Patents

Literature

136results about How to "Prevent abnormal discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

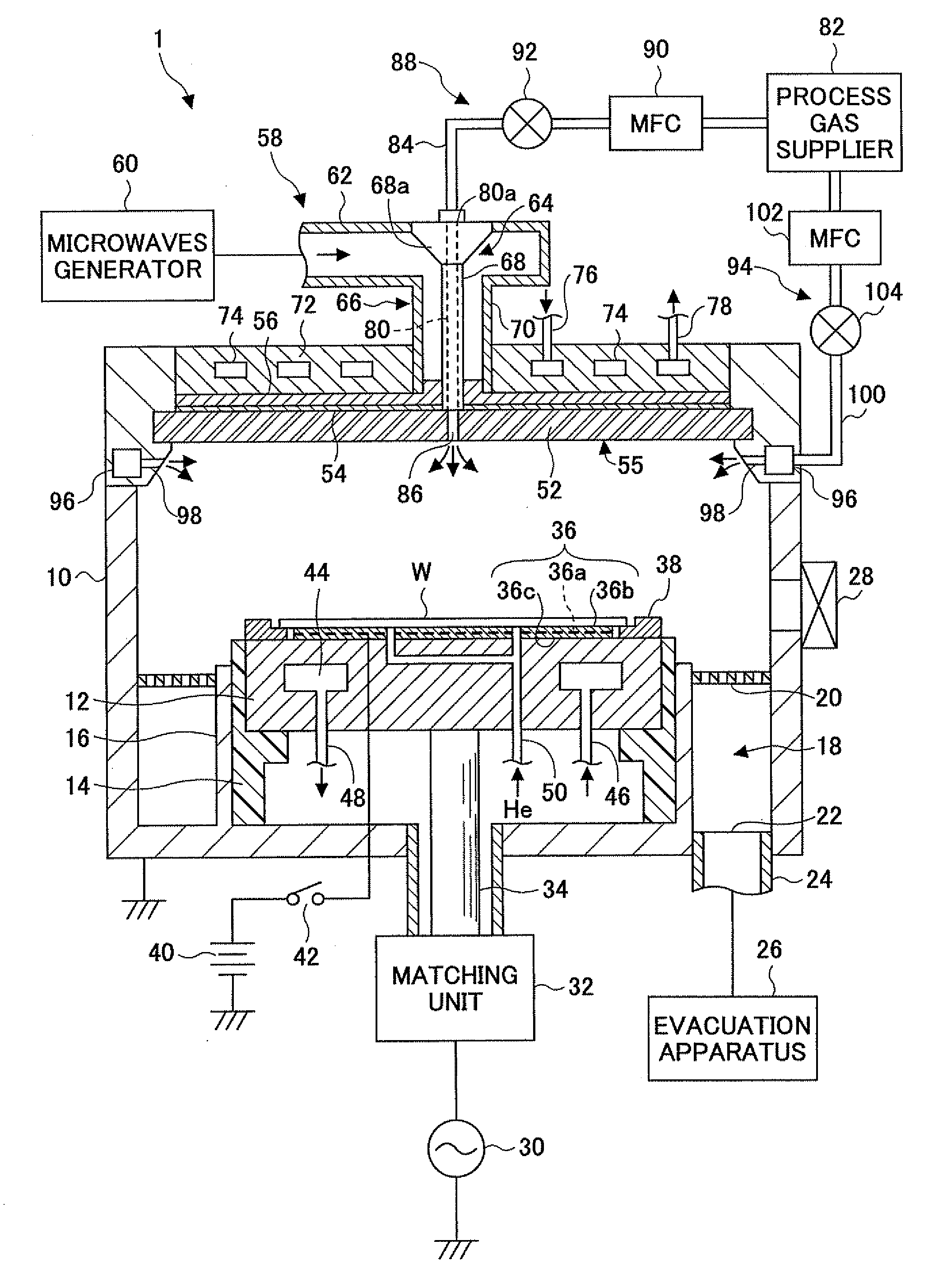

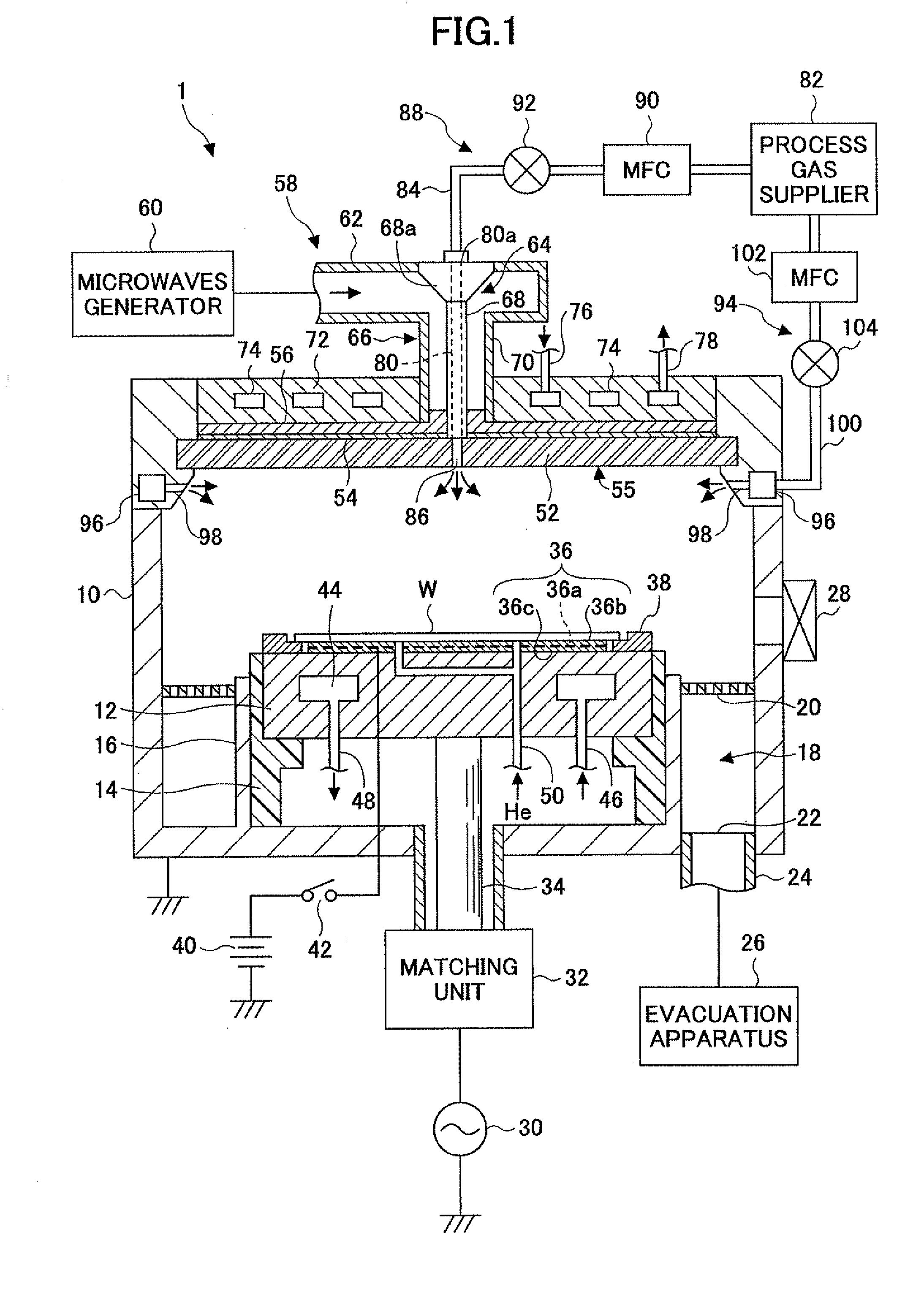

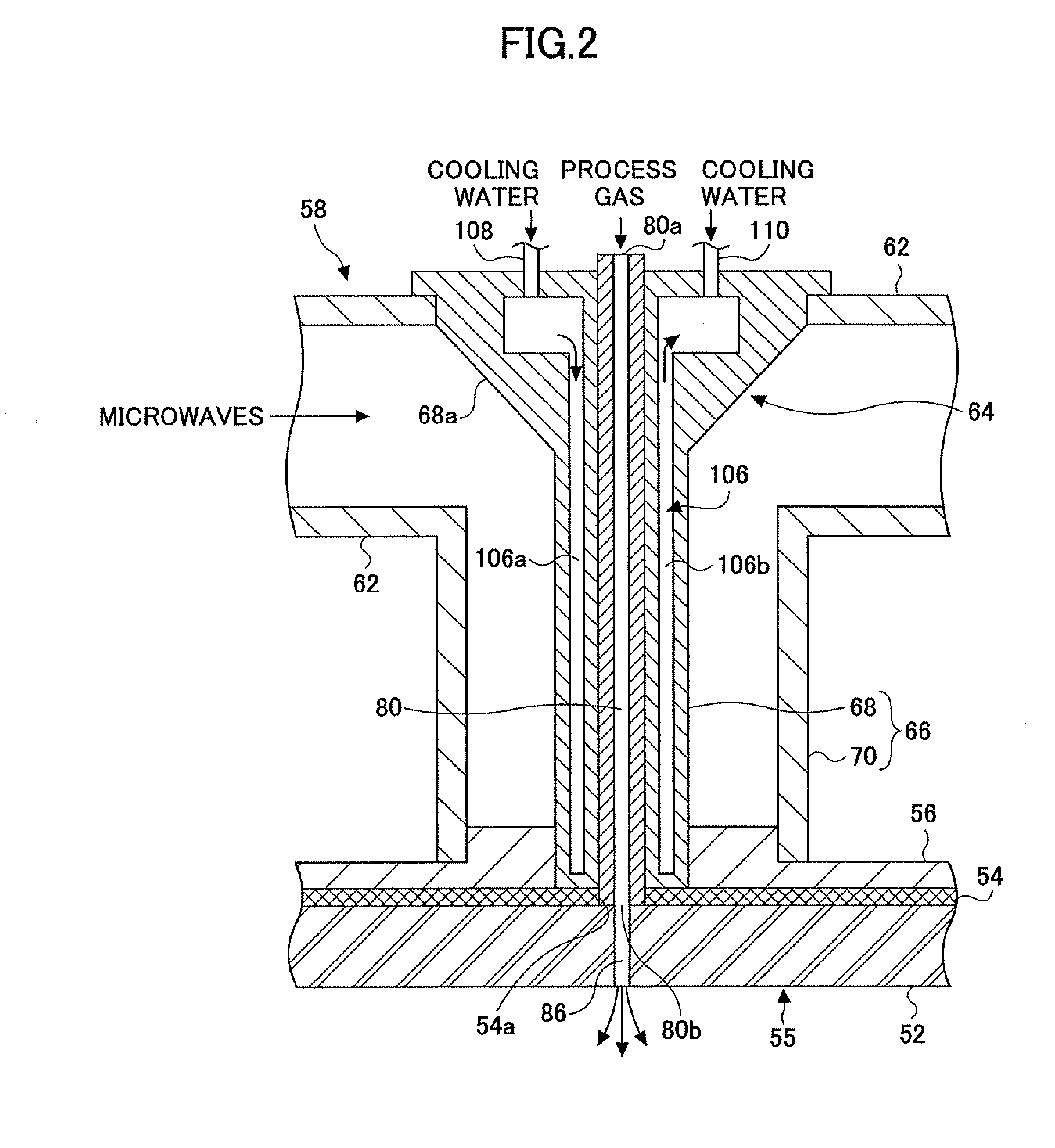

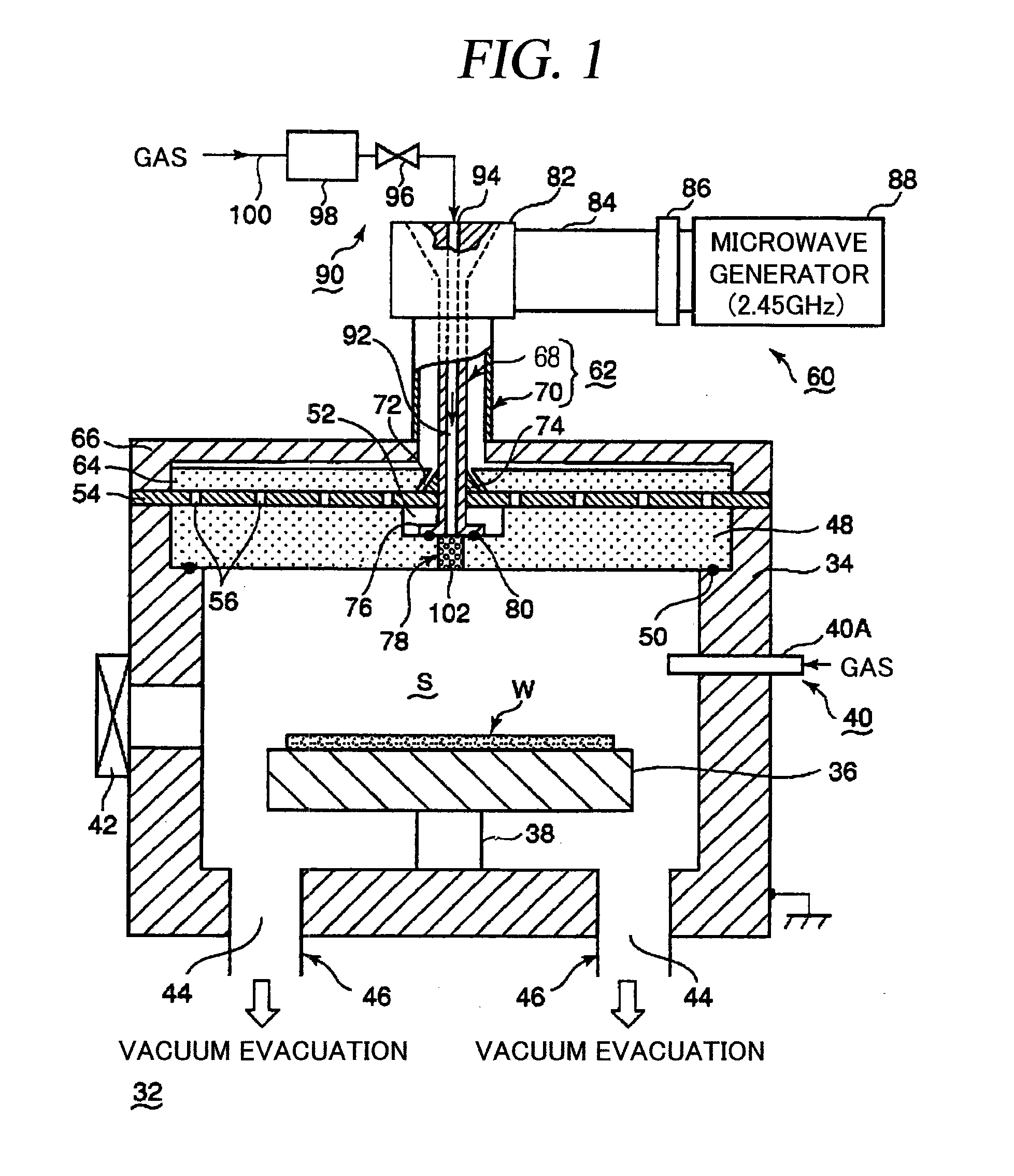

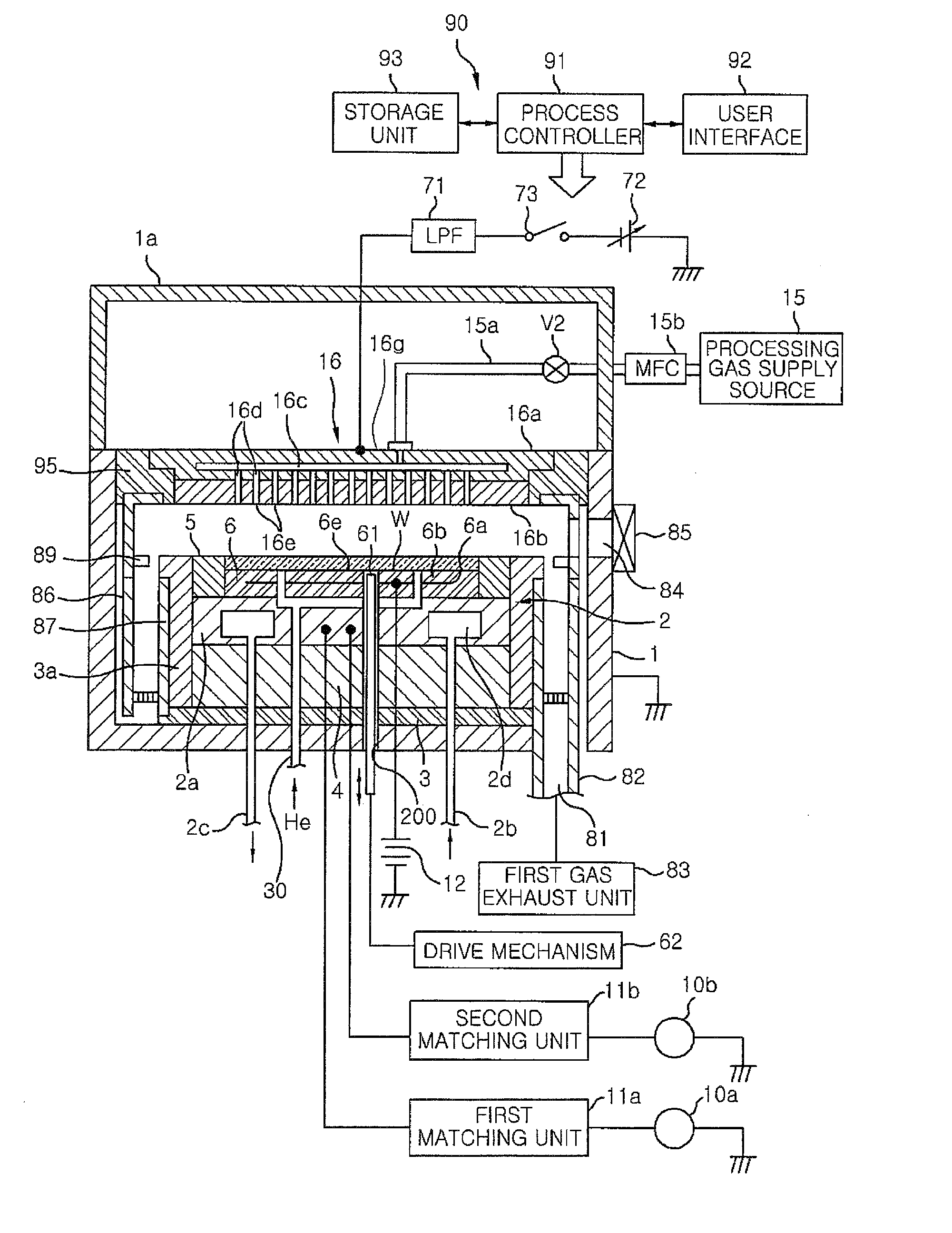

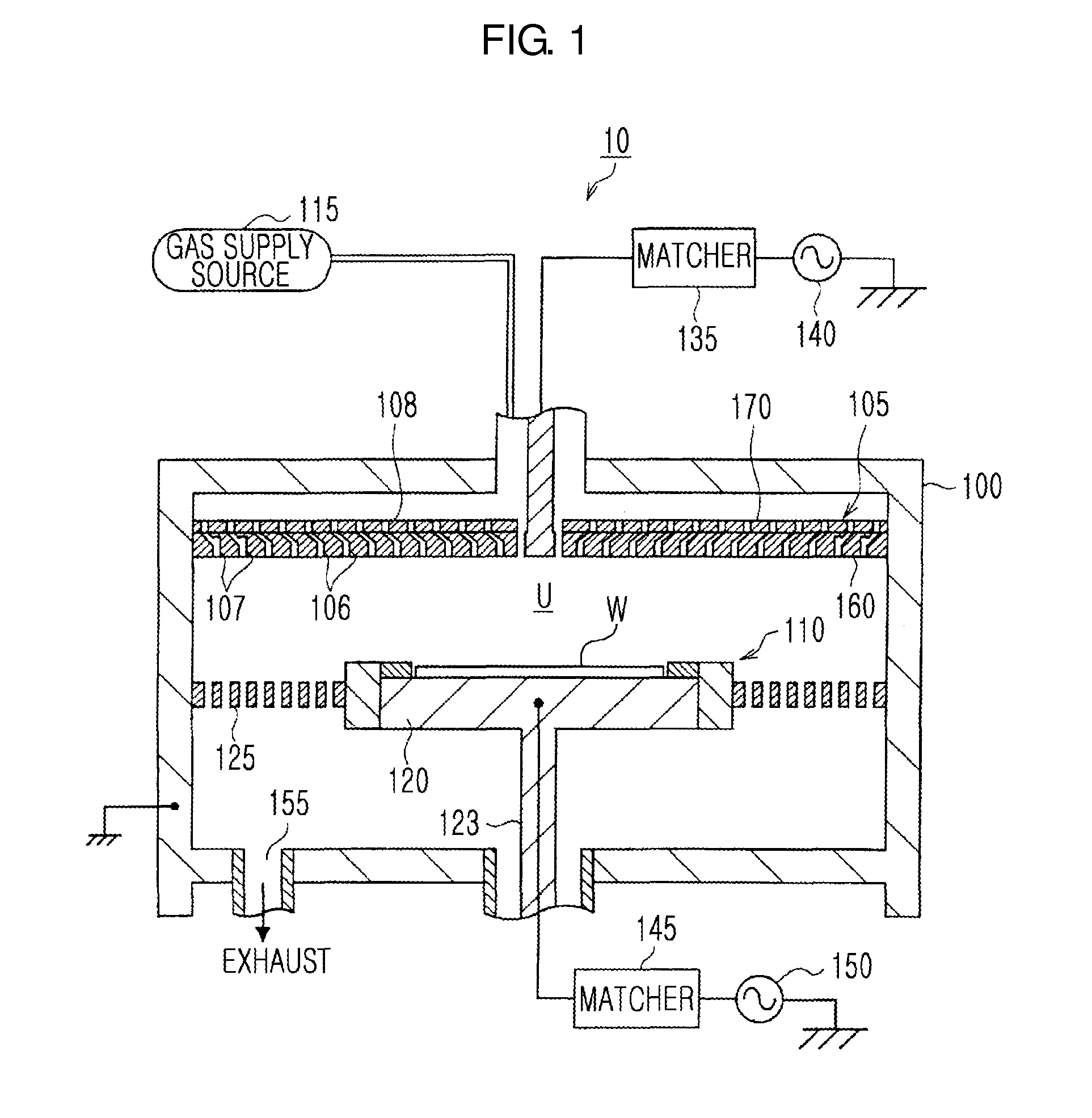

Plasma process apparatus

InactiveUS20100101728A1Excellent in plasma density uniformityImprove controllabilityElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveEngineering

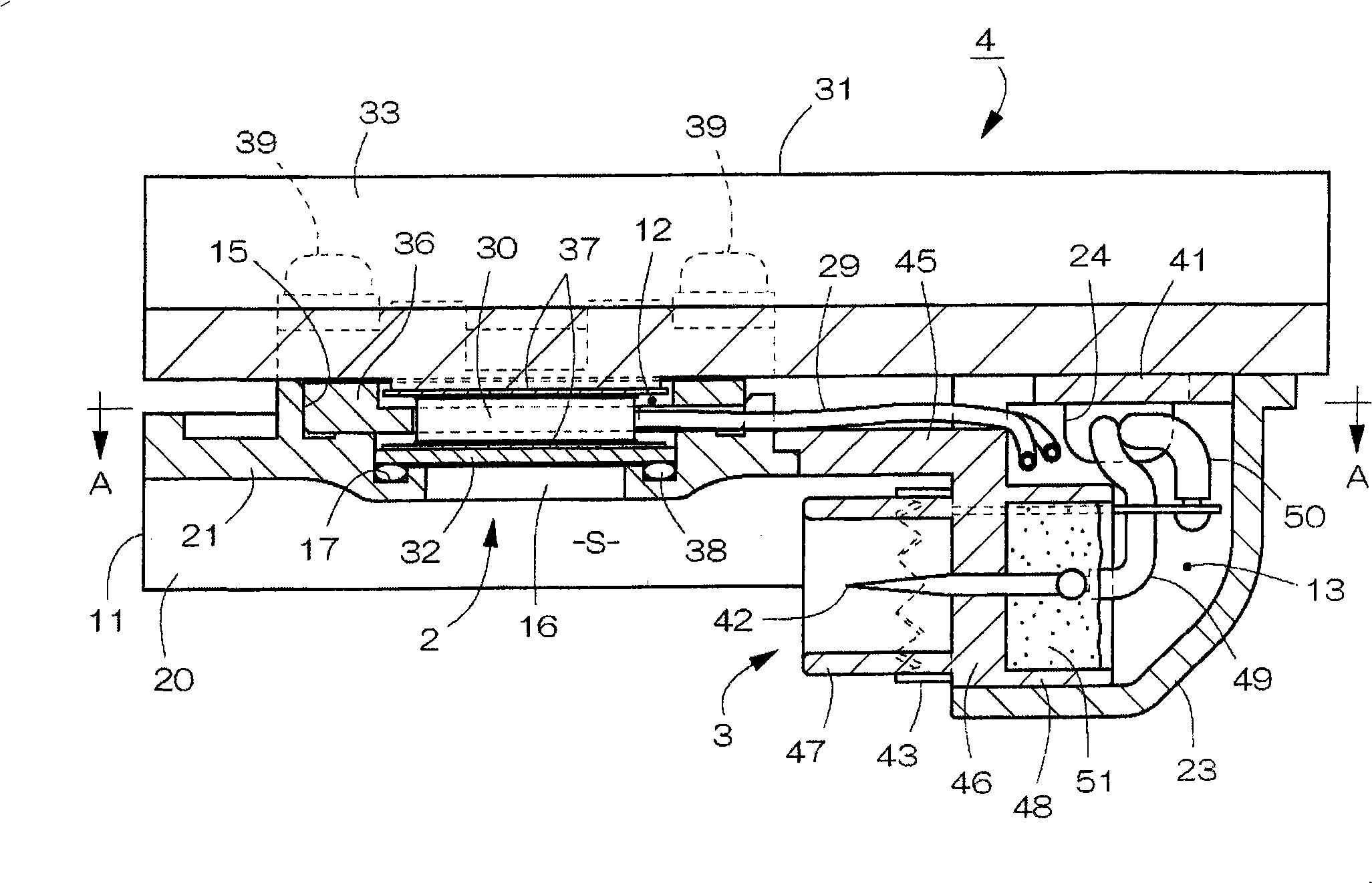

A disclosed a plasma process apparatus includes a process chamber that houses a substrate subjected to a predetermined plasma process and may be evacuated to a reduced pressure; a microwave generator that generates microwaves for generating plasma; a waveguide pipe that transmits the microwaves from the microwave generator to the process chamber; a waveguide pipe / coaxial pipe converter connected to one end of the waveguide pipe; and a coaxial pipe that forms a line through which the microwaves are transmitted from the waveguide pipe-coaxial pipe converter to the process chamber. An inner conductive body of the coaxial pipe has a hollow portion; and a first process gas supplying portion that supplies a process gas into the process chamber through the hollow portion of the inner conductive body of the coaxial pipe.

