Patents

Literature

40results about How to "Stable sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sputtering target transparent conductive oxide, and method for preparing sputtering target

InactiveCN1379827AInhibitionStable sputteringVacuum evaporation coatingSputtering coatingCrystalliteElectrically conductive

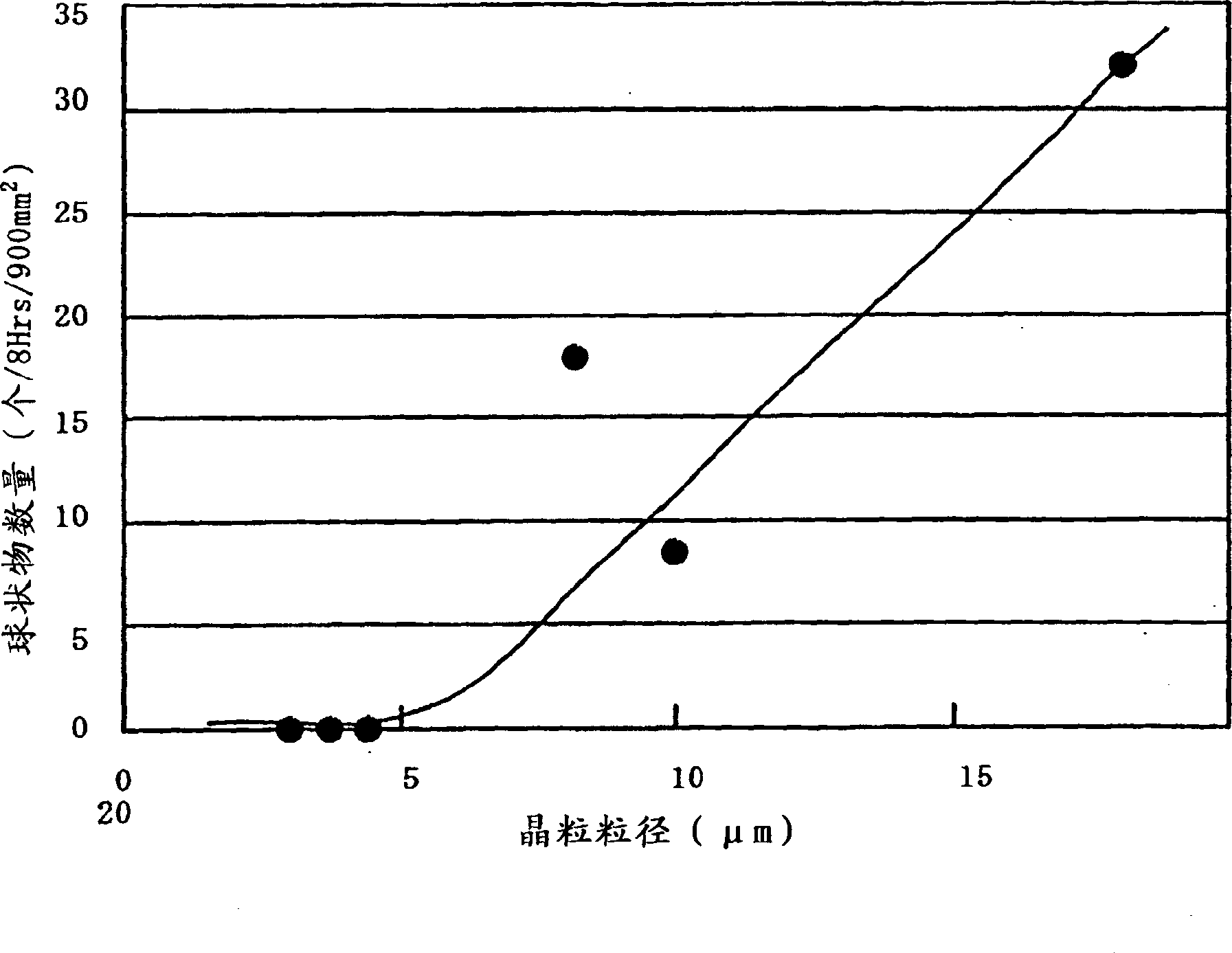

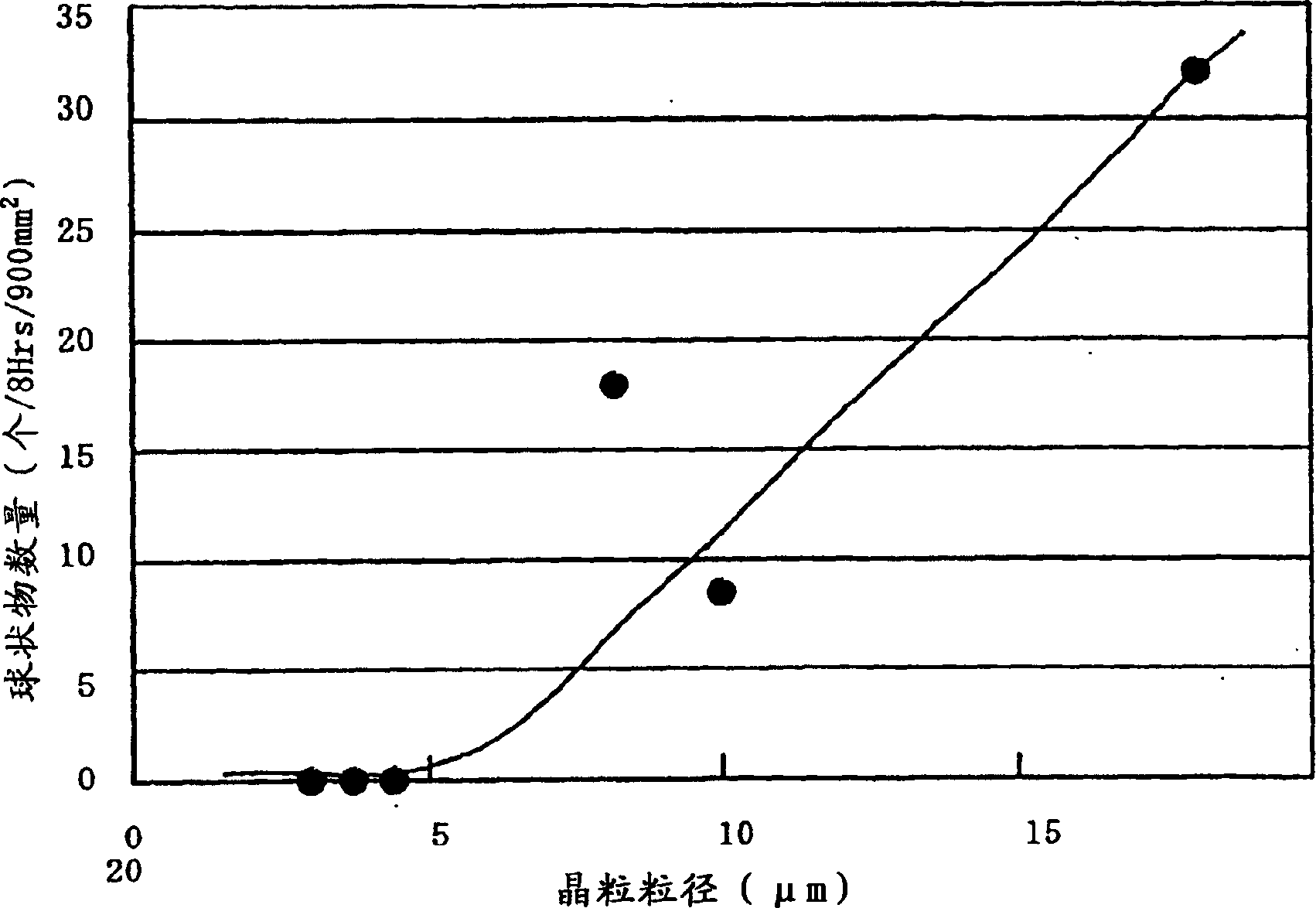

The present invention relates to a sputtering target comprising at least indium oxide and zinc oxide, wherein the atomic ratio represented by In / (In+Zn) is 0.75 to 0.97, including a hexagonal layered compound represented by In2O3(ZnO)m, Wherein m is a positive integer ranging from 2 to 20, and the grain size of the hexagonal layered compound is 5 microns or less.

