Substrate processing apparatus

A substrate processing device and substrate technology, which are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inability to efficiently heat the current gathering ring, and reduced thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, refer to the attached Figure one The first embodiment of the present invention will be described in detail.

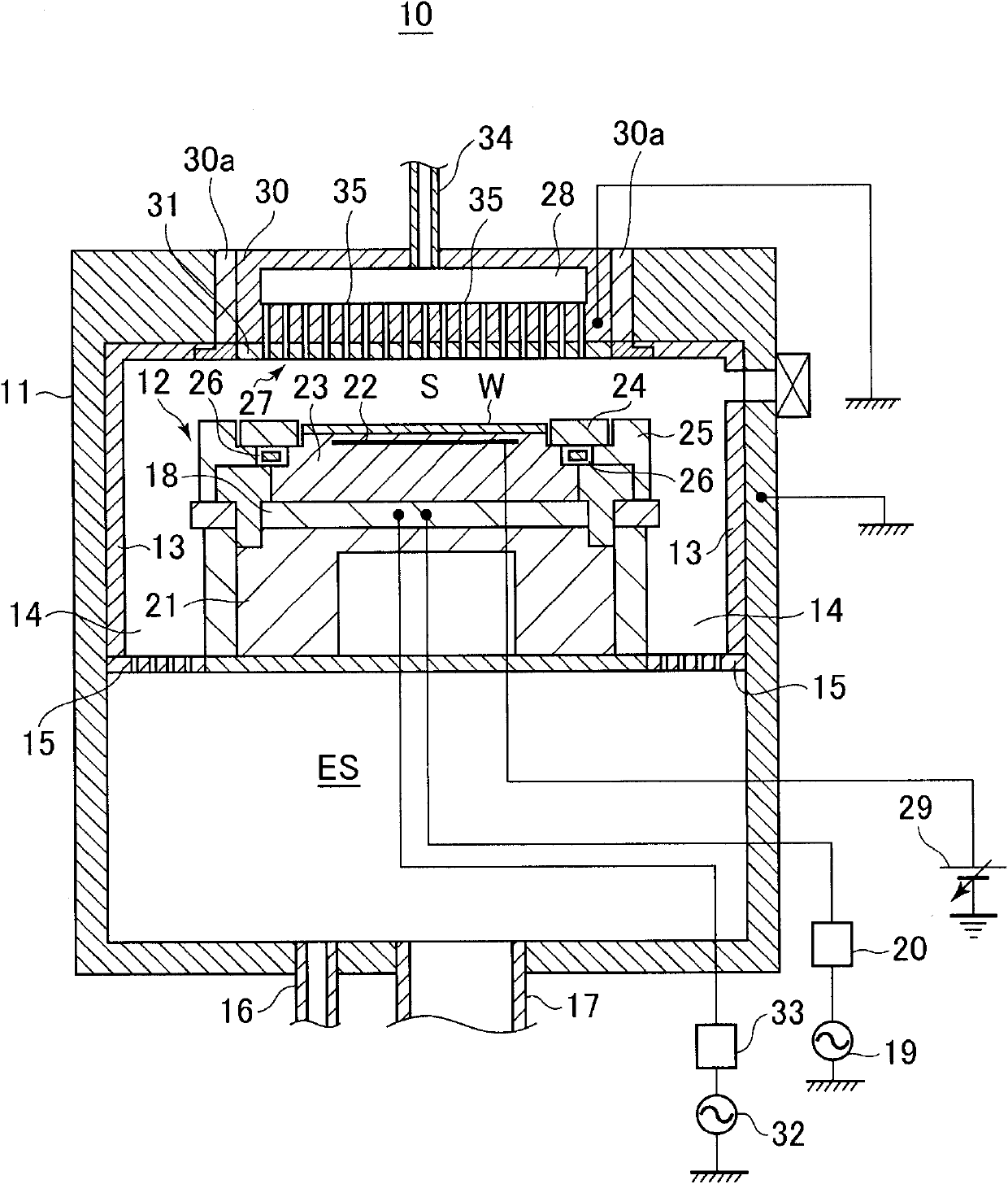

[0039] figure 1 It is a cross-sectional view schematically showing the configuration of the substrate processing apparatus according to the first embodiment of the present invention. This substrate processing apparatus is configured to perform RIE (Reactive Ion Etching) processing on a semiconductor wafer W as a substrate.

[0040] in figure 1 Among them, the substrate processing apparatus 10 has a cylindrical processing chamber 11 having a processing space S above the inside. The plasma described later is generated in the processing space S. In the processing chamber 11, a cylindrical susceptor 12 is arranged as a substrate mounting table on which a semiconductor wafer W (hereinafter, simply referred to as "wafer W") having a diameter of, for example, 300 mm is mounted. The inner wall surface of the processing chamber 11 is covered with a side wall member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com