Owner:TOKYO ELECTRON LTD

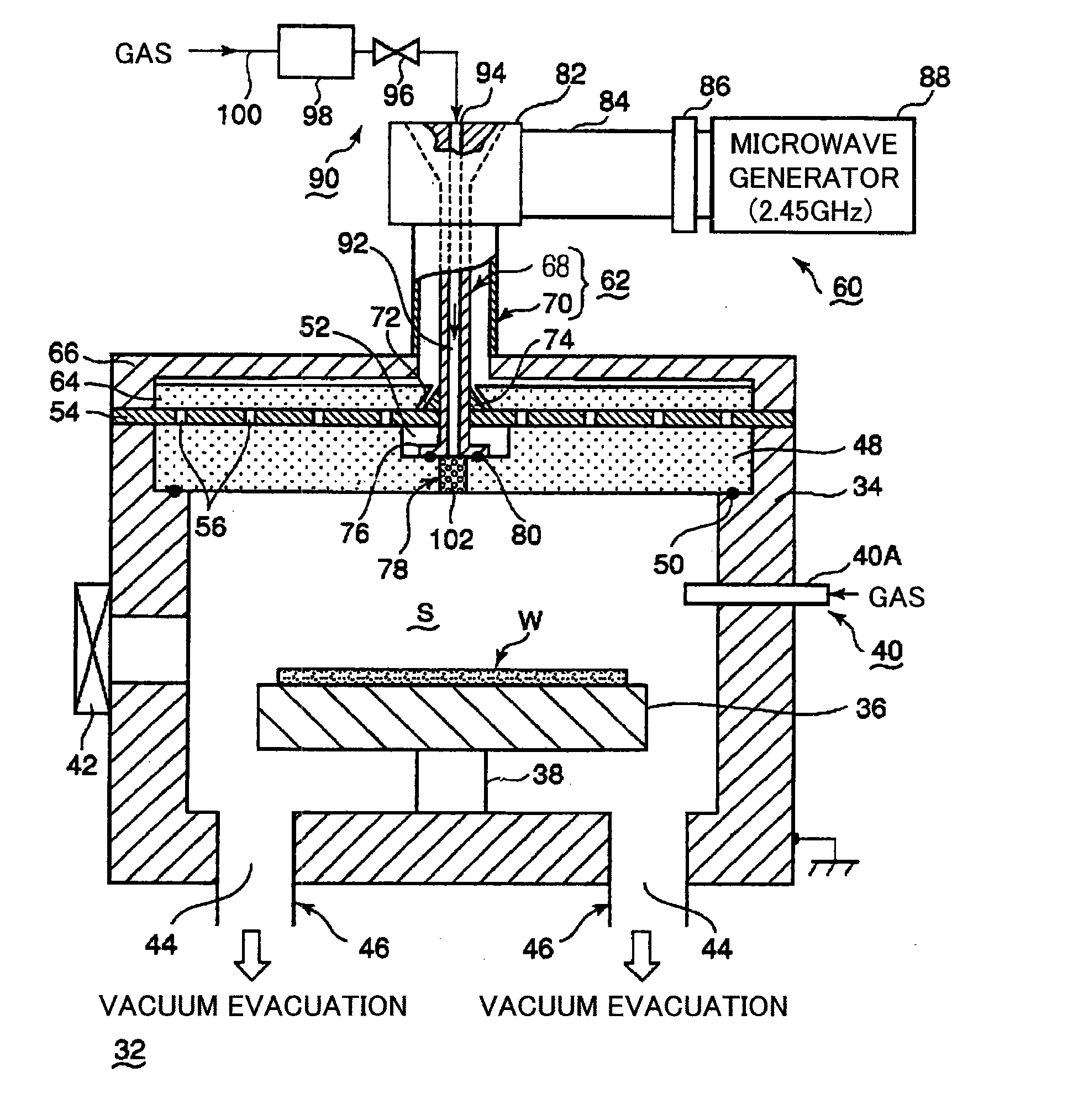

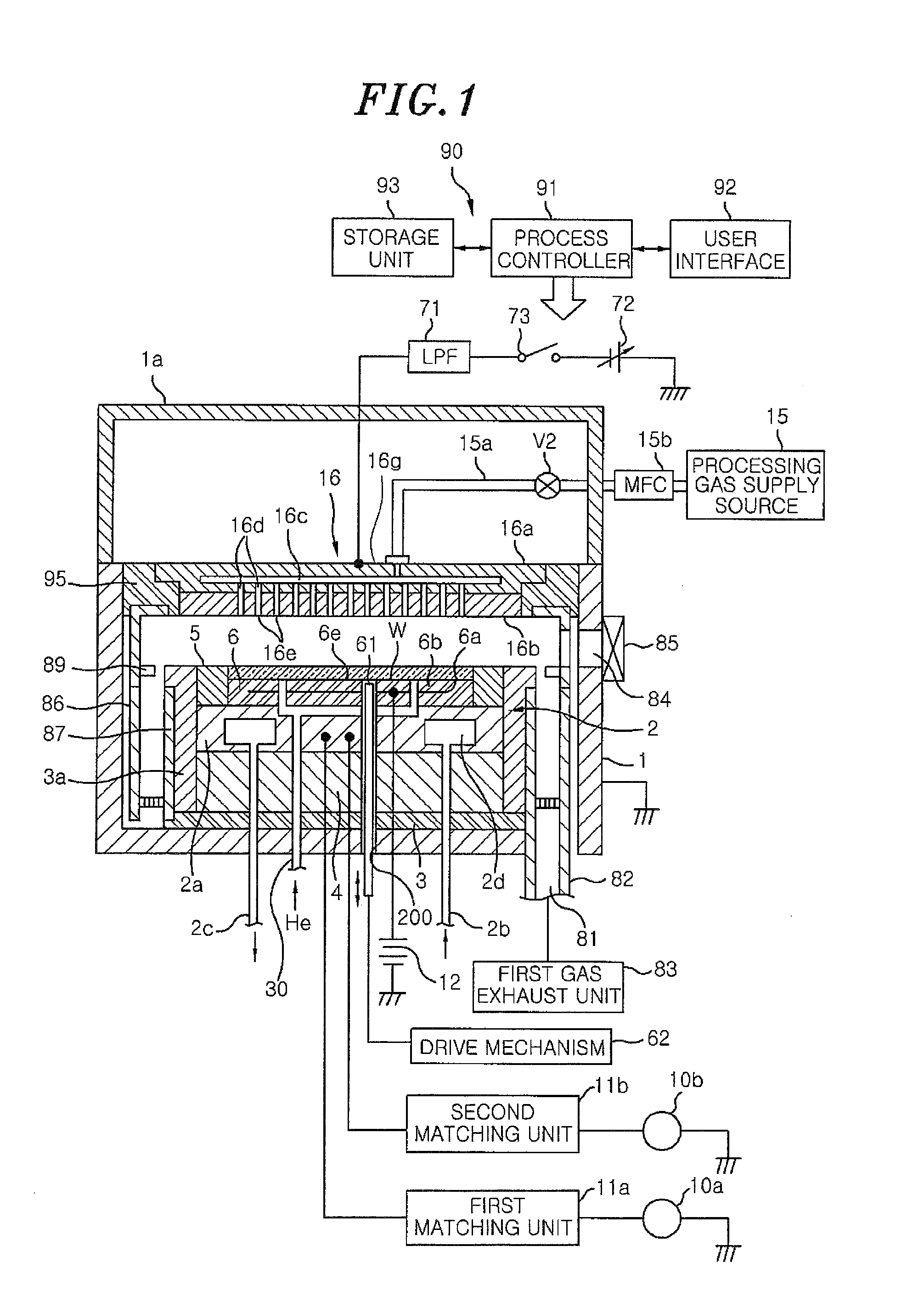

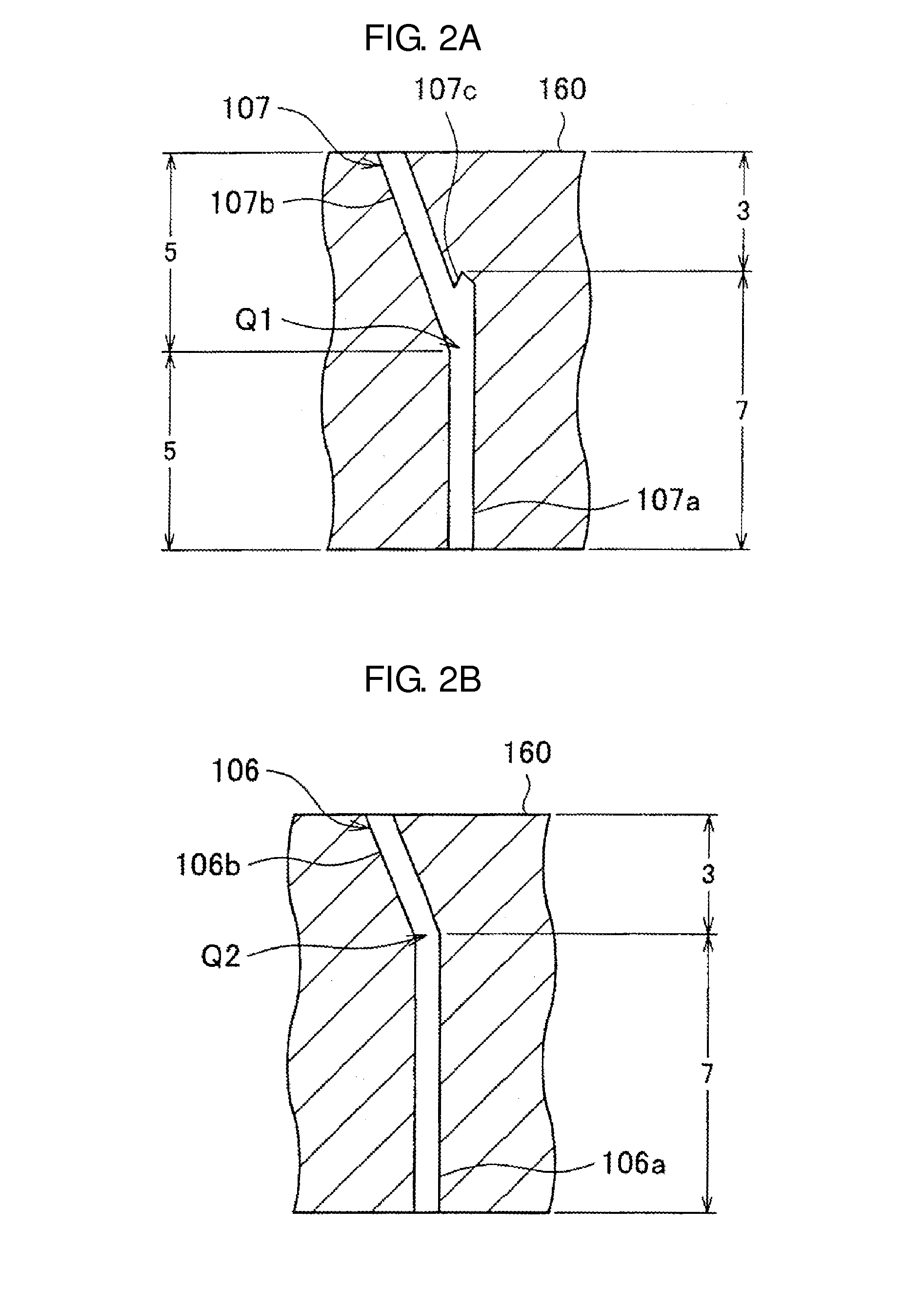

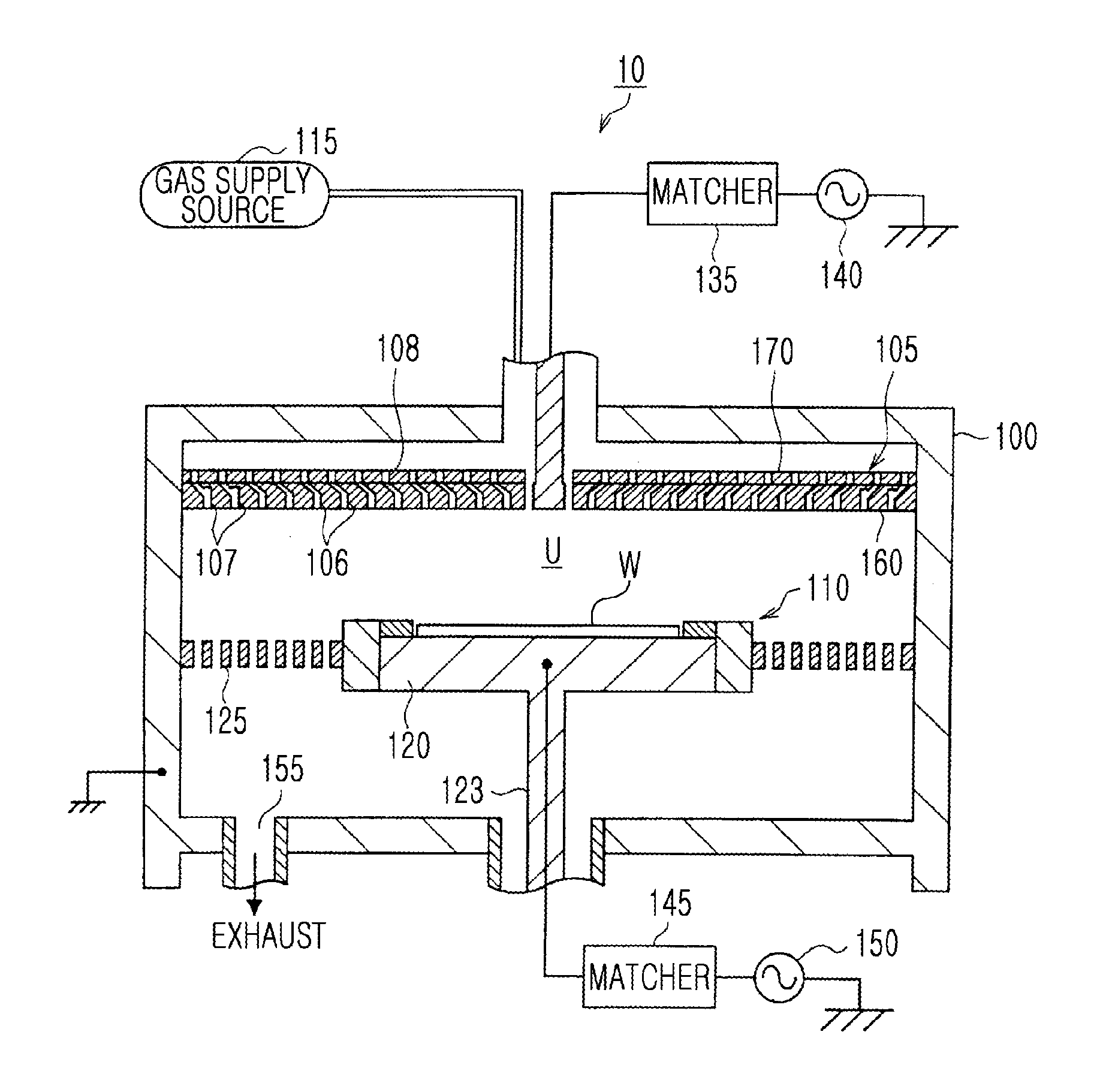

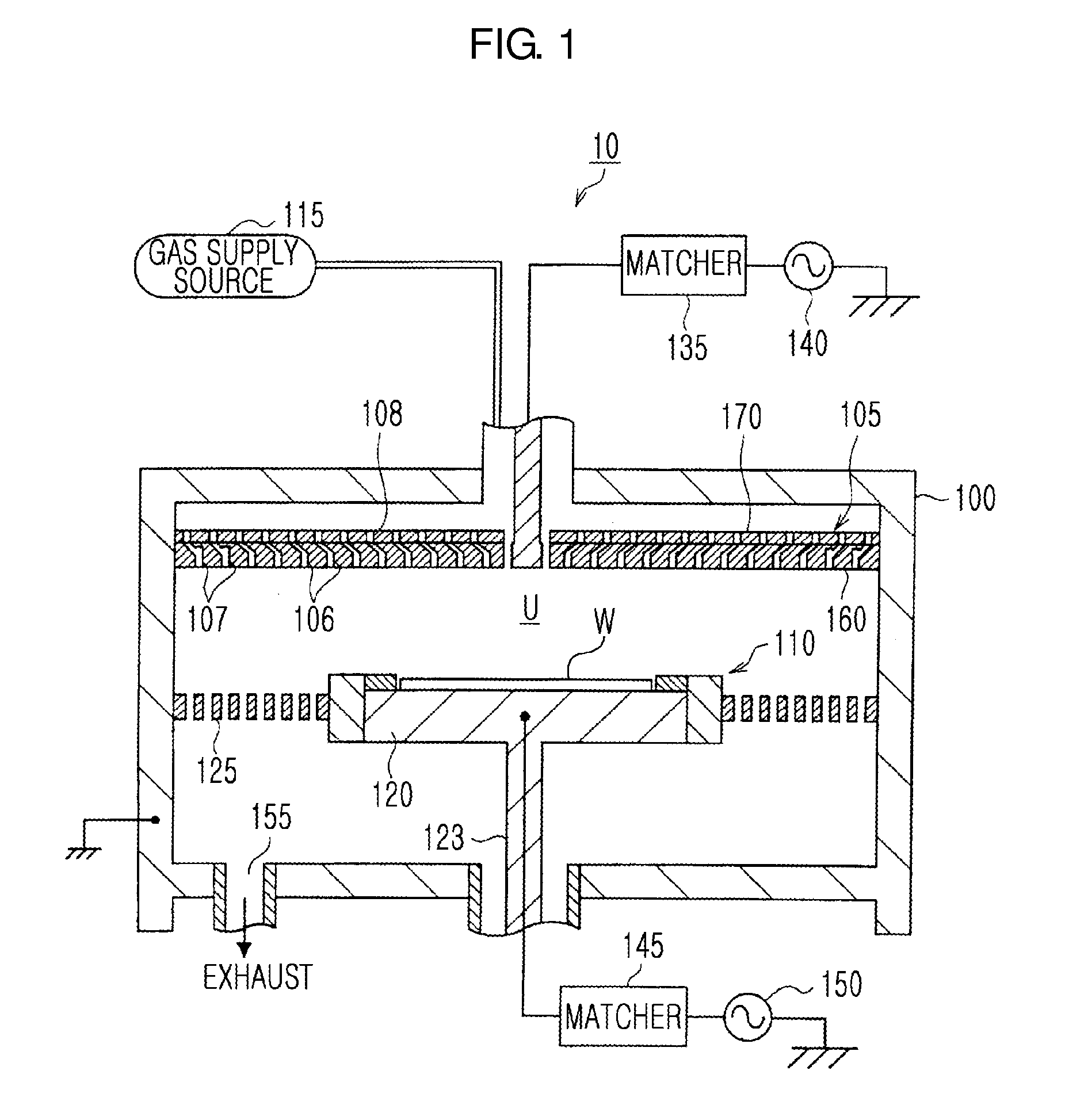

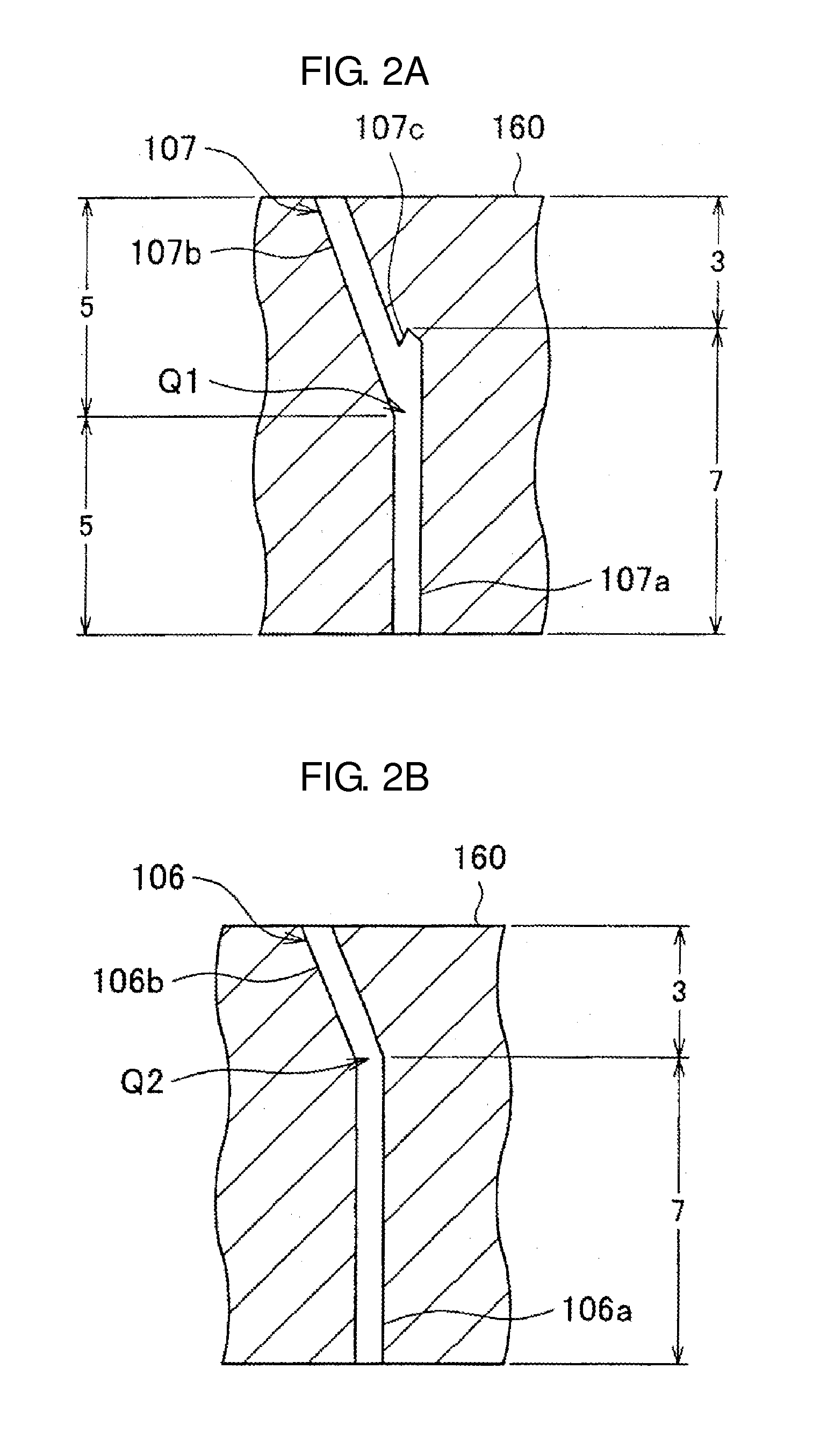

Plasma processing apparatus

ActiveUS20090242130A1Efficient solutionSuppressing discharge of plasmaElectric discharge tubesDecorative surface effectsElectrical conductorCoaxial waveguides

The present invention relates to a plasma processing apparatus including: a processing chamber whose ceiling portion is opened and the inside thereof can be evacuated to vacuum; a ceiling plate which is made of dielectric material and is airtightly mounted to an opening of the ceiling portion; a planar antenna member which is installed on a top surface of the ceiling plate, for introducing a microwave into the processing chamber; and a coaxial waveguide, which has a central conductor connected to the planar antenna member, for supplying the microwave, wherein a gas passage is formed to pass through the central conductor, the planar antenna member, and the ceiling plate, and an electric field attenuating recess for attenuating an electric field intensity of the center portion of the ceiling plate is installed on a top surface of a center area of the ceiling plate.

Owner:TOKYO ELECTRON LTD

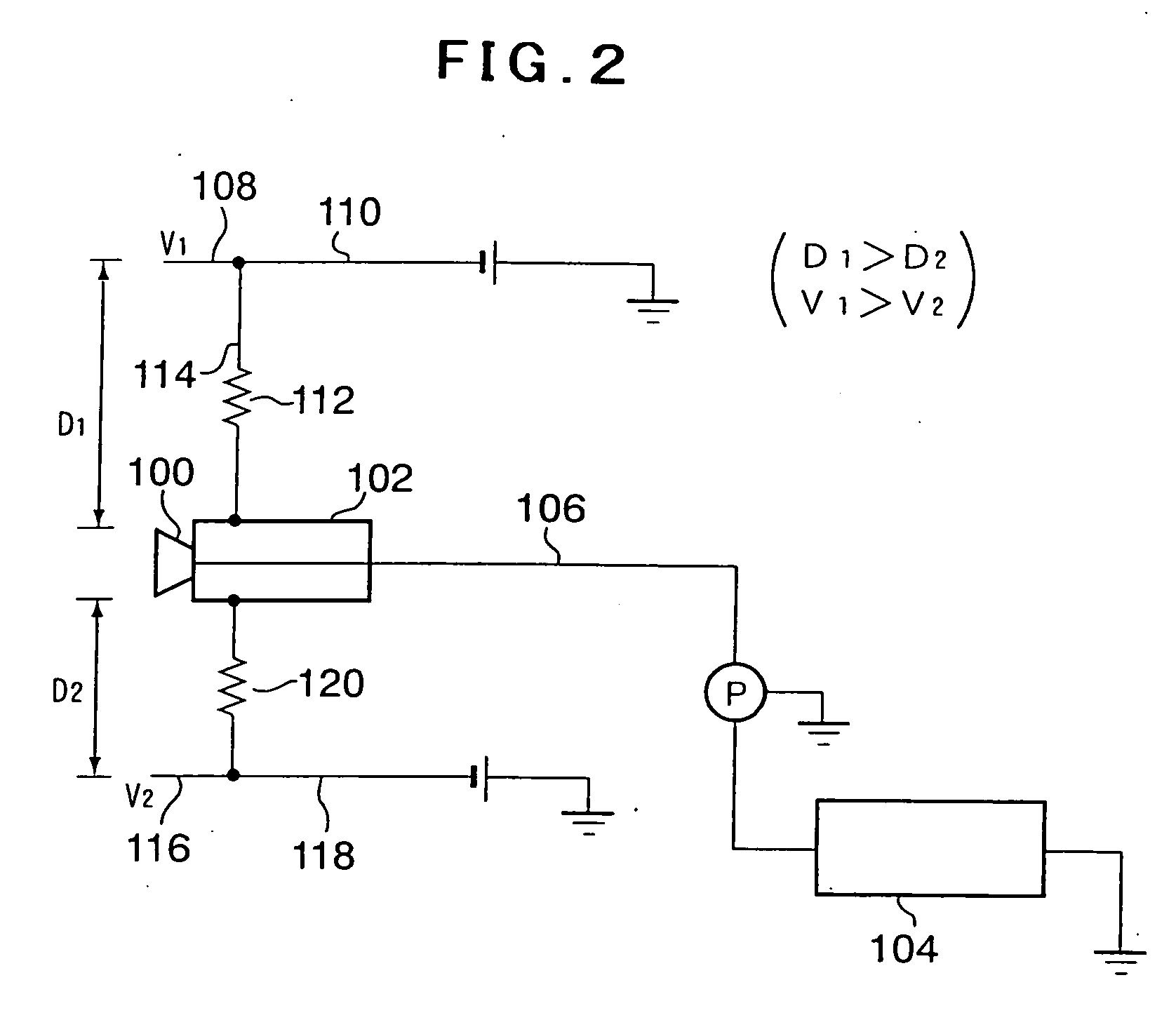

Electrostatic spraying apparatus

InactiveUS20060081729A1Deterioration of contaminationDeterioration of efficiencyBurnersElectrostatic spraying apparatusEngineeringHigh pressure

To prevent contamination by abnormal discharge in direct-charging electrostatic atomizers, a new electrostatic atomizer uses a main external electrode (13) and an auxiliary external electrode (17) located radially outward of an atomizer main body (4). A high-voltage supply line (15) for supplying a high voltage to the main external electrode (13) is connected to a head member (5) of the atomizer main body (4) by an additional conductor line (18), in which an auxiliary external electrode (17) is connected between a first and a second resistors (19, 20). When water paint is supplied to the rotary atomizing head (2) through a paint supply passage (10), the rotary atomizing head (2) is connected to the ground potential by the water paint itself, and automatically configured to operate as an indirect-charging electrostatic atomizer.

Owner:CARLISLE FLUID TECH RANSBURG JAPAN KK

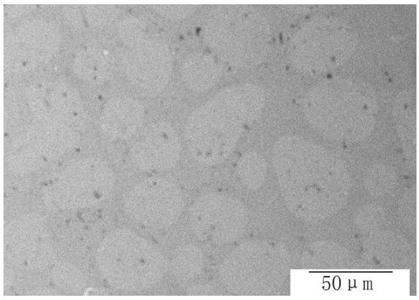

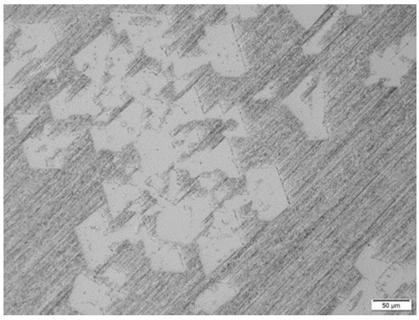

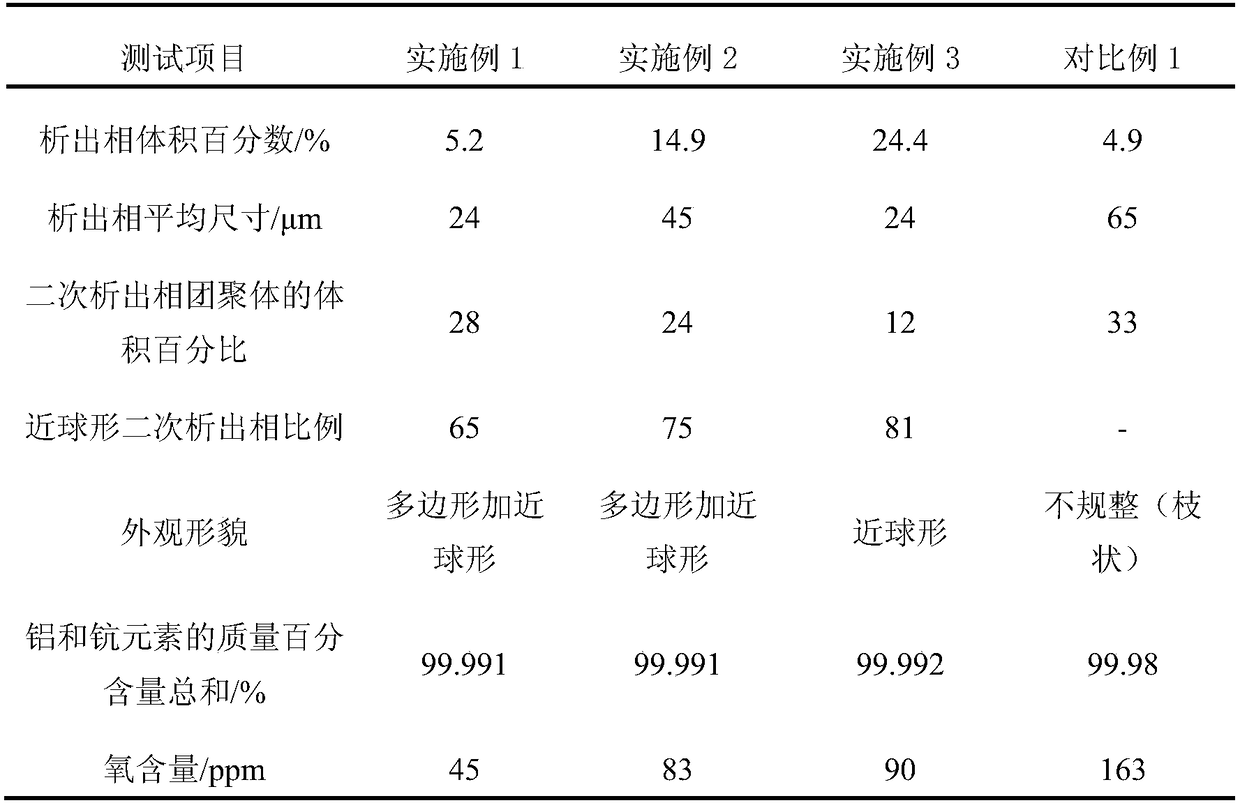

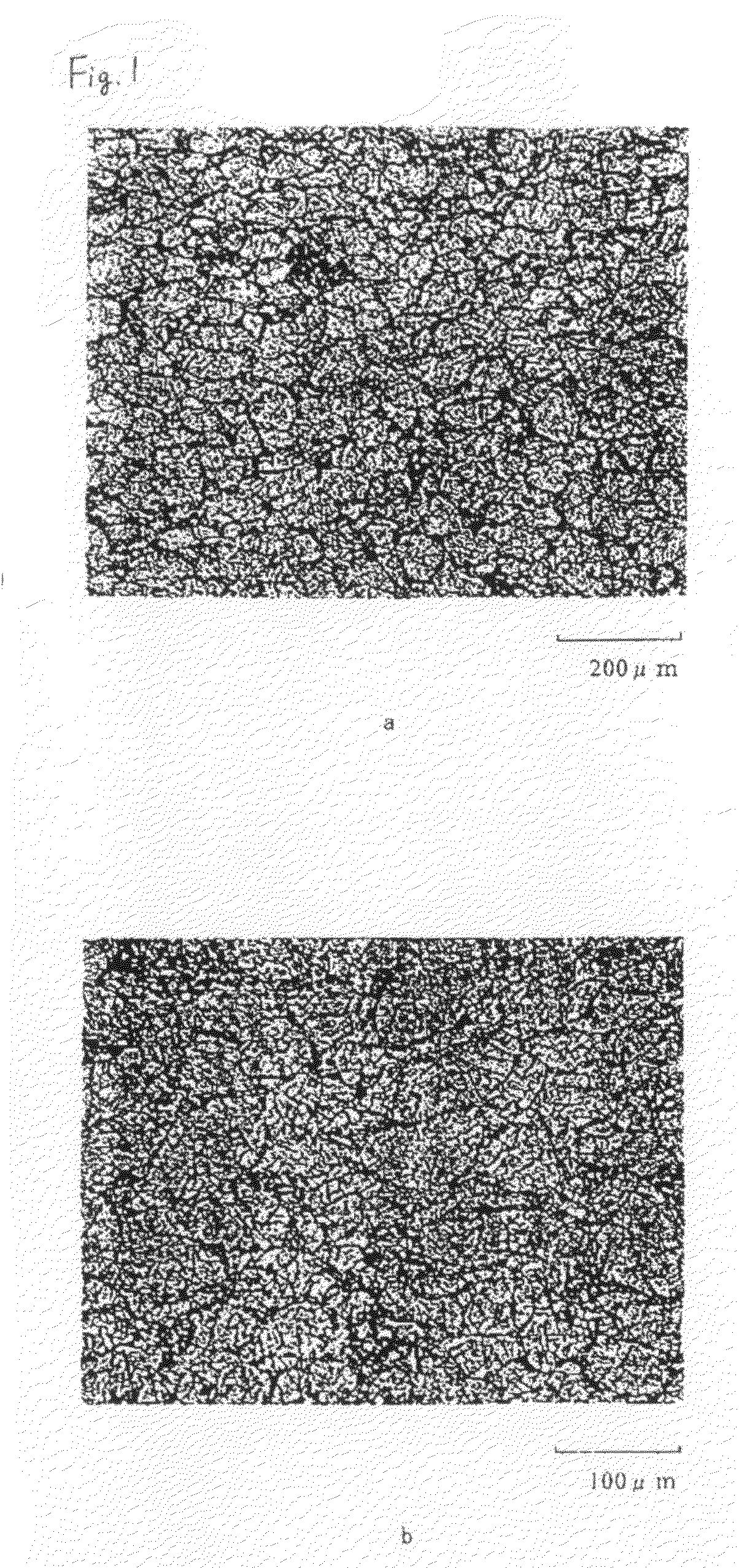

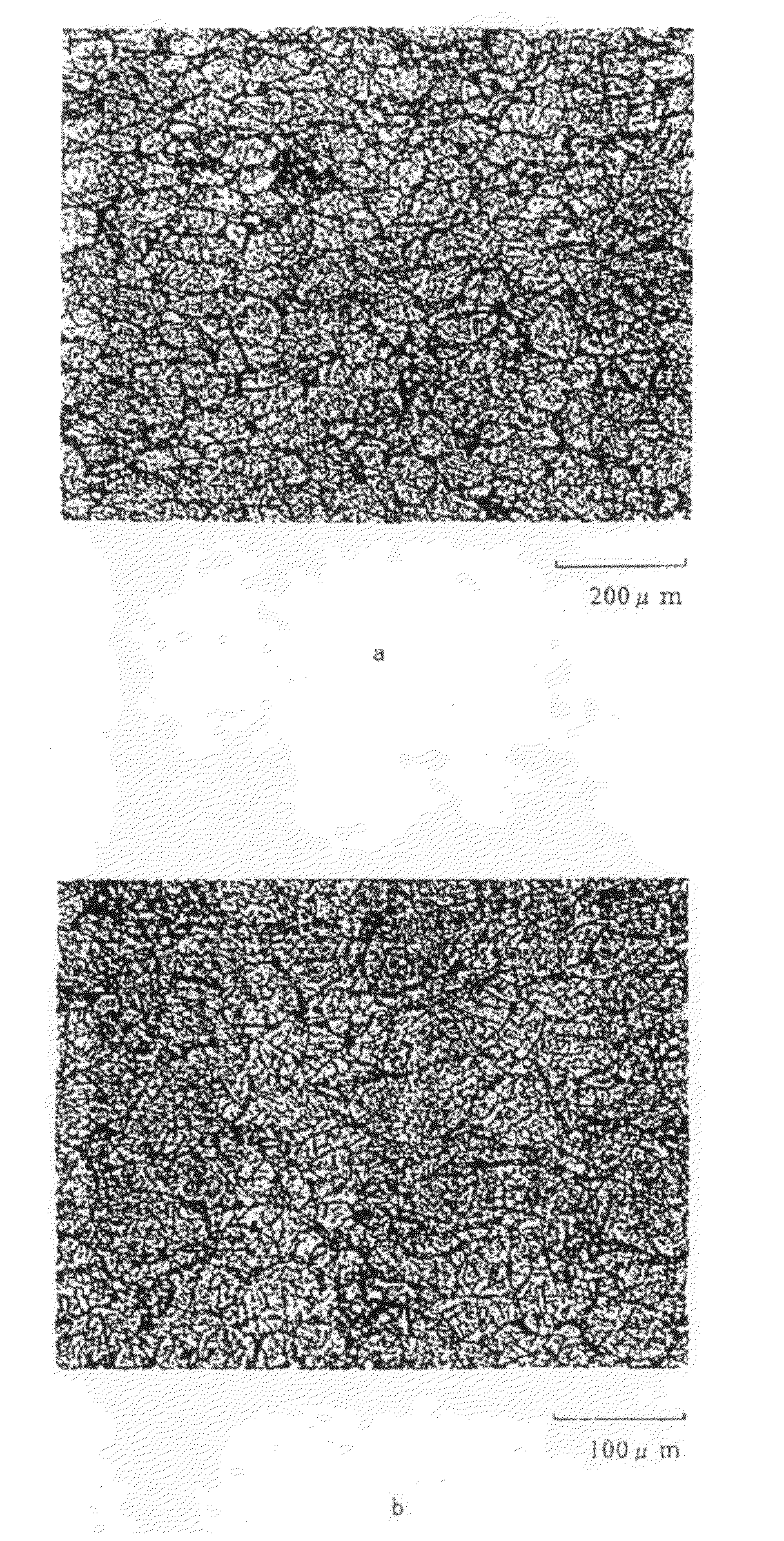

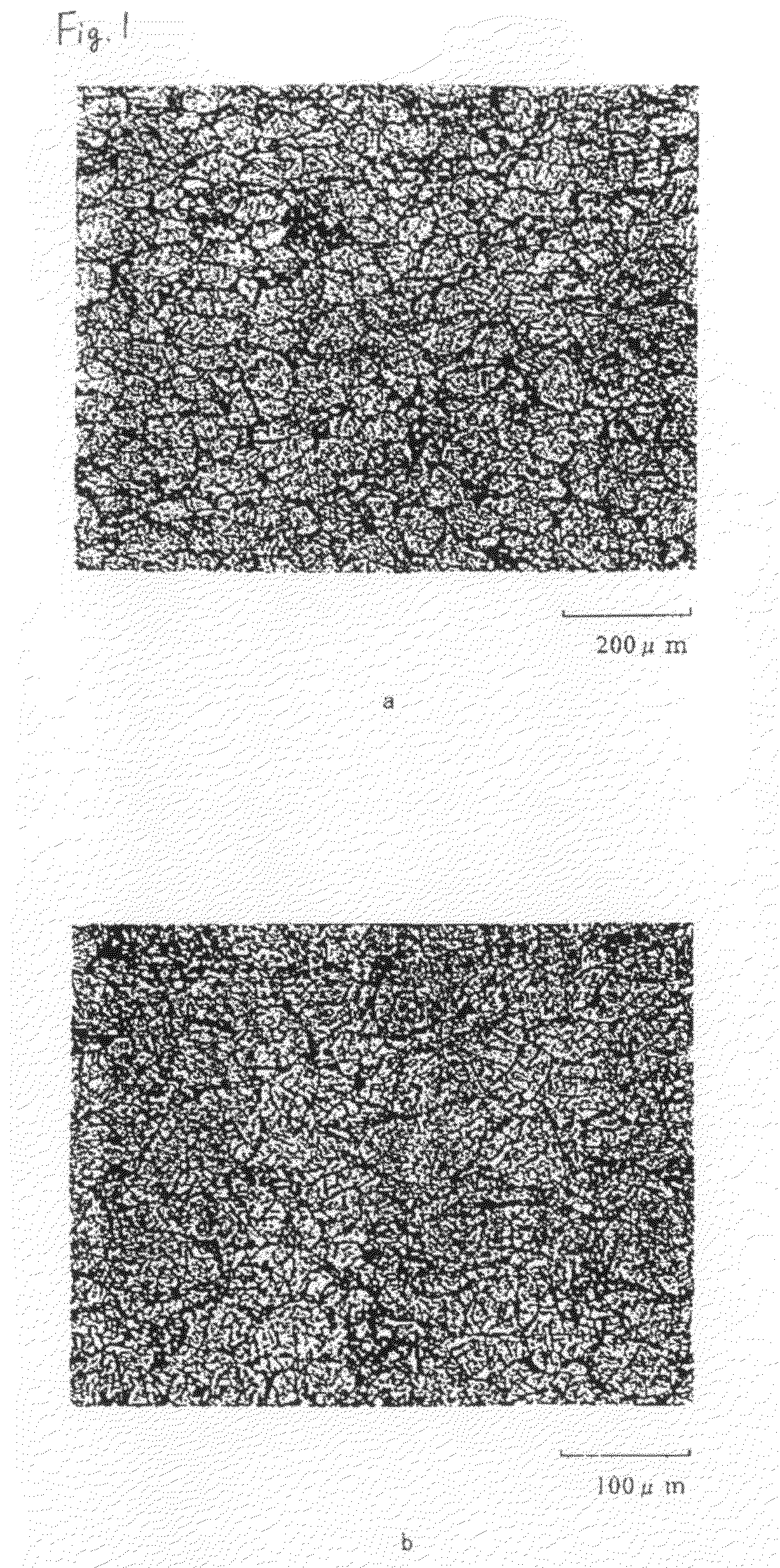

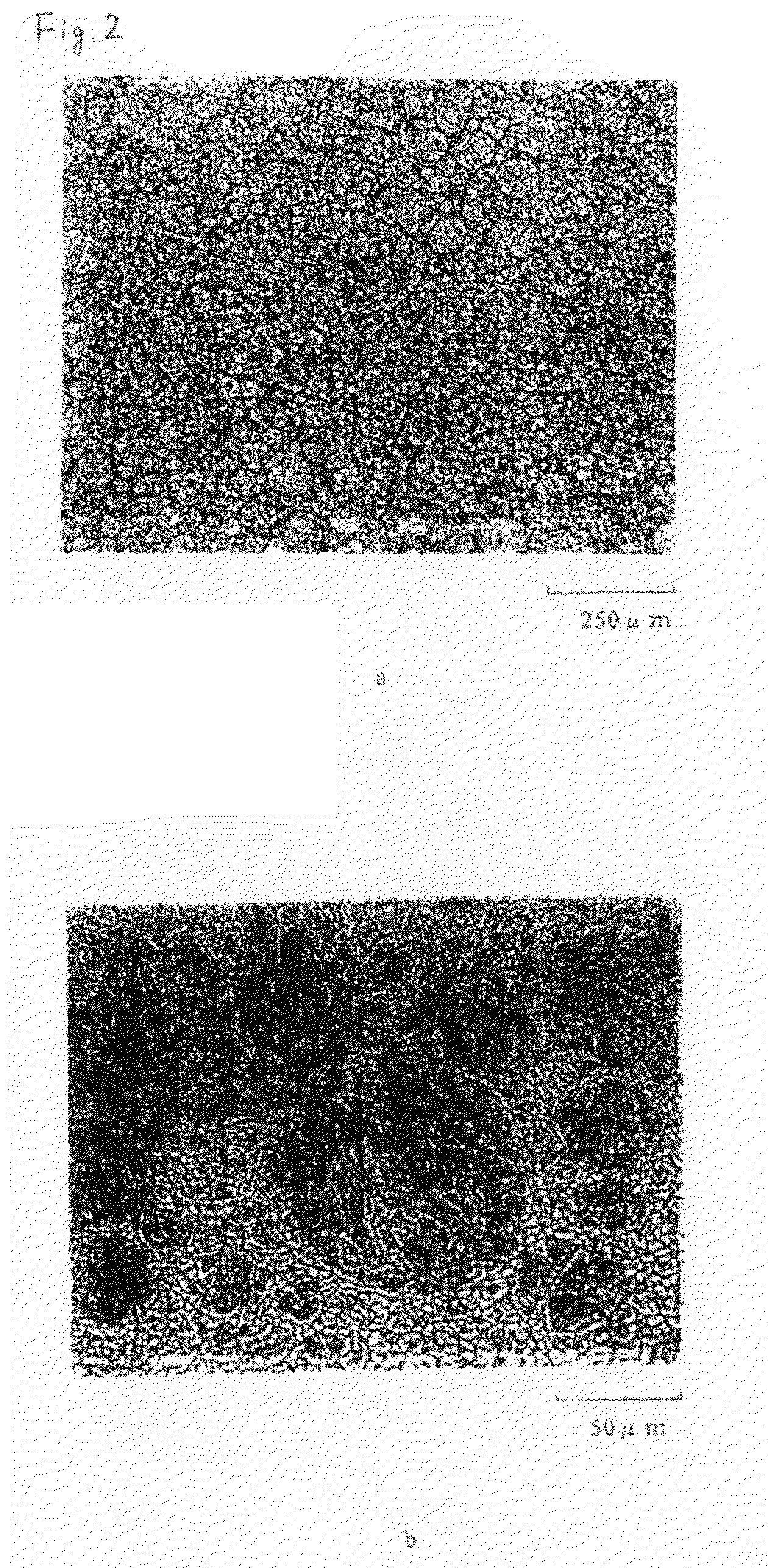

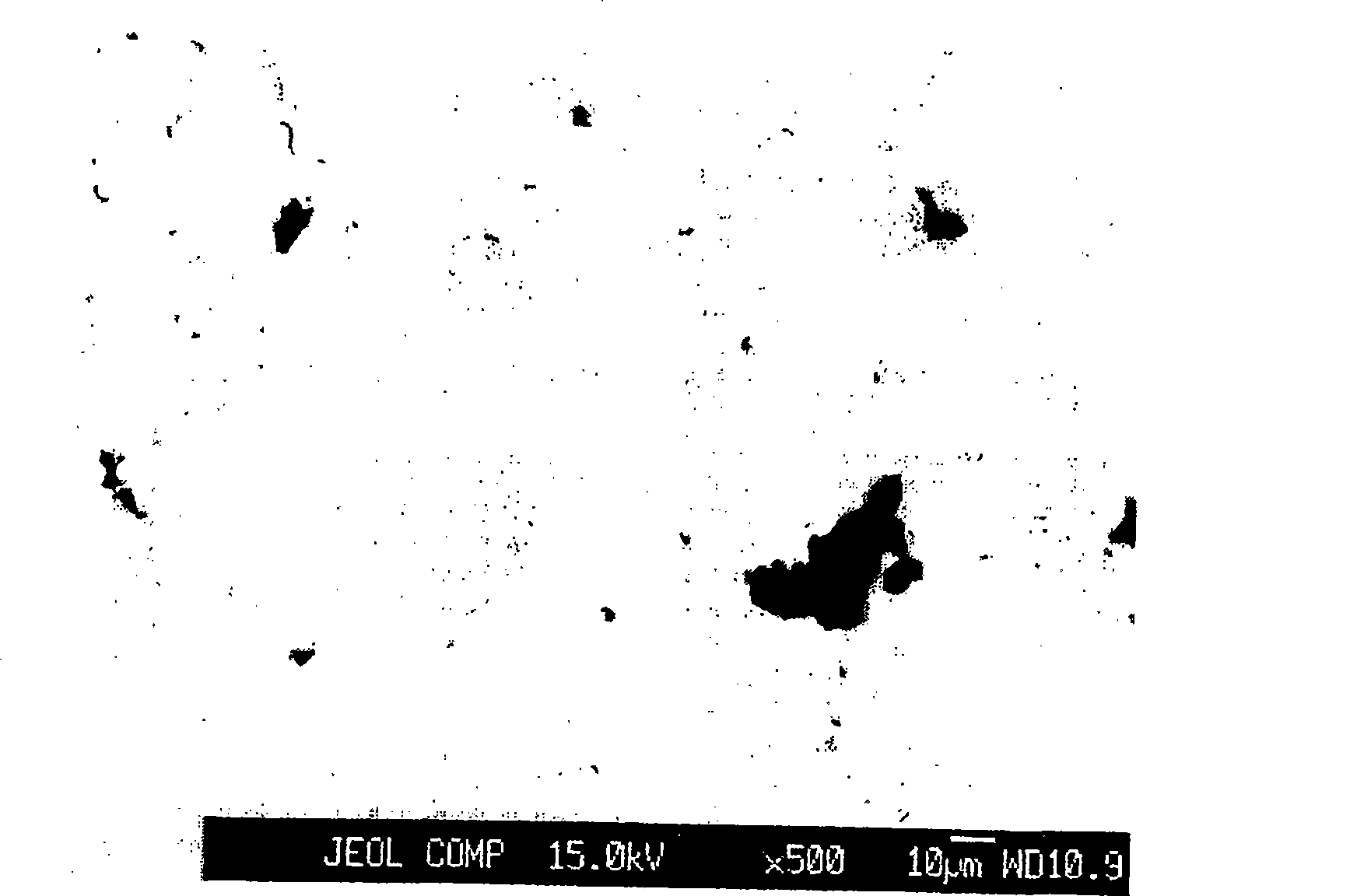

Aluminum-scandium alloy target blank, and preparation method and application thereof

InactiveCN109252142AHigh purityLow oxygenVacuum evaporation coatingSputtering coatingSpherical shapedAlloy

The invention discloses an aluminum-scandium alloy target blank, and a preparation method and an application thereof, and belongs to the technical field of aluminum-scandium alloys. The aluminum-scandium alloy target blank prepared by combination of cold crucible levitation melting and variable-frequency electromagnetic stirring has an oxygen content of below 100 ppm and a total aluminum and scandium element content of 99.95 mass%, and has a high purity and a low oxygen content, so later high-quality film formation is facilitated; the volume percentage of a secondary precipitated phase in thealuminum-scandium alloy target blank is 5-25%, the average size is 20-45 [mu]m, and the blank has polygonal and nearly spherical shapes, a uniform microstructure and a significantly improved density,so micro-cracks and other internal defects in the ingot casting and deformation processing processes are effectively avoided, and the quality and yield of a target are significantly improved.