Owner:JX NIPPON MINING & METALS CO LTD

Sputtering Target And Method For Production Thereof

ActiveUS20160126072A1Eliminate riskStable sputteringCellsElectric discharge tubesMetallurgyRelative density

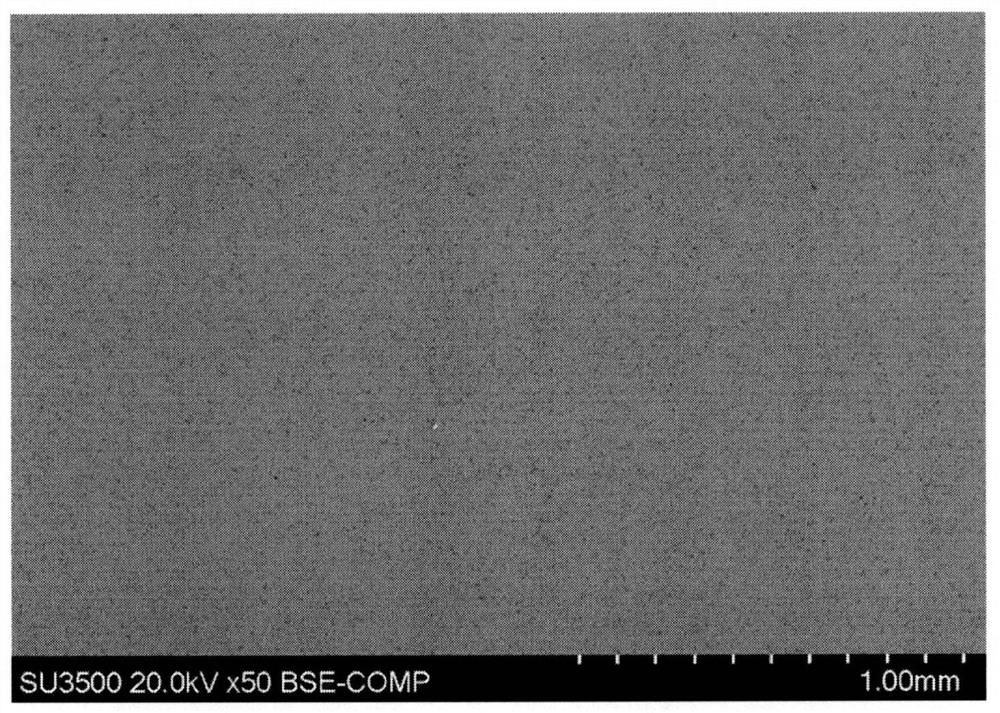

A sputtering target according to the disclosure includes 5 wtppm to 10,000 wtppm of Cu and the balance of In and has a relative density of 99% or more and an average grain size of 3,000 μm or less.

Owner:JX NIPPON MINING & METALS CO LTD

Sputtering target of sintered Sb-Te-based alloy

ActiveCN105917021AImprove featuresPrevent abnormal dischargeElectric discharge tubesVacuum evaporation coatingSputteringAlloy

