope in situ sample rod which comprises a coarse adjusting device, a signal adapter, a sample rod shell, a coarse adjustment adapter, a switching fixed rod, a coaxial ring, a transmission rod, a piezoelectric ceramic holder, a sample rod head, a piezoelectric ceramic tube, a fixed part, a needle fixed device, a conductive needle tube, a conductive electrode, a nano tip and a test electrode. Test and the control signal lines are inserted into the signal adapter, the electrical control connection of an external control testing module and the piezoelectric ceramic tube, the nano tip and a sample is realized. After the sample rod is inserted into a transmission electron microscope, the coarse adjusting device is controlled to accurately move the nano tip to the fine adjustment range of the sample, through adjusting the driving signal of the external control testing module, the in situ deformation of the piezoelectric ceramic tube is controlled, thus the nano tip is controlled to accurately move in a nano level in a fine adjustment range, finally the mechanical and optical contact of the nano tip and a testing sample is realized, and a force and electric performance in situ experiment is completed.

Owner:LANZHOU UNIVERSITY

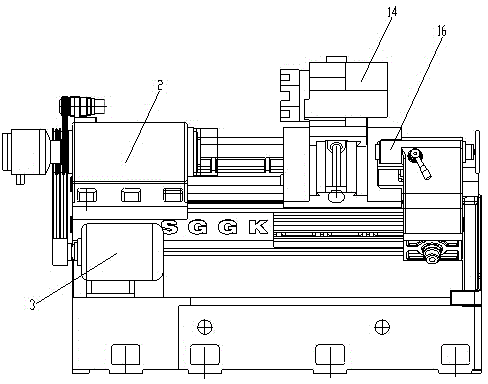

High-rigidity hard-guide-rail inclined numerical control lathe

InactiveCN104475767AImprove rigidityImprove processing efficiencyAutomatic/semiautomatic turning machinesFeeding apparatusNumerical controlEngineering

The invention relates to a high-rigidity hard-guide-rail inclined numerical control lathe which comprises a lathe body, a spindle box device, a main motor, a hydraulic tailstock device and a power tool turret mechanism. The lathe body is a split lathe body inclining by 45 degrees, the spindle box device is arranged at one end of the lathe body and connected with the main motor arranged on the lathe body in an inclined manner, the hydraulic tailstock device is arranged at the other end of the lathe body, and the power tool turret mechanism is arranged between the spindle box device and the hydraulic tailstock device. The high-rigidity hard-guide-rail inclined numerical control lathe is high in rigidity, machining efficiency and chip removing capability, easy in tensioning of a belt and capable of automatically programming rotating speed of a spindle for automatic gear shifting according to a machining process, meets needs on machining high-accuracy parts well, is suitable for most machining enterprises and has high practical value and popularization value.

