Scalable force and electric field transmission electron microscope in situ sample rod

An electron microscope and sample rod technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of difficult installation, single function, high price, etc., and achieve the effect of shortening the service life, broadening the research field, and reducing the difficulty of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

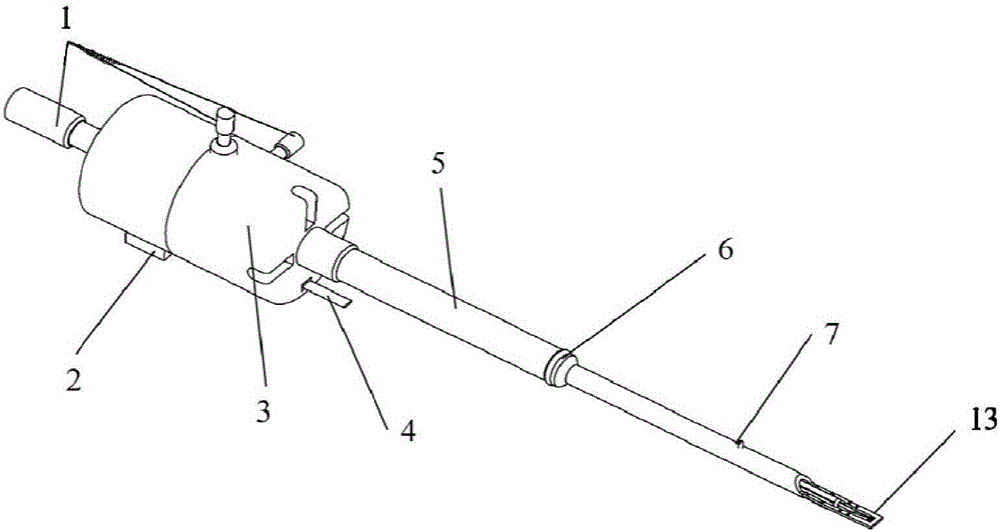

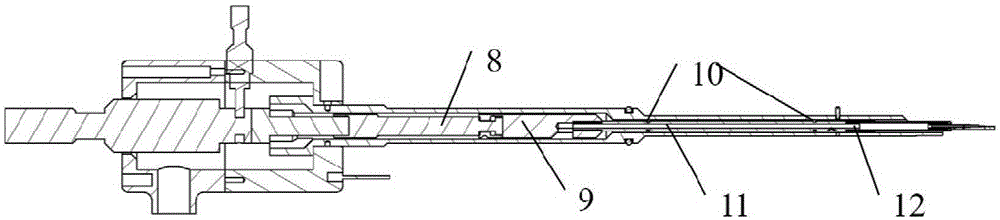

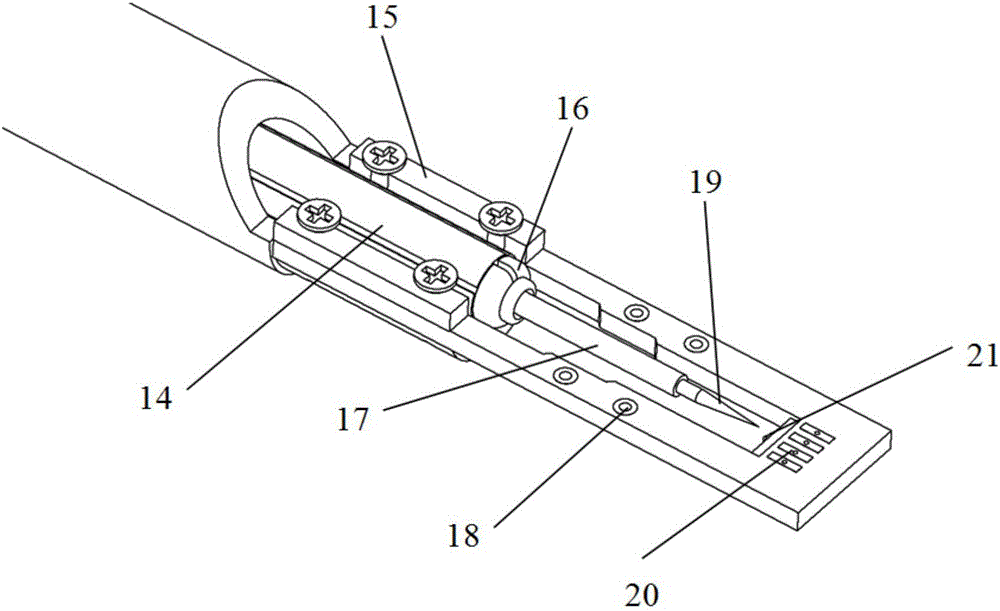

[0029] Example 1, such as Figure 1-3 As shown, the in-situ sample rod of the extensible electromechanical two-field transmission electron microscope includes a coarse adjuster 1, a signal adapter 2, a sample rod housing 5, a coarse adjustment adapter 8, an adapter fixing rod 9, a coaxial ring 10, Transmission rod 11, piezoelectric ceramic holder 12, sample rod head 13, piezoelectric ceramic tube 14, fixed part 15, needle tip holder 16, conductive needle tube 17, conductive electrode 18, nano needle tip 19 and test electrode 20;

[0030] The axial part of the coarse adjuster 1 is mechanically connected coaxially with the sample rod housing 5, and the axial part and the radial part of the coarse adjuster 1 are respectively mechanically connected with the sample rod housing 5 to realize the coaxial fixation of the coarse adjuster. 1 is connected with the coarse adjustment adapter 8 to realize the conversion of the rotational movement and the axial telescopic movement, the coarse...

Embodiment 2

[0033] Example 2, such as figure 1 As shown, on the basis of Example 1, the in-situ sample rod of the expandable force-electric two-field transmission electron microscope also includes a hand handle 3, which is connected to the sample rod shell 5 to realize the movement of the sample rod Use, and can achieve a large range of movement.

Embodiment 3

[0034] Embodiment 3, on the basis of Embodiment 2, the handle 3 is provided with a sensing pin 4, and the sensing pin 4 is used to realize the sensing positioning of the sample rod inserted into the transmission electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com