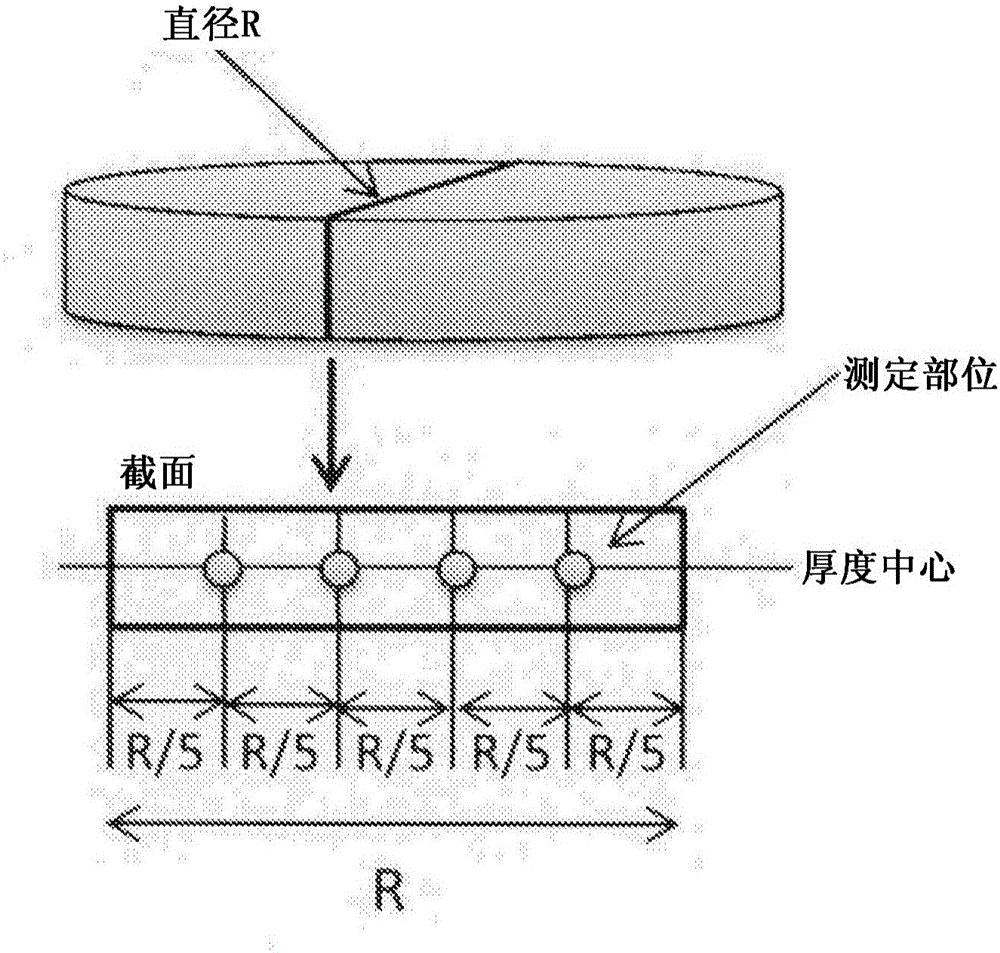

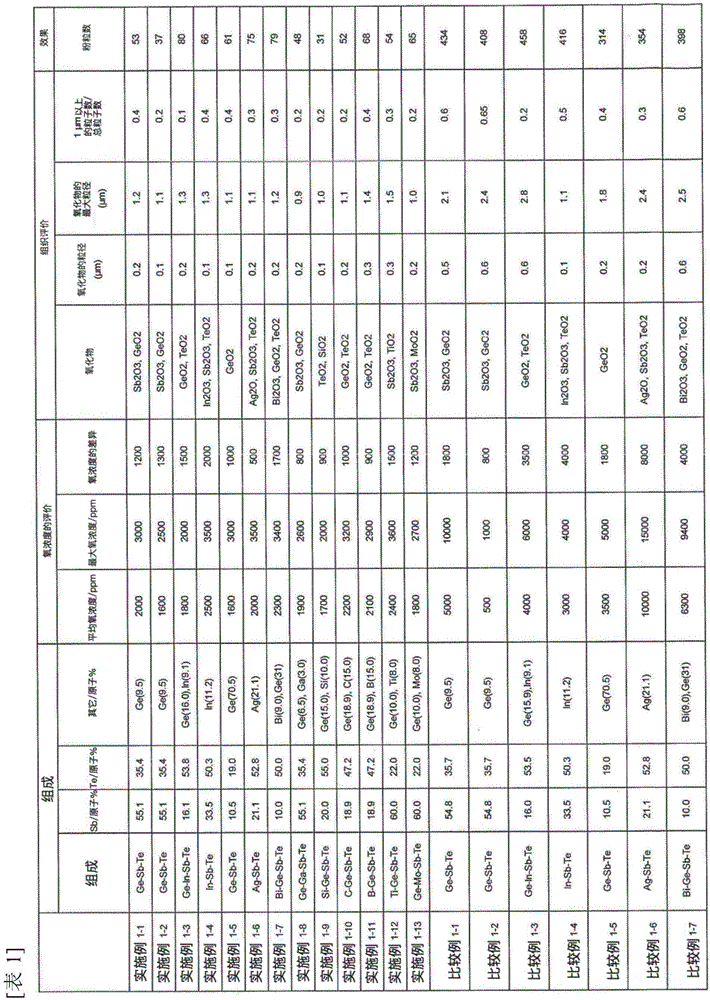

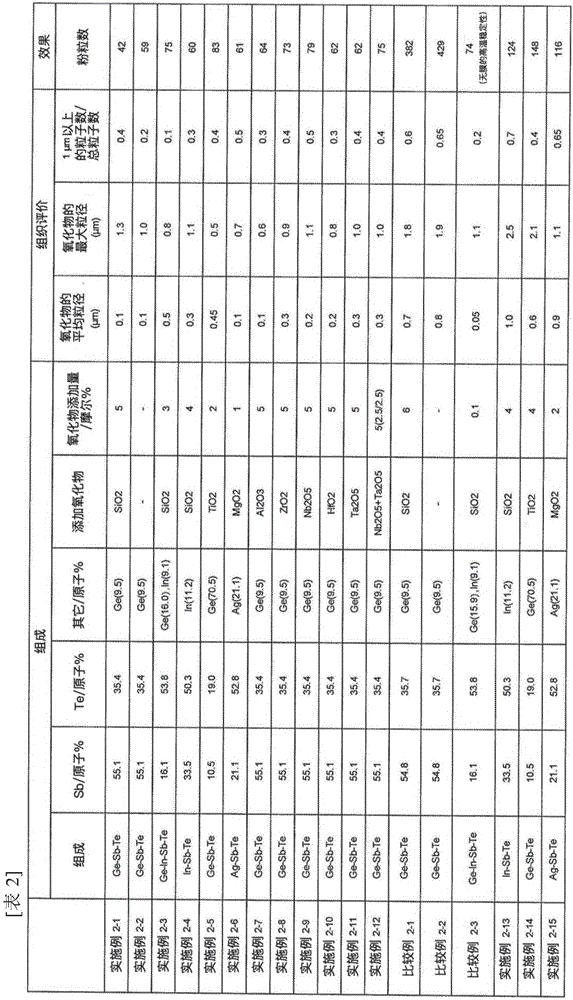

A sputtering target of a sintered Sb-Te-based alloy which is a sputtering target having an Sb content of 10-60 at% and a Te content of 20-60 at%, the remainder comprising one or more elements selected from among Ag, In, and Ge and unavoidable impurities. The sputtering target is characterized in that the oxides have an average grain diameter of 0.5 [mu]m or smaller. The objective of the invention is to achieve an improved structure of the sputtering target of the sintered Sb-Te-based alloy so that the occurrence of arcing during sputtering is prevented and that a film to be deposited by the sputtering has improved thermal stability.