Owner:YANCHENG SUGONG GAOKE MACHINERY CO LTD

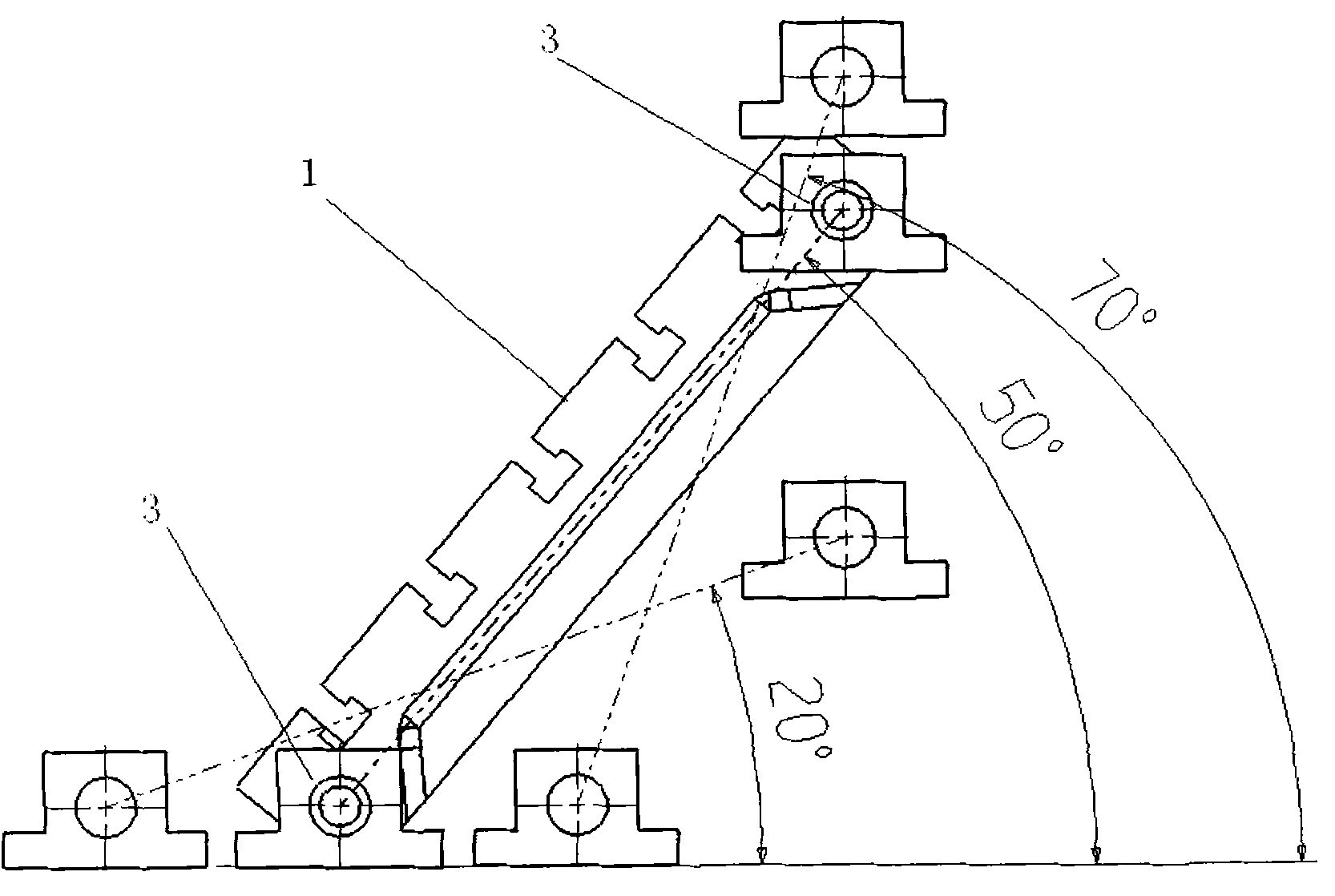

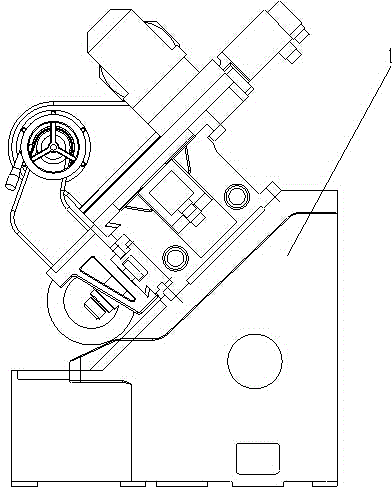

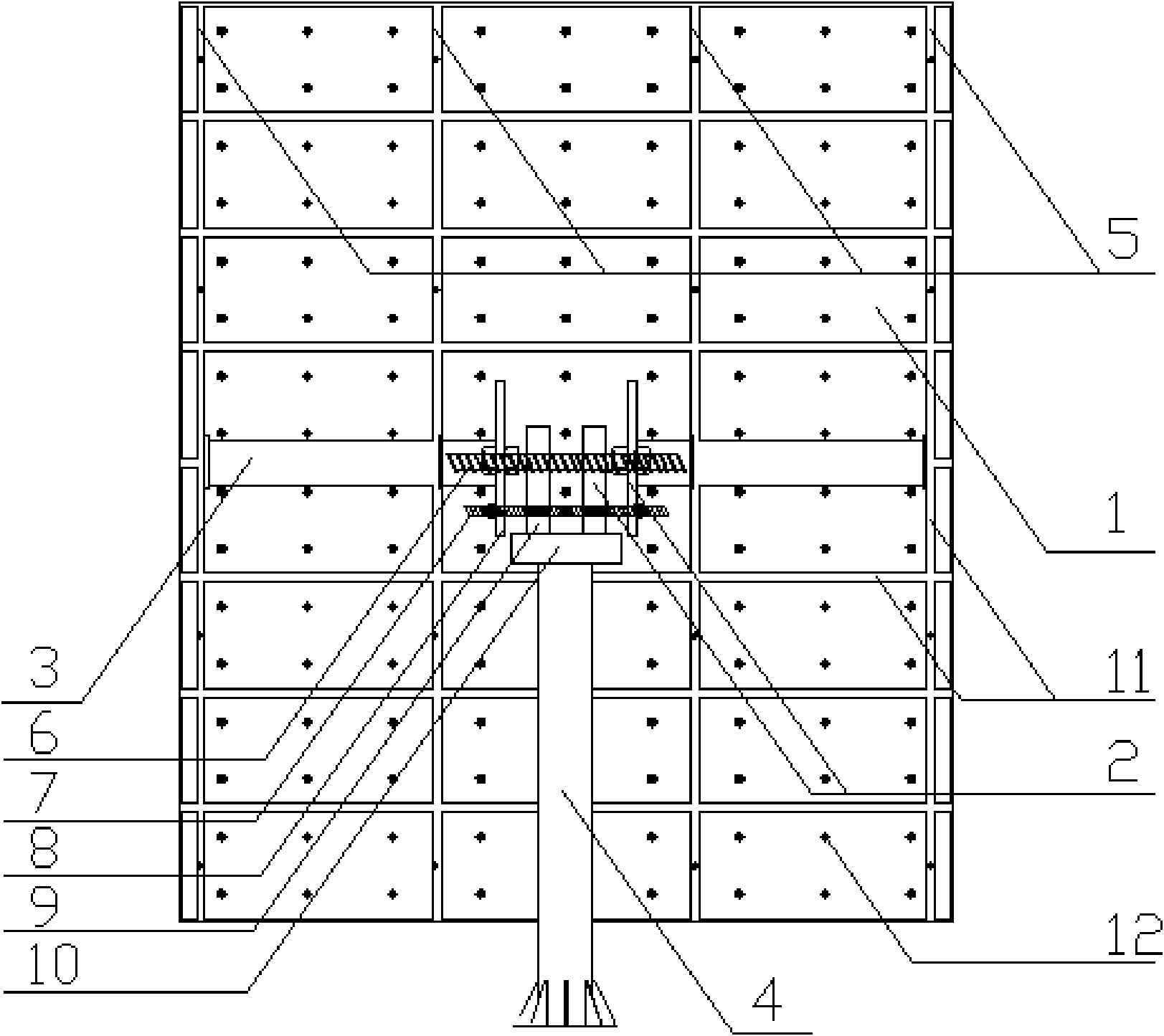

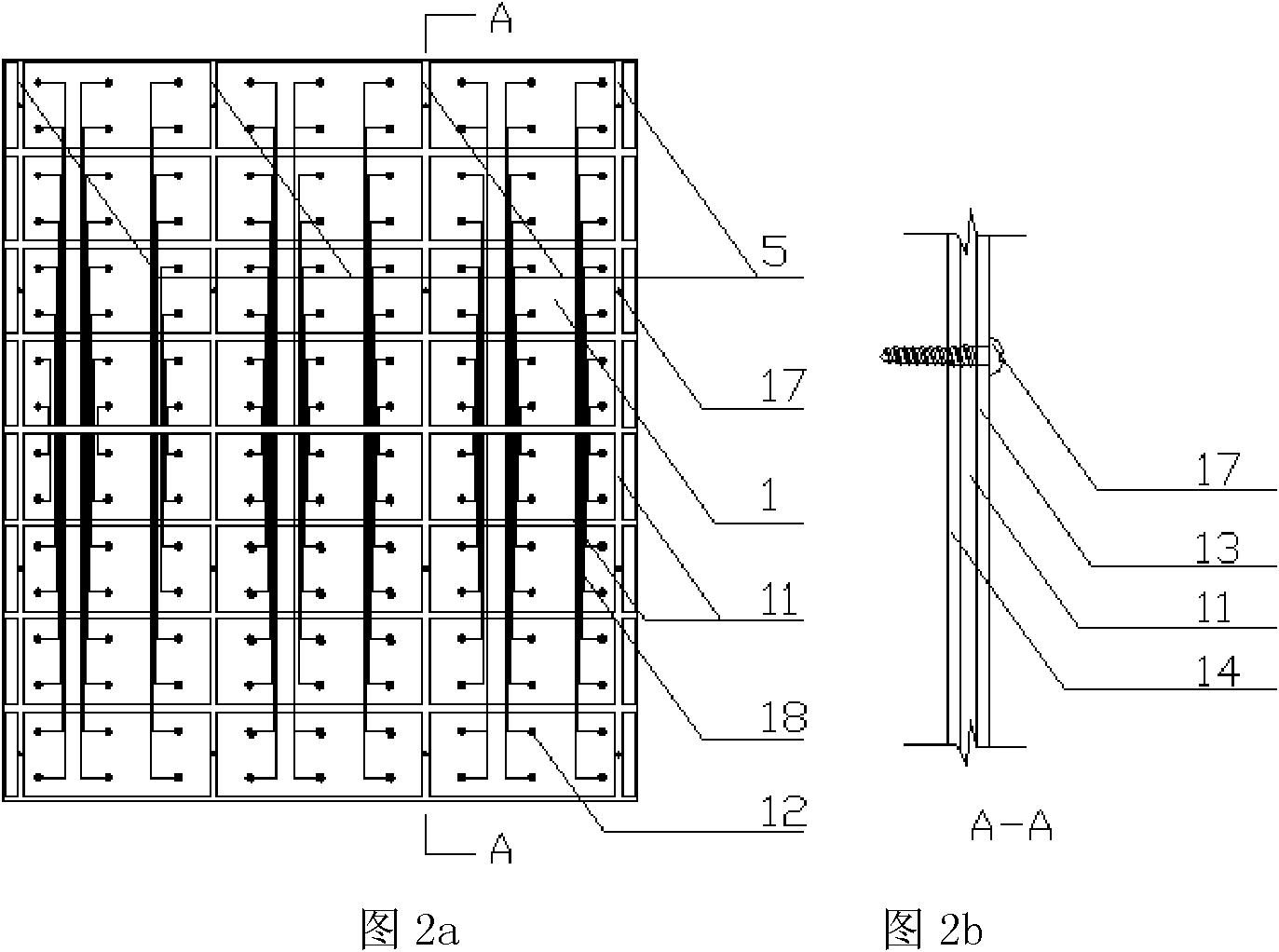

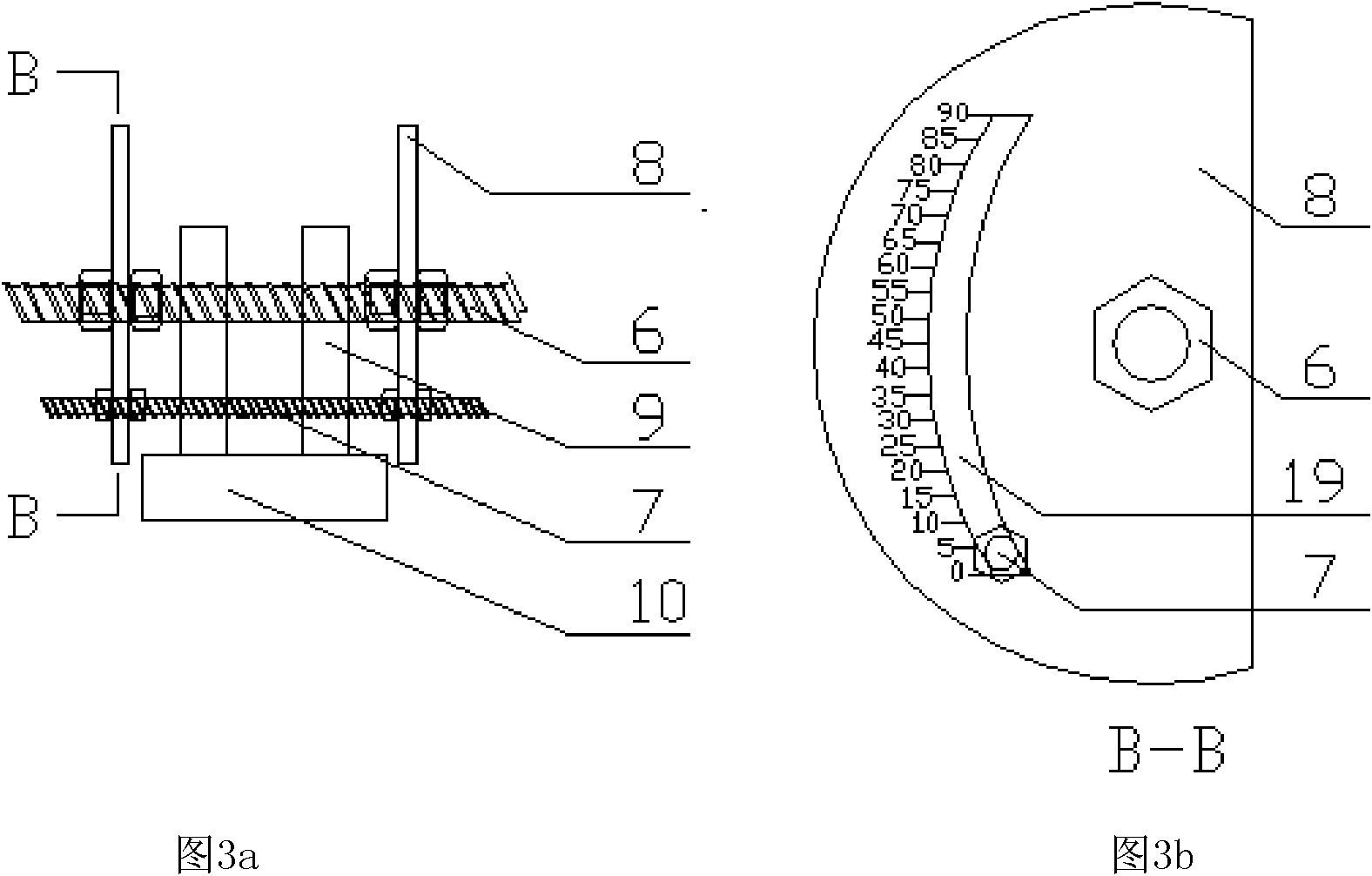

Pitching direction-rotating heliostat model for wind tunnel test

InactiveCN102175422AWith force test requirementsMeet the requirements of the force testAerodynamic testingMountingsHeliostatEngineering

The invention discloses a pitching direction-rotating heliostat model for wind tunnel test, which is composed of a mirror surface reflector plate (1), a rotating device (2), a rotating shaft (3), a vertical prop (4) and a support member (5), wherein all the components are made of organic glass. The mirror surface reflector plate (1) is formed by jointing flat plates (13) and (14), pressure testing holes (12) are uniformly and symmetrically distributed on front and rear surfaces of the mirror surface reflector plate (1) in order to conduct the measurement for wind pressure distribution and pulsation characteristics. The rotating device (2) is composed of a positioning plate (9) and a flange rotating disc (8), a positioning bolt hole of the positioning plate (9) is linked with a scale slot (19) of the flange rotating disc (8) via a positioning screw (7), the positioning screw (7) can freely slide in the scale slot (19) from 0 degree to 90 degrees so as to lead the model to perform the pitching rotation. The support member (5) is manufactured in the detachable form.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