Owner:有研新材料股份有限公司

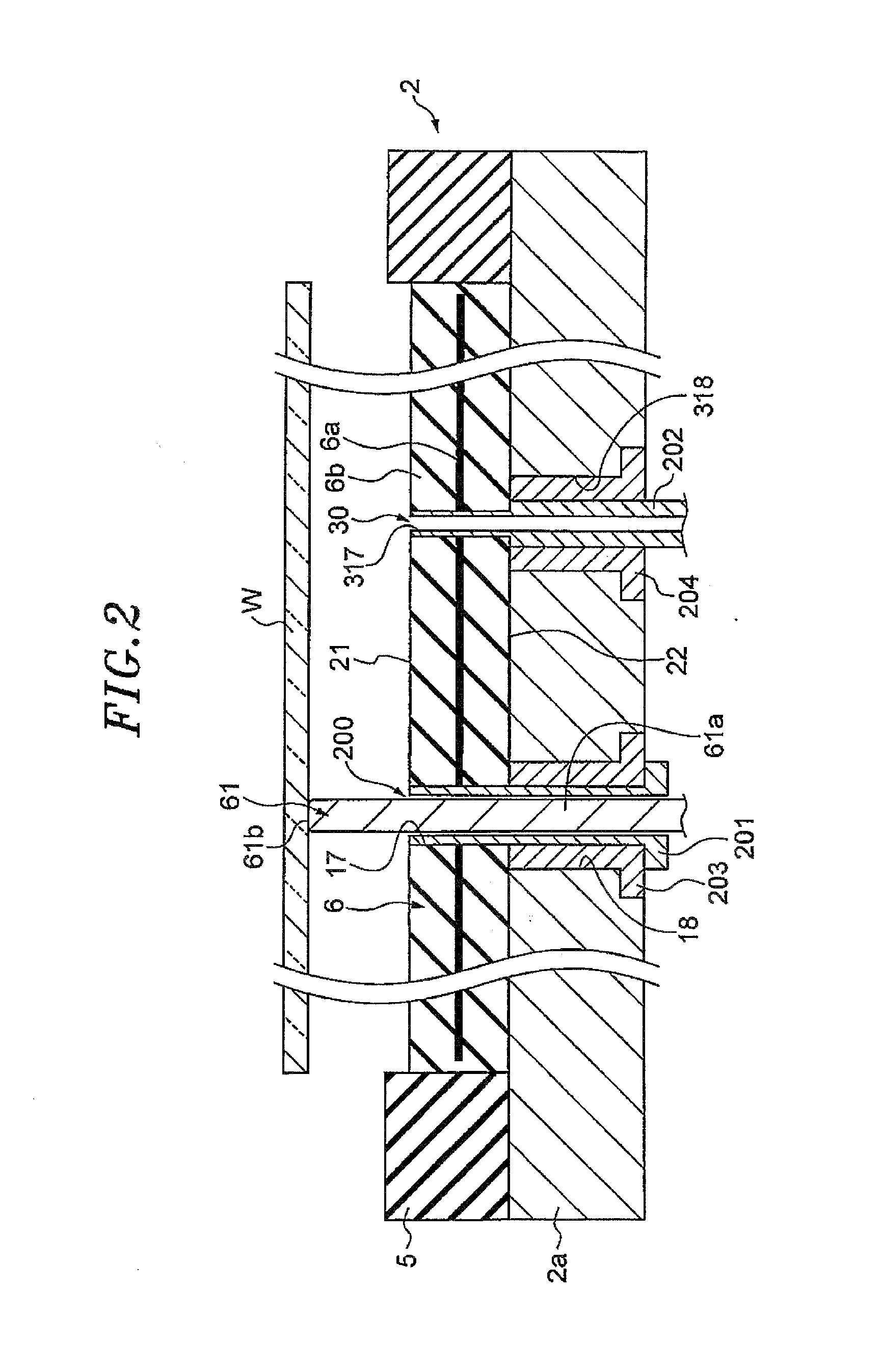

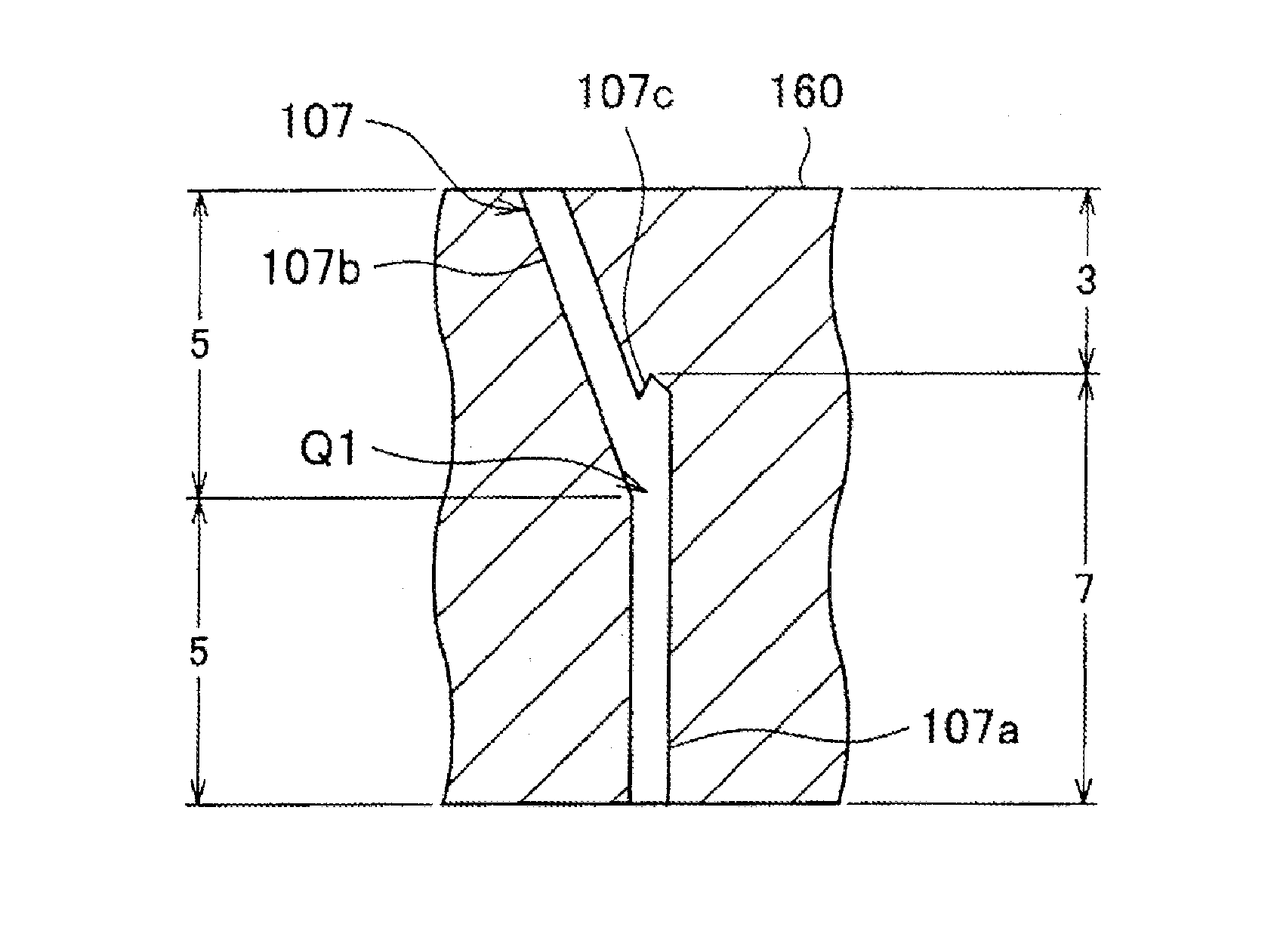

Mounting table and plasma processing apparatus

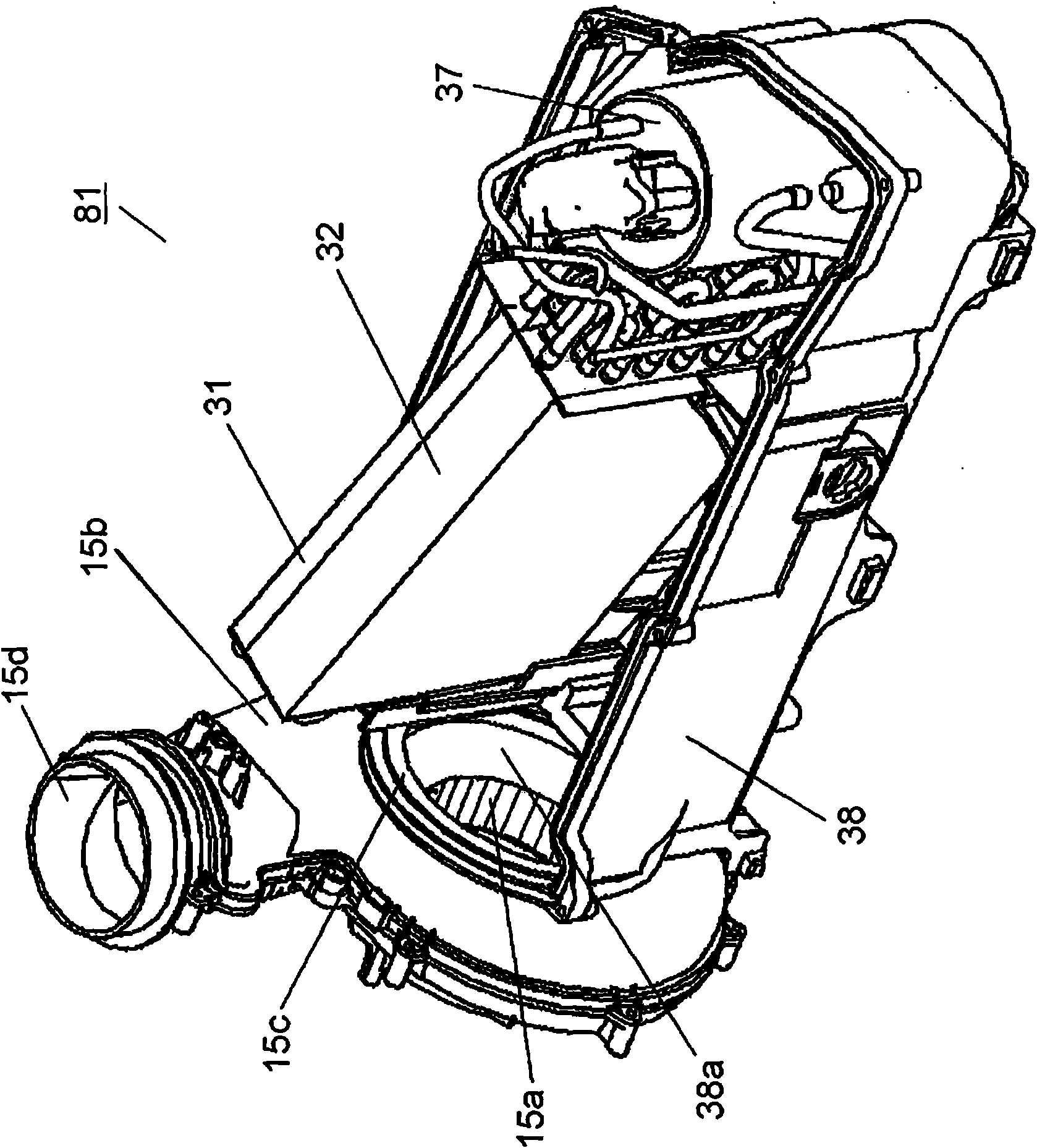

ActiveUS20140202635A1Eliminate spacePrevent abnormal dischargeSleeve/socket jointsElectric discharge tubesEngineeringMechanical engineering

A mounting table includes an electrostatic chuck having a mounting surface and a backside opposite to the mounting surface, a first through hole being formed in the mounting table; a base joined to the backside of the electrostatic chuck and having a second through hole in communication with the first through hole; a lifter pin which is received in a pin hole formed by the first through hole and the second through hole, the lifter pin being movable up and down to protrude beyond and retract below the mounting surface. An upper end portion of the lifter pin has a shape in which a diameter decreases toward a lower end of the lifter pin to correspond to a shape of the upper end portion of the pin hole. The upper end portion of the lifter pin is in surface contact with the upper end portion of the pin hole.

Owner:TOKYO ELECTRON LTD

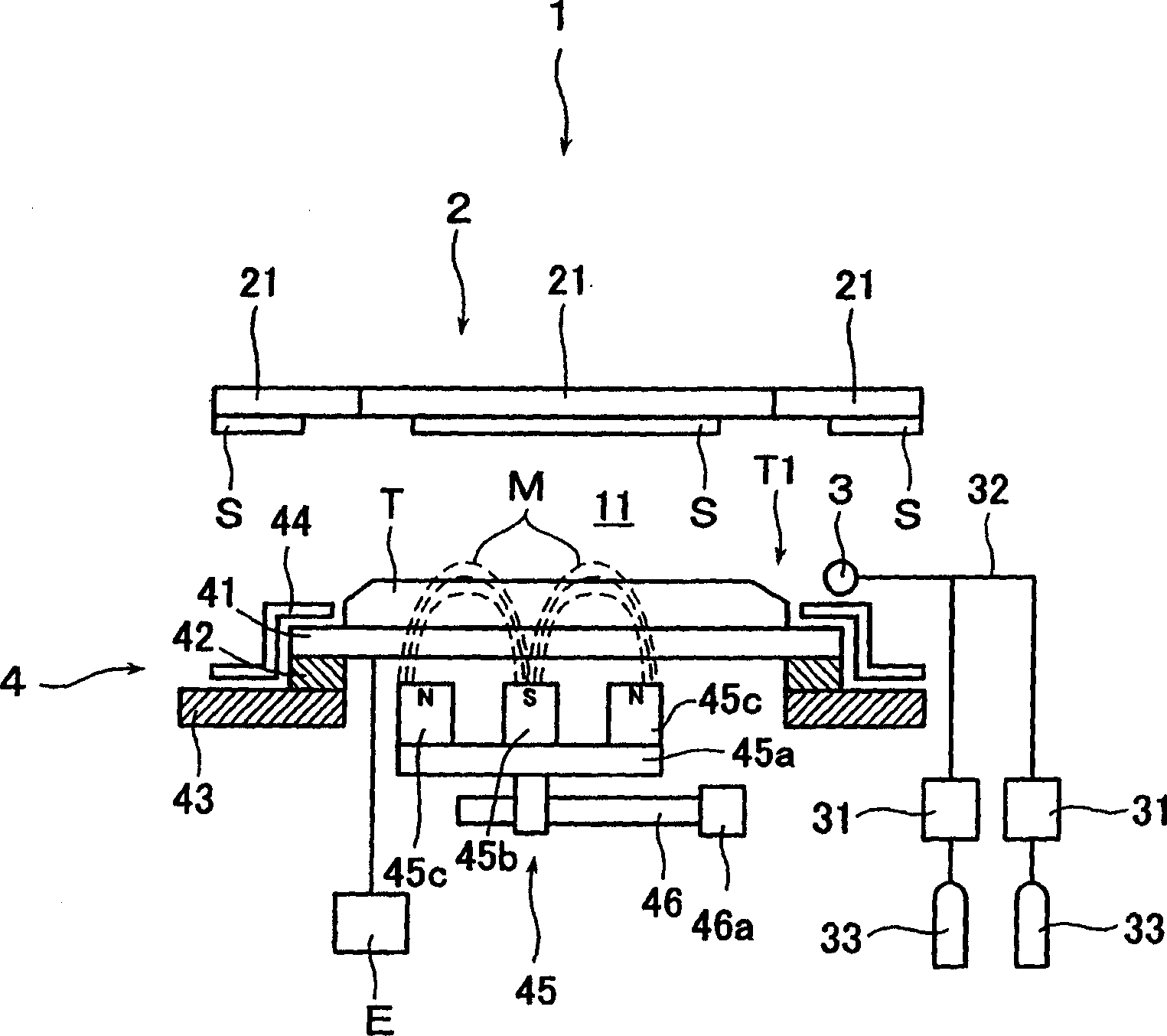

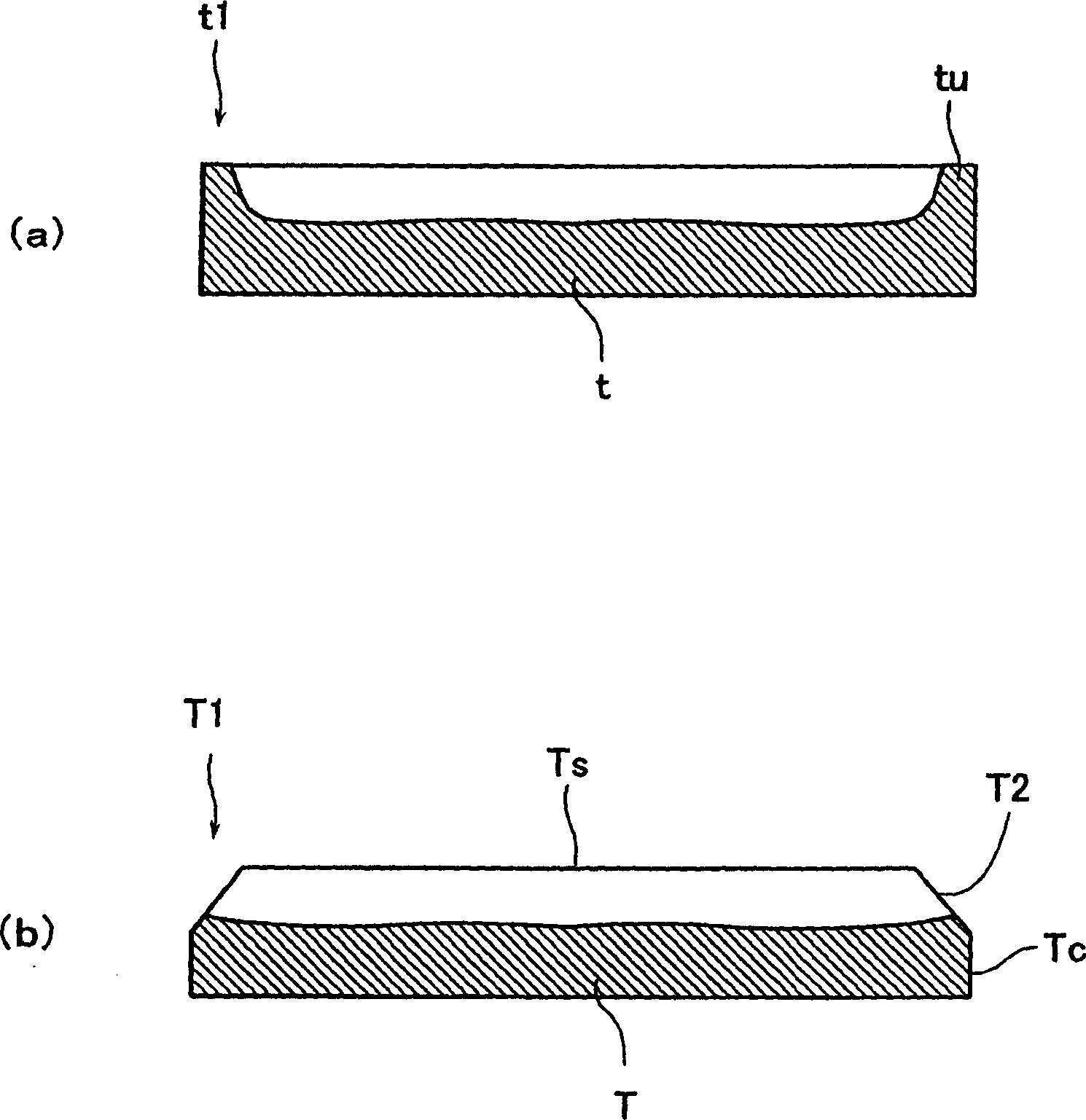

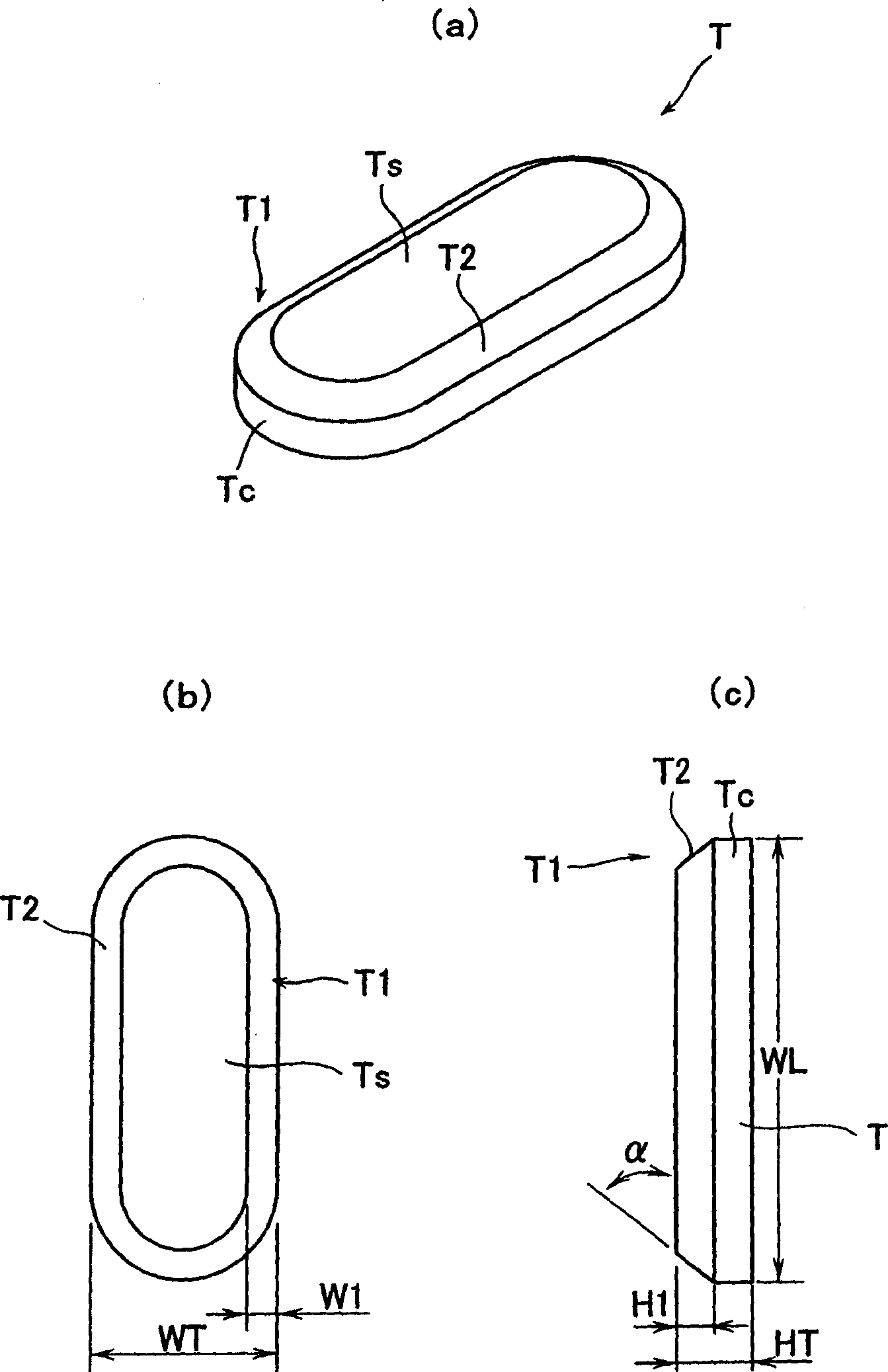

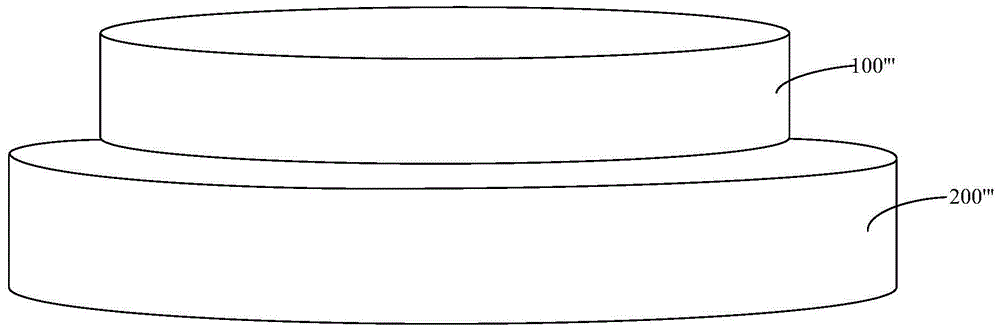

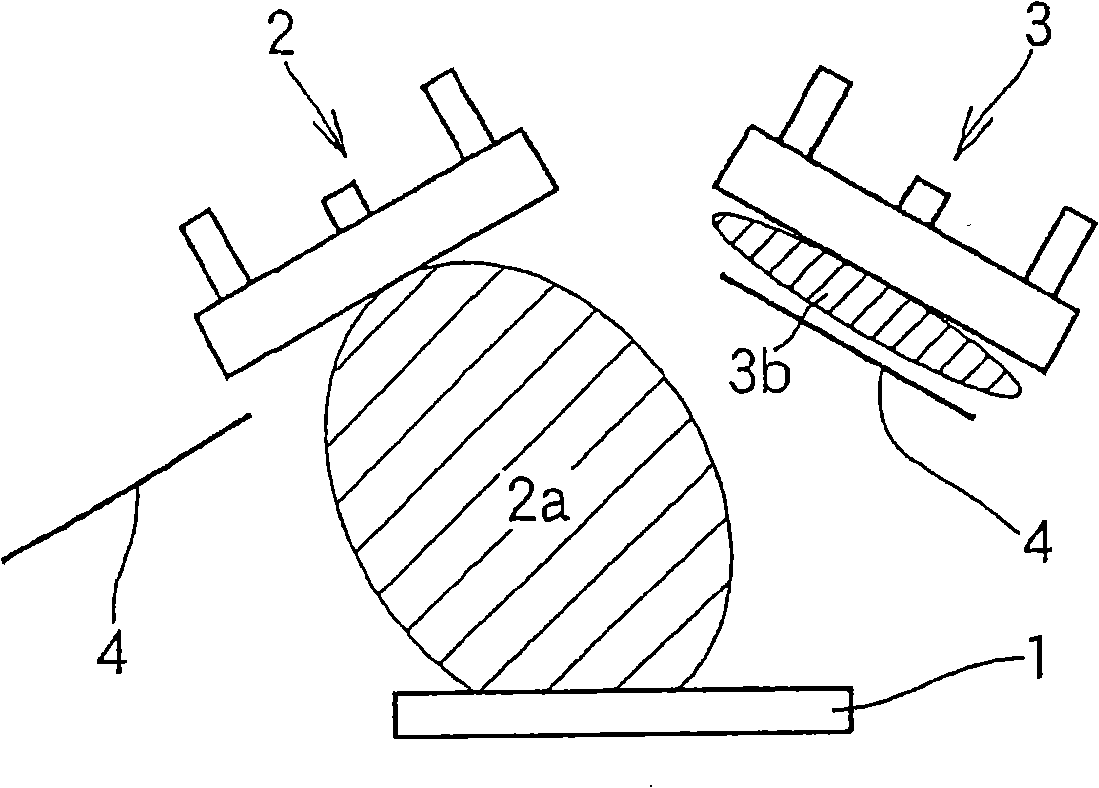

Sputtering target and sputtering method using the target

ActiveCN1693531AHigh formation reproducibilityPrevent abnormal dischargeElectric discharge tubesVacuum evaporation coatingSputteringMaterials science

The invention solves a problem that a target made by a prior art leaves its peripheral part unsputtered and consequently uneroded, when sputtered after having been mounted on a sputtering apparatus and surrounded by an earth shield, because when plasma is generated, an electric current passes to the earth shield from the target and the plasma is not formed on the surface of the peripheral part of the target. The sputtering target T has a predetermined outer shape which has a slope T2 formed on the whole periphery at which a sputtered surface intersects with a peripheral wall surface.

Owner:ULVAC INC

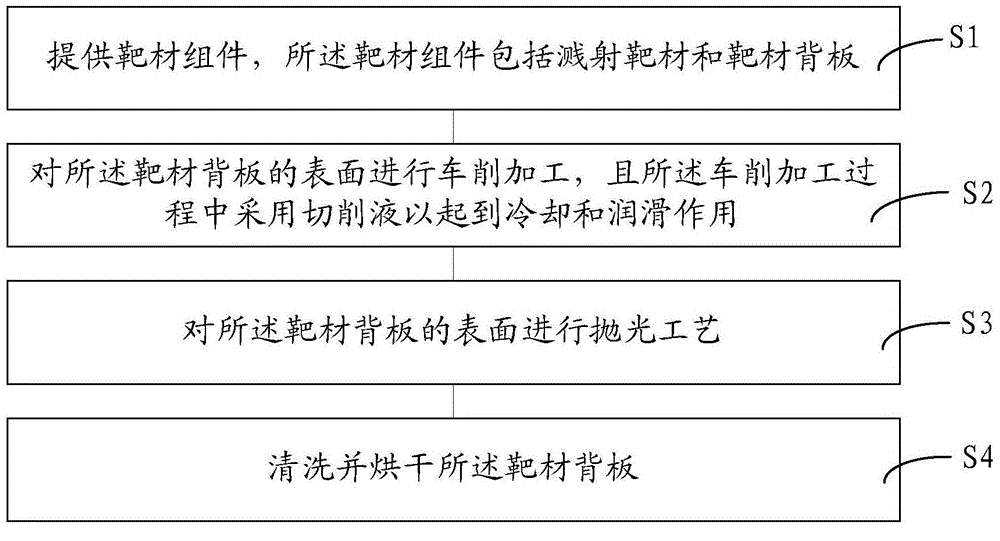

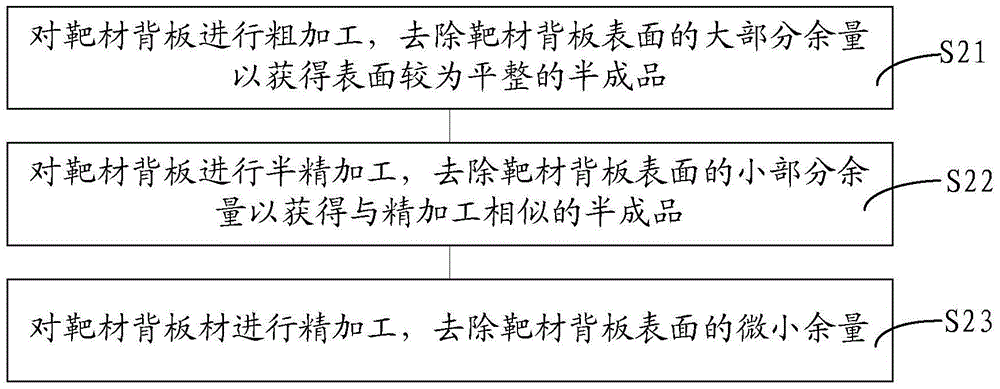

Machining method of target assembly

ActiveCN106312565AAntioxidantPrevent conductivity dropOther manufacturing equipments/toolsOxidation resistantEngineering

The invention provides a machining method of a target assembly. The method comprises the steps that the sputtering target assembly is provided and comprises a target backboard, and aluminum is contained in target materials; and after the surface of the target backboard is subjected to the turning process, the surface, obtained after the turning process, of the target backboard is subjected to the polishing process at least two times. By means of the polishing process, pores in the surface of the target backboard are closed, the target backboard has the antioxidation function under the natural condition, and therefore the problem that the electric conductivity of the target backboard is reduced due to oxidation of the target backboard is avoided, then the phenomenon of abnormal discharge or outage of a sputtering target in the sputtering process is avoided, and the quality of the sputtering target is guaranteed.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

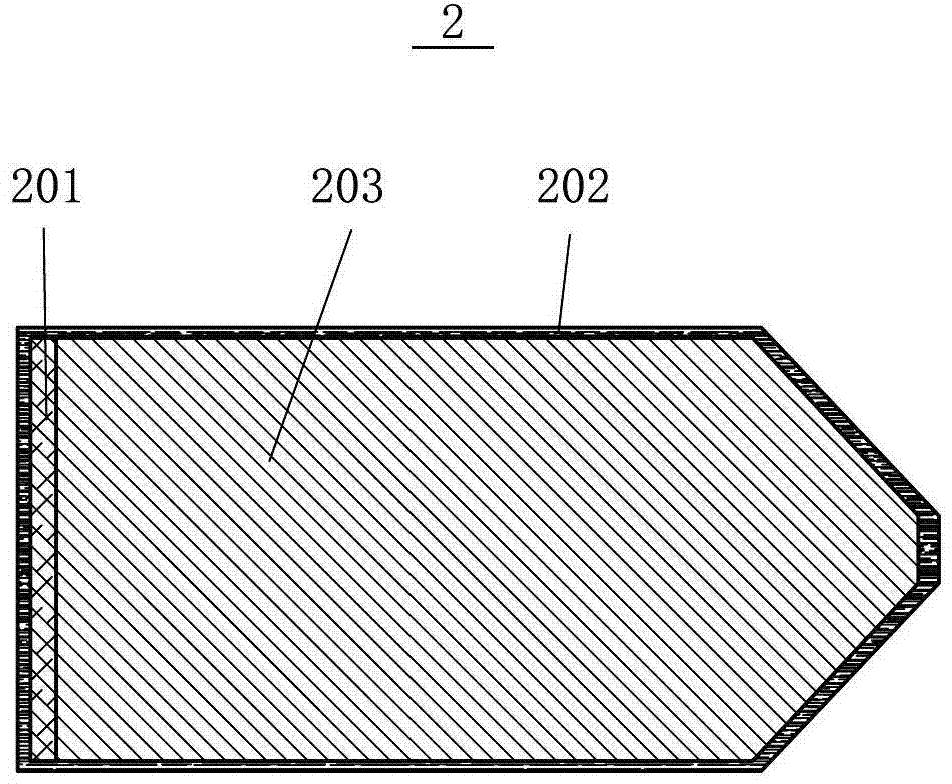

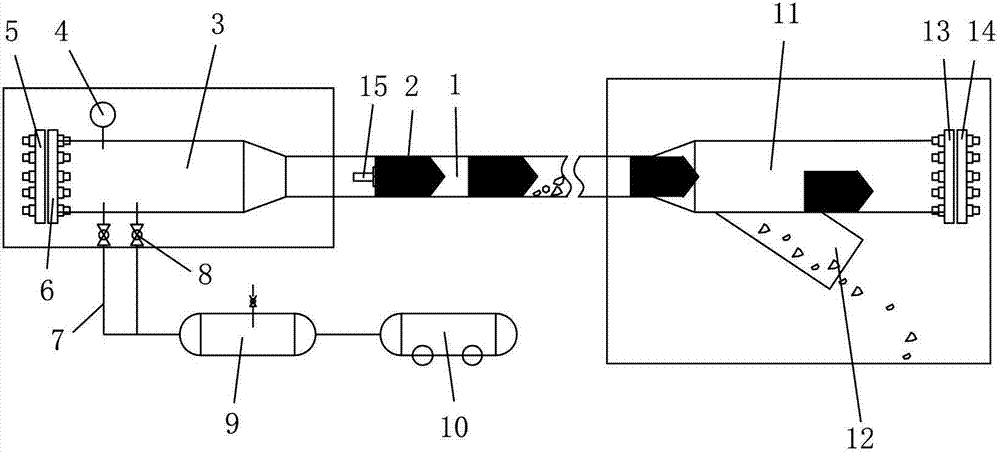

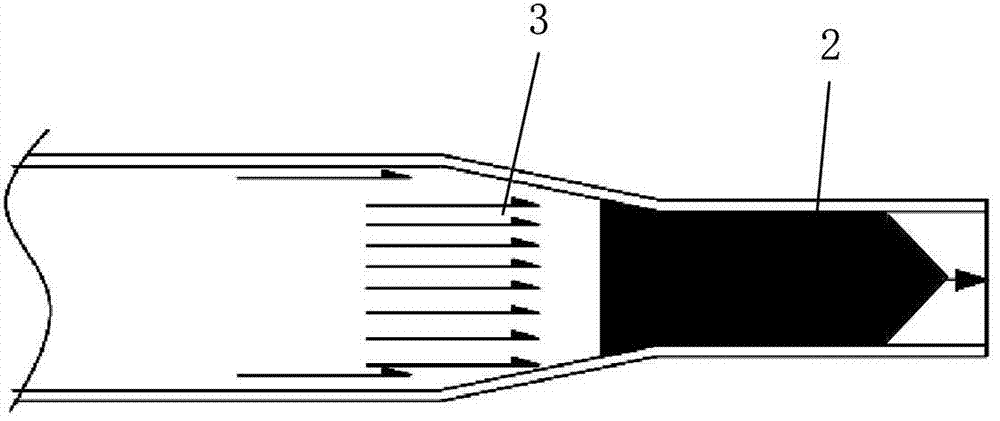

Elastic cleaning ball, cleaning device, cleaning method and pressure test device and method

InactiveCN103071653AImprove cleanlinessHigh strengthMeasurement of fluid loss/gain rateHollow article cleaningTest efficiencyElastic solids

The invention discloses an elastic cleaning ball, a cleaning device and a cleaning method and a pressure test device and a pressure test method for a pipeline. The elastic cleaning ball comprises an elastic solid core, an elastic reinforcing plate arranged on the rear surface of the elastic solid core and an elastic coating which wraps the elastic solid core and the elastic reinforcing plate. The cleaning device comprises a ball serving device and a ball receiving device which are connected to both ends of the pipeline, and at least one elastic cleaning ball. The elastic cleaning ball is compactly contacted with the inner wall of the pipeline in the cleaning process. According to the cleaning device and cleaning method provided by the invention, the pipeline for conveying ore pulp is efficiently cleaned. The pressure test device comprises a first end water injection device, a water injection pump and a rear end emptying device which are connected to both ends of the pipeline as well as the elastic cleaning ball for emptying air in the pipeline. According to the pressure test device and method provided by the invention, the efficient pressure test efficiency is realized, and air in the pipeline can be completely emptied.