Owner:JX NIPPON MINING & METALS CORP

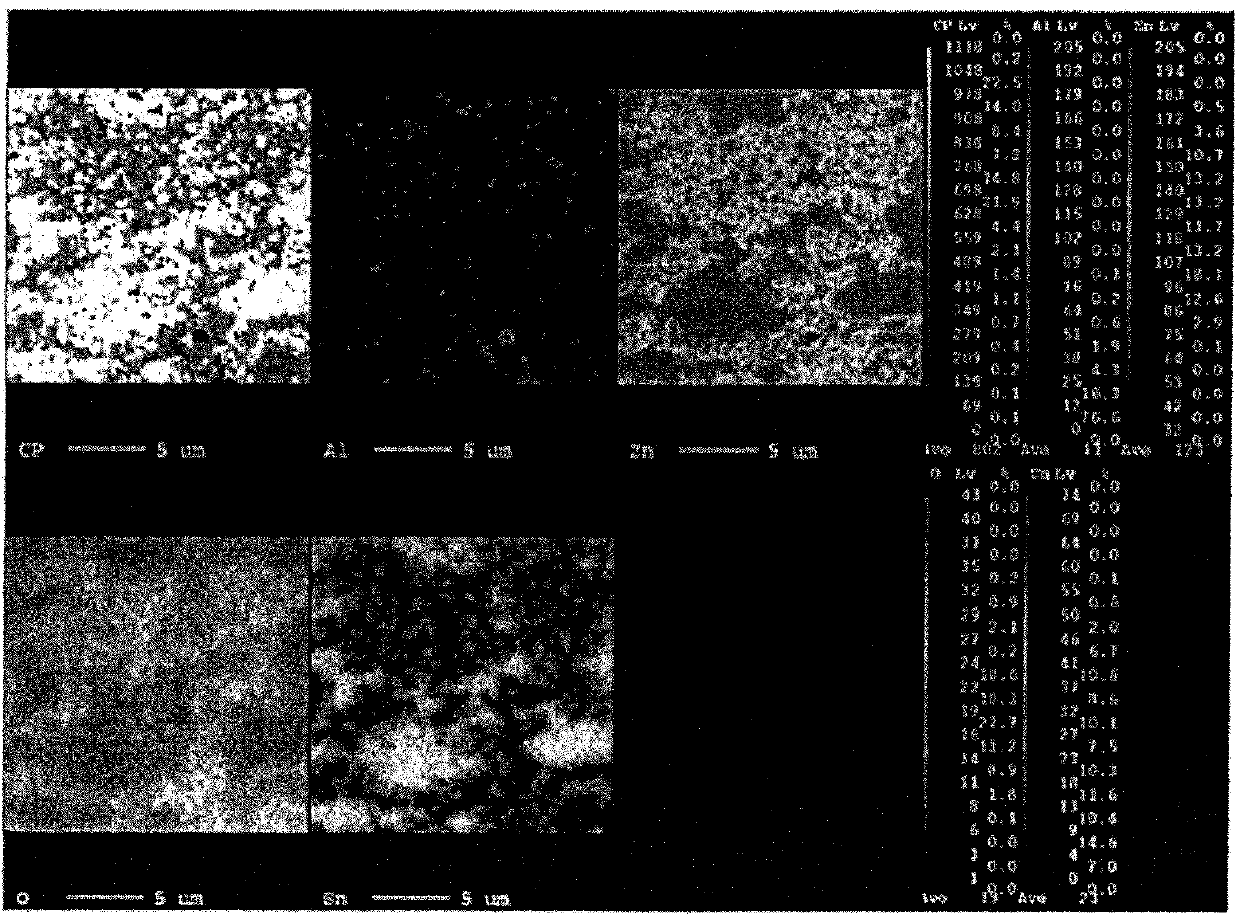

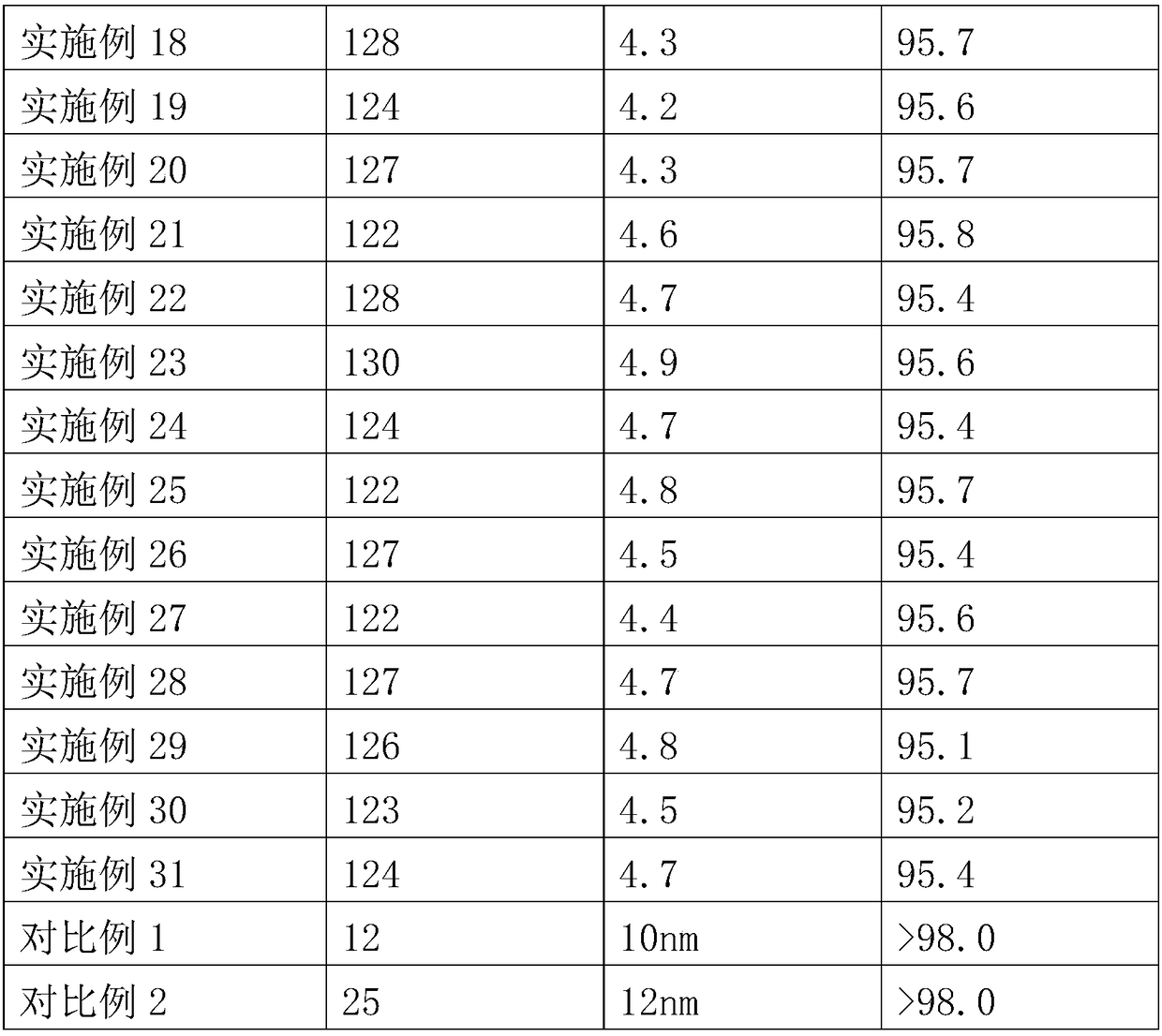

Preparation method of intelligent glass cathode electrochromic layer coating material

InactiveCN108658472AImprove density and uniformityHigh chemical stabilityVacuum evaporation coatingSputtering coatingOxygen vacancyOxide

The invention discloses a preparation method of an intelligent glass cathode electrochromic layer coating material. In a process of preparing the intelligent glass cathode electrochromic layer tungsten oxide coating material, various oxides are fully and uniformly mixed by using slip casting, so that the density and uniformity of a target material are improved, and then the service life of the target material is prolonged. The chemical stability of the tungsten oxide material is improved by adding a second oxide into the tungsten oxide. Oxygen vacancies are formed by the vacuum treatment in asintering process, so that the material has conductivity, and stable sputtering is facilitated. In addition, a process of staged heating sintering is adopted, and other gases are added in argon gas, so that the film-forming rate can be improved, the surface roughness can be reduced, the sputtering rate can be improved, the film roughness can be reduced, the activation of equipment can be improved,the production cost can be reduced, the application of the tungsten oxide film in electrochromic devices is greatly improved, the production requirements are met, and the market promotion and productpopularization are facilitated.

