Full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting

A full-closed-loop, main-drive technology, applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve the problems of poor running stability of the rotary table, poor processing flexibility and adaptability, and low load-bearing of the rotary table, so as to improve the rotary response speed , Processing flexibility and adaptability, the effect of improving accuracy and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

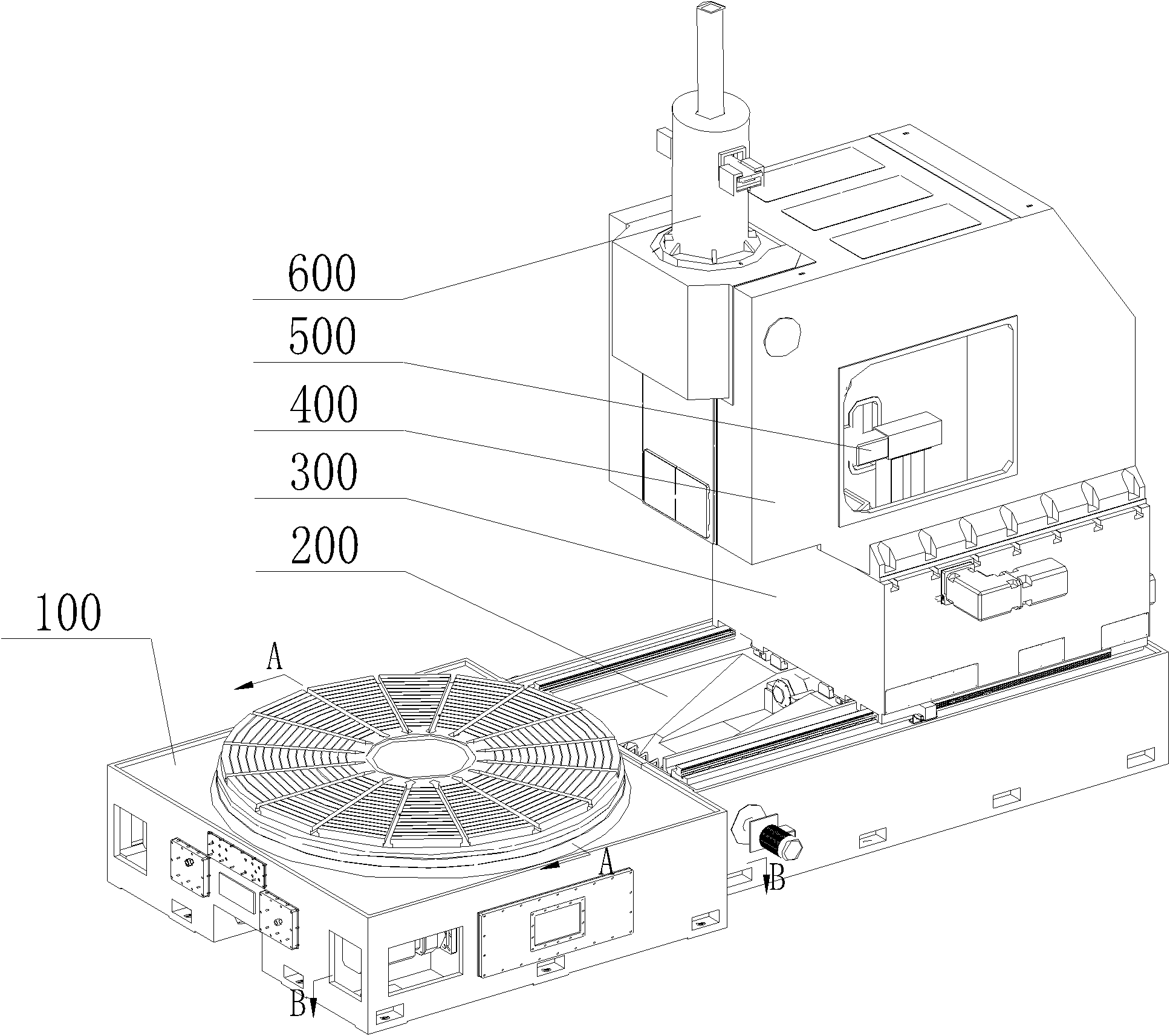

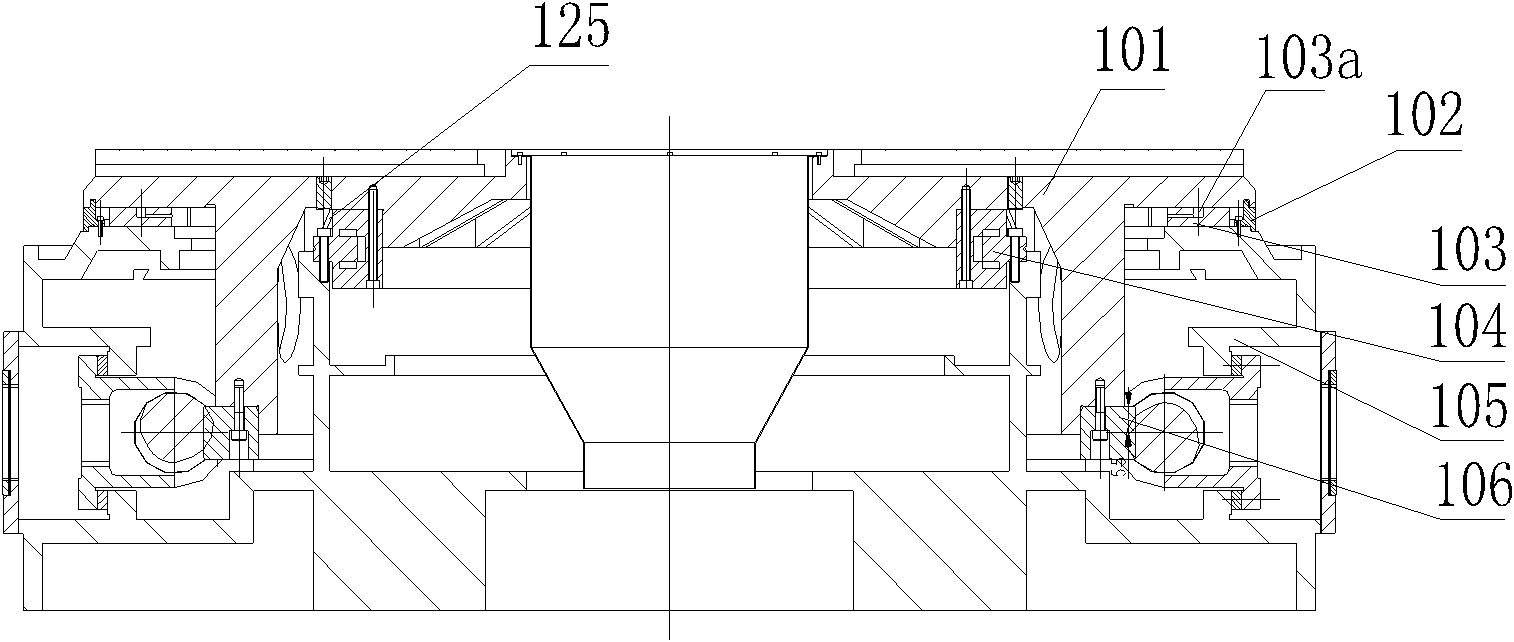

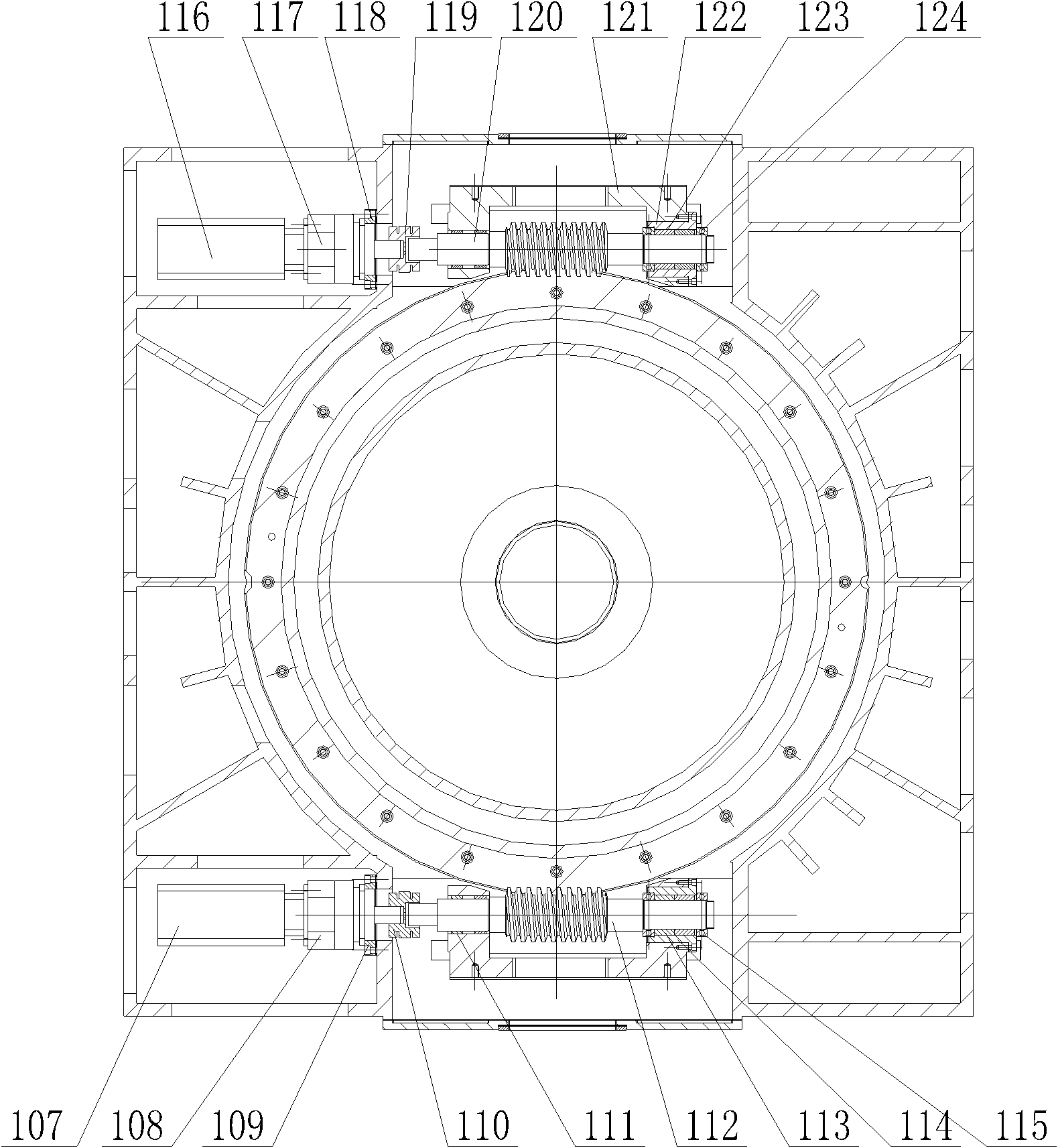

[0040] see figure 1 , Figure 4 and Figure 5 , large-scale hydraulic main drive cutting full-closed-loop CNC gear shaper, including: rotary table 100, bed assembly 200, middle bed assembly 300, column 400, tool letting mechanism 500, tool rest mechanism 600, numerical control system, hydraulic pressure system, lubrication system and cooling chip removal system, the numerical control system, hydraulic system, lubrication system and cooling chip removal system are not represented in the figure. The rotary table and the bed assembly are docked front and rear, the servo motor 208 of the radial feed mechanism is connected to the reducer 207, the output shaft of the reducer is connected to the coupling 206, the other end of the coupling is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com