Owner:PANGANG GRP ENG TECH

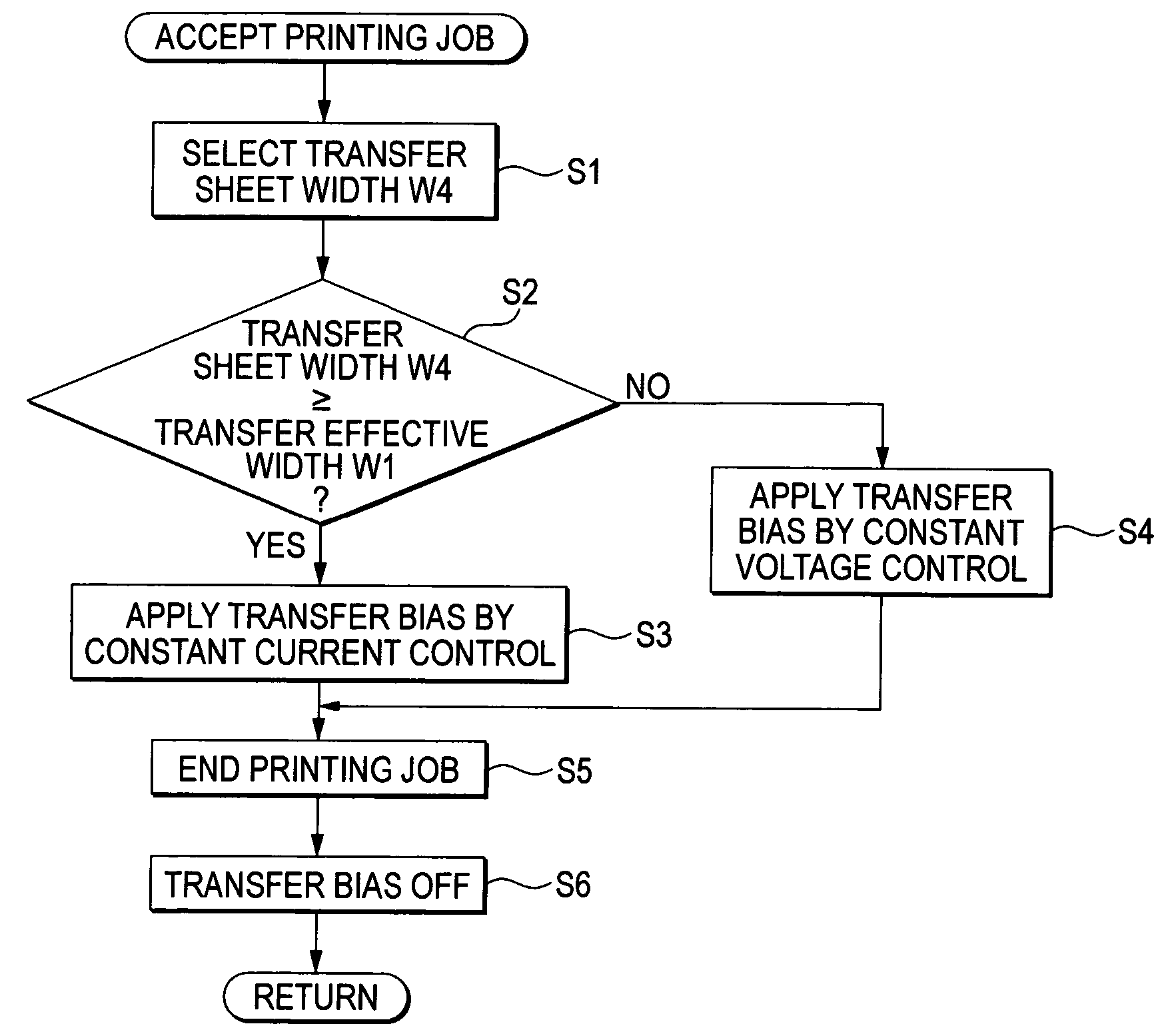

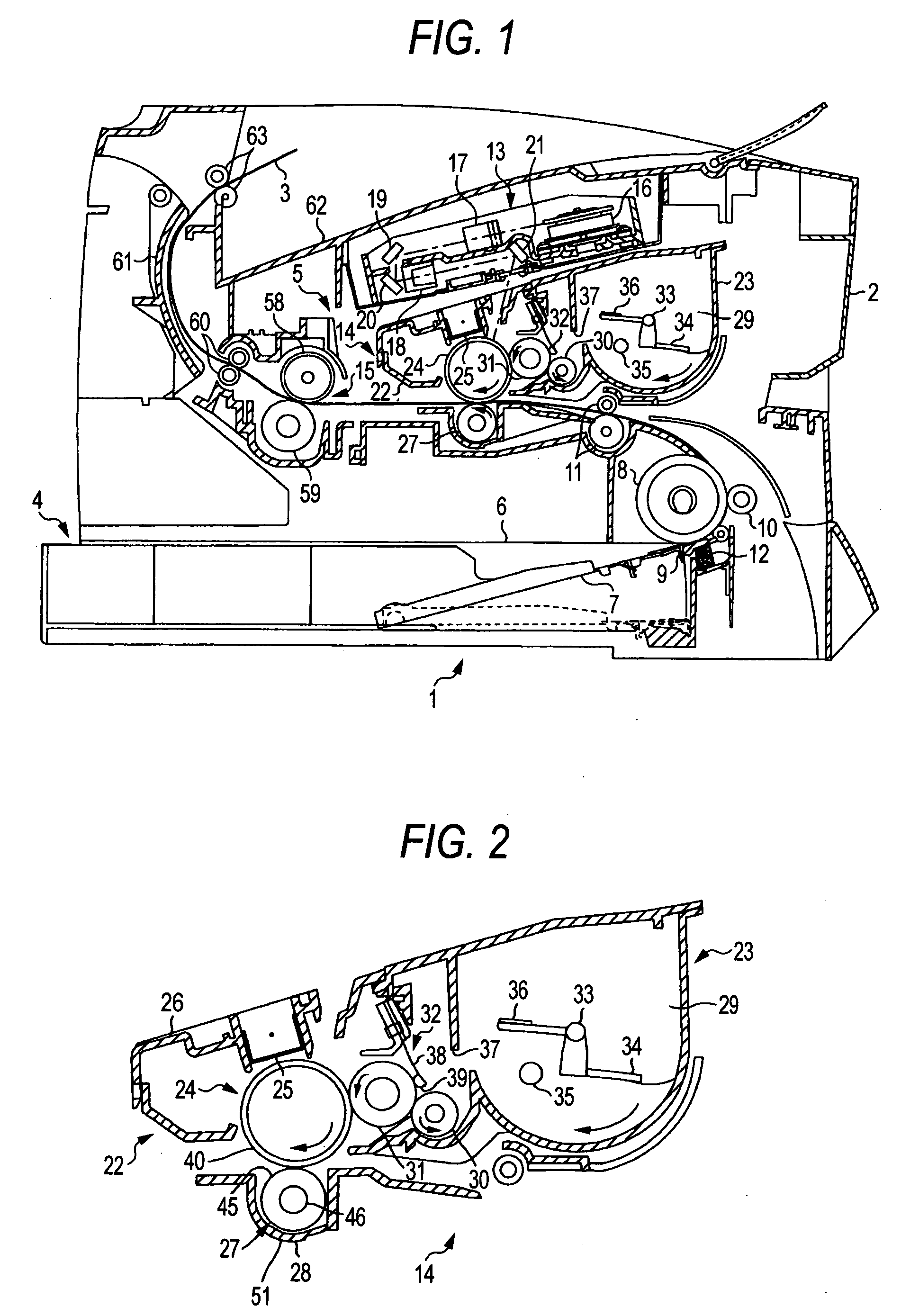

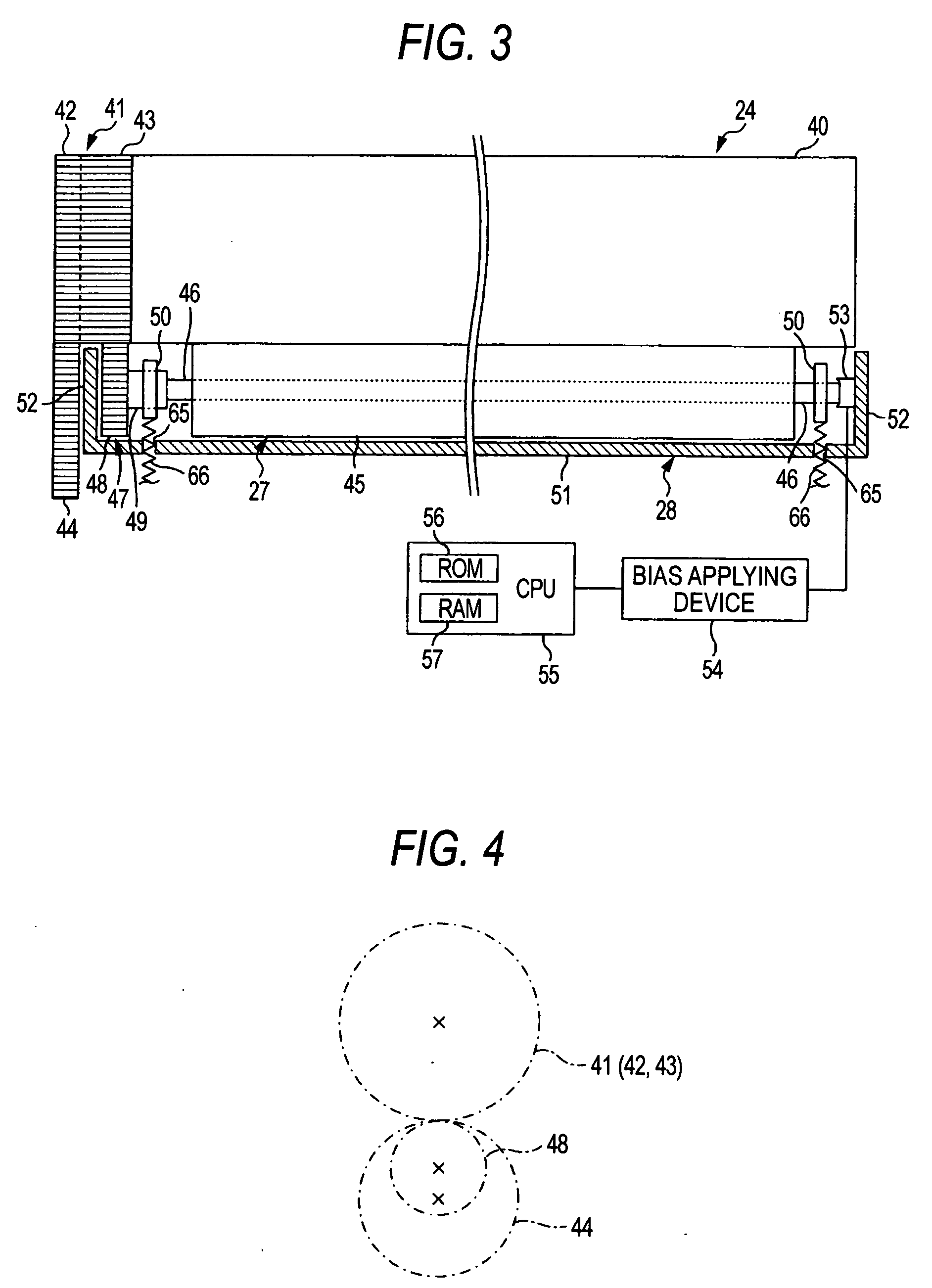

Image forming apparatus and process cartridge

ActiveUS20050100357A1Prevent abnormal dischargeReduce harmElectrographic process apparatusElectrical and Electronics engineeringControl unit

An image forming apparatus includes: a transfer member that transfers a developer image onto a transfer medium to form an image on the transfer medium; a bias applying unit that applies a transfer bias to the transfer member; and a bias control unit that controls the transfer bias to be applied to the transfer member by the bias applying unit, wherein a longitudinal length of the transfer member is formed to be shorter than a width of the transfer medium having a maximum width on which the image is to be formed with the image forming apparatus.

Owner:BROTHER KOGYO KK

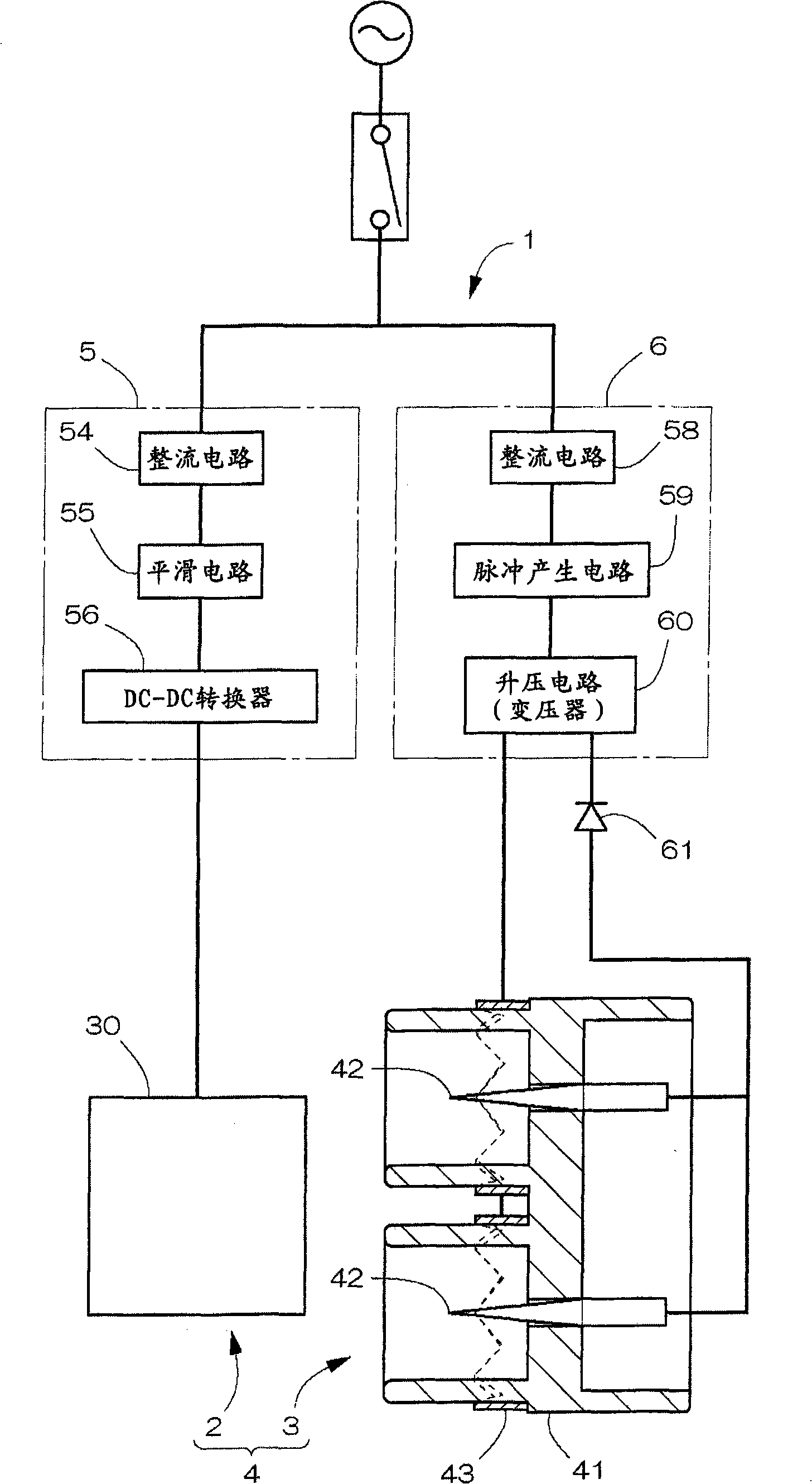

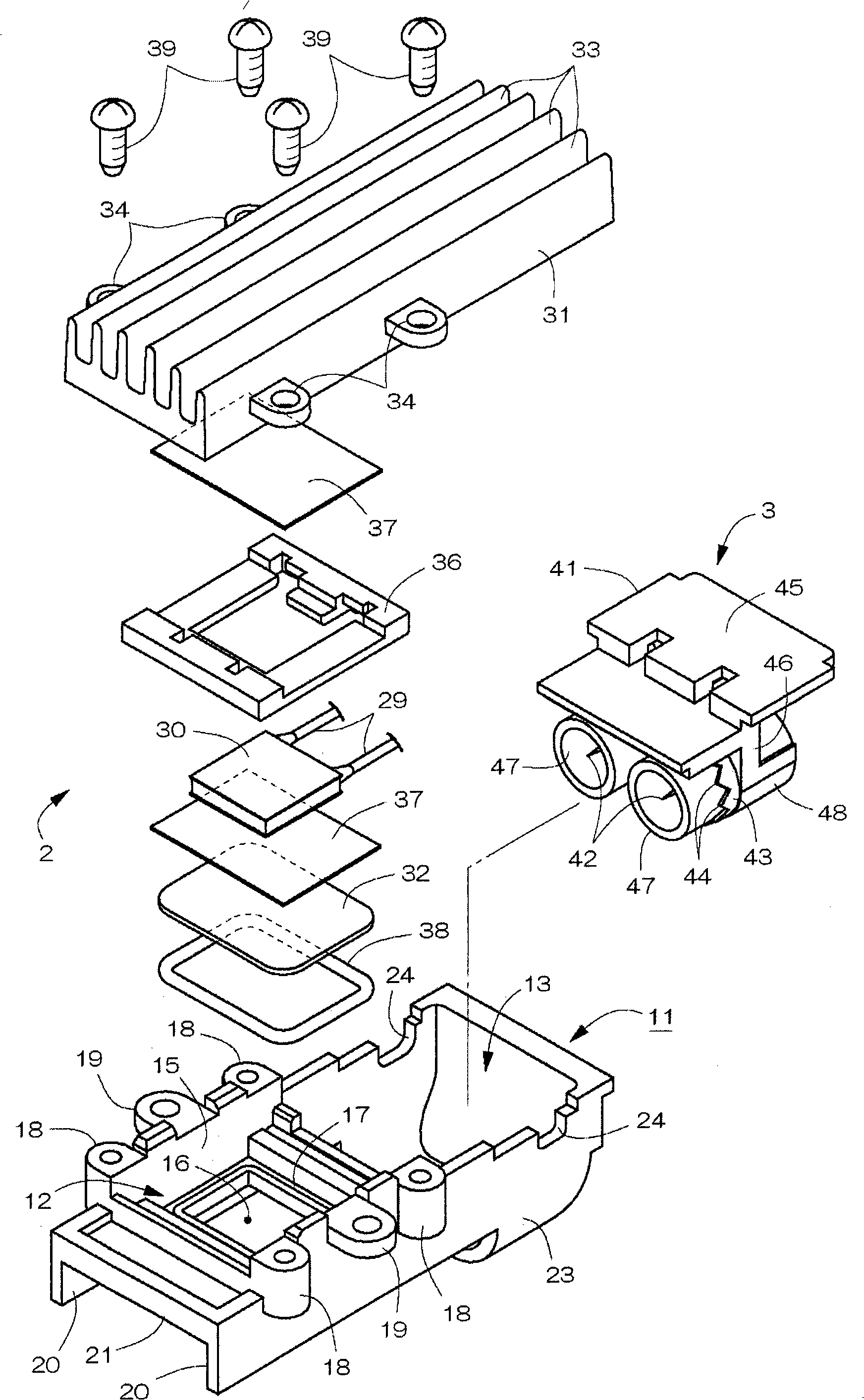

Ion generating device

ActiveCN101335427AIncrease productionEliminate Discharge State DisordersCorona dischargeLitterCorona discharge

The present invention relates to an ion generating device, and provides an ion generating device which can not be influenced by litter deviation of machining precision or assembly precision and can stably execute corona discharge. The ion generating device of the invention is provided with a barrel wall (47), an acicular discharge electrode (42) arranged at the center of the barrel wall (47), and a barrel relative electrode (43) arranged at the circumference of the barrel wall (47). The edge of the relative electrode (43) is formed with a group of sharp convex parts (44).