Owner:SHENZHEN KING CHUANG TECH & ELECTRONICS

Oxide sputtering target and protective film for optical recording medium

InactiveCN104136655ASmall change in reflectivityImprove the preservation effectElectric discharge tubesVacuum evaporation coatingSputteringOptical recording

This invention provides an oxide sputtering target, as used for forming an optical recording medium protective film, capable of forming a flexible, difficult-to-crack film with high storage ability, and capable of direct-current sputtering with few particles during sputtering. The oxide sputtering target is an oxide sintered body containing, with respect to the total amount of metal component, at least a total of 0.15at% of at least one of Al, Ga, and In, at least 7at% of Sn, and no more than a total of 36at% of Al, Ga, In, and Sn, the remainder comprising Zn and unavoidable impurities.

Owner:MITSUBISHI MATERIALS CORP

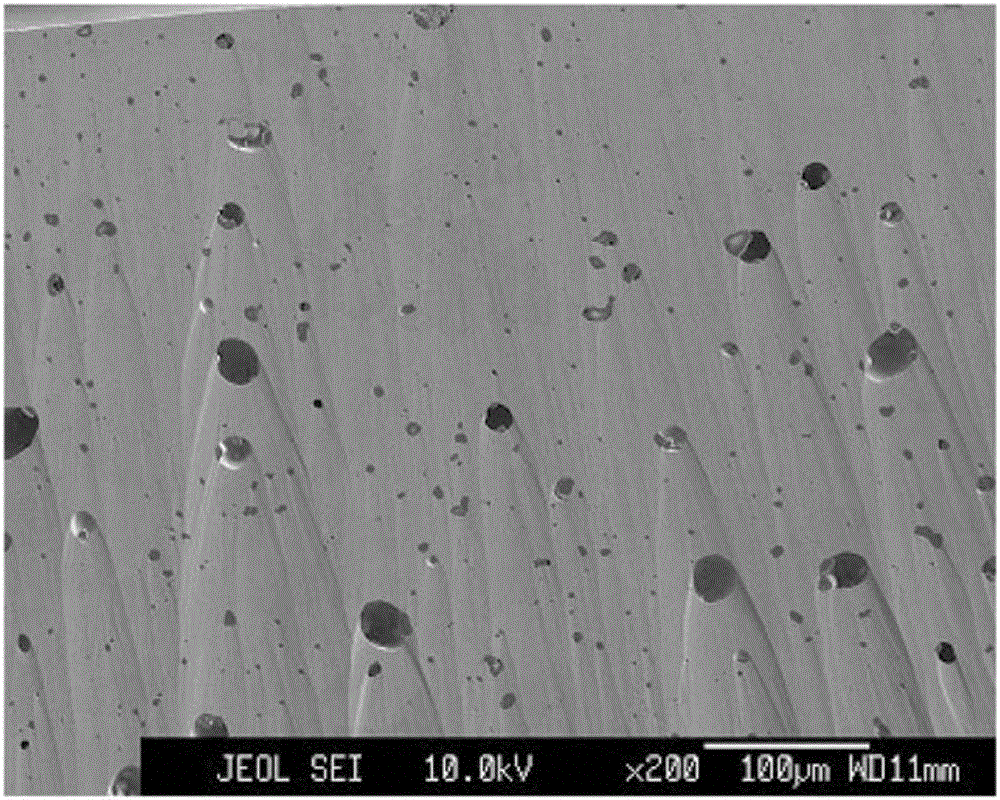

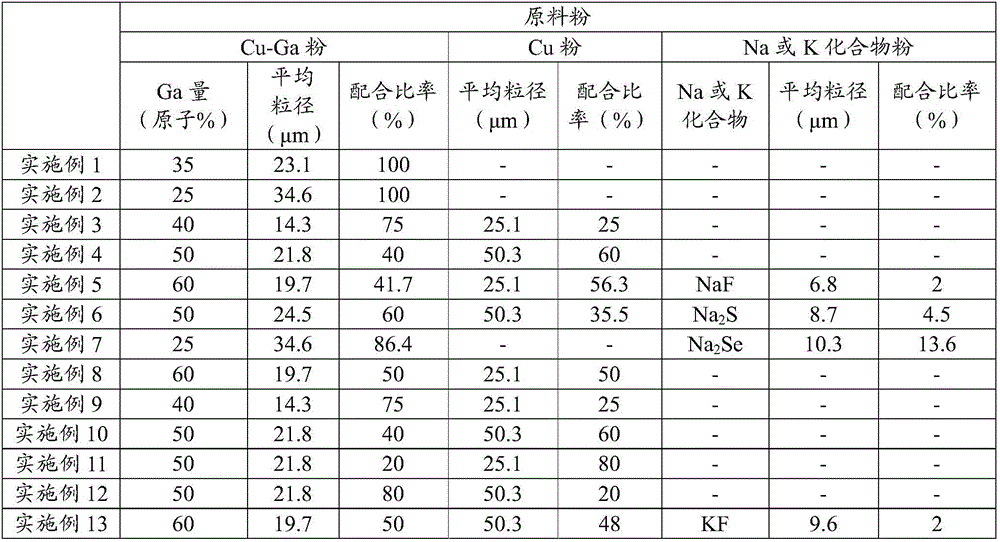

Cu-Ga alloy sputtering target and method for manufacturing same

ActiveCN106170581AReduce oxygen contentSuppress generationElectric discharge tubesTransportation and packagingPorosityAlloy

This Cu-Ga alloy sputtering target has a component composition containing 0.1-40.0% (atom basis) of Ga with the remainder made up by Cu and unavoidable impurities, wherein the porosity of the target is 3.0% or less, the average diameter of inscribed circles of the pores is 150 [mu]m or less, and the average crystal grain diameter of Cu-Ga alloy grains is 50 [mu]m or less.