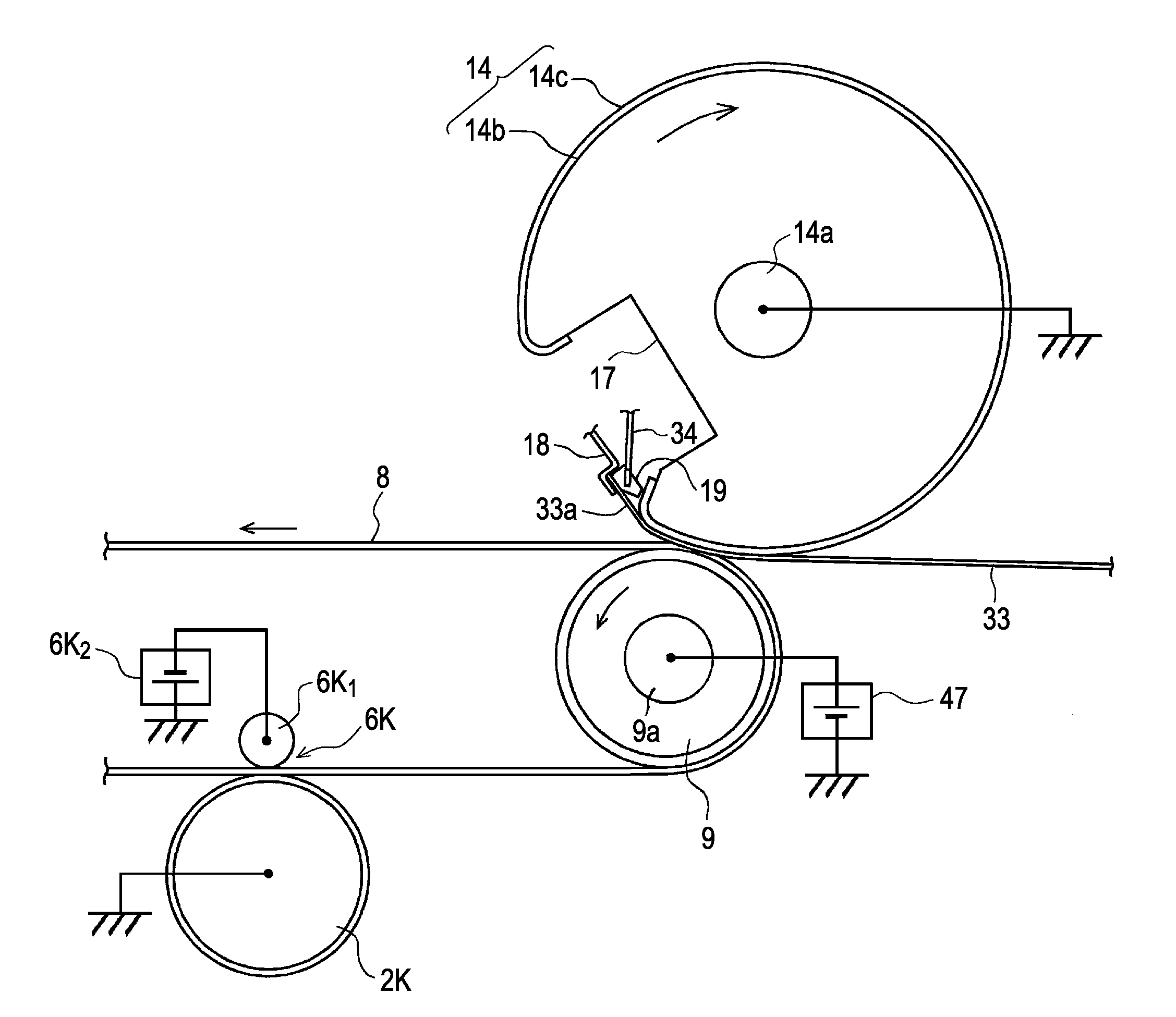

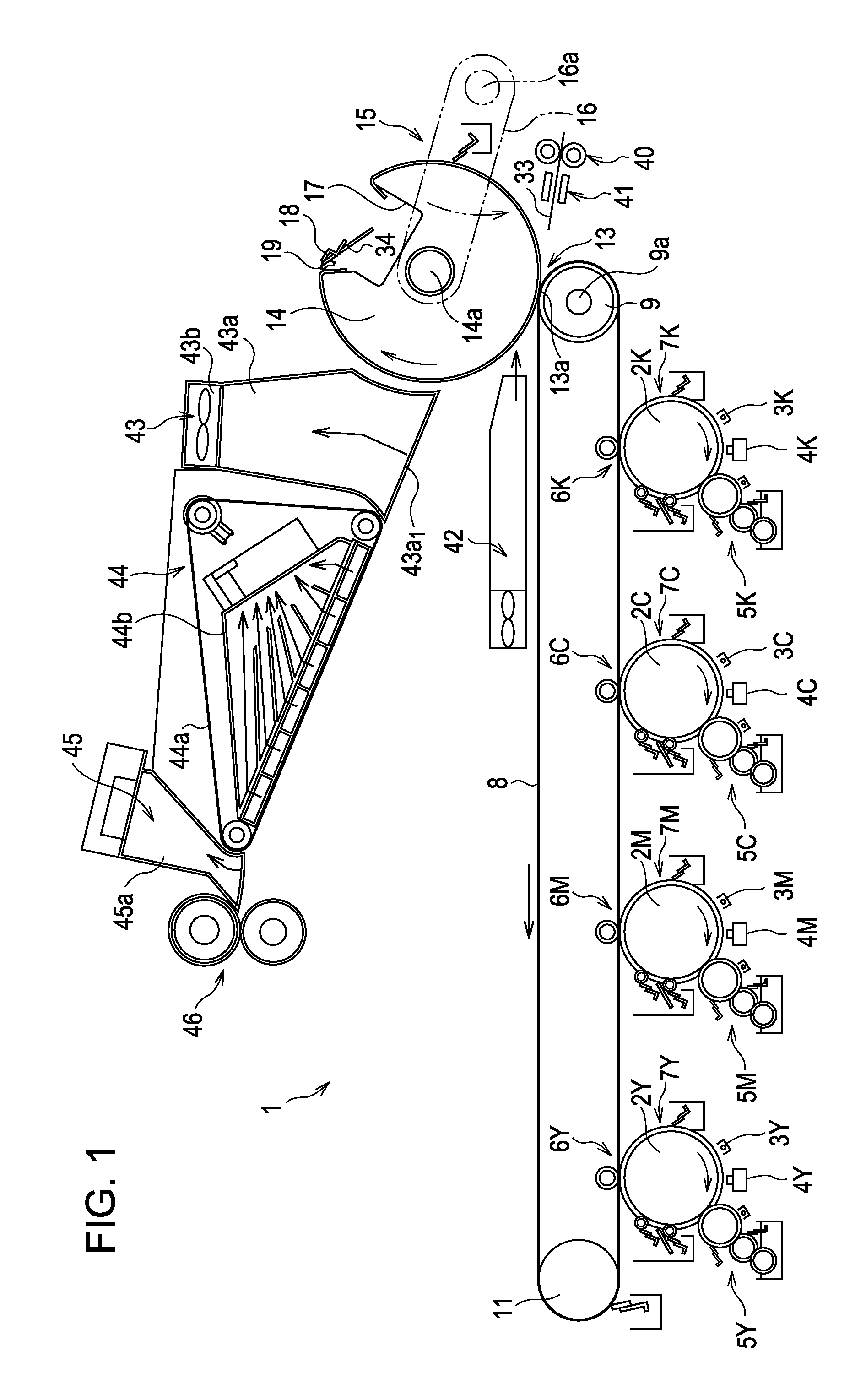

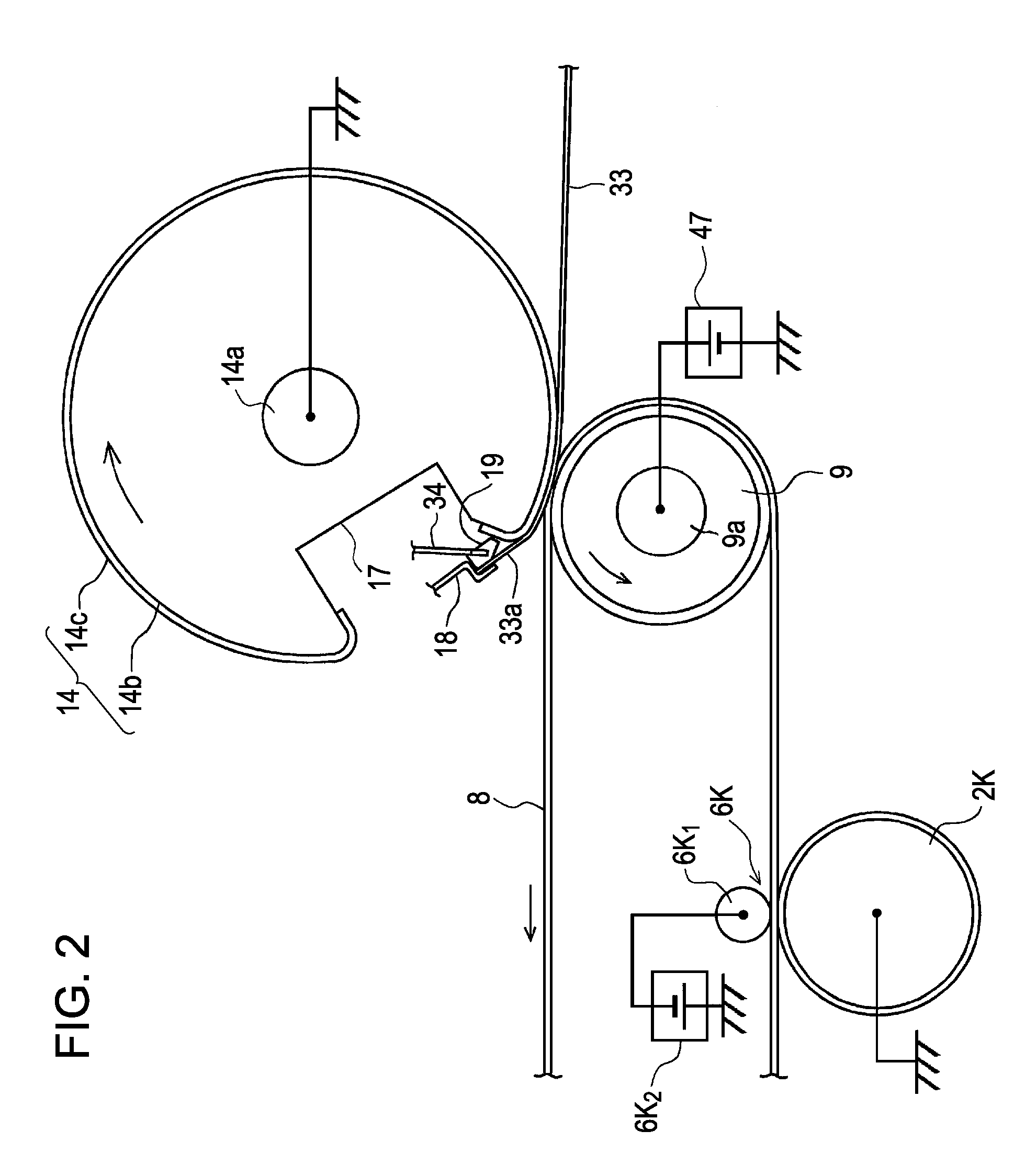

Image forming apparatus and image forming method

InactiveUS20100272480A1Easy to separateSeparateElectrographic process apparatusElectrical resistance and conductanceImage formation

Owner:SEIKO EPSON CORP

Substrate holding/rotating device, substrate processing apparatus including the same, and substrate processing method

ActiveUS10192771B2Satisfy processingEasy positioningSemiconductor/solid-state device manufacturingFlexible article cleaningMagnetic polesEngineering

Owner:DAINIPPON SCREEN MTG CO LTD

Multi-functional machine tool

InactiveCN109968031ASimple structureExquisite designFeeding apparatusOther manufacturing equipments/toolsGear wheelMachining process

The invention discloses a multi-functional machine tool. The multi-functional machine tool comprises a machine tool body, wherein an engaging cavity is formed in the machine tool body in a fixed mode,a main motor is fixedly arranged in the inner wall of the left side of the