Owner:MAXELL HLDG LTD

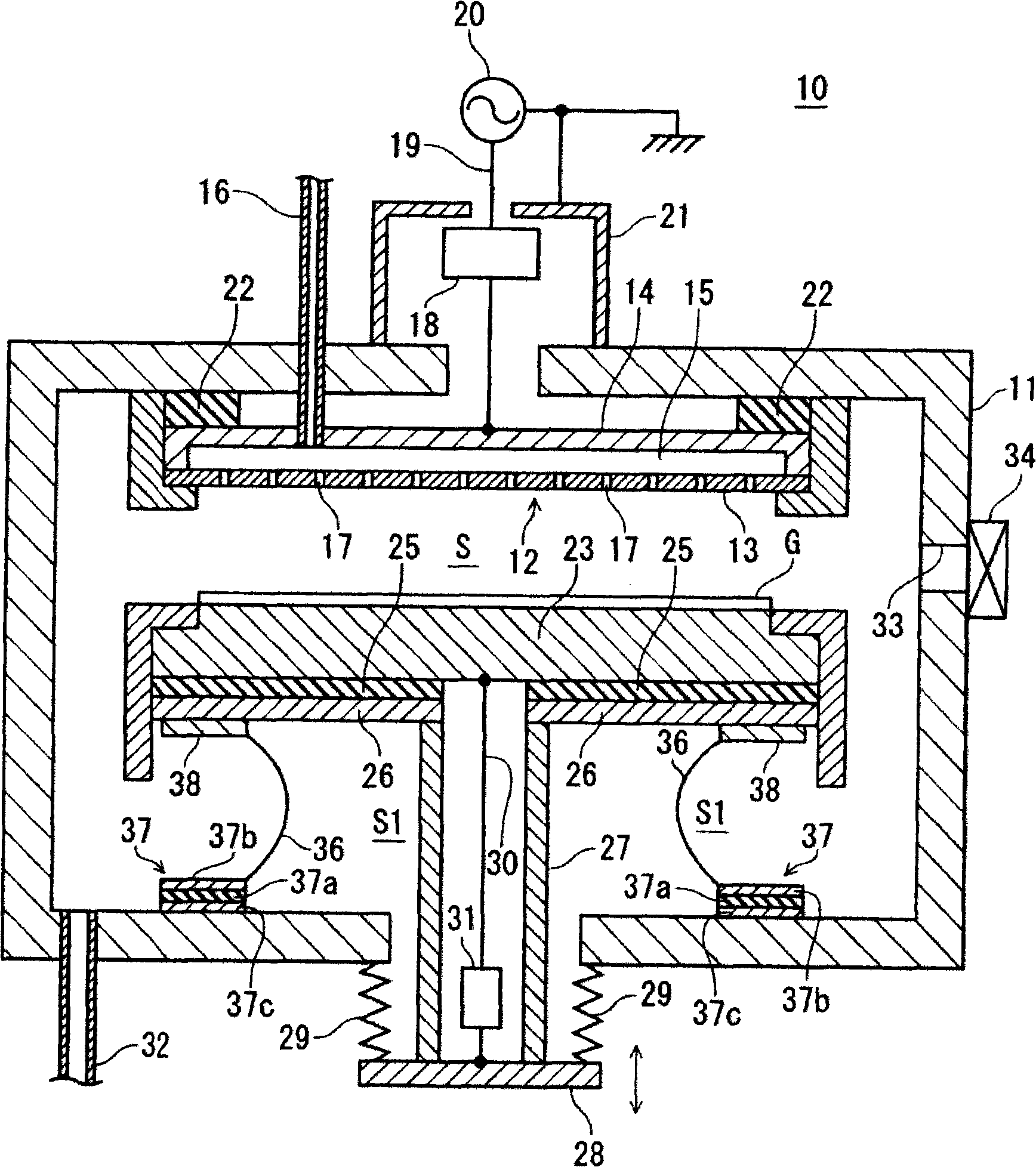

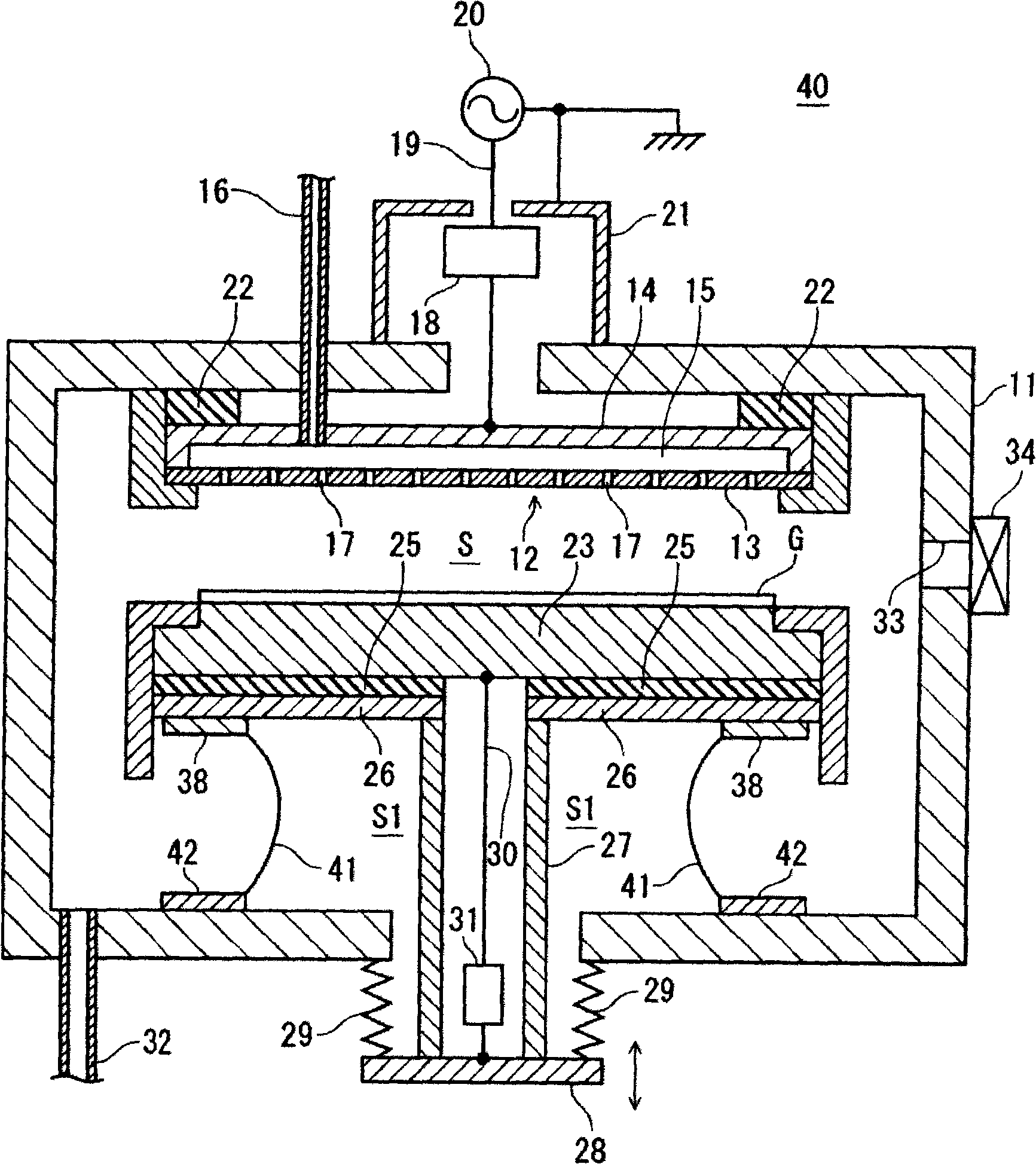

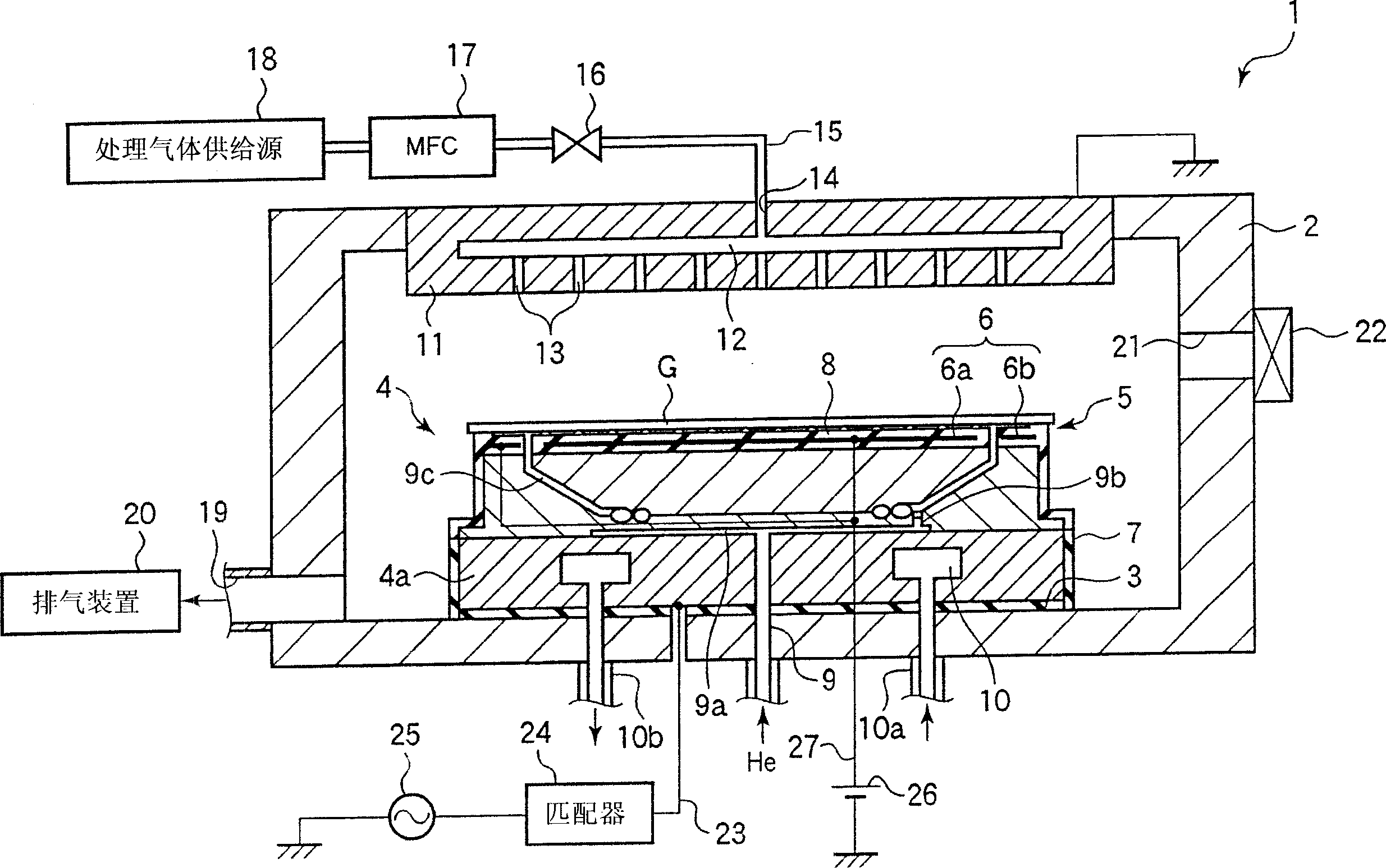

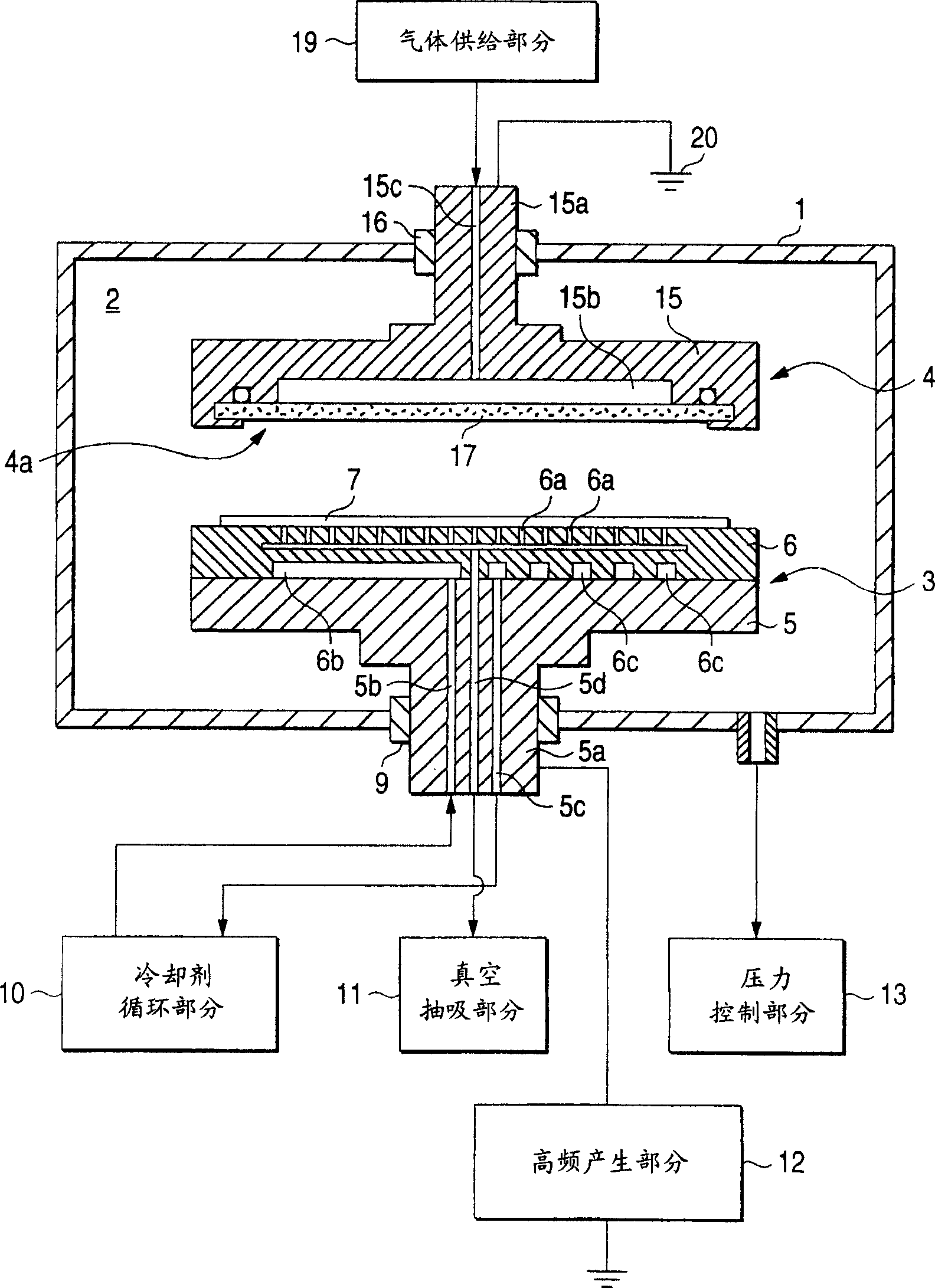

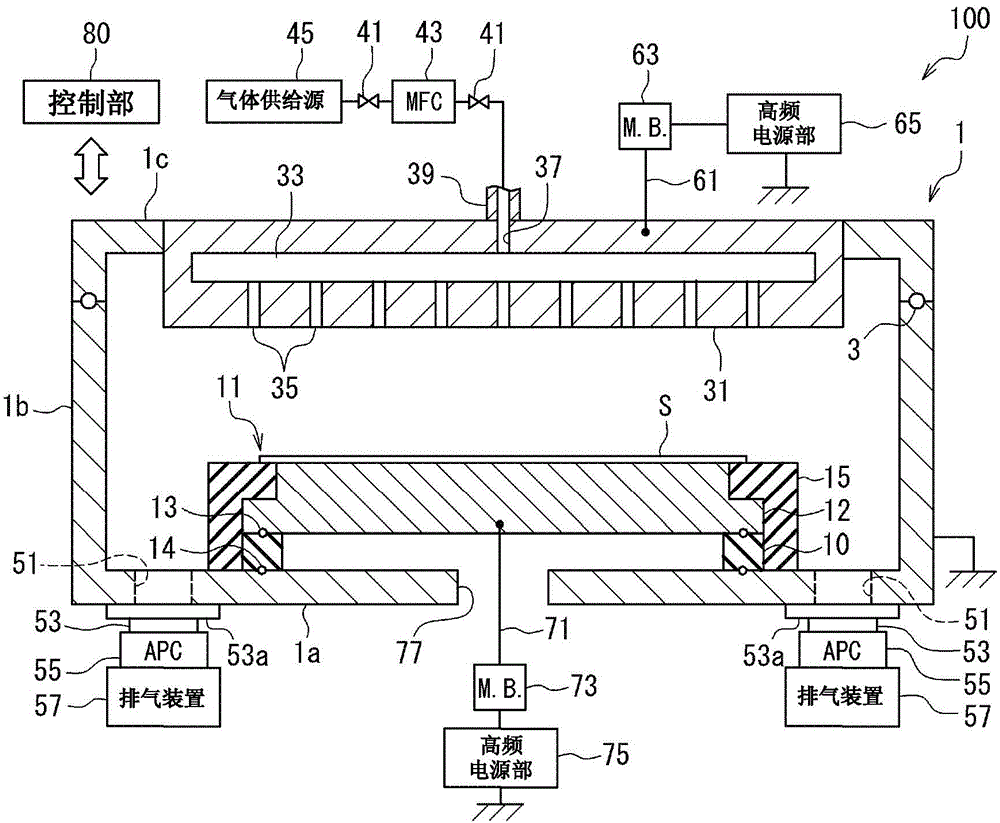

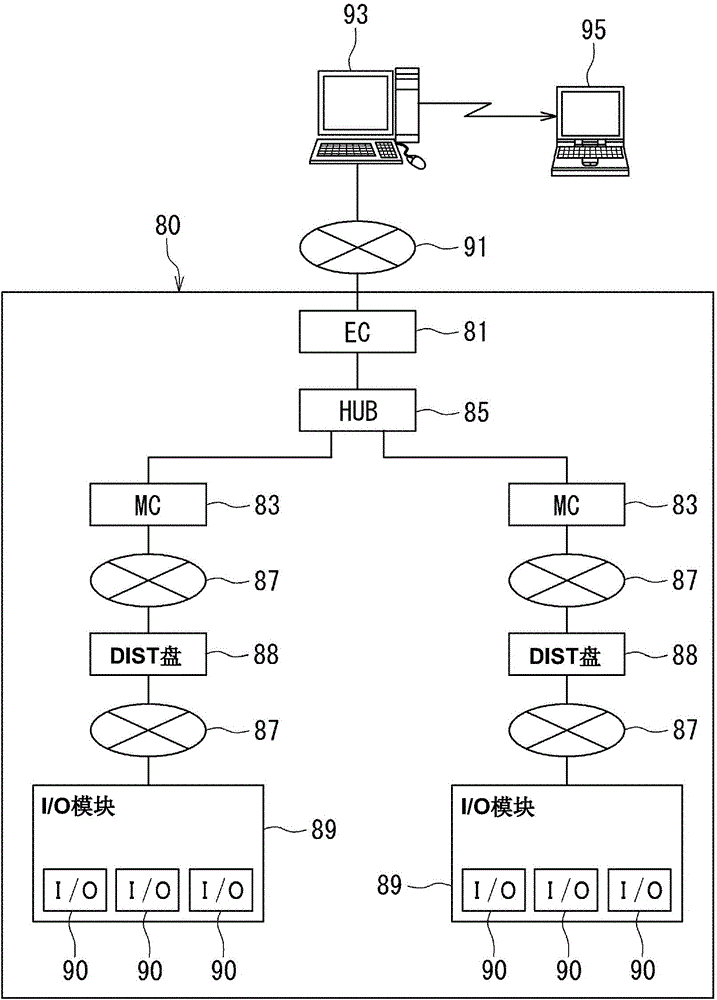

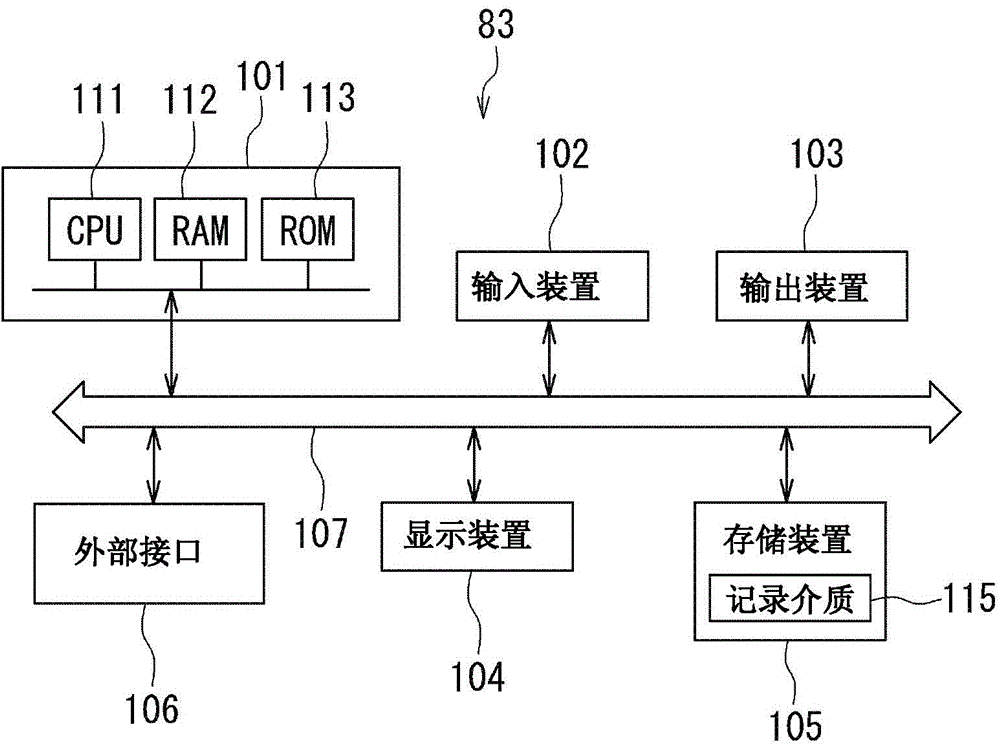

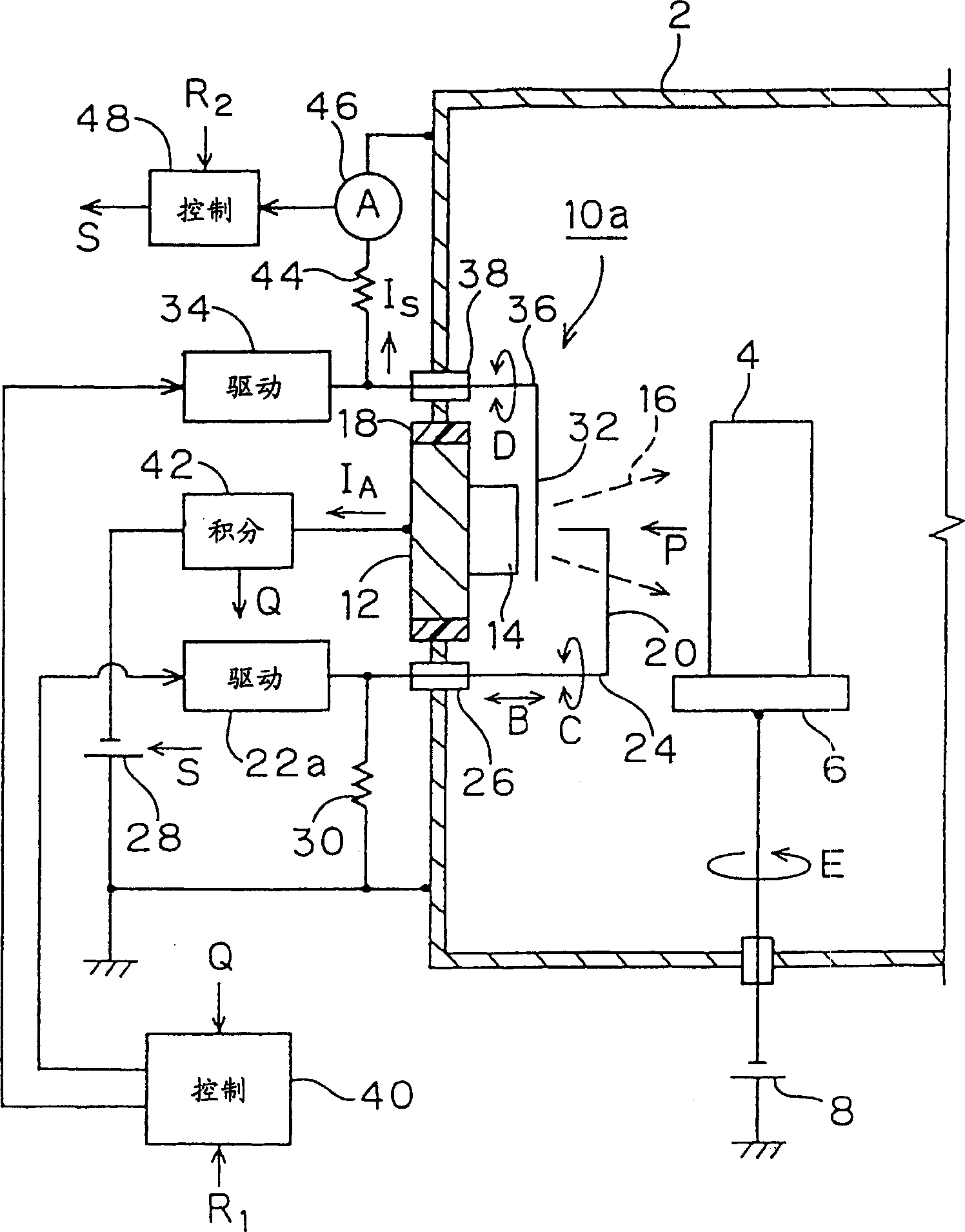

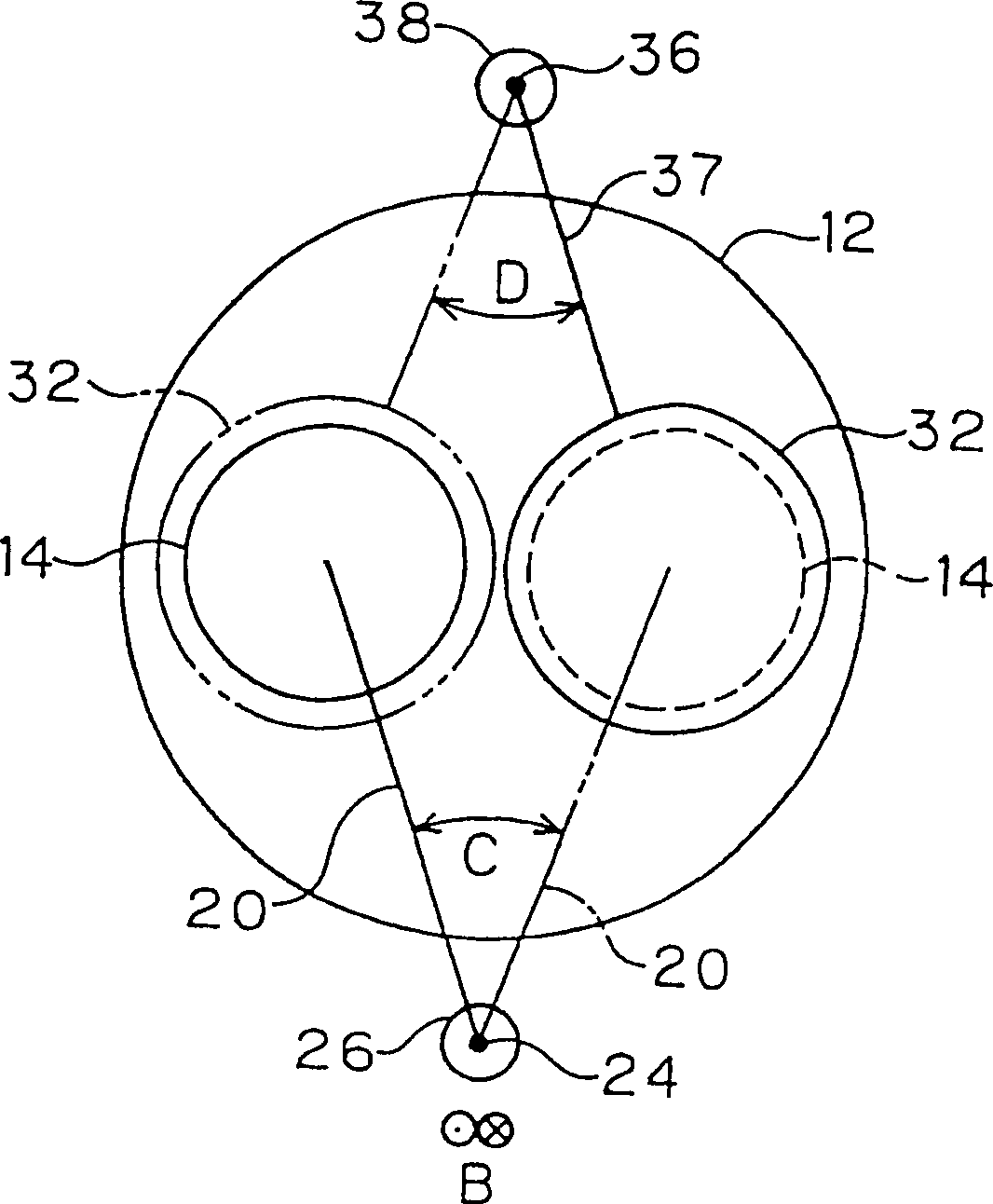

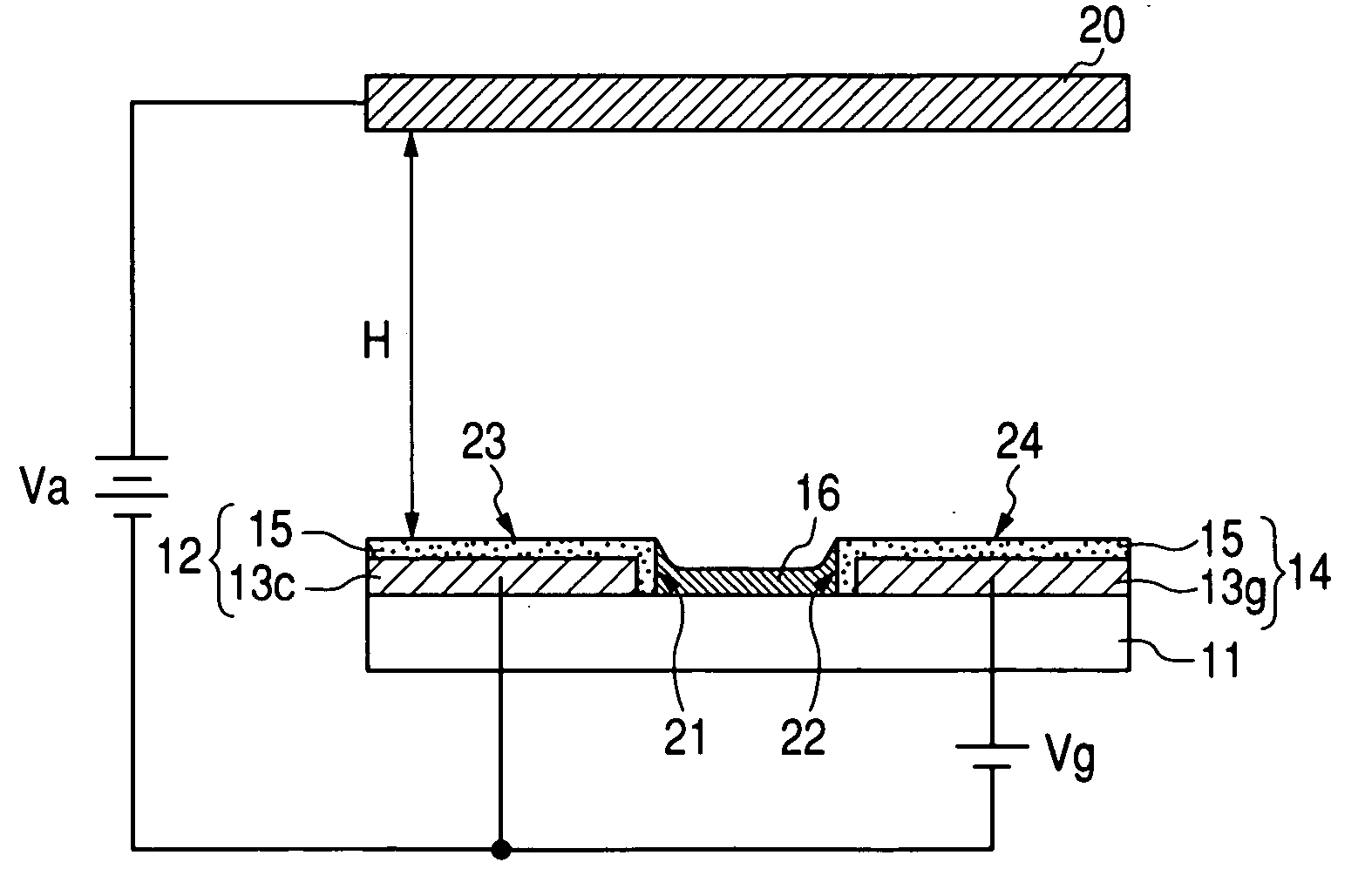

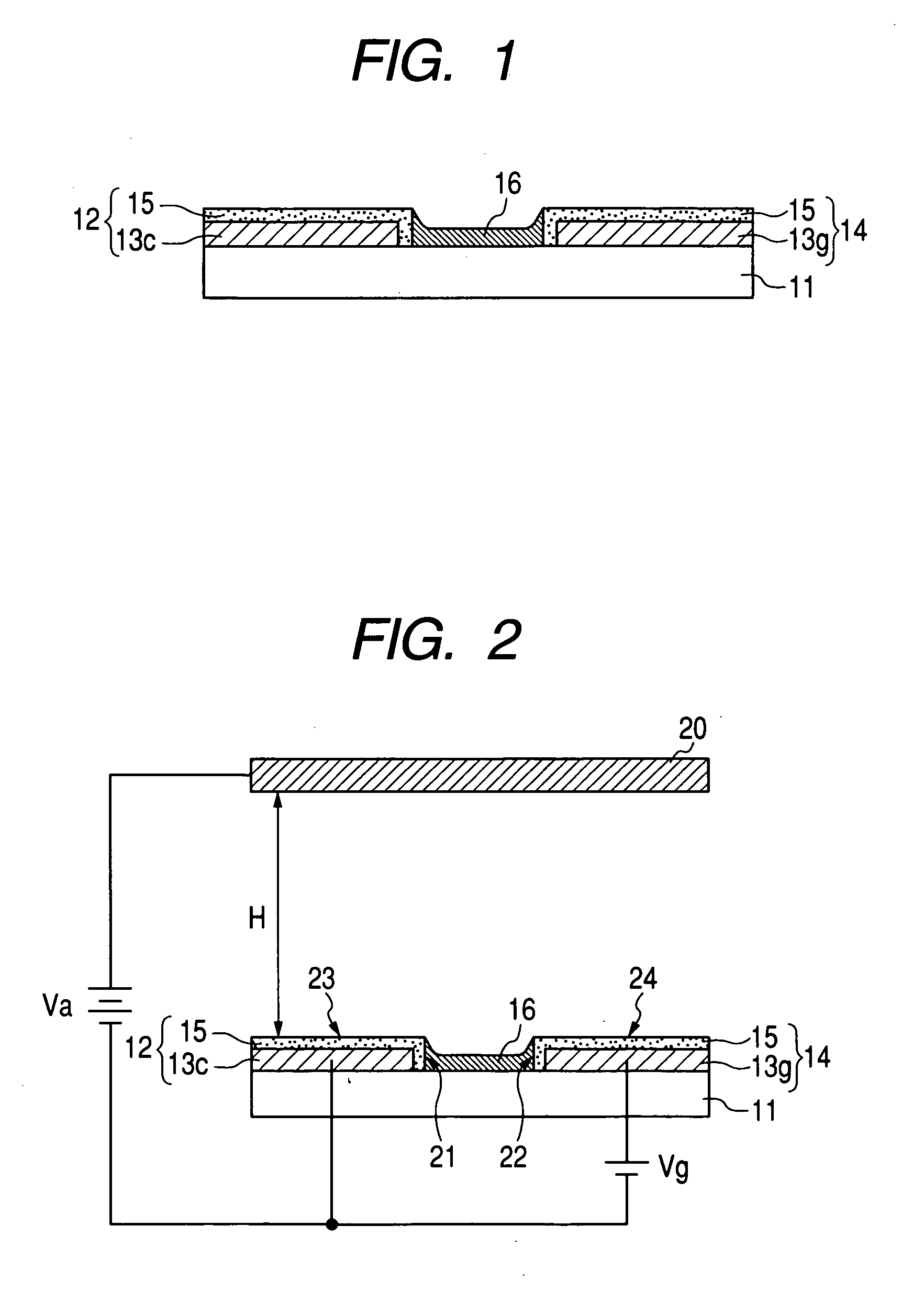

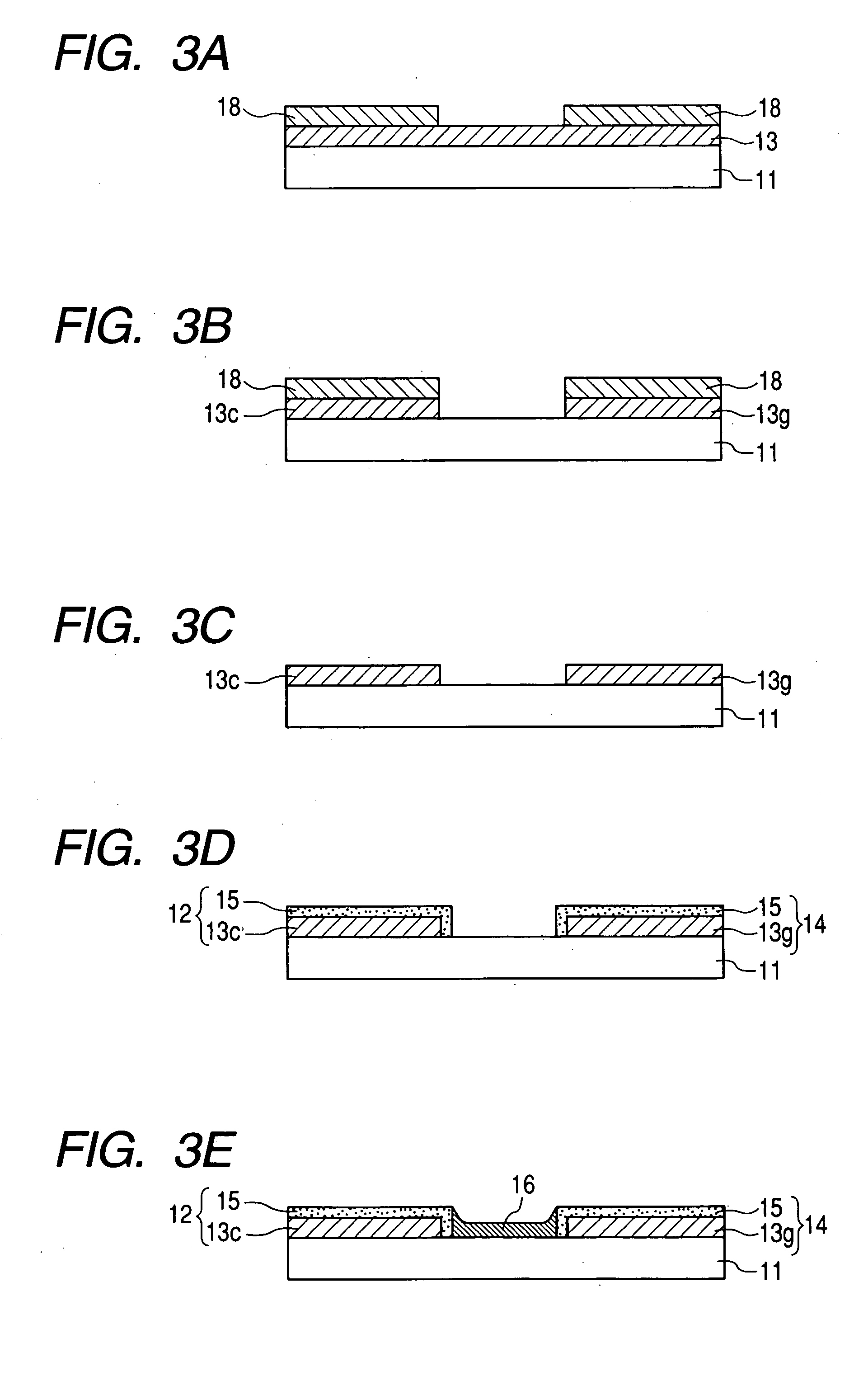

Plasma treatment apparatus and short circuit of high frequency current

InactiveCN101290869AReduce potential differenceSuppress abnormal dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingHigh frequency powerPotential difference

The invention provides a plasma treatment apparatus capable of reducing potential difference between a ground substrate which holds at least either a lower electrode or an upper electrode, and the inner wall of a housing vessel. The plasma treatment apparatus 10 includes: a chamber 11 for housing a glass substrate G; a lower electrode board 23 as a mounting face, which is arranged in the chamber 11 for mounting the glass substrate G; a shower head 12 arranged facing the lower electrode board 23 for supplying raw gas into the chamber 11; a high-frequency power supply 20 connected to the upper electrode 13 of the shower head 12; a ground substrate 26 placed in a state of being spaced apart from the inner wall of the chamber 11, while supporting the lower electrode board 23 through a lower insulation part 25; and a shorting bar 36 for shunting the ground substrate 26 and the inner wall of the chamber 11. A capacitor 37 is interposed between the shorting bar 36 and the inner wall of the camber 11, and is provided on the inner wall of the camber 11.

Owner:TOKYO ELECTRON LTD

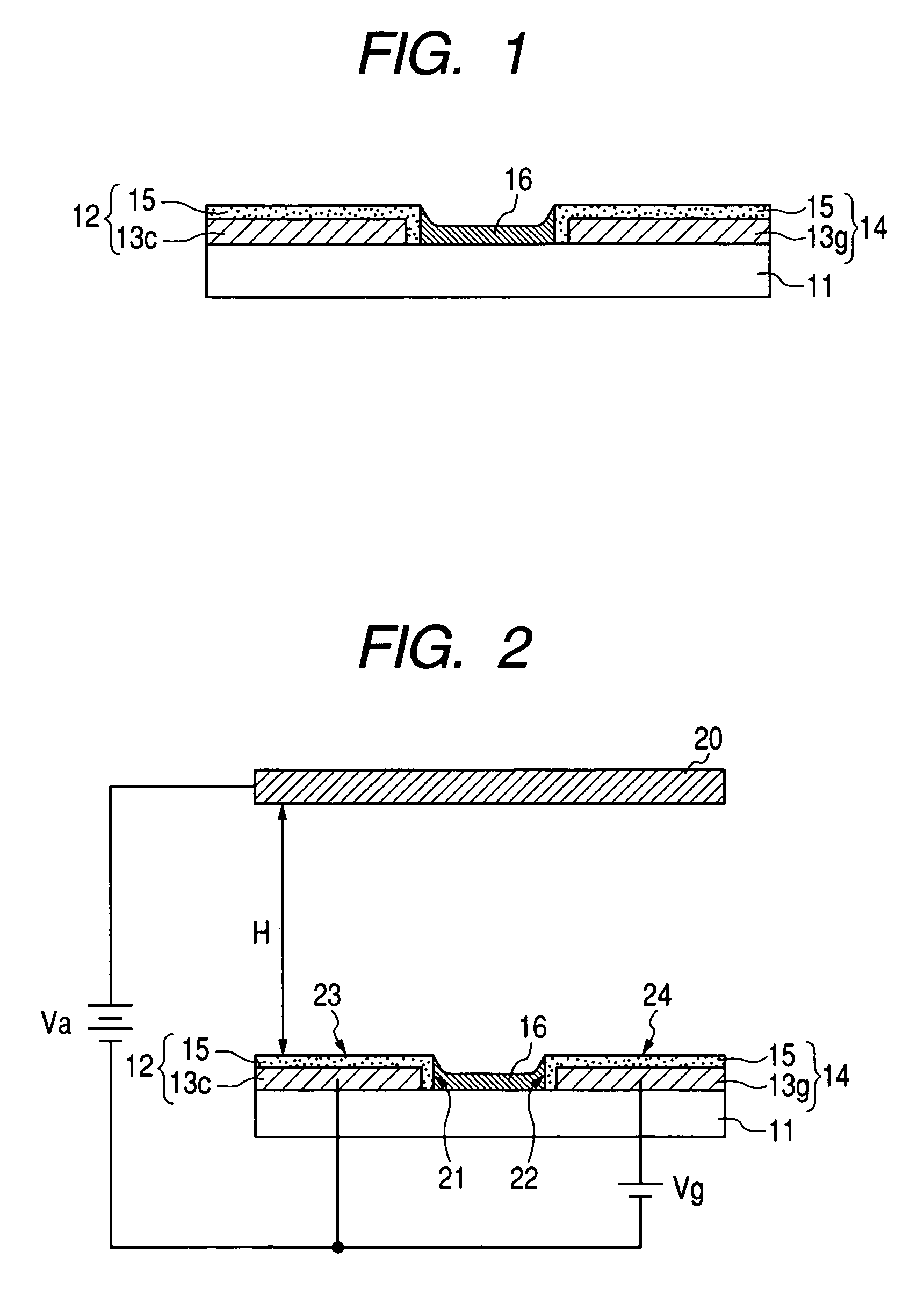

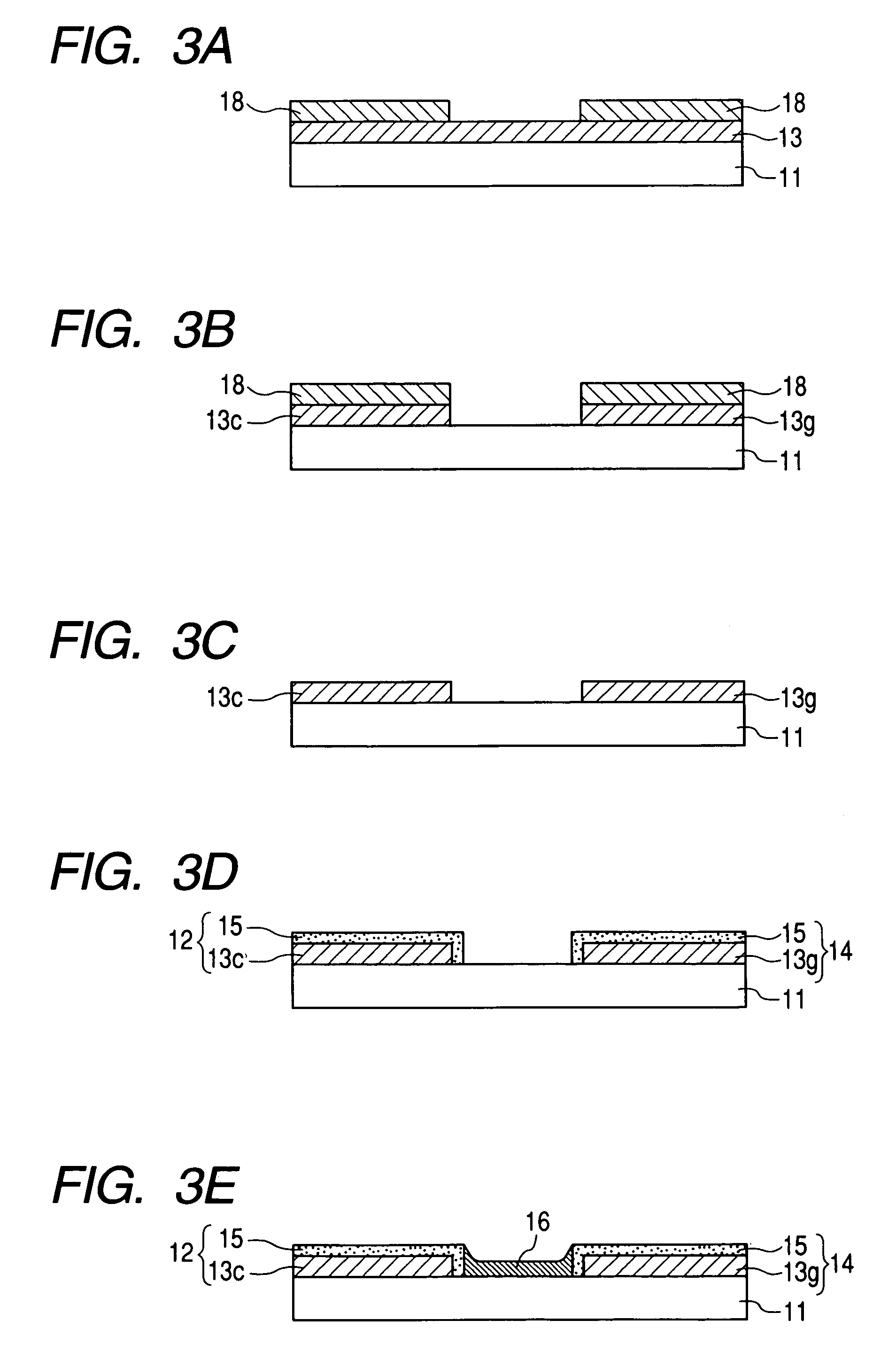

Electron-emitting device, electron source, image display device and information display and reproduction apparatus using image display device, and method of manufacturing the same

InactiveUS7391150B2Stable characteristicsPrevent abnormal dischargeDischarge tube luminescnet screensLamp detailsElectron sourceDisplay device

The present invention provide a lateral type electron-emitting device in which abnormal discharge near an electron-emitting region is suppressed, electron emission characteristics are stable, and electron emission efficiency is high. A method of manufacturing an electron-emitting device of the invention includes: a first step of preparing an electron-emitting electrode and a control electrode that are arranged on a surface of an insulating substrate; and a second step of covering the surface of the insulating substrate, which is located between the electron-emitting electrode and the control electrode, with a resistive film to connect the electron-emitting electrode and the control electrode. In the method of manufacturing an electron-emitting device, the resistive film is arranged to cover an end of a surface of the electron-emitting electrode opposed to the control electrode.