Owner:MITSUBISHI MATERIALS CORP

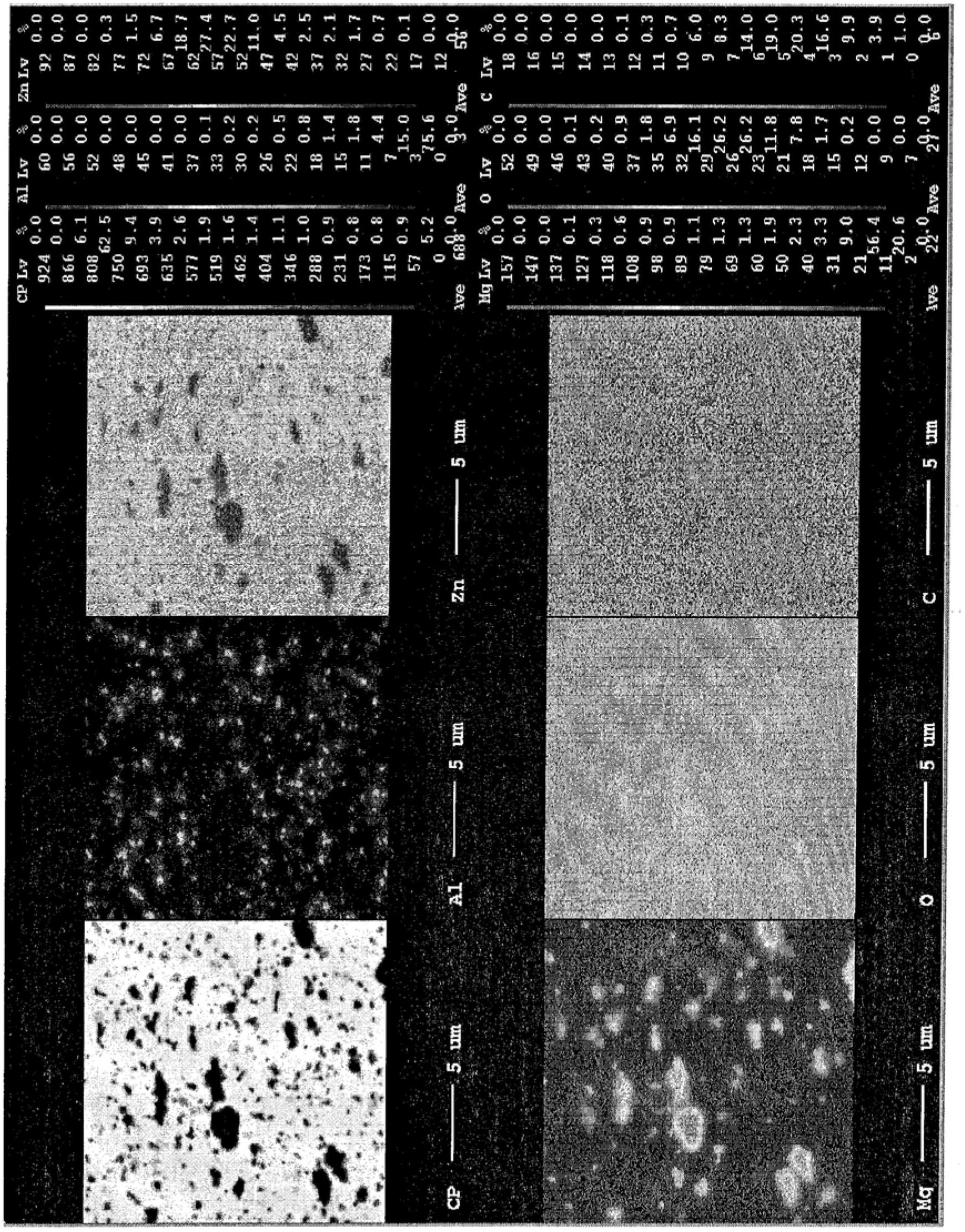

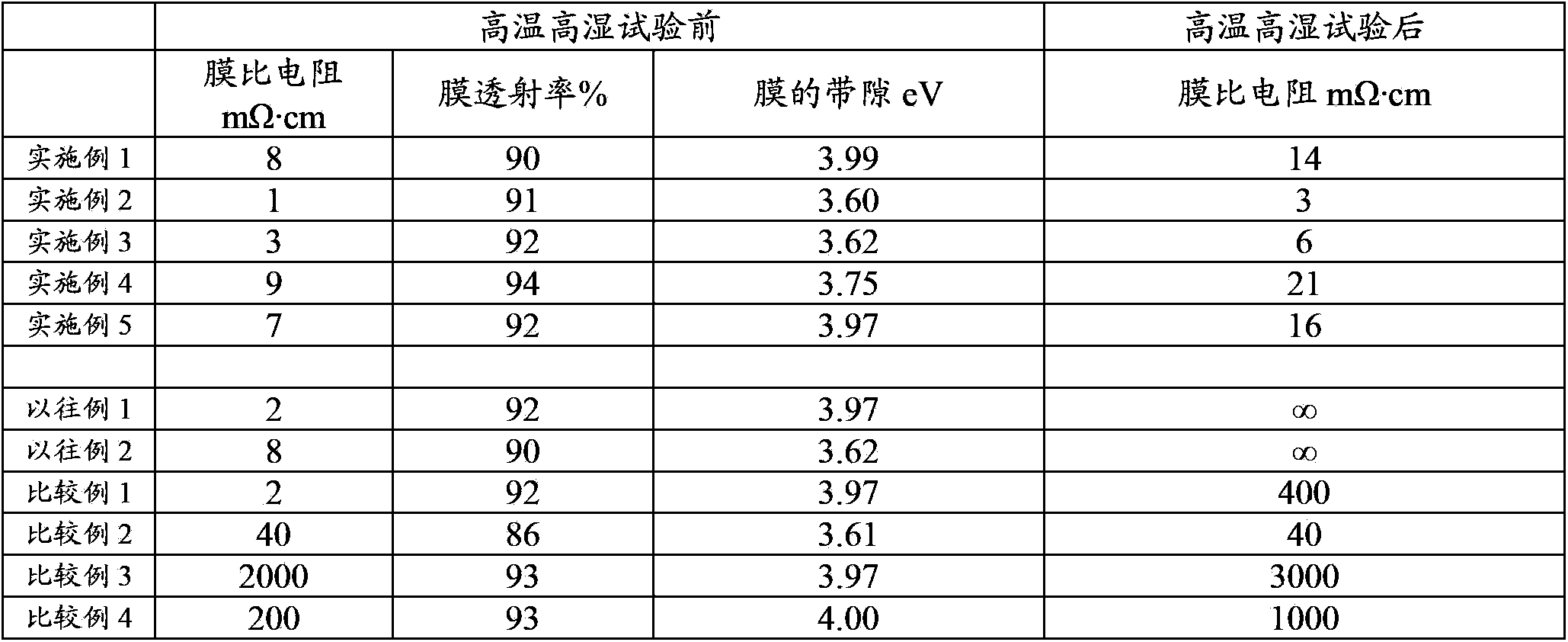

Transparent conductive film, solar cell using same, sputtering target for forming said transparent conductive film, and manufacturing method therefor

ActiveCN102666910AImprove moisture resistanceLess increase in specific resistanceConductive layers on insulating-supportsVacuum evaporation coatingElectrically conductiveLiquid-crystal display

Provided is a transparent conductive film used in liquid-crystal display devices, electroluminescent display devices, and the like, and is particularly suitable for use in solar cells. Also provided is a solar cell using said transparent conductive film and a sputtering target suited to forming said transparent conductive film. The provided transparent conductive film, which is highly moisture-resistant, comprises oxides of aluminum, magnesium, gallium, and zinc. Between 0.7% and 7% of the metal atoms in the transparent conductive film are aluminum, between 9.2% and 25% are magnesium, between 0.015% and 0.085% are gallium, and the remainder are zinc.