engaging cavity, a main transmission shaft extending into the engaging cavity is connected to the right end of the main motor in a driving cooperation mode, a first bevel gear is fixedly arranged on the main transmission shaft, and a second bevel gear is engaged with the upper side of the first bevel gear; the level of themachining accuracy of the machine tool is an important index to measure the developing degree of the national manufacturing industry, how to improve the machining accuracy of the machine tool is therefore a problem technical personnel need to solve currently. In the prior machining art, lathing a shaft shoulder by using lathing operation, milling a key slot by using milling operation are usuallyused when shaft parts are machined, but lathing and milling are two different machining processes of the machine tool, after a machining process is completed, a workpiece needs to be dismounted and then be mounted onto another machine tool to be machined, and because of the existence of an operation of re-fixing the workpiece during the process, new machining errors are generated.

Owner:浦江升广科技有限责任公司

Method to produce tesserae of glass mosaic containing a metal foil

InactiveUS20050118432A1Reduce heat dissipationReduce energy consumptionDecorative surface effectsOrnamental structuresMetal foilSoftening

Method and plant to make tesserae (11) for glass mosaic, containing ornamental metal foil (14) inside. The method comprises the steps of positioning a first glass strip (30), with a metal foil (14) associated above, on a work plane (20) including first molding means (22), localized heating of the work plane (20) to obtain a softening of the first glass strip (30), casting a quantity of glass onto the metal foil (14), pressing the semi-worked product (29) in its plastic state, and molding the semi-worked product (29) to define the contours of the tesserae (11), by means of cooperation between second molding means (19) and the first molding means (22). One or more of the steps are performed sequentially in at least one work station (40-49).

Owner:BISAZZA SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com