Owner:CANON KK

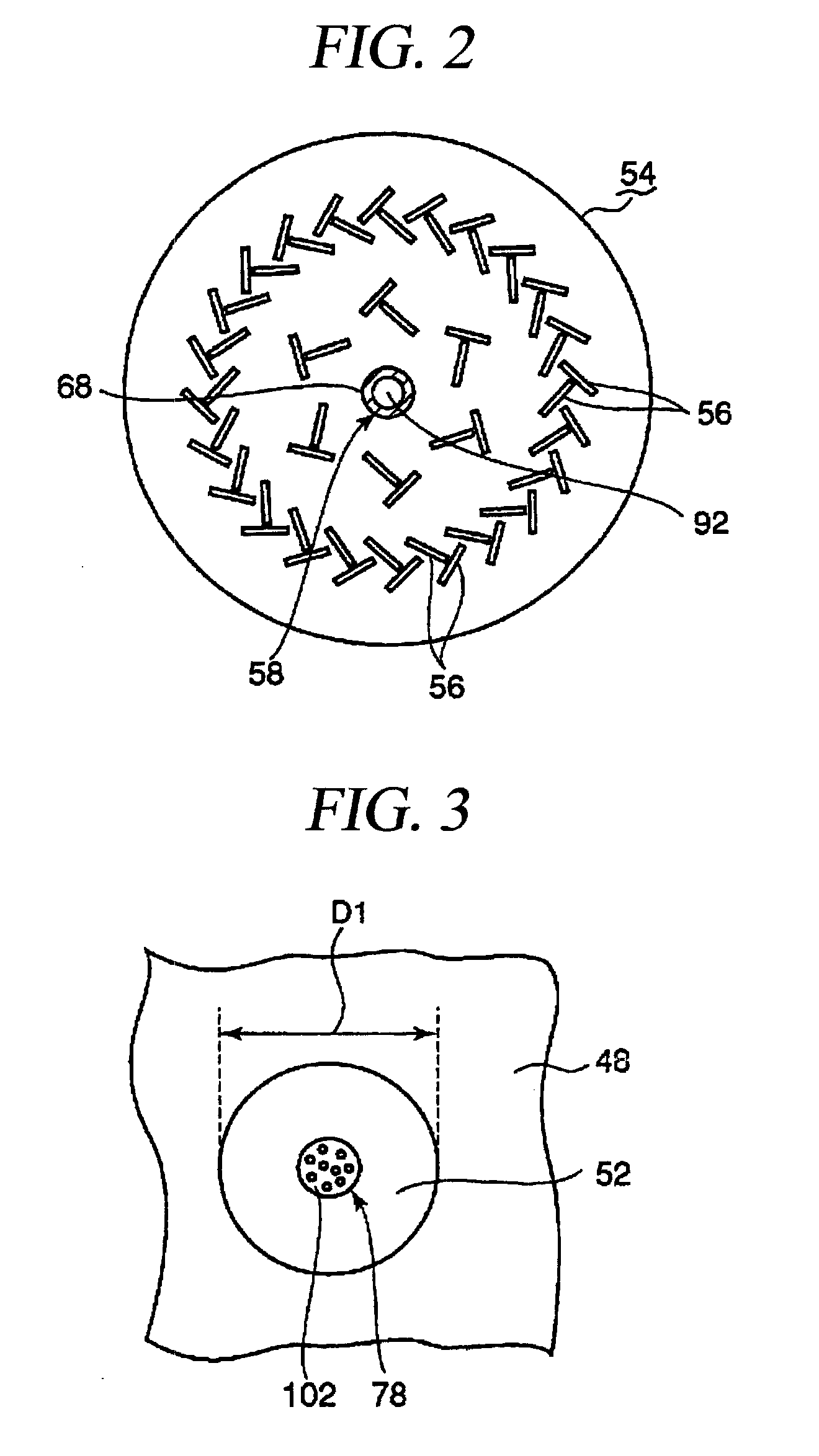

Electrode plate for plasma etching and plasma etching apparatus

ActiveUS9117635B2Prevent abnormal dischargeConvenient ArrangementElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma etchingPhysics

An electrode plate for a plasma etching is formed as a disc shape having a predetermined thickness, a plurality of gas holes penetrating a surface of the electrode plate perpendicularly to the surface are provided on different circumferences of a plurality of concentric circles, the electrode plate is divided in a radial direction of the electrode plate into two or more regions, types of gas holes provided in the two or more regions are different from each other by region.

Owner:TOKYO ELECTRON LTD

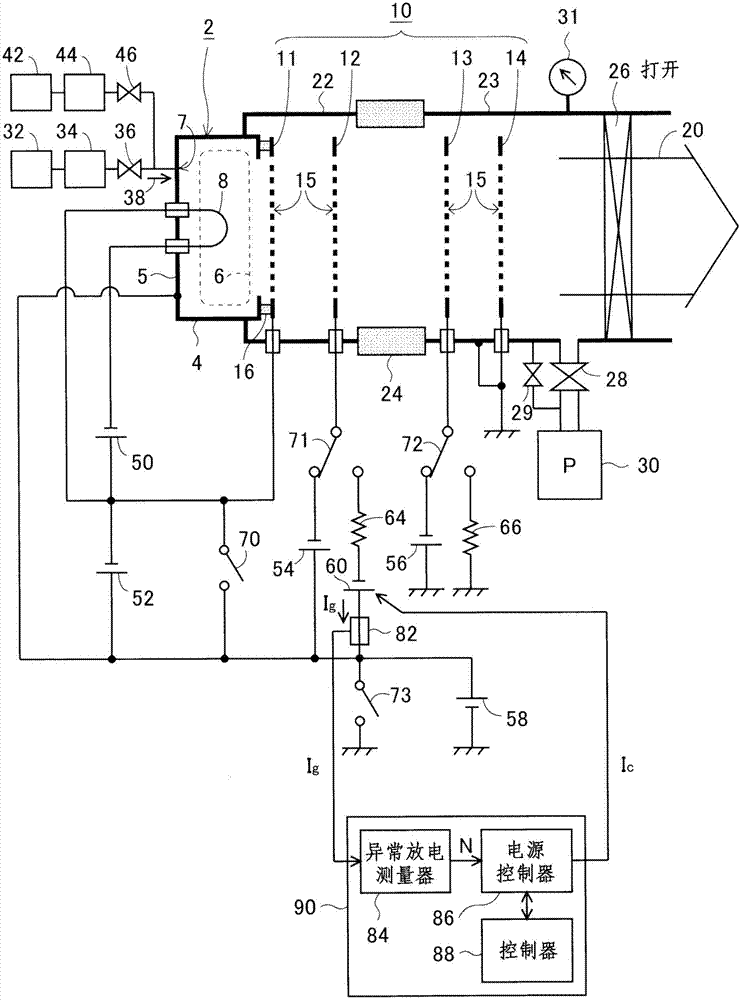

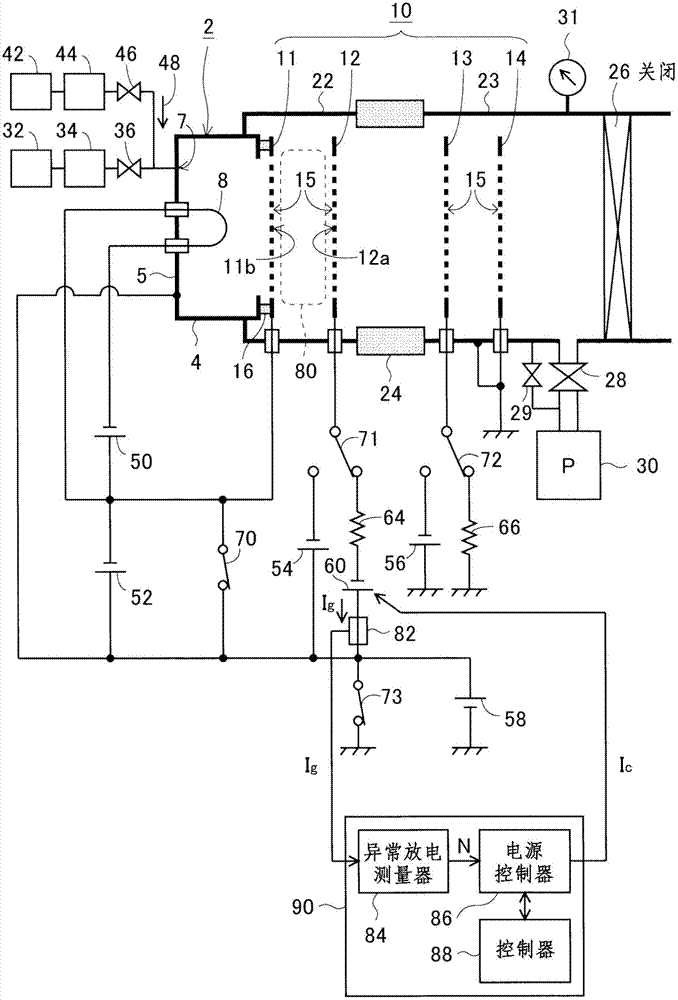

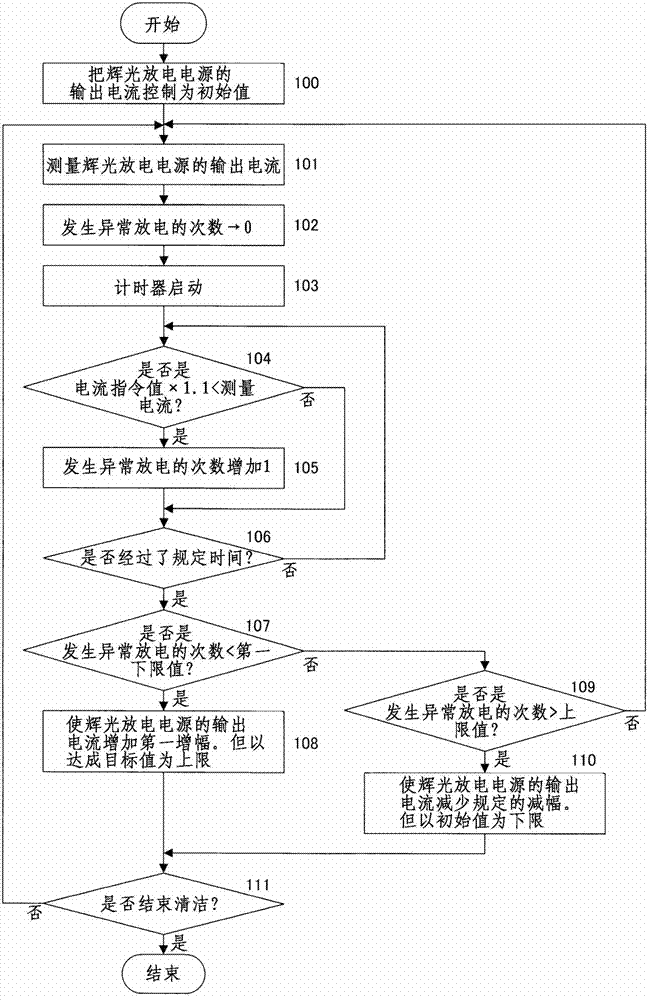

Cleaning apparatus of ion source extraction electrode system

ActiveCN103094028AHigh speed removalStable and powerful cleaningIon beam tubesPlasma techniqueWide areaPower controller

The present invention provides a cleaning apparatus of an ion source extraction electrode system, which can eliminate deposit in high speed along a wide area that form a leading-out electrode system of an ion source. The cleaning apparatus comprises the following components: a cleaning gas source (42) which supplies cleaning gas (48) between two opposite electrodes (11,12) of a leading-out electrode system (10), thereby keeping the gas pressure between the two electrodes to a gas pressure for generating glow discharge; and a glow discharge power supply (60) which applies DC voltage between the electrodes (11,12) for generating glow discharge (80). The cleaning apparatus further comprises the following components: an abnormal discharge measurer (84) which measures times (N) of abnormal discharge between the the electrodes (11,12) in preset time; and a power supply controller (86) which controls through the measured time (N) of abnormal discharge for increasing or reducing the output current of the glow discharge power supply (60) for a preset amplitude.

Owner:NISSIN ION EQUIP CO LTD

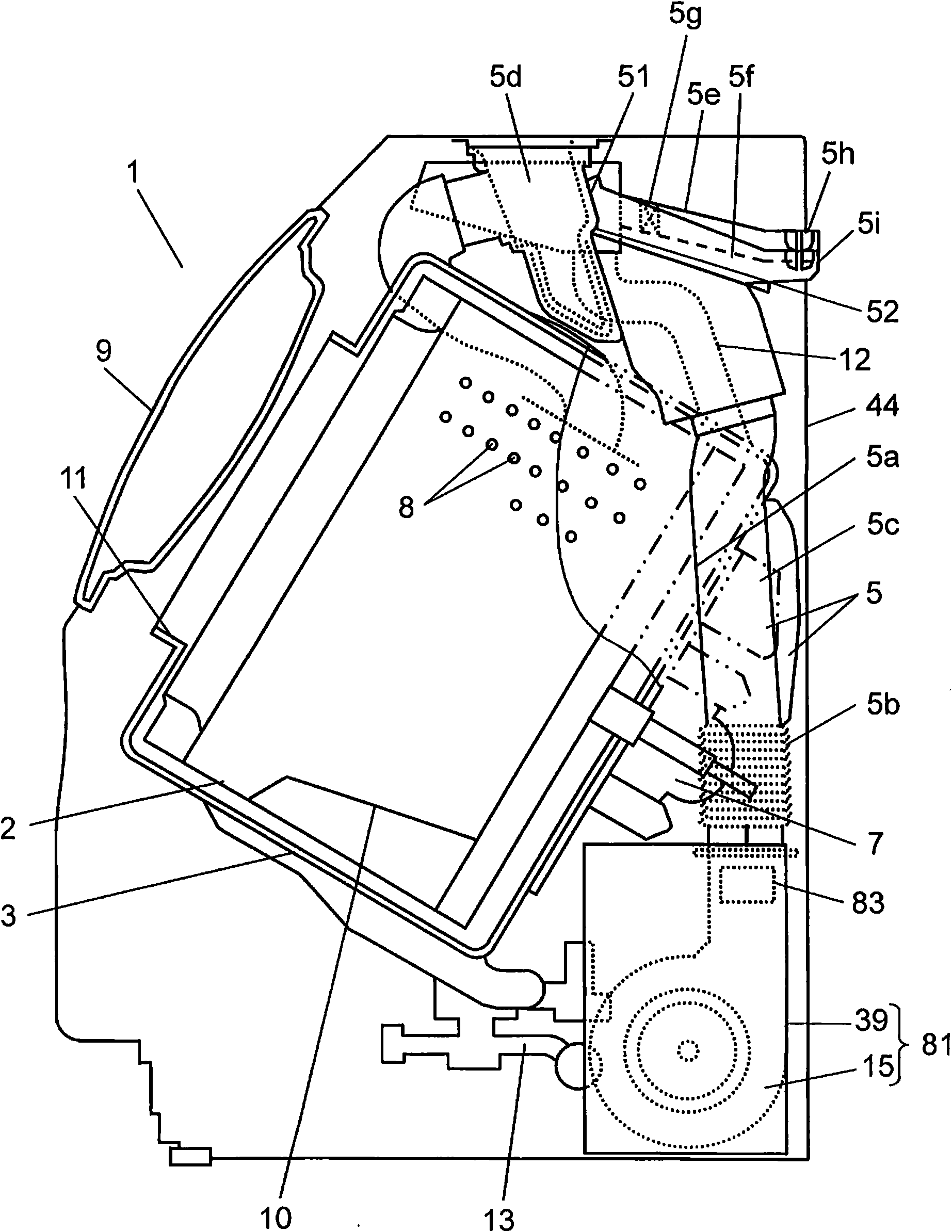

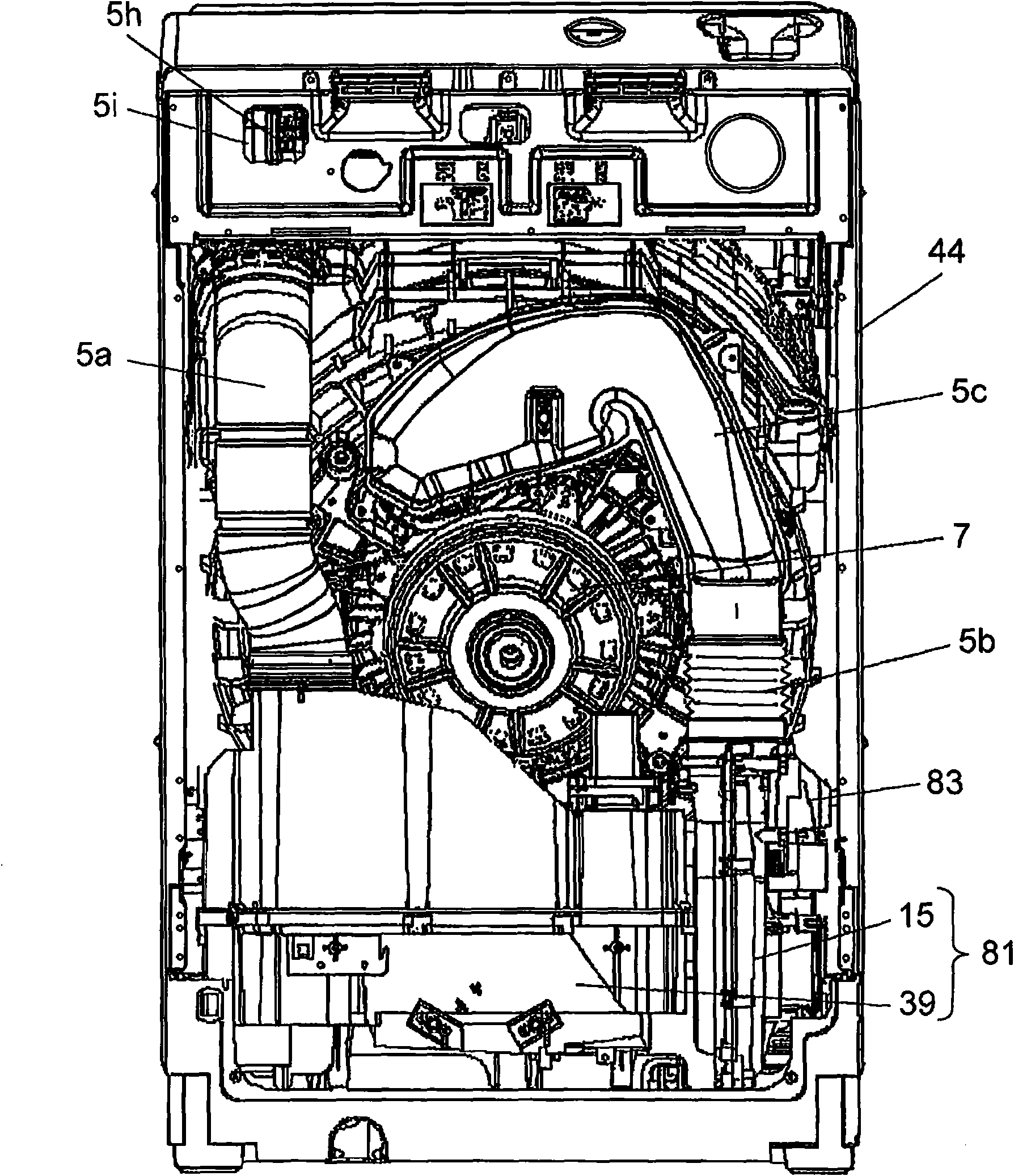

Washing dryer

ActiveCN101671935APrevent abnormal dischargeControl devices for washing apparatusLavatory sanitoryWaste managementWater supply

The present invention provides a washing dryer which comprises the following components: a washing tank; a outer tank; a housing which elastically supports the outer tank; a water supply device whichsupplies washing water to the outer tank; a heating device which heats the air in the outer tank; a circulating air feeding path for circulating the air in the outer tank through the heating device; an air feeding device which pressurizes and conveys the air in the circulating air feeding path for circulating; an electrostatic atomization generator which is provided in the circulating air feedingpath and supplies the particles through electrostatic atomization into the outer tank, wherein the circulating air feeding path is provided with an outer air entering part which causes the outer air to enter and a circulating air discharging part that discharges the air in the circulating air feeding path. The outer air entering part is composed of a first opening, an outer air guiding channel connected with the first opening, and an open and close valve. The circulating air discharging part is composed of a second opening and a circulating air discharging channel connected with the second opening.

Owner:PANASONIC CORP

Electrode plate for plasma etching and plasma etching apparatus

ActiveUS20120073753A1Prevent abnormal dischargeConvenient ArrangementElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma etchingPhysics

An electrode plate for a plasma etching is formed as a disc shape having a predetermined thickness, a plurality of gas holes penetrating a surface of the electrode plate perpendicularly to the surface are provided on different circumferences of a plurality of concentric circles, the electrode plate is divided in a radial direction of the electrode plate into two or more regions, types of gas holes provided in the two or more regions are different from each other by region.

Owner:TOKYO ELECTRON LTD

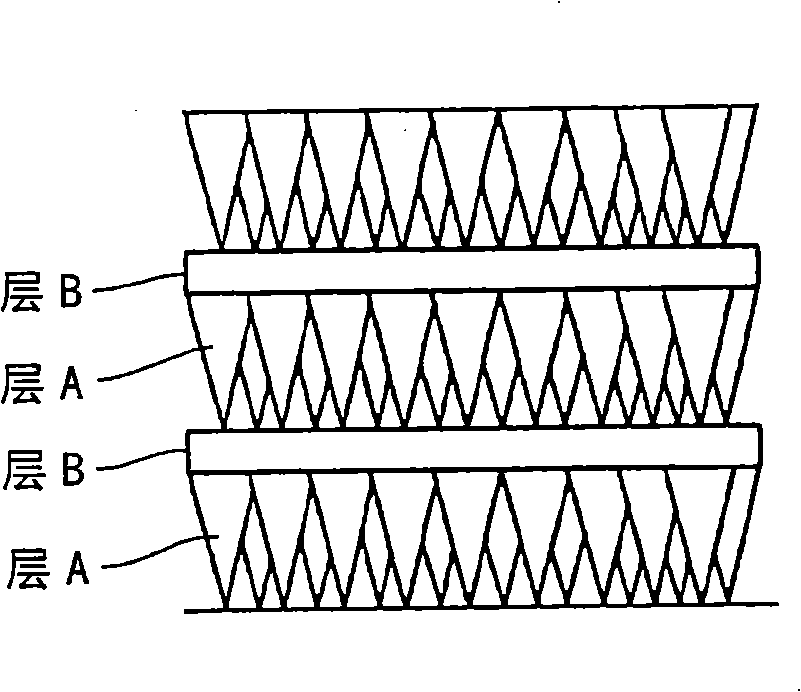

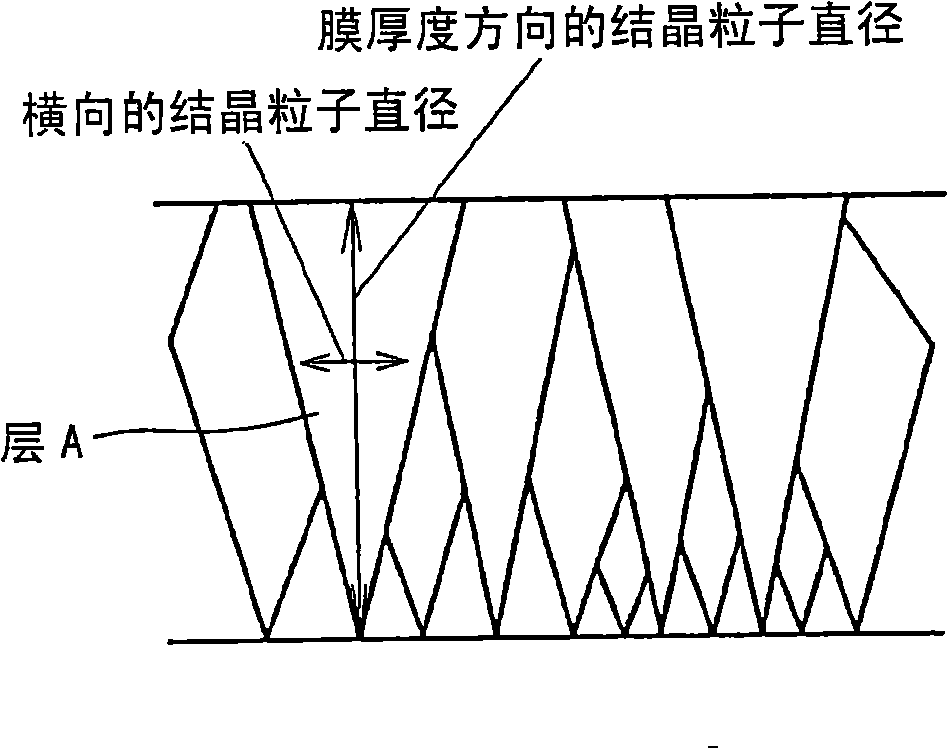

Hard laminated film

ActiveCN101254674AGrowth inhibitionImprove wear resistanceLayered productsVacuum evaporation coatingAlloyCeramic metal

A hard laminated film is provided, wherein a layer A and a layer B having specific compositions are deposited alternately so that the compositions of layer A and layer B are different. The thickness of layer A per layer is twice or more the thickness of layer B per layer, the thickness of layer B per layer is 0.5 nm or more, and the thickness of layer A per layer is 200 nm or less. Thereby, the invention provides a cutting tool used as the basis materials, such as the extra hard alloy, the ceramic metal or the high speed steel and the like, or the abrasion resistance capsule of the vehicle slide unit and the like.

Owner:KOBE STEEL LTD

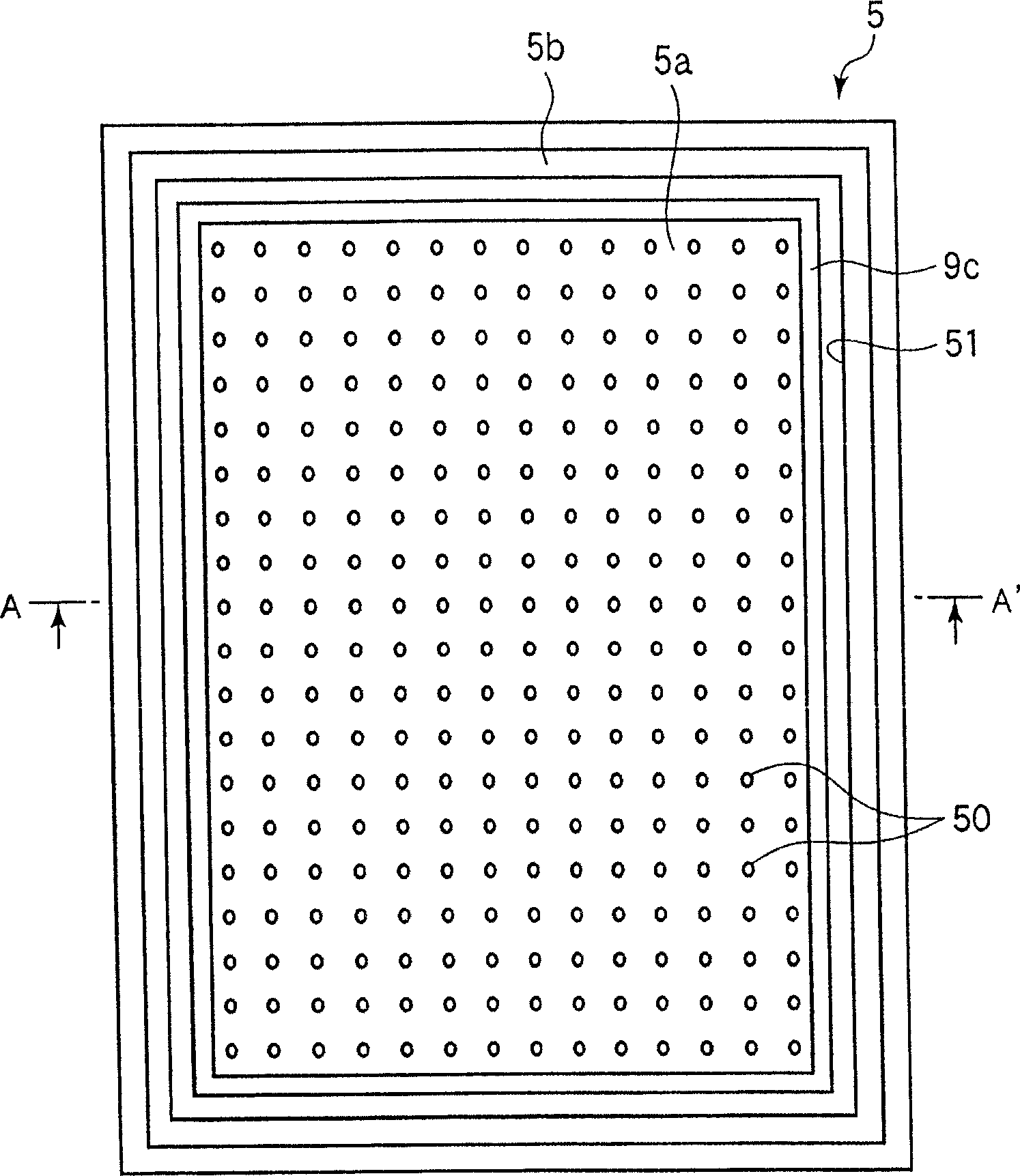

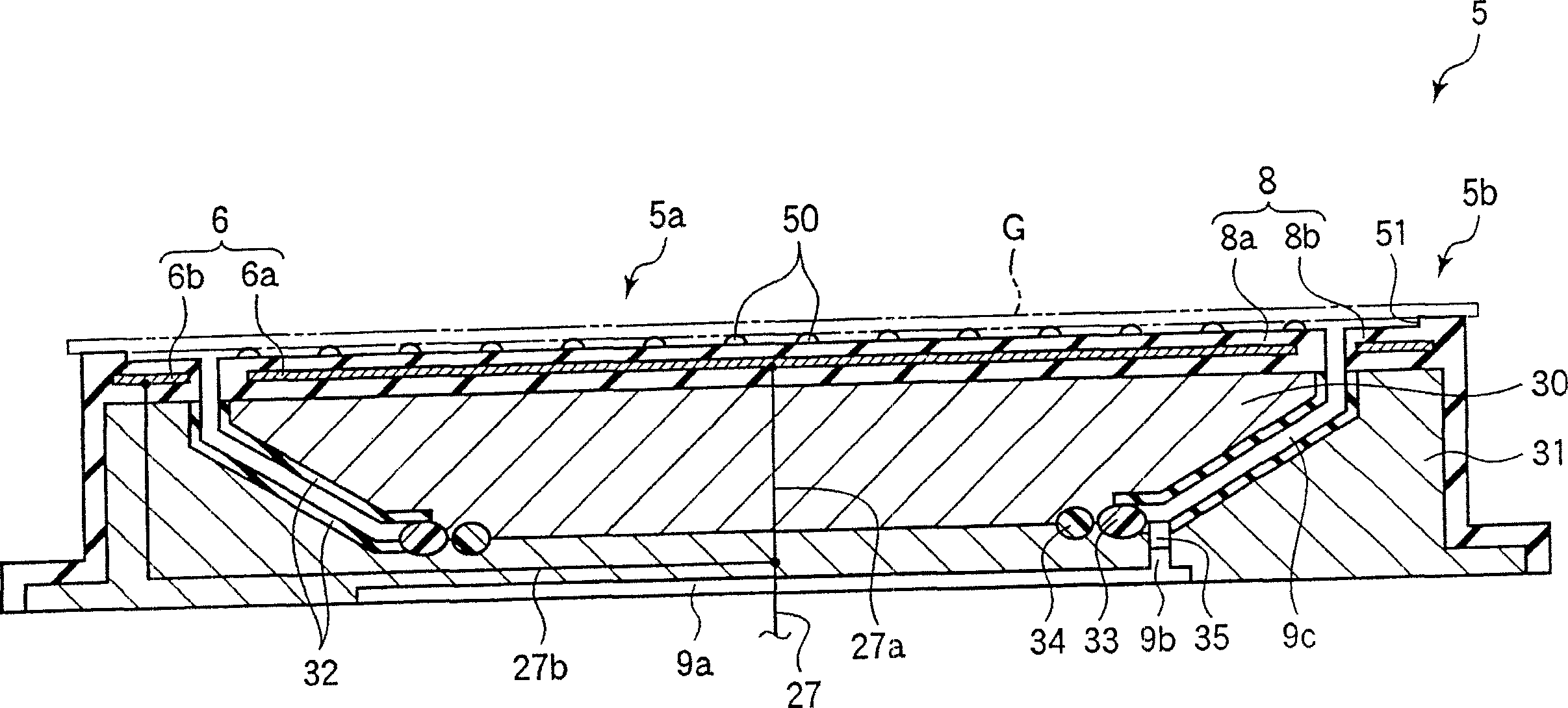

Electrostatic absorption electrode and treating apparatus

InactiveCN1870242AImprove conduction abilityImprove heat transfer efficiencyElectric discharge tubesSemiconductor/solid-state device manufacturingComposite constructionAbnormal discharge

The invention provides preventing abnormal discharge in gas flow circuit of electrostatic absorption electrode, and even if occurring abnormal discharge in gas flow circuit, the electrostatic absorption electrode can be easily repaired. The electrostatic sucker (5) is a composite construction which having the first substrate material (30) and the second substrate material (31) that can separate one another. Embedding electrode (6b) in dielectric materials film (8) of the second substrate material (31). In the state of combining the first substrate material (30) and the second substrate material (31), forming clearance tween in the manner of enveloping the first substrate material (30) surrounding, the clearance supplying gas to gap (9c) by the way of supplying heat-transfer gas.

