Sputtering target of sintered Sb-Te-based alloy

A sputtering target and sintered body technology, applied in the field of Sb-Te-based alloy sintered body targets, can solve the problems of insufficient diversity of Sb-Te-based alloy targets, unclear which forms exist, and insufficient target characteristics and functions. , to achieve the effect of improving characteristics, improving uniformity and preventing abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

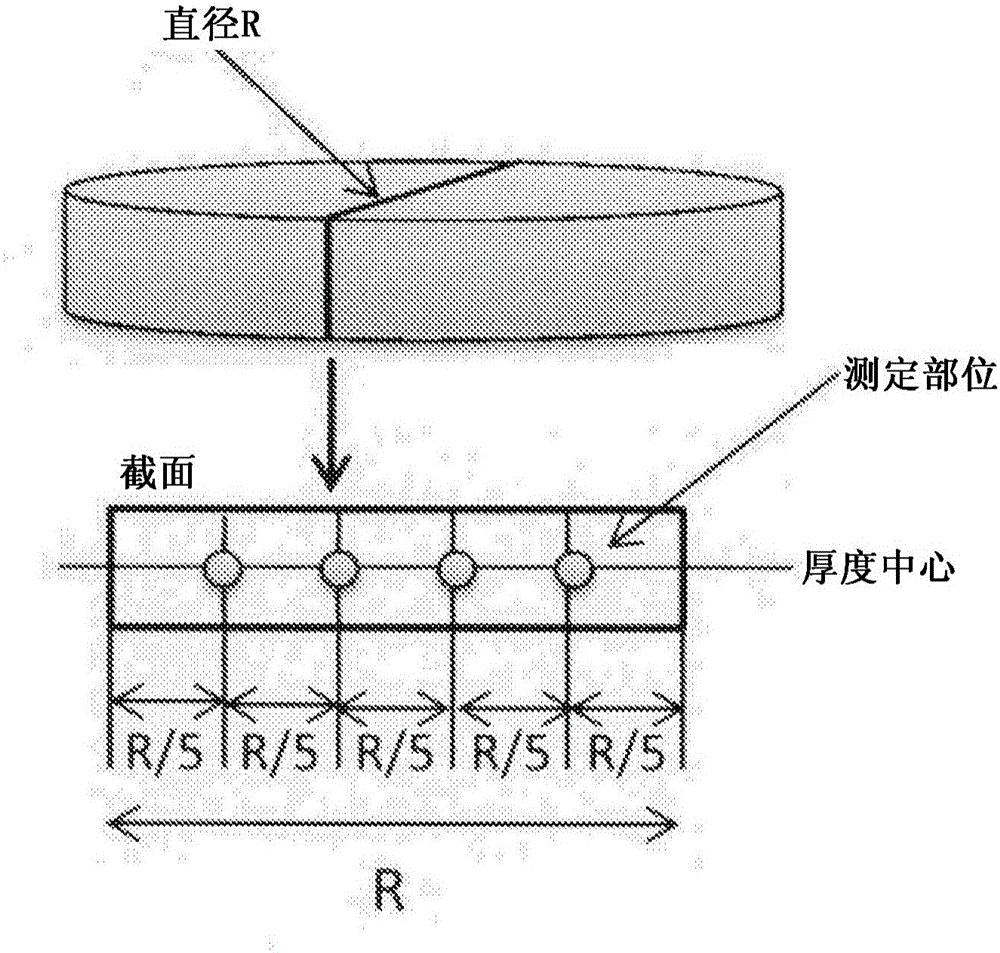

Image

Examples

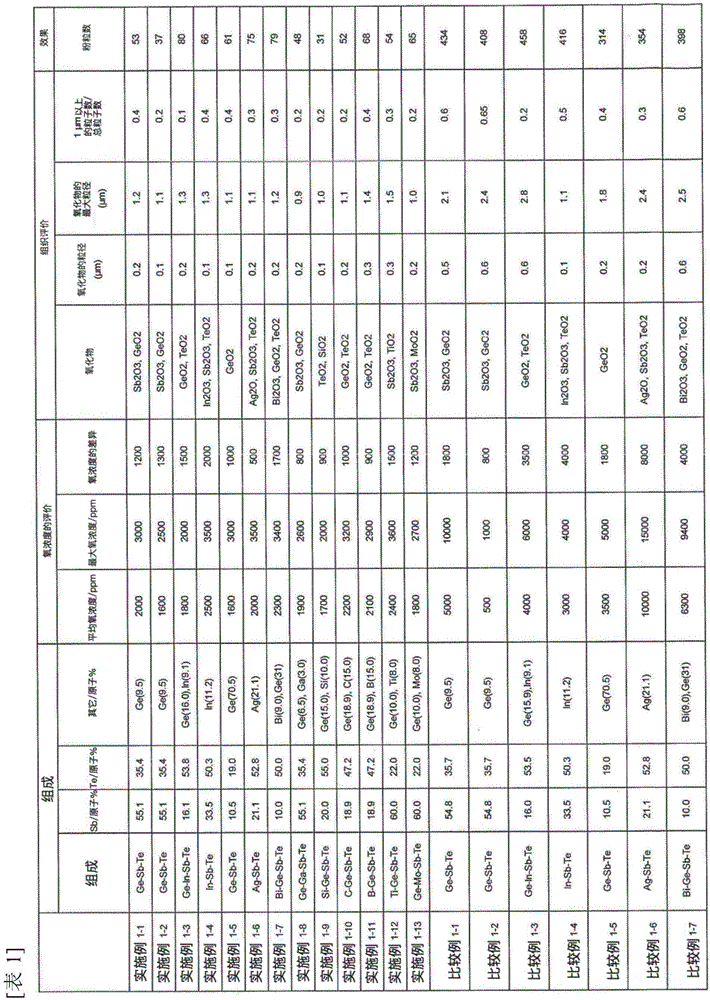

Embodiment 1-1

[0063] As shown in Table 1, raw material particles of Te, Sb, and Ge with a purity of 99.999% (5N) excluding gas components were weighed so that Ge: 9.5 atomic %, Sb: 55.1 atomic %, and Te: 35.4 atomic %. For the purpose of preventing oxidation, the material with a particle size of 5mm or less is selected as the raw material. Next, these powders were evacuated to a vacuum degree of 8.5×10 -3 High-frequency melting was carried out by maintaining at 950° C. for 10 minutes in a melting furnace below pa. After melting, gas atomization was performed using high-purity Ar gas with a particle diameter of 20 μm.

[0064] In order to refine and uniformly disperse the oxides in the powder, jet mill pulverization was carried out. Thus, a raw material powder having an average particle diameter of 2 μm, a maximum grain size of 5 μm, and an oxygen content of 2000 ppm by weight was obtained. By hot pressing (vacuum, heating rate 5°C / min, final temperature: 570°C, pressing pressure 200kgf / c...

Embodiment 1-2