Owner:MITSUBISHI MATERIALS CORP

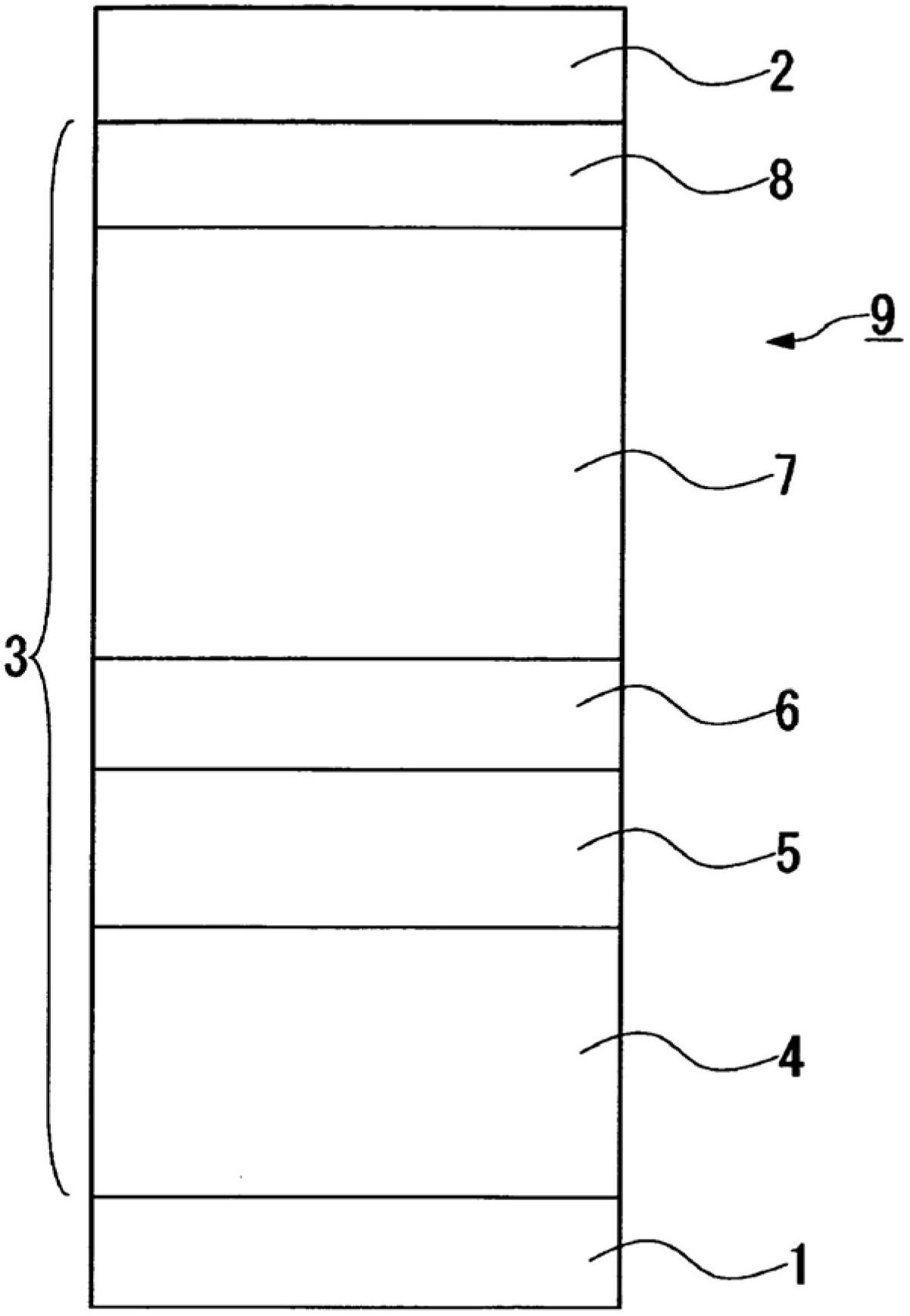

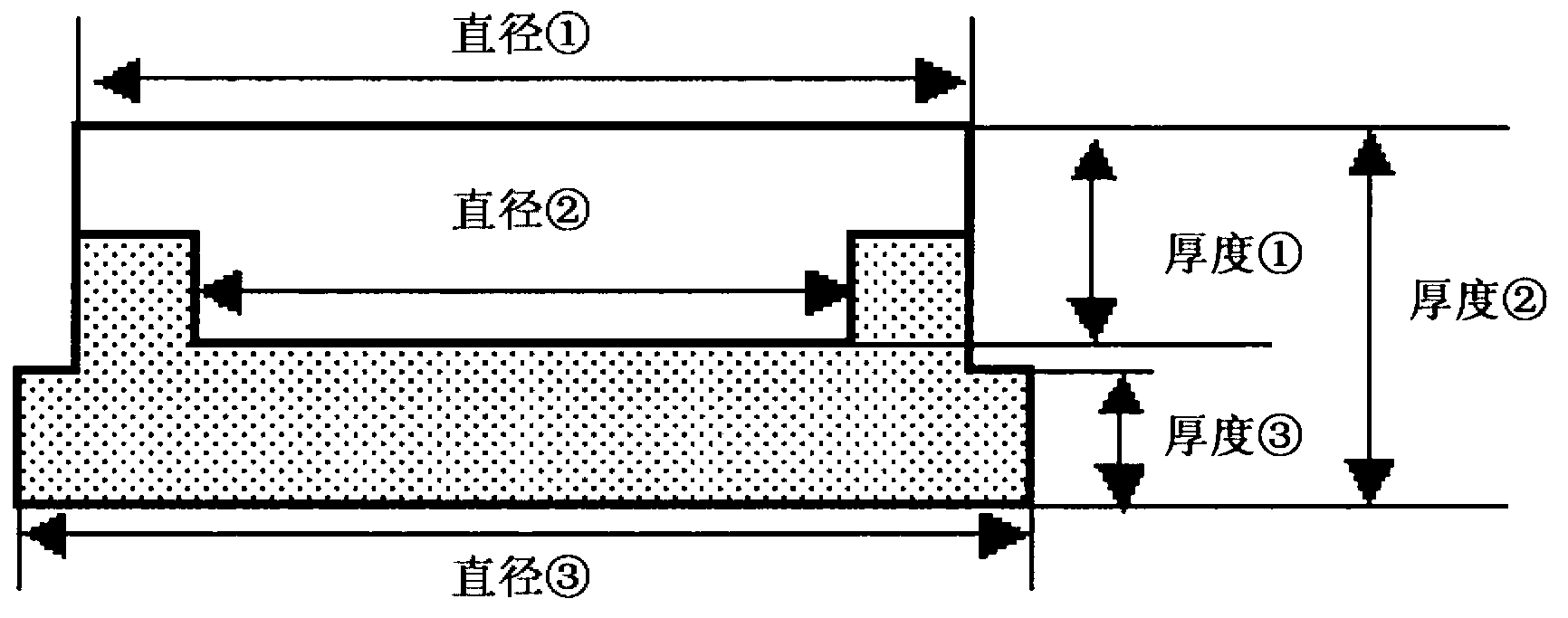

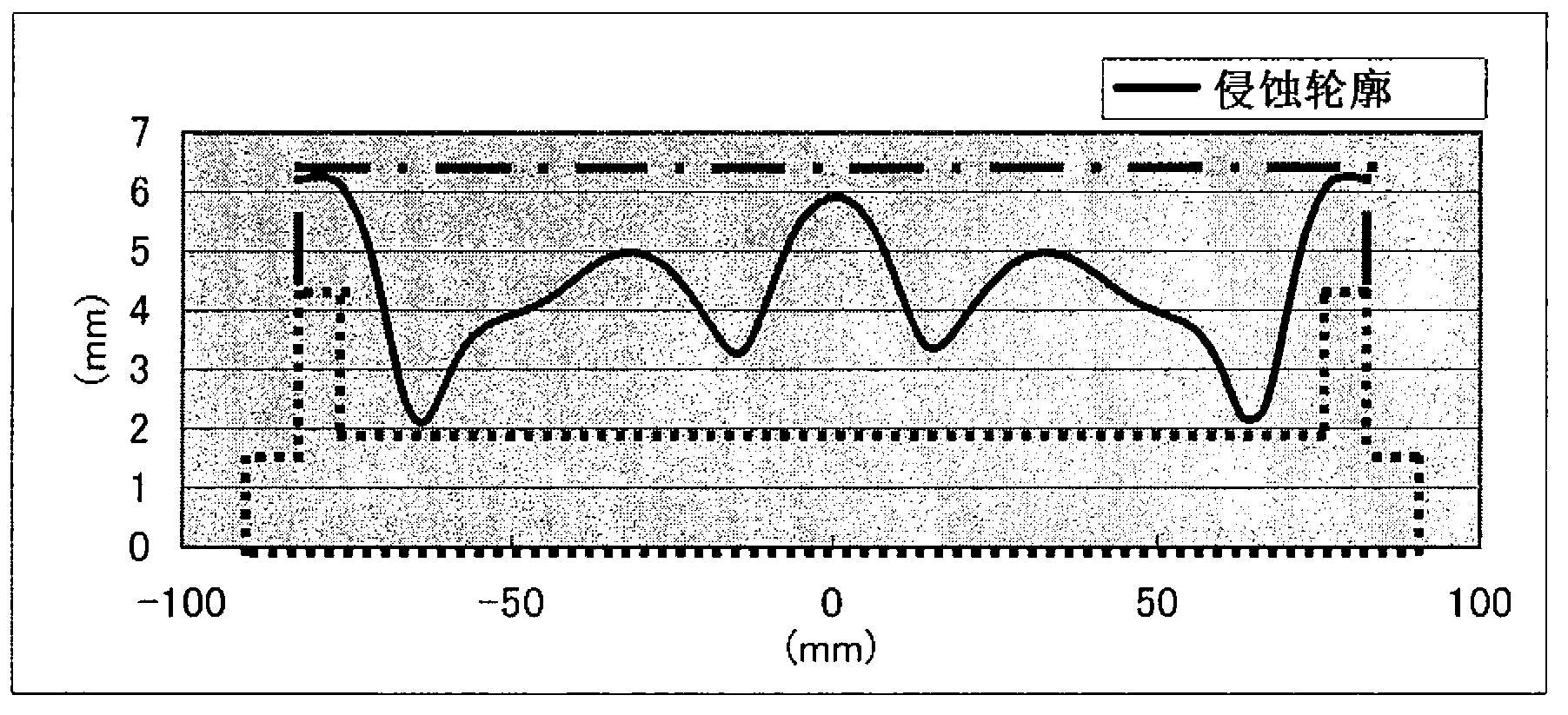

Sputtering target-backing plate assembly

InactiveUS20120318669A1Stable sputteringQuality improvementCellsVacuum evaporation coatingSputteringMetallurgy

Provided is a sputtering target-backing plate assembly where a raw material powder prepared so as to have the composition of a magnetic material sputtering target is filled in a die together with a backing plate and hot-pressed, thereby being bonded to the backing plate simultaneously with sintering of the magnetic material target powder.It is an object of the present invention to provide a sputtering target-backing plate assembly having a high average pass through flux and allowing more stable sputtering, by disposing the raw material powder for a target on the backing plate and sintering them.By simultaneously performing sintering and bonding, a sputtering target-backing plate assembly has a shorter manufacturing process, can shorten manufacturing period, and does not cause a problem of detachment due to an increase in temperature during sputtering. In addition, it is also an object of the present invention to provide a sputtering target-backing plate assembly at a reduced cost and with an improved average pass through flux (PTF).

Owner:JX NIPPON MINING& METALS CORP

Sputtering target-backing plate assembly

InactiveCN102812152AImprove qualityHigh quality productsVacuum evaporation coatingSputtering coatingSputteringMetallurgy

Owner:JX NIPPON MINING & METALS CORP

SPUTTERING TARGET OF SINTERED Sb-Te-BASED ALLOY

ActiveUS20160314945A1Improve featuresImprove uniformityElectric discharge tubesVacuum evaporation coatingSputteringAlloy

Sb—Te-based alloy sintered sputtering target having a Sb content of 10 to 60 at %, a Te content of 20 to 60 at %, and remainder being one or more types of elements selected from Ag, In, and Ge and unavoidable impurities, wherein an average grain size of oxides is 0.5 μm or less. An object of this invention is to improve the texture of the Sb—Te-based alloy sintered sputtering target in order to prevent the generation of arcing during sputtering and improve the thermal stability of the sputtered film.

Owner:JX NIPPON MINING & METALS CO LTD

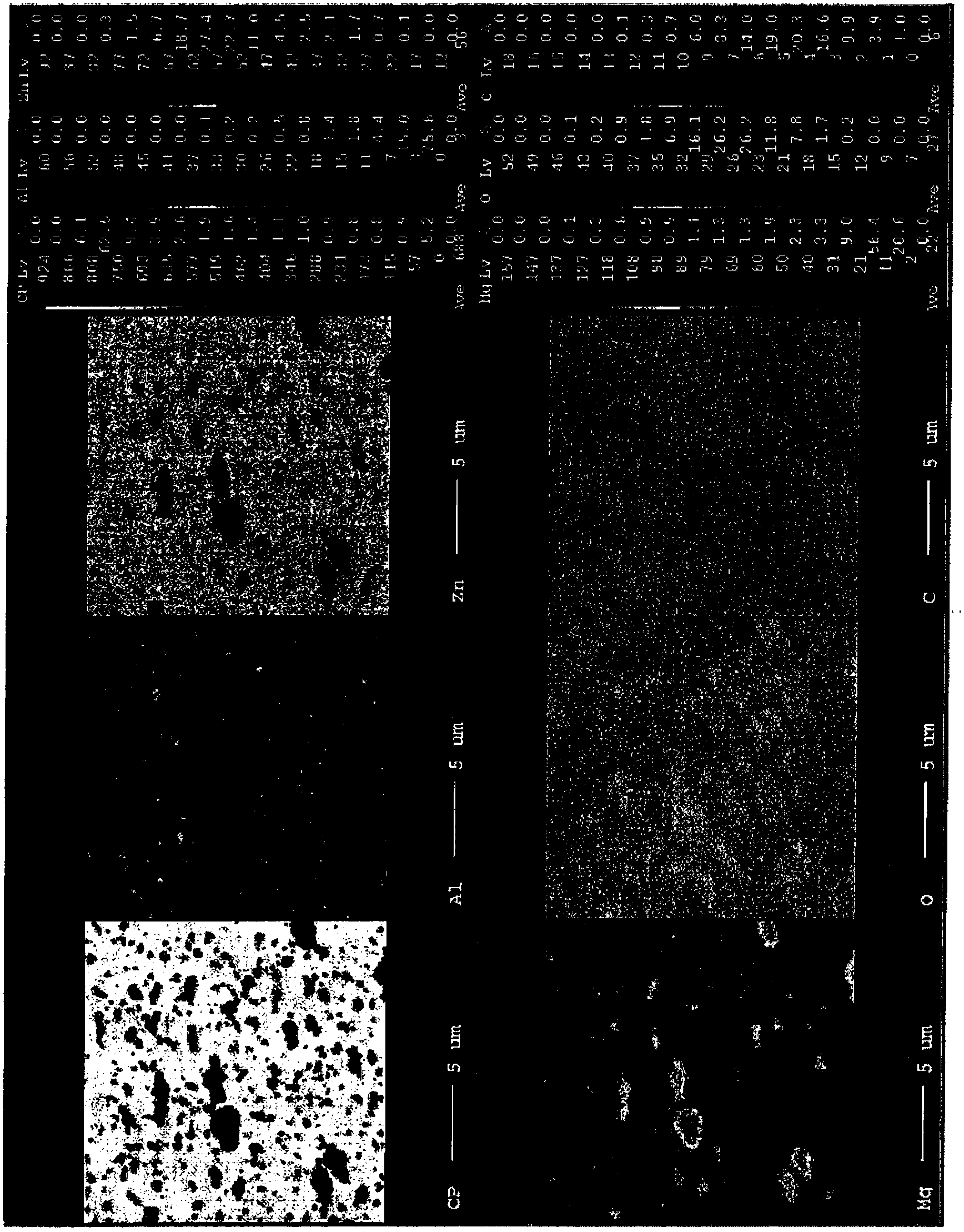

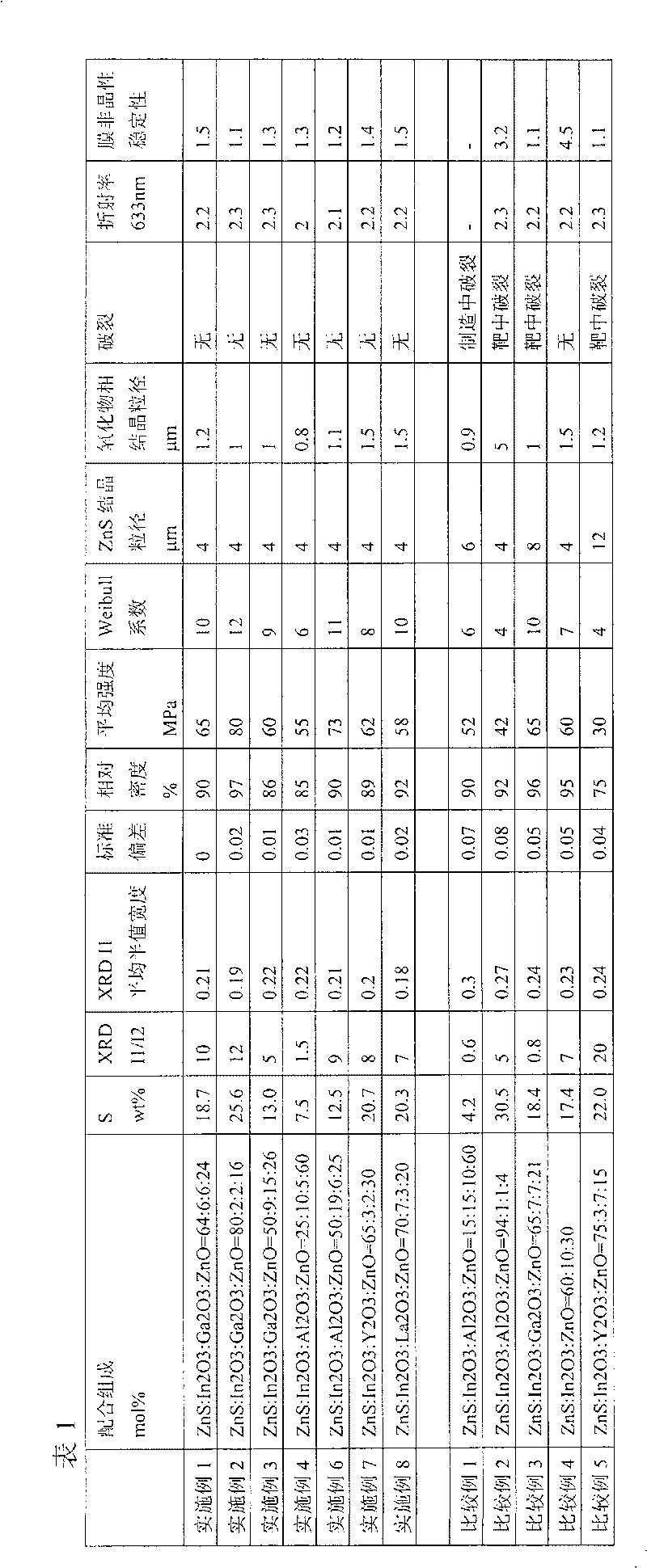

Sputtering target and thin film for optical information recording medium

ActiveCN101208451AStable sputteringExcellent adhesionVacuum evaporation coatingSputtering coatingCrystal systemIndium

The present invention relates to a sputtering target, wherein zinc sulfide and an oxide composed of indium oxide, zinc oxide and other trivalent positive elements A are used as main components, and the ratio of sulfur to all constituent components is 5 to 30 wt. %, the (111) peak intensity I1 of cubic ZnS measured by XRD and the (100) peak intensity I2 of hexagonal ZnS coexist and satisfy I1>I2. The object of the present invention is to provide a high-strength sputtering target capable of preventing the target from cracking when the target is manufactured or when a film is formed by sputtering, and a manufacturing method thereof, and to obtain a thin film for optical information recording media that is most suitable for use as a protective film, and to manufacture the same method.

Owner:JX NIPPON MINING & METALS CO LTD

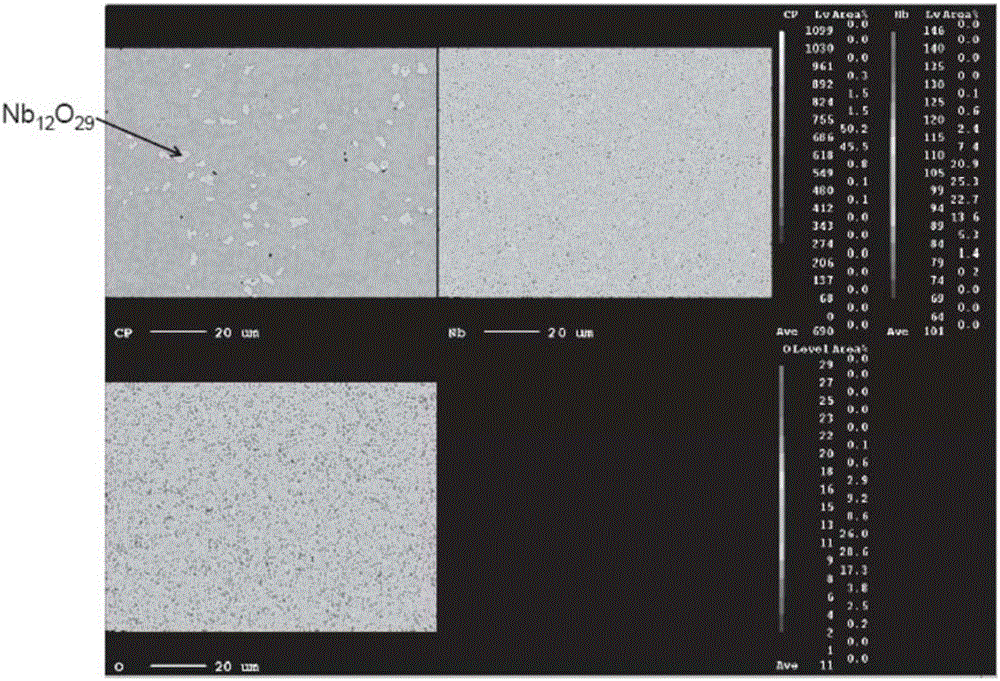

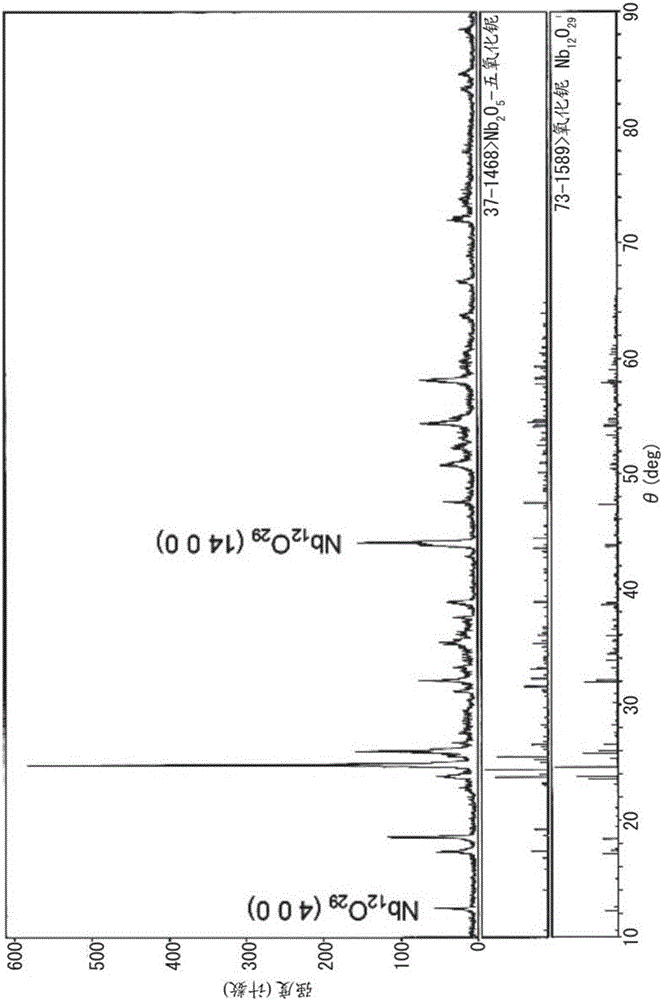

