Shrink-proof treatment method for cashmere fibres

A cashmere fiber and anti-shrinkage treatment technology, which is applied in fiber treatment, biochemical fiber treatment, animal fiber, etc., can solve the problems of fabric color and color light influence, and achieve the effect of less fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

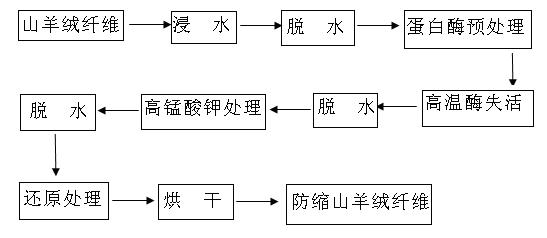

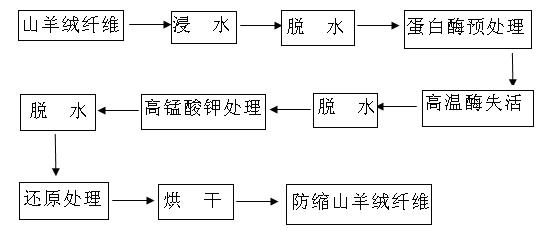

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Soak the cashmere fibers in water for 5 minutes, and then dehydrate them with a centrifuge.

[0033] Step 2: Protease pretreatment: put the cashmere fiber obtained in the previous step in a Savinase protease solution with a mass concentration of 2%, and treat it at a temperature of 30°C for 0.3h, and maintain a pH value of 7.

[0034] Step 3: high-temperature enzyme inactivation: put the cashmere fiber obtained in the previous step in a water bath at 70°C for 20 minutes to inactivate the enzyme, and then dehydrate it with a centrifuge.

[0035] Step 4: Potassium permanganate treatment: place the cashmere fiber obtained in the previous step in a solution with a mass concentration of 2% potassium permanganate, and treat it at a temperature of 30°C for 0.5h, keep the pH value at 1, and then Dehydrate in a centrifuge.

[0036] Step 5: Reduction treatment: place the cashmere fibers obtained in the previous step in a reduction treatment solution, treat them at a temp...

Embodiment 2

[0038] Step 1: Soak the cashmere fiber in water for 20 minutes, and then dehydrate it with a centrifuge.

[0039] Step 2: Protease pretreatment: put the cashmere fiber obtained in the previous step in a Savinase protease solution with a mass concentration of 8%, and treat it at a temperature of 60°C for 1 hour, and keep the pH value at 10.

[0040] Step 3: high-temperature enzyme inactivation: put the cashmere fiber obtained in the previous step in a water bath at 90° C. for 20 minutes to inactivate the enzyme, and then dehydrate it with a centrifuge.

[0041] Step 4: Potassium permanganate treatment: place the cashmere fiber obtained in the previous step in a solution of potassium permanganate with a mass concentration of 15%, and treat it for 1 hour at a temperature of 60°C, keep the pH value at 6, and then use Centrifuge to dehydrate.

[0042] Step 5: Reduction treatment: place the cashmere fibers obtained in the previous step in a reduction treatment solution, treat them ...

Embodiment 3

[0044] Step 1: Soak the cashmere fibers in water for 10 minutes, and then dehydrate them with a centrifuge.

[0045]Step 2: Protease pretreatment: put the cashmere fiber obtained in the previous step in a Savinase protease solution with a mass concentration of 6%, treat it at a temperature of 50°C for 0.5h, and maintain a pH value of 9.

[0046] Step 3: high-temperature enzyme inactivation: put the cashmere fiber obtained in the previous step in a water bath at 80° C. for 10 minutes to inactivate the enzyme, and then dehydrate it with a centrifuge.

[0047] Step 4: Potassium permanganate treatment: place the cashmere fiber obtained in the previous step in a solution with a mass concentration of 12% potassium permanganate, treat it at a temperature of 50°C for 0.8h, and keep the pH value at 5, then Dehydrate in a centrifuge.

[0048] Step 5: Reduction treatment: place the cashmere fibers obtained in the previous step in a reduction treatment solution, treat them at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com