[0067] According to the composition shown in Table 1, a sintered body was produced under the same production conditions as in Example 1-1. The average oxygen concentration of the obtained target was 1600 ppm, the maximum value of the oxygen concentration was 2500 ppm, and the variation of the oxygen concentration was 1300 ppm. As an oxide, Sb was confirmed 2 o 3 、GeO 2 . In addition, the average particle size of the oxide was 0.1 μm, the maximum particle size was 1.1 μm, and the number of particles of 1 μm or more was 0.2% with respect to the total number of particles.

[0068] The number of particles at the time of sputtering of the target obtained in this way was 37, and the number of particles was further reduced compared with Example 1, which was a favorable result. Table 1 shows the above results. Table 1 also shows the main oxides present in the target.

Embodiment 1-3

[0070] As shown in Table 1, except that In was added, a sintered body was produced under the same production conditions as in Example 1-1. Evaluation of the target thus obtained revealed that the average value of the oxygen concentration was 1800 ppm, the maximum concentration was 2000 ppm, and the difference in oxygen concentration was 1500 ppm. As an oxide, GeO was confirmed 2 , TeO 2 . The average particle size of the oxide was 0.2 μm, the maximum particle size was 1.3 μm, and the number of particles of 1 μm or more was 0.1% with respect to the total number of particles.

[0071] In addition, the number of particles during sputtering was 80, which was a target of 100 or less, which was a good result. Table 1 shows the above results. Table 1 also shows the main oxides present in the target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com