Owner:TOKYO ELECTRON LTD

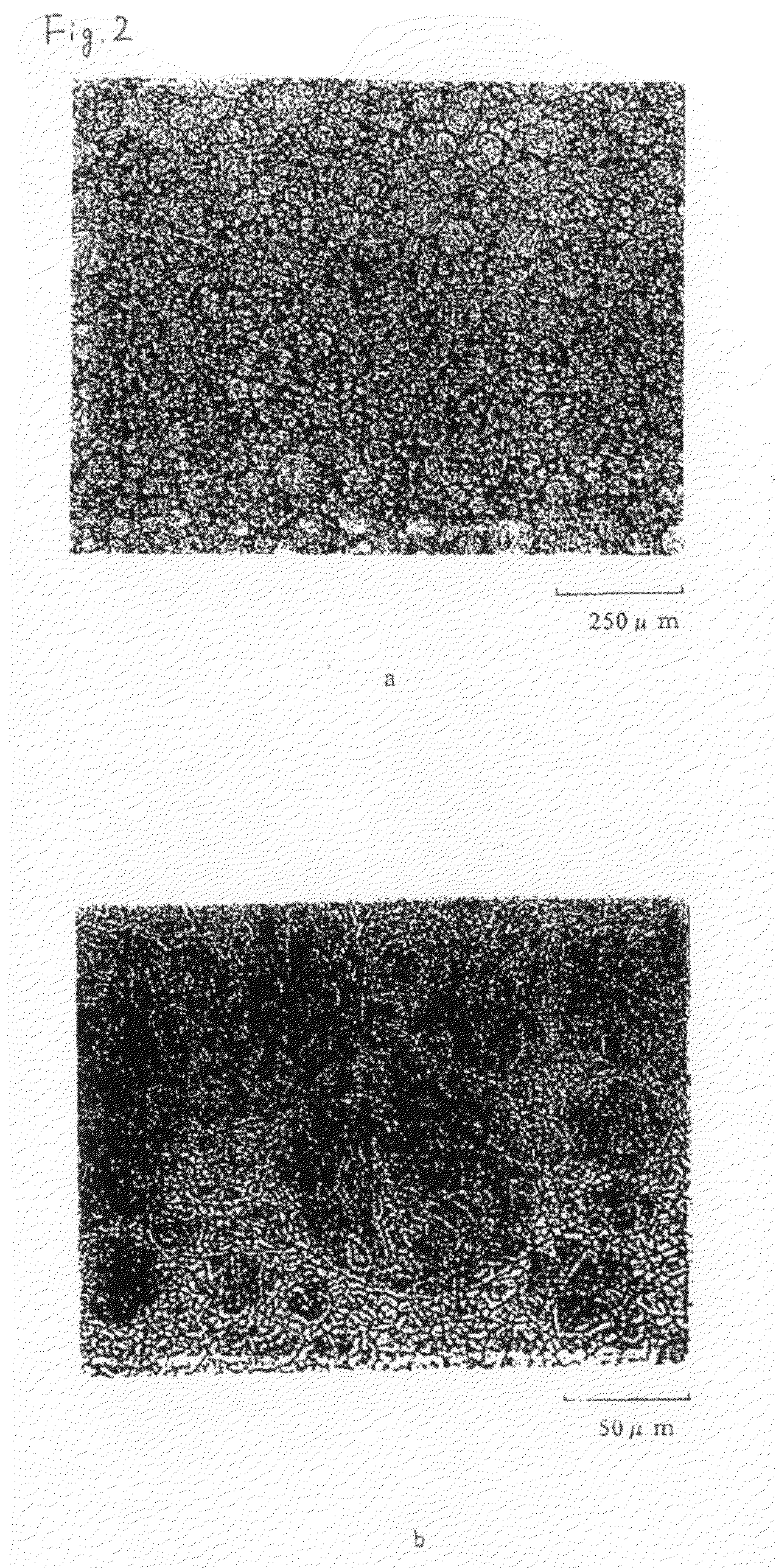

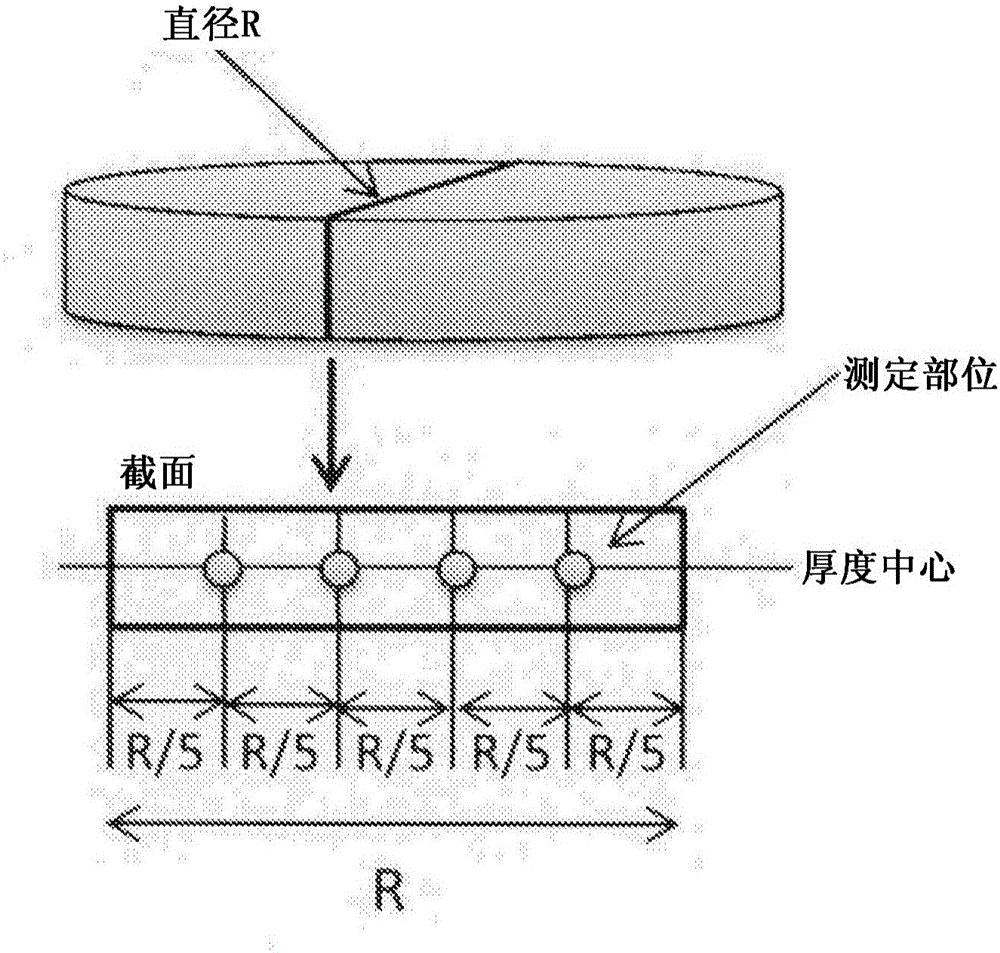

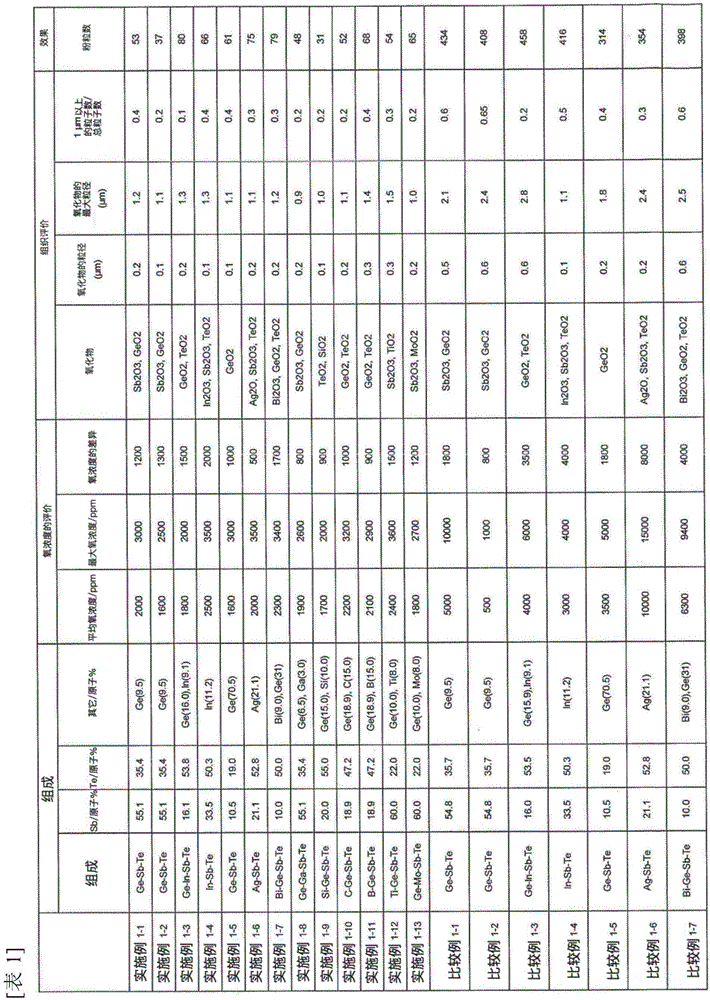

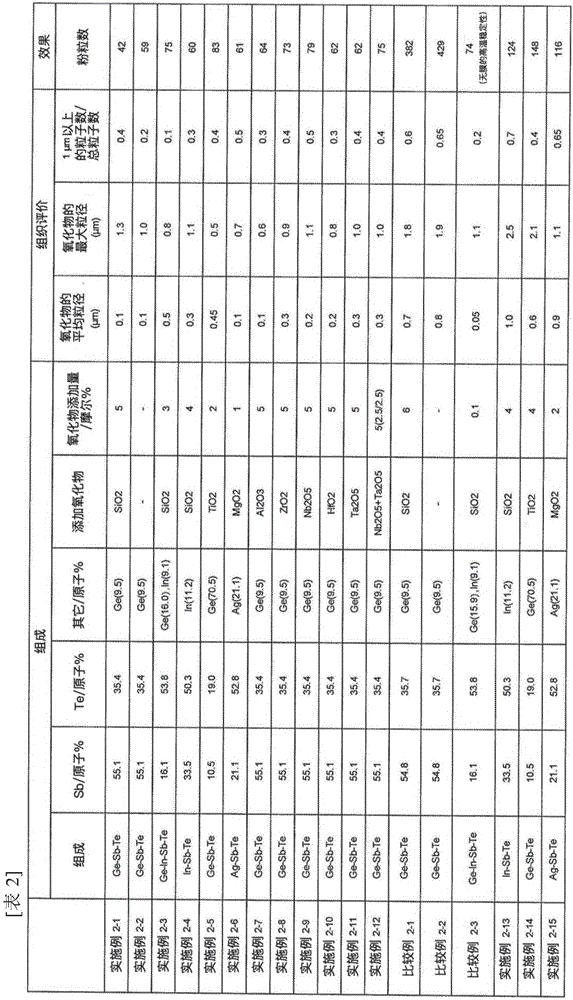

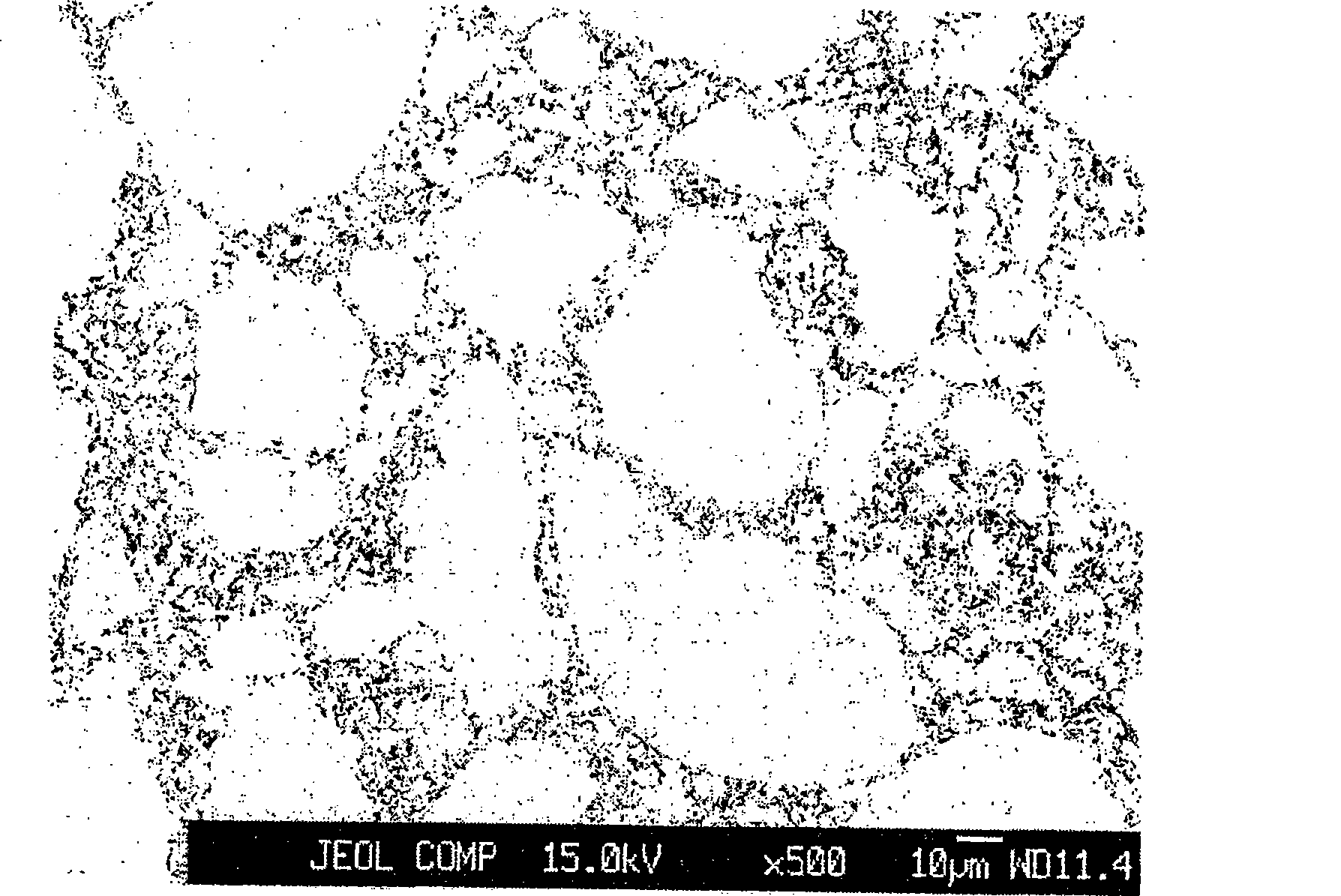

Sb-Te Alloy Sintered Compact Target and Manufacturing Method Thereof

ActiveUS20100025236A1Reduce generationLow oxygenCellsTransportation and packagingTarget surfaceSputtering

Provided is an Sb—Te alloy sintered compact target using atomized powder consisting of substantially spherical particles of an Sb—Te alloy, wherein the spherical atomized powder consists of particles that were crushed and flattened, and the flattened particles exhibiting a ratio (flatness ratio) of short axis and long axis of 0.6 or less occupy 50% or more of the overall particles. With this Sb—Te alloy sintered compact target, particles exhibiting a long axis orientation aligned within ±45° in a direction that is parallel to the target surface occupy 60% or more of the overall particles. In addition, the oxygen concentration in this Sb—Te alloy sintered compact target is 1500 wtppm or less. Thus, the Sb—Te alloy sputtering target structure can be uniformalized and refined, generation of cracks in the sintered target can be inhibited, and generation of arcing during sputtering can be inhibited. Further, surface ruggedness caused by sputter erosion can be reduced in order to obtain a high quality Sb—Te alloy sputtering target.

Owner:JX NIPPON MINING& METALS CORP

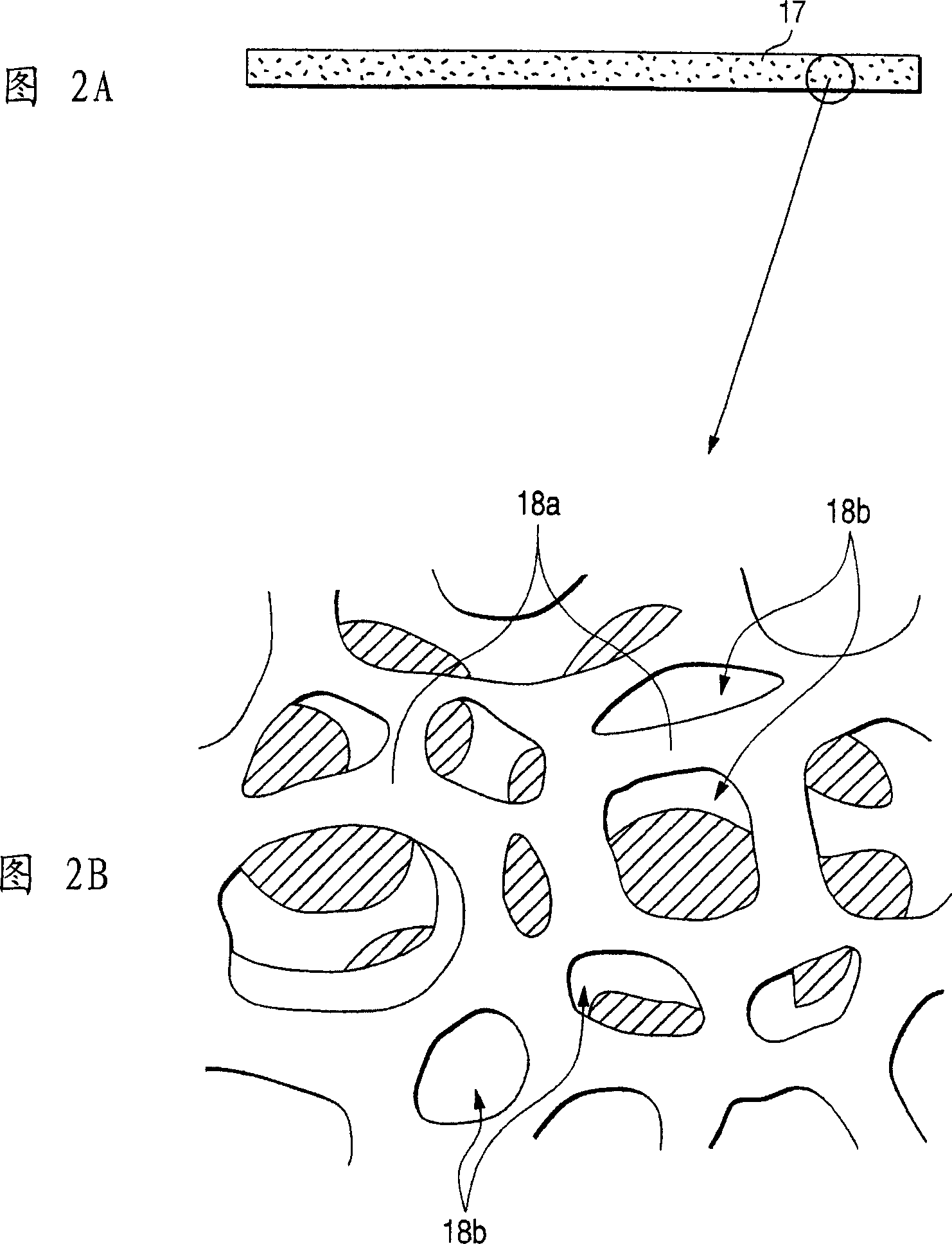

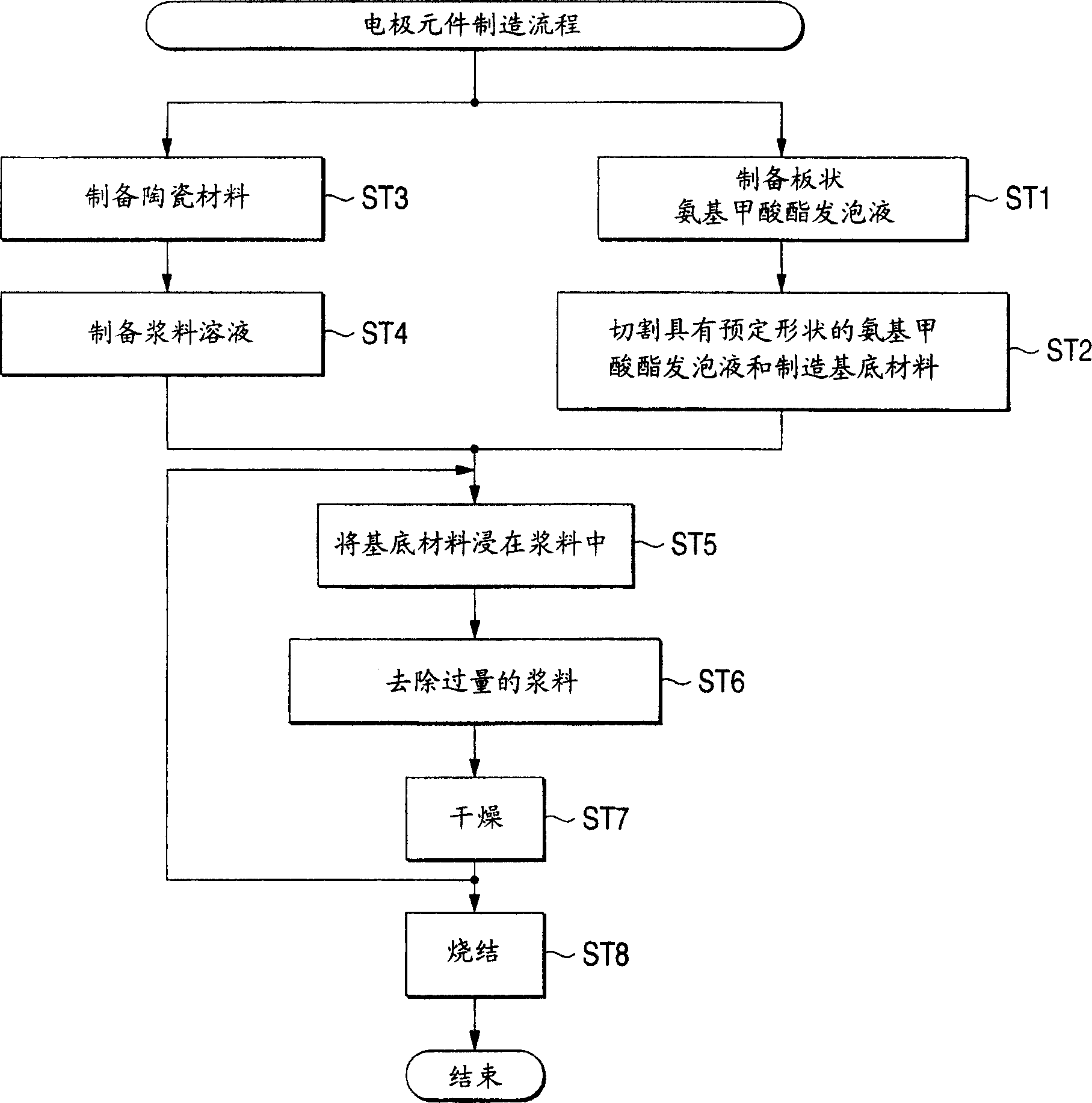

Electrode member for plasma treating appts., plasma treating appts. and plasma treating method

InactiveCN1520604AEvenly distributedSpeed up the flowElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingNetwork structure

In a plasma treating apparatus, a ceramic porous substance having a three-dimensional network structure in which a frame portion formed of ceramic containing alumina is provided continuously like a three-dimensional network is used for the material of an electrode member for the plasma treating apparatus to be attached to the front surface of a gas supplying port of an electrode for plasma generation, and a gas for plasma generation is caused to pass through a hole portion formed irregularly in the three-dimensional network structure. Consequently, the distribution of the gas to be supplied is made uniform to prevent an abnormal discharge so that uniform etching having no variation can be carried out.

Owner:PANASONIC CORP

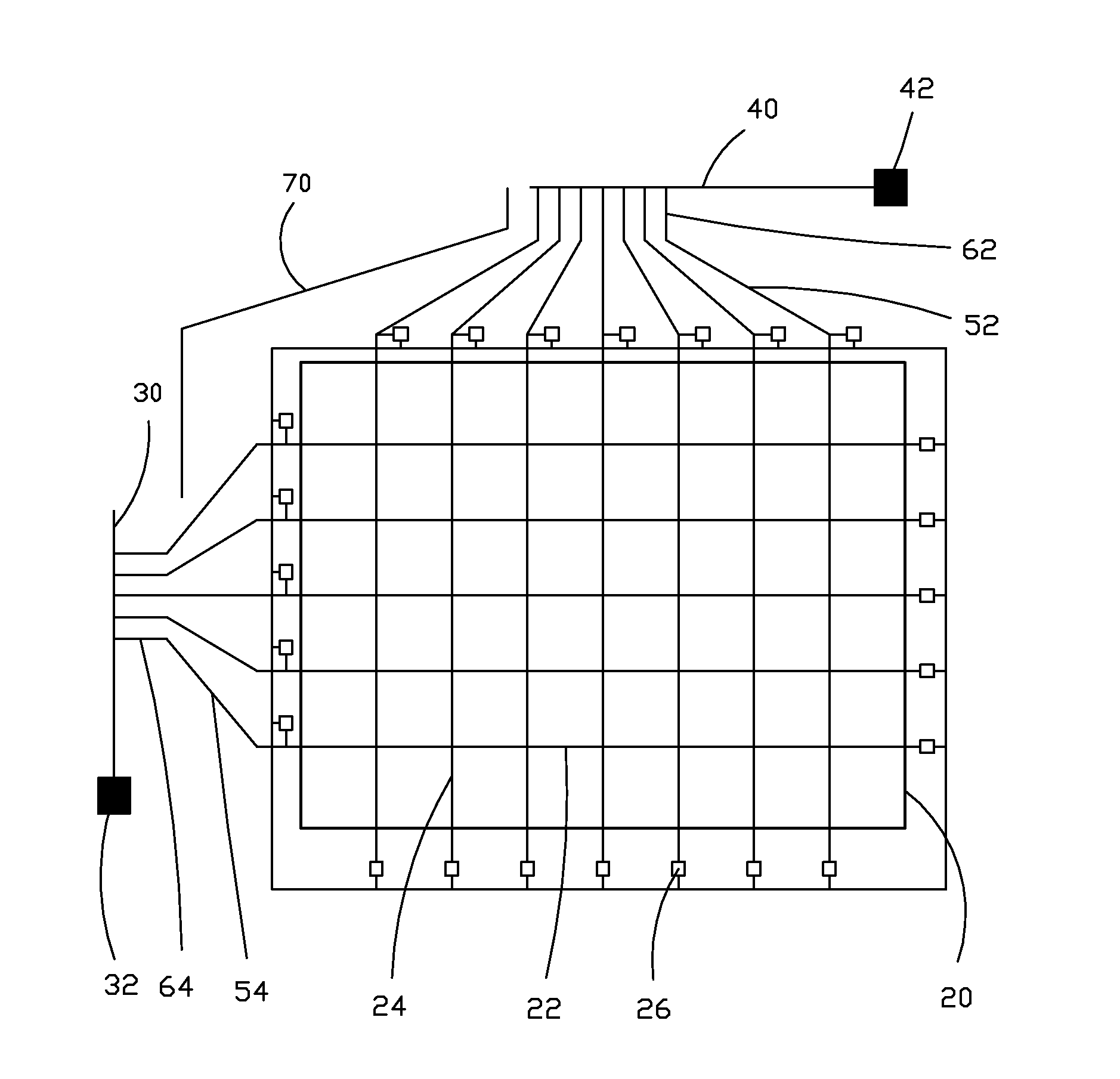

Anti-static structure of array substrate

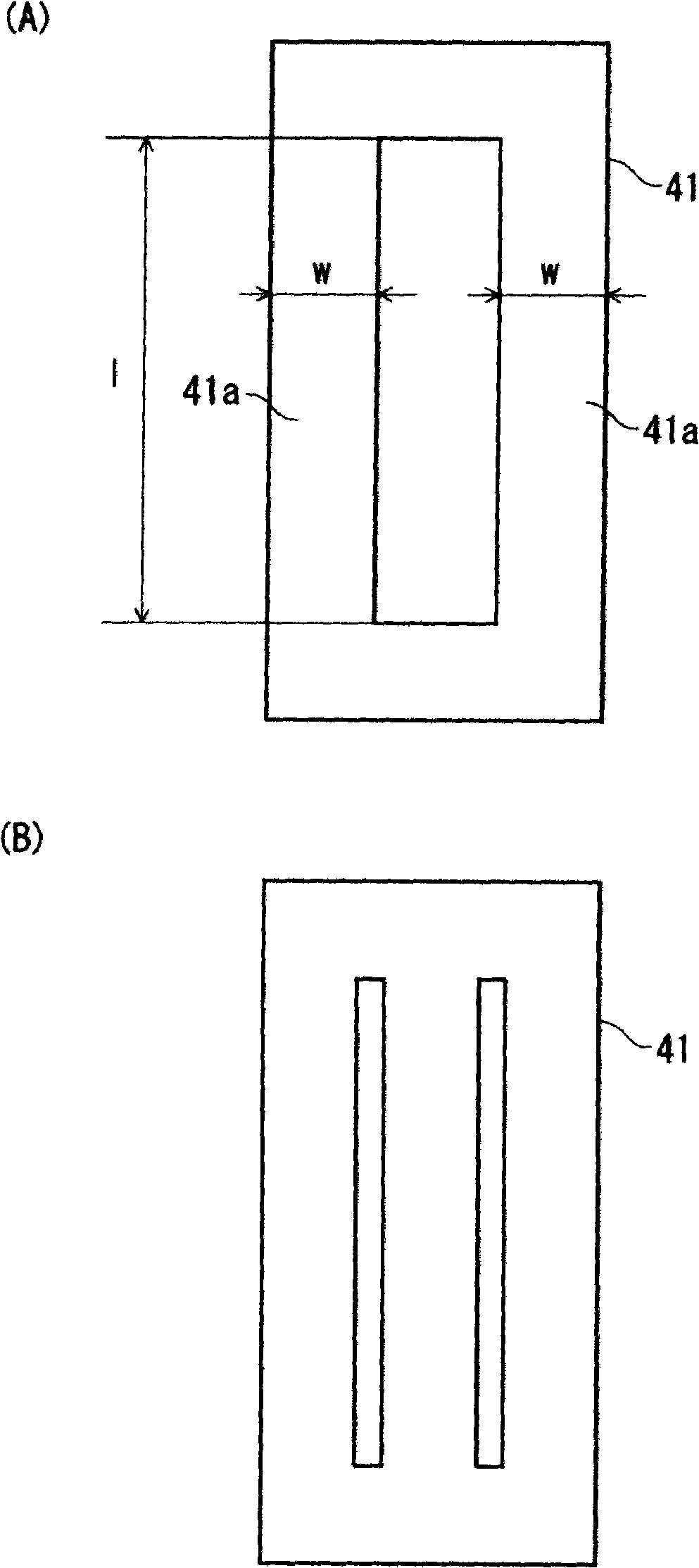

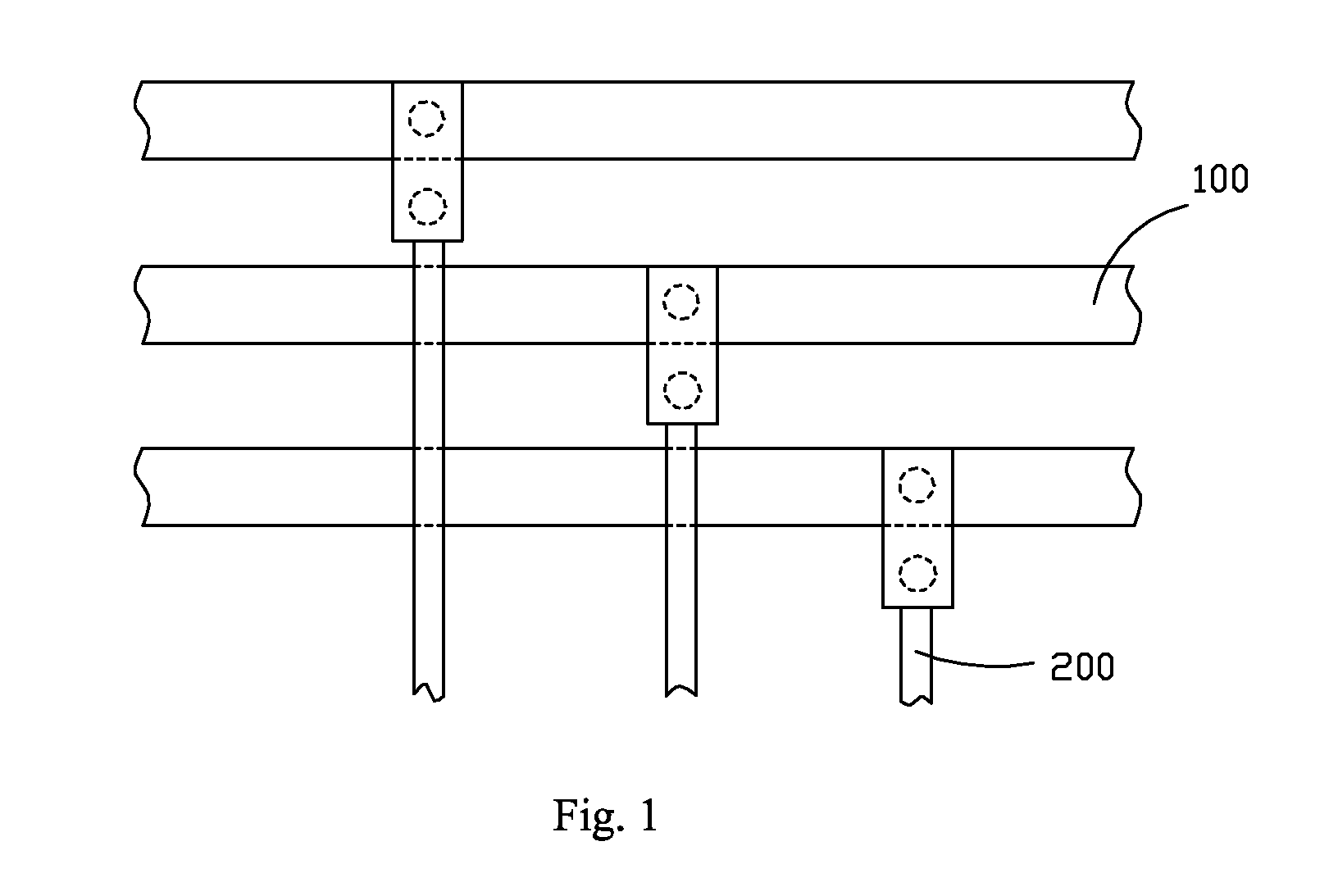

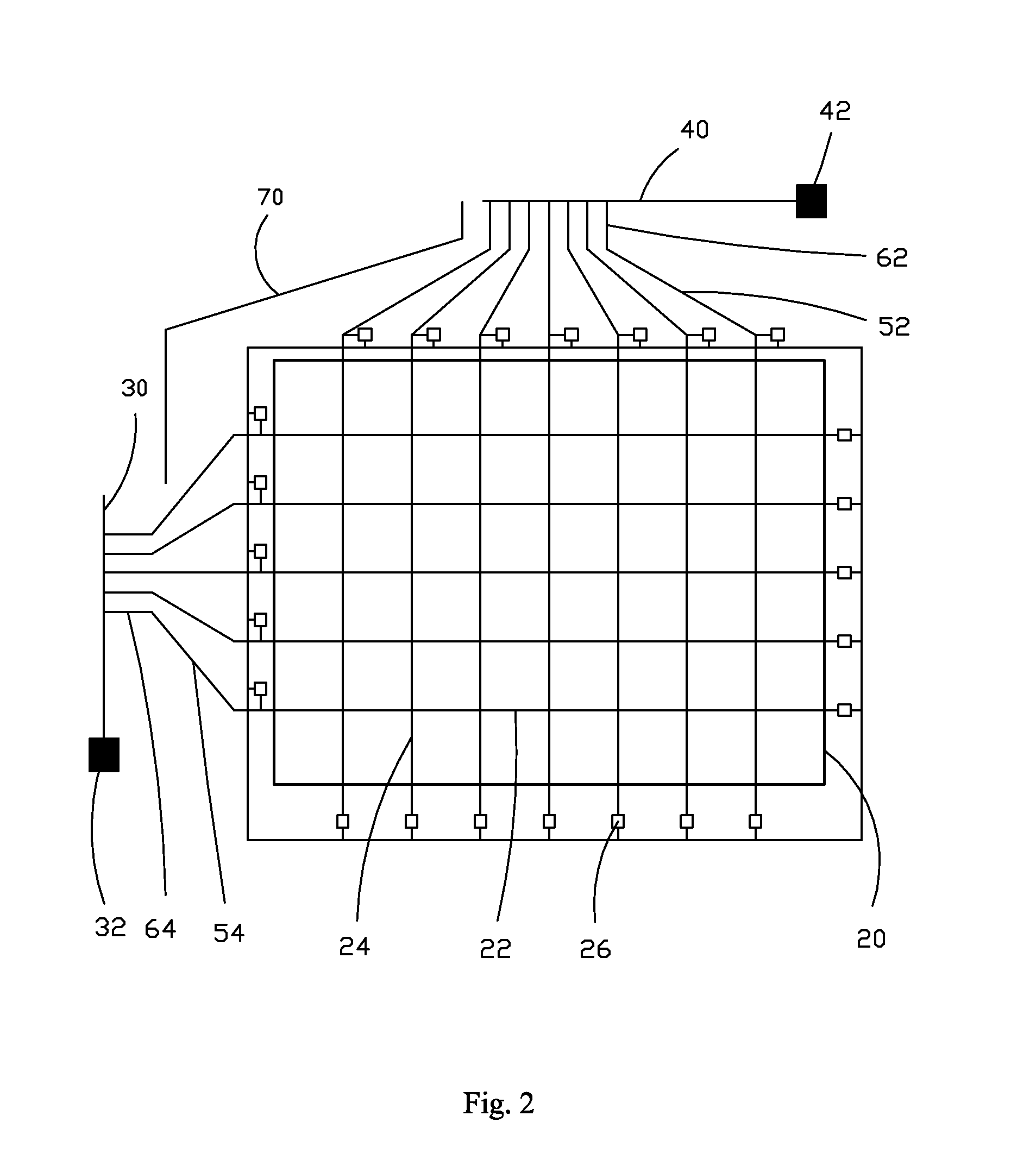

ActiveUS20150187801A1Improve product qualityIncrease productivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsAbnormal dischargeComputer engineering

The present invention provides an anti-static structure of an array substrate, which comprises: an effective region 20 of the array substrate, a gate line shorting bar 30 and a data line shorting bar 40, the effective region 20 of the array substrate is provided with a plurality of parallel gate lines 22 and data lines 24, the gate line shorting bar 30 is electrically connected with one side of the plurality of gate lines 22, the data line shorting bar 40 is electrically connected with one side of the plurality of data lines 24. The present invention only utilizes a gate line shorting bar to short all gate lines and utilizes a data line shorting bar to short all data lines, in order to greatly avoid the abnormal discharge of the plasma generated when the hole is formed cause static damage to the metal overlapping traces of the shorting bar.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

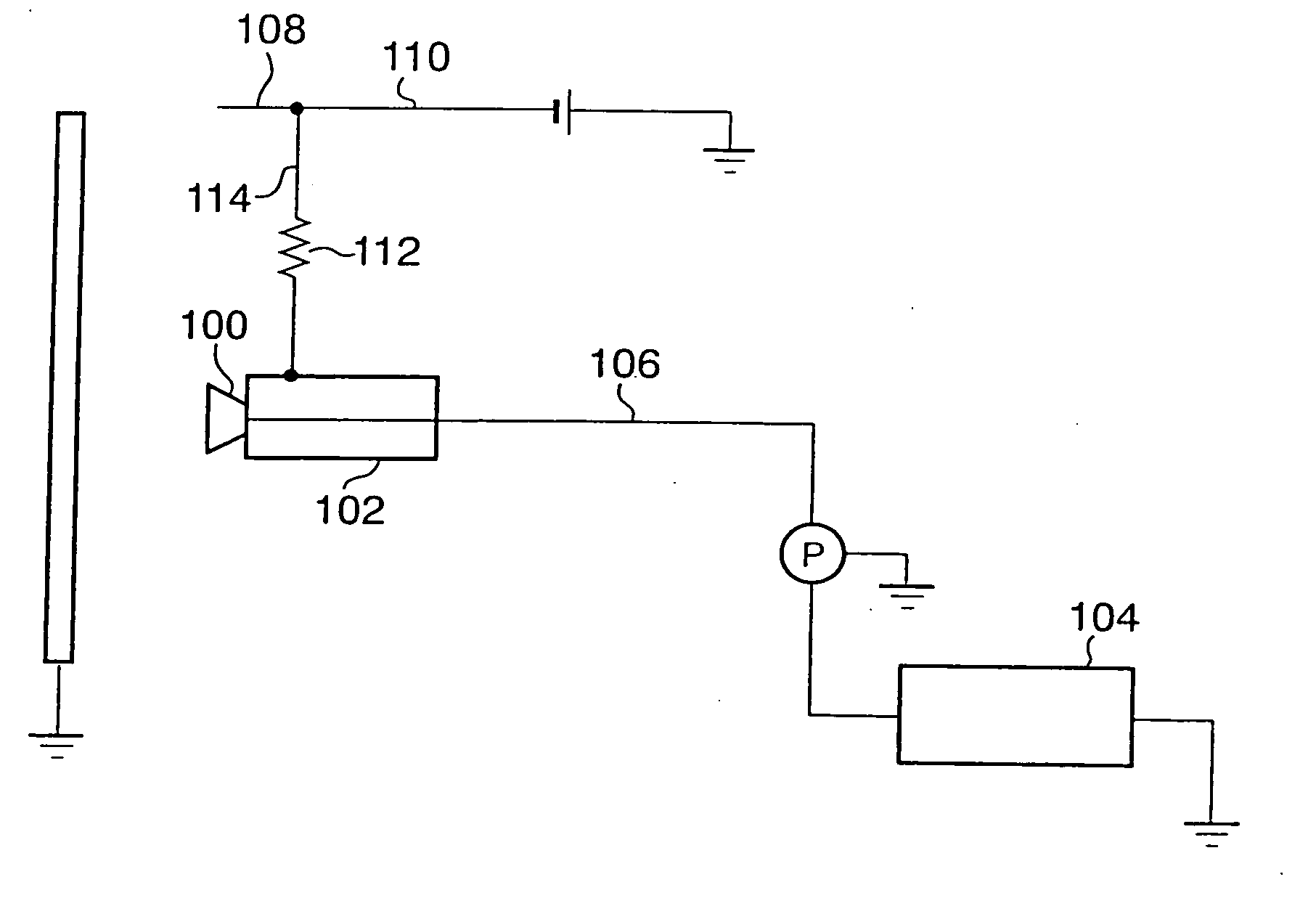

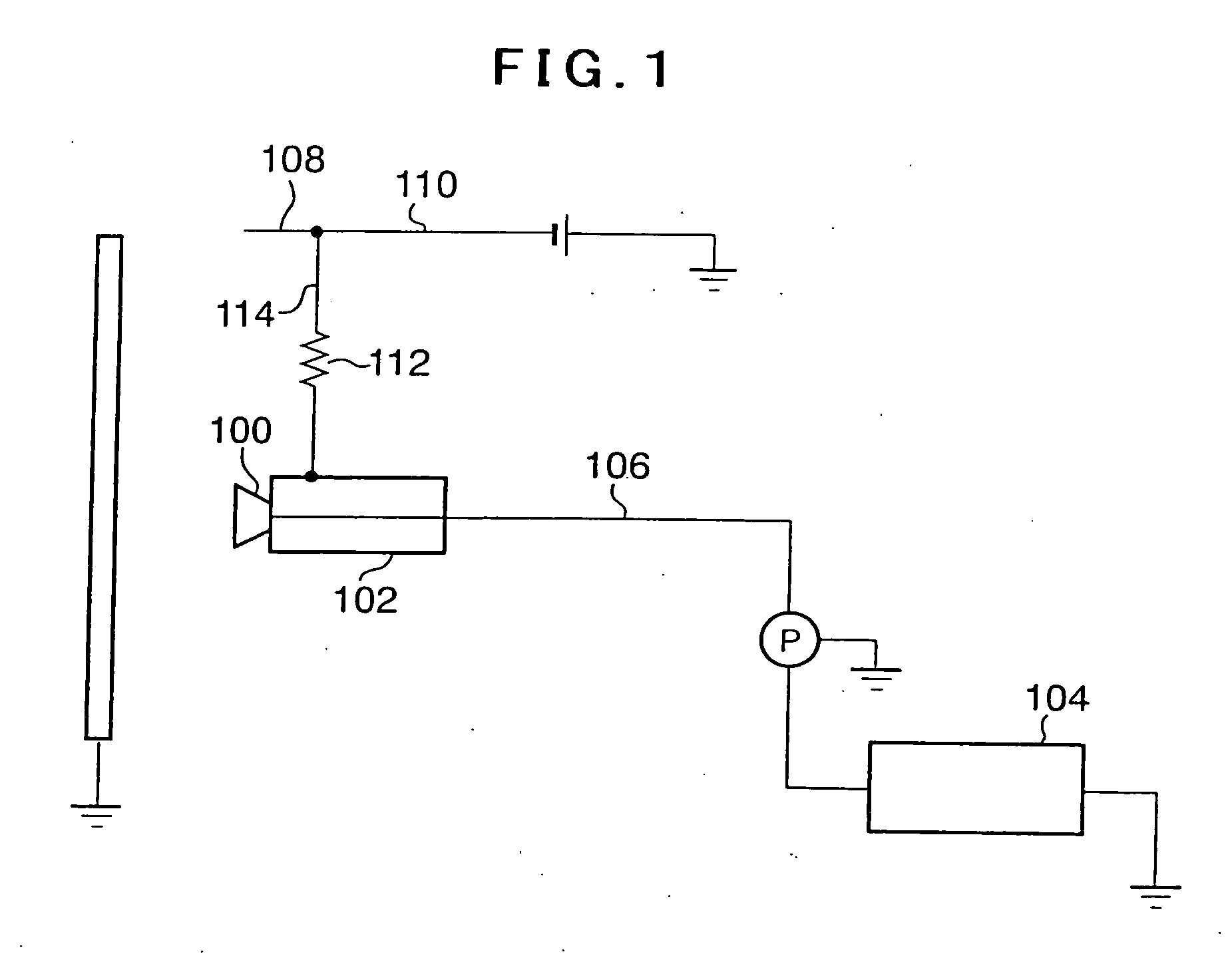

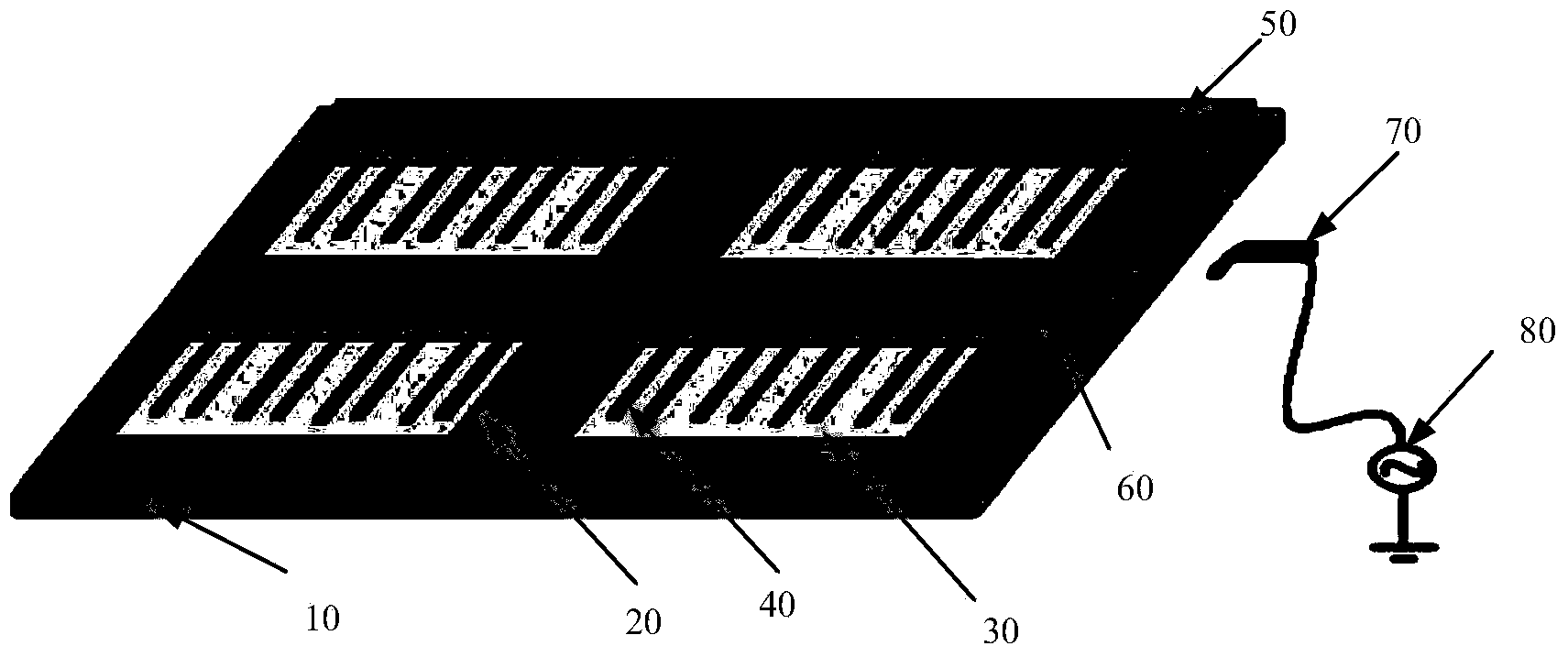

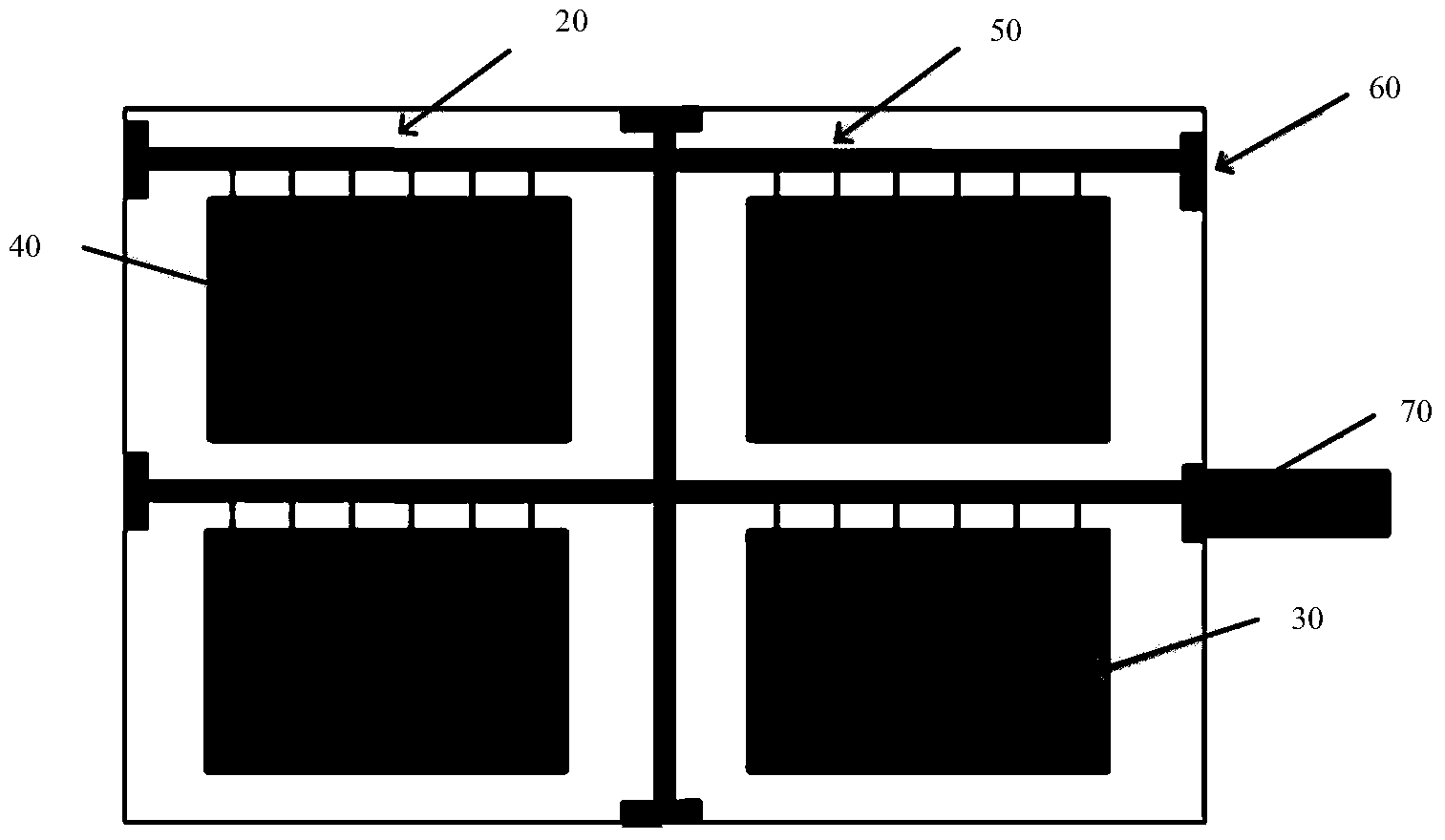

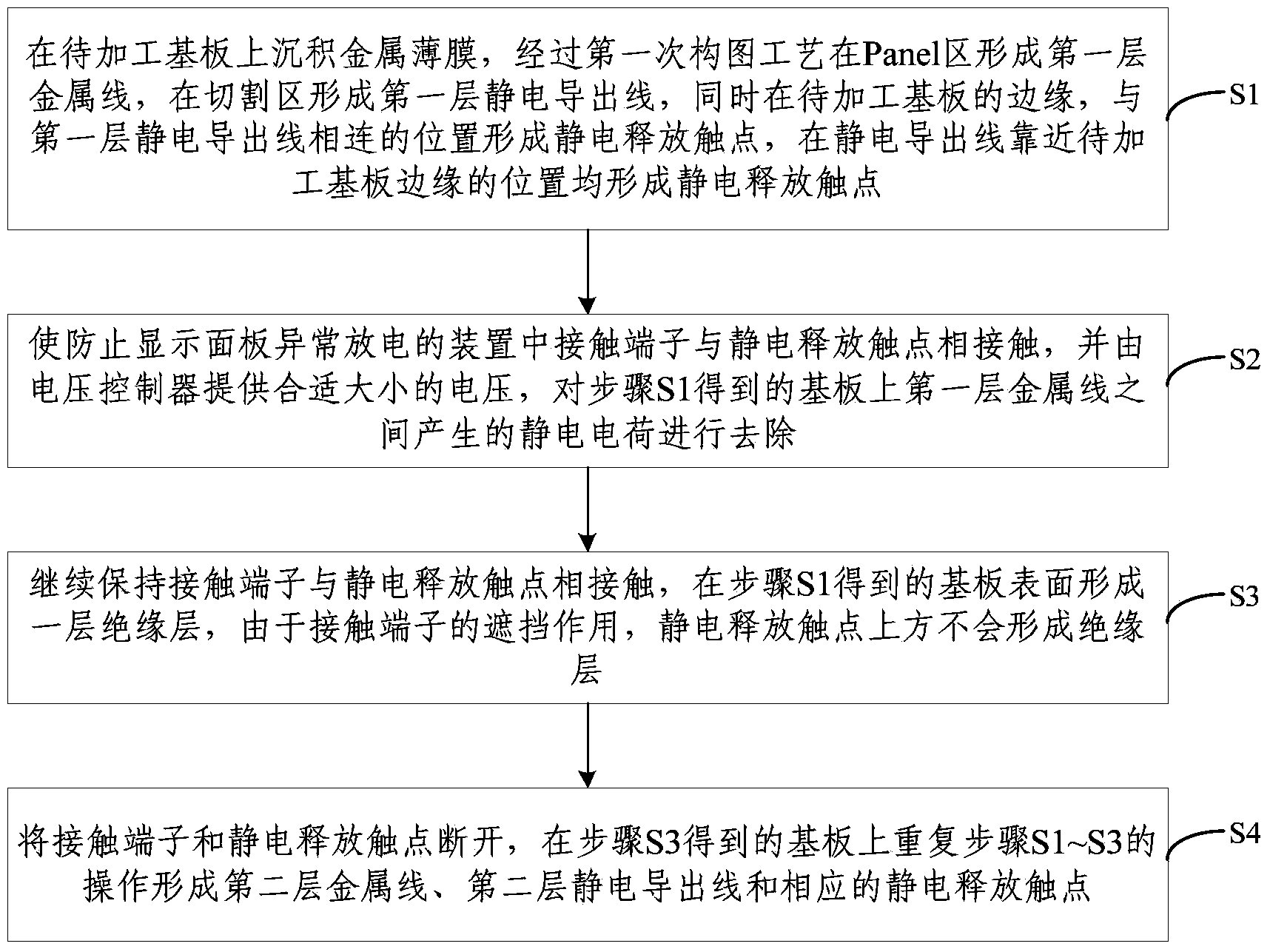

Device used for preventing display panel paradoxical discharge and display panel preparation system

ActiveCN104049392AAvoid controlEasy to controlElectrostatic discharge protectionNon-linear opticsElectrical conductorPixel density

The invention discloses a device used for preventing display panel paradoxical discharge and a display panel preparation system based on the device. The device used for preventing the display panel paradoxical discharge comprises a contact terminal and a voltage controller, wherein the contact terminal is a conductor and is used for being connected with an electrostatic discharge contact of a substrate to be processed; the voltage controller is connected with the contact terminal and is used for adjusting the voltage of the contact terminal and removing static electricity on the substrate to be processed. The device and the system are particularly suitable for the manufacturing process of a display panel with large size or high pixel density, a static electricity leading-out line absorb charges to eliminate a large number of charges which are accumulated on the surface of the display panel, when the voltage controller is connected to the electrostatic discharge contact by the contact terminal, the charges on the surface of the display panel are eliminated by adjusting voltage by the voltage controller, the control on the paradoxical discharge of the charges gathered on the surface of the display panel is realized, and the charges on the surface of the display panel and a plasma electric field in a technology reaction cavity are kept balanced.

Owner:BOE TECH GRP CO LTD +1

Hot-rolled copper plate

ActiveUS20160047017A1Improve workabilityImproved fatigue characteristicConductive materialVacuum evaporation coatingCopperGrain boundary

A hot-rolled copper plate consists of pure copper having a purity of 99.99 mass % or greater, the hot-rolled copper plate having an average crystal grain diameter of 40 μm or less, and a (Σ3+Σ9) grain boundary length ratio (L σ3+σ9) / L), which is a ratio between a total crystal grain boundary length L measured by an EBSD method and a sum L (σ3+σ9) of a Σ3 grain boundary length Lσ3 and a Σ9 grain boundary length Lσ9, being 28% or greater.

Owner:MITSUBISHI MATERIALS CORP

Plasma processing device and method of operating the same

InactiveCN103943451APrevent abnormal dischargeElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityHigh frequency power

The present invention provides a plasma processing device, wherein the plasma-related high-frequency power is supplied to an upper electrode and / or a lower electrode respectively from at least two high-frequency power supplies and the fluctuation of reflected waves is reliably detected. Meanwhile, the occurrence of abnormal discharge is avoided. A threshold setting part (123) is configured to switch a level of an obstructing threshold into a relatively low level of the obstructing threshold in a first high-frequency power supply part (65) and a second high-frequency power supply part (75) at a time point (T3) when the high-frequency power supply of the second high-frequency power supply part (75) is stabilized. The relatively low level of the obstructing threshold is continued at the same time point in the first high-frequency power supply part (65) and in the second high-frequency power supply part (75). At a time point (T4), the threshold setting part sets the obstructing threshold for a second time when the first power supply of the first high-frequency power supply part (65) is increased. Meanwhile, the level of the obstructing threshold is respectively raised to a relatively high level. The relatively high level is continued at the same time point in the first high-frequency power supply part (65) and in the second high-frequency power supply part (75).

Owner:TOKYO ELECTRON LTD

Sputtering target of sintered Sb-Te-based alloy

ActiveCN105917021AImprove featuresPrevent abnormal dischargeElectric discharge tubesVacuum evaporation coatingSputteringAlloy

A sputtering target of a sintered Sb-Te-based alloy which is a sputtering target having an Sb content of 10-60 at% and a Te content of 20-60 at%, the remainder comprising one or more elements selected from among Ag, In, and Ge and unavoidable impurities. The sputtering target is characterized in that the oxides have an average grain diameter of 0.5 [mu]m or smaller. The objective of the invention is to achieve an improved structure of the sputtering target of the sintered Sb-Te-based alloy so that the occurrence of arcing during sputtering is prevented and that a film to be deposited by the sputtering has improved thermal stability.

Owner:JX NIPPON MINING & METALS CORP

Vacuum electric arc deposition equipment

InactiveCN1495282APrevent electrodriftPrevent abnormal dischargeElectric discharge tubesVacuum evaporation coatingEvaporationVacuum arc

An arc evaporation source constituting this vacuum arc deposition apparatus has a plurality of cathodes, a trigger electrode, a trigger drive unit, a shutter, and a shutter drive unit. The trigger drive unit changes over the position of the trigger electrode to thereby position the trigger electrode in front of a desired cathode, and connects / disconnects the trigger electrode to / from the desired cathode in the changed-over position. The shutter covers the fronts of all the cathodes except the desired cathode..: The shutter drive unit moves the shutter to thereby change over the cathode not covered with the shutter. Further, the vacuum arc deposition apparatus has a changeover control unit for controlling the shutter drive unit and the trigger drive unit to thereby change over the cathode not covered with the shutter and to thereby position the trigger electrode in front of the cathode not covered with the shutter.

Owner:NISSIN ELECTRIC CO LTD

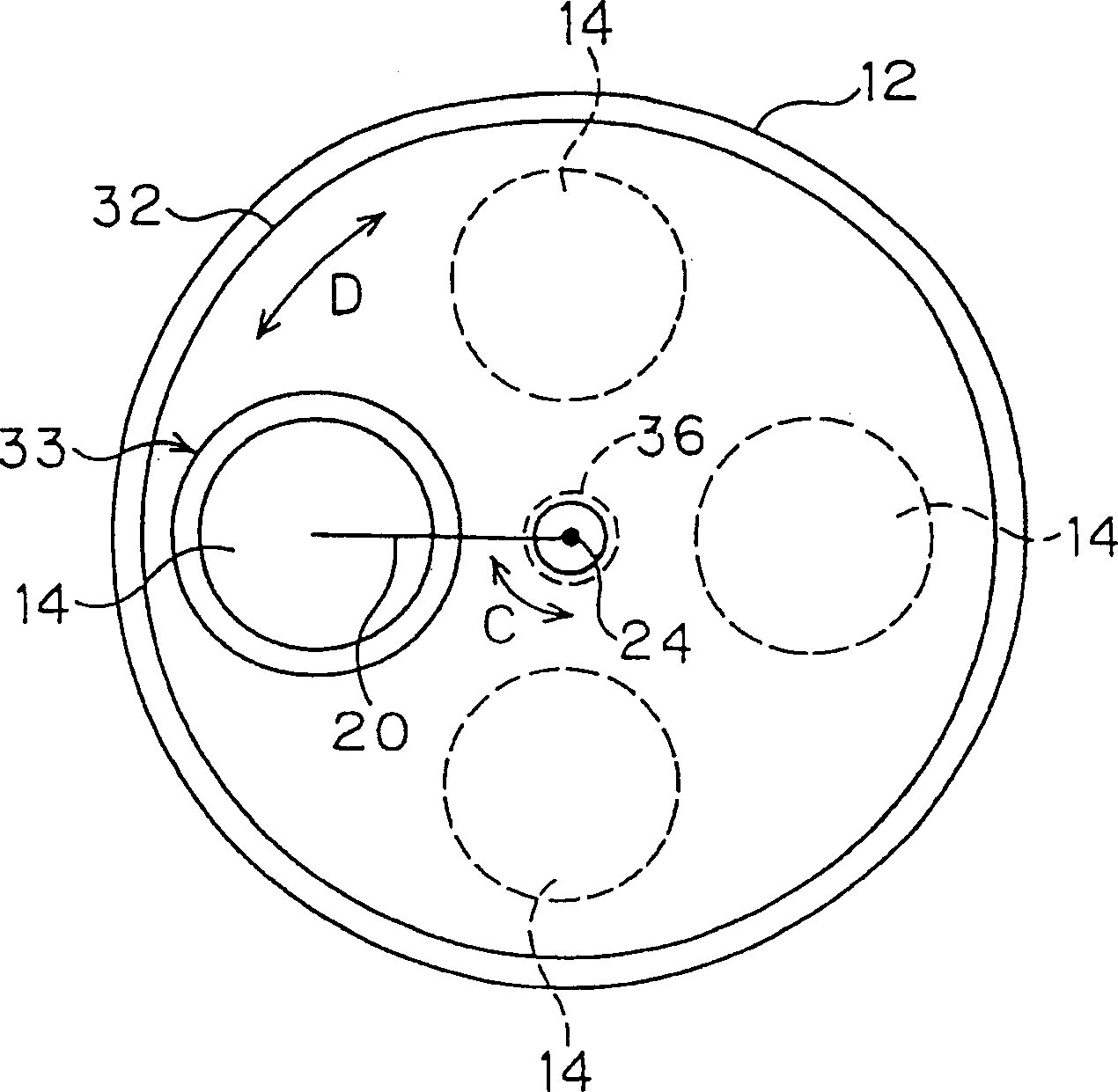

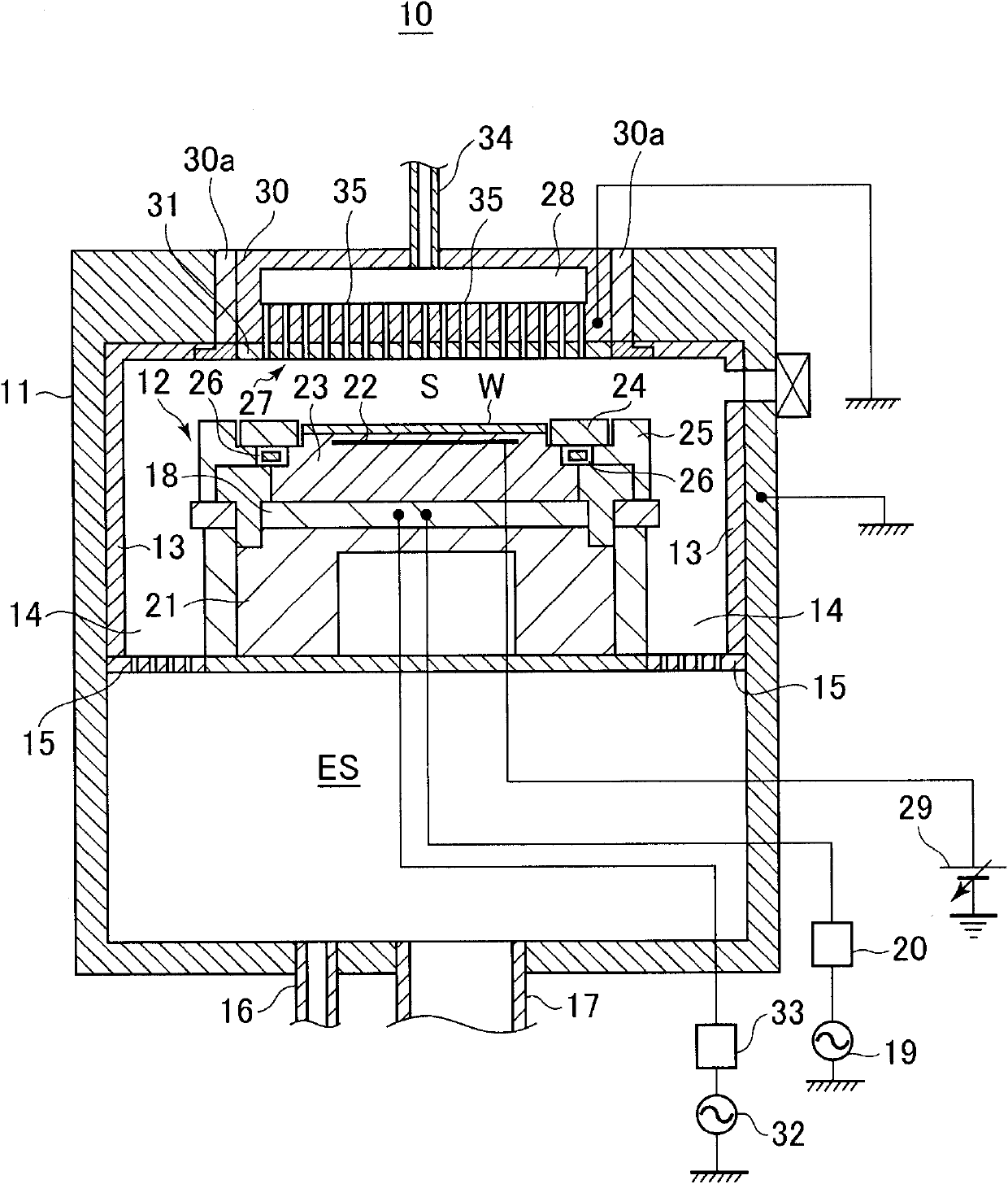

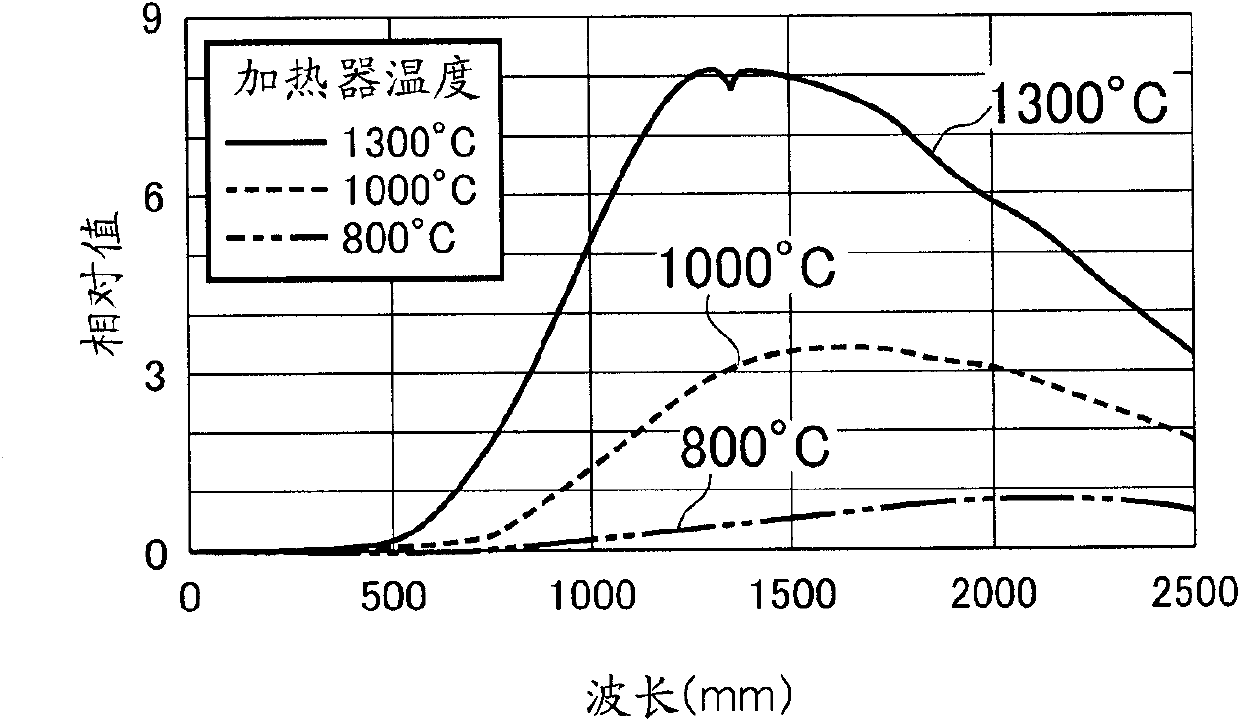

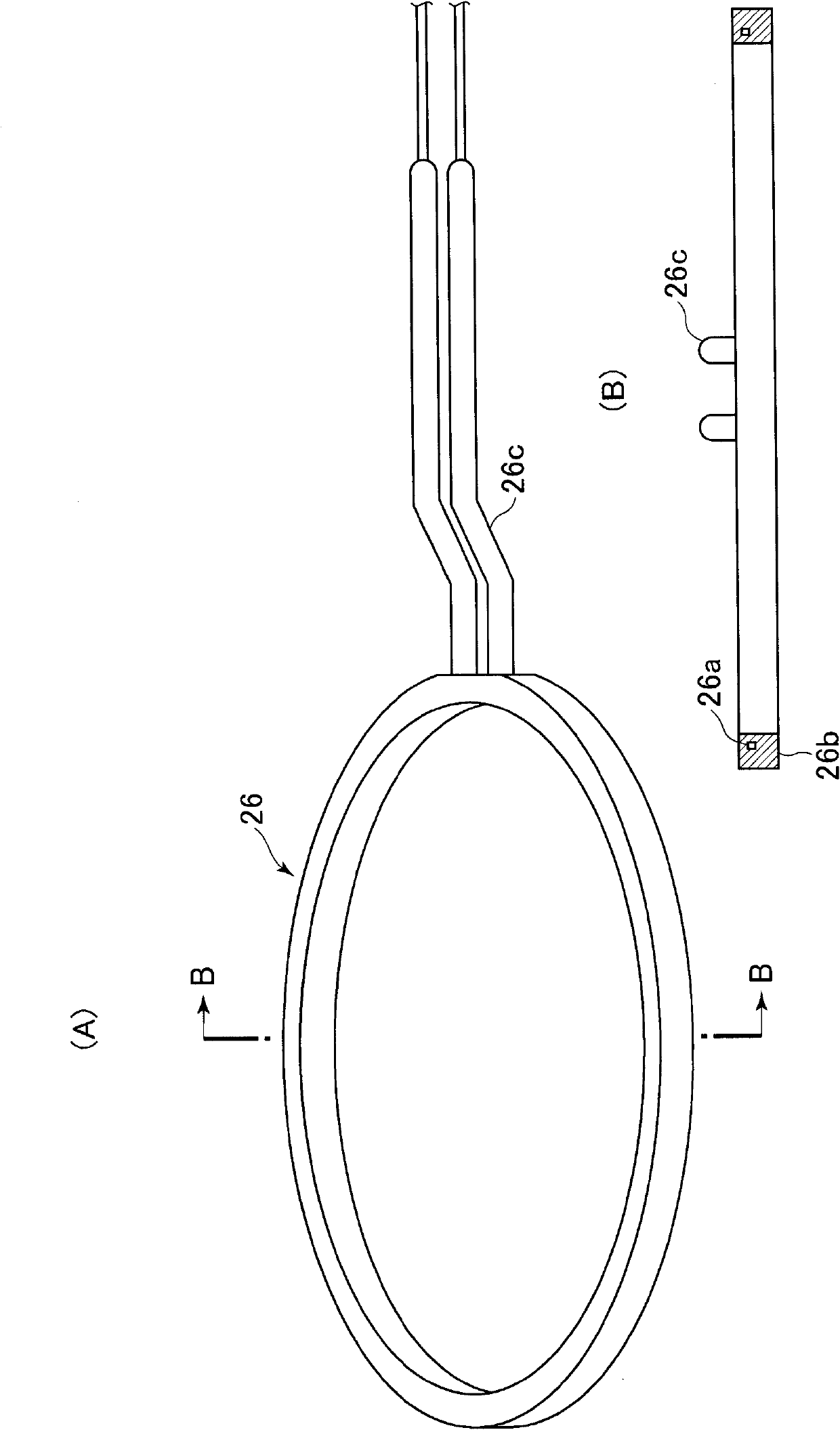

Substrate processing apparatus

InactiveCN101908468APrevent abnormal dischargeEfficient heatingSemiconductor/solid-state device manufacturingInfraredRadiant heater

Provided is a substrate processing apparatus capable of effectively heating each component without generating an abnormal electric discharge. The substrate processing apparatus 10 includes: a depressurizable processing chamber 11; a susceptor 12 provided within the processing chamber 11; a shower head 27 provided at a ceiling portion of the processing chamber 11 so as to face the susceptor 12; a focus ring 24 provided at an outer peripheral portion of a top surface of the susceptor 12; and a ring-shaped infrared radiant heater 26 provided in a vicinity of the focus ring 24. The heater 26 includes an infrared radiator 26a and a quartz ring 26b for sealing the infrared radiator 26a therein so that there is not a member for blocking the infrared radiation between the focus ring 24 and the heater 26.

Owner:TOKYO ELECTRON LTD

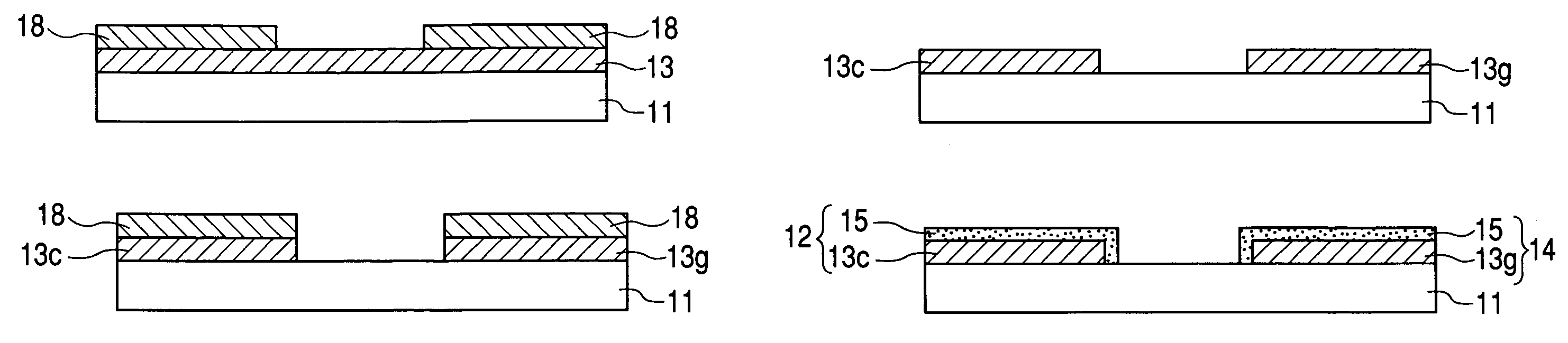

Electron-emitting device, electron source, image display device and information display and reproduction apparatus using image display device, and method of manufacturing the same

InactiveUS20050200266A1Stable characteristicsPrevent abnormal dischargeDischarge tube luminescnet screensLamp detailsElectron sourceAbnormal discharge

The present invention provide a lateral type electron-emitting device in which abnormal discharge near an electron-emitting region is suppressed, electron emission characteristics are stable, and electron emission efficiency is high. A method of manufacturing an electron-emitting device of the invention includes: a first step of preparing an electron-emitting electrode and a control electrode that are arranged on a surface of an insulating substrate; and a second step of covering the surface of the insulating substrate, which is located between the electron-emitting electrode and the control electrode, with a resistive film to connect the electron-emitting electrode and the control electrode. In the method of manufacturing an electron-emitting device, the resistive film is arranged to cover an end of a surface of the electron-emitting electrode opposed to the control electrode.

Owner:CANON KK

Sb-Te alloy sintered compact target and manufacturing method thereof

ActiveUS7943021B2Reduce generationPrevent abnormal dischargeCellsTransportation and packagingTarget surfaceSputtering

Owner:JX NIPPON MINING & METALS CORP

Sb-te base alloy sinter sputtering target

ActiveCN101522940AInhibitionAvoid it happening againVacuum evaporation coatingSputtering coatingMean diameterAlloy

The invention provides an Sb-Te base alloy sinter sputtering target having Sb and Te as its primary component and comprising a structure in which Sb-Te base alloy particles are surrounded by fine carbon or boron particles; wherein, if the mean diameter of the Sb-Te base alloy particles is X and the particle size of carbon or boron is Y, Y / X is within the range of 1 / 10 to 1 / 10000. The present invention seeks to improve the Sb-Te base alloy sputtering target structure, inhibit the generation of cracks in the sintered target, and prevent the generation of arcing during the sputtering process.

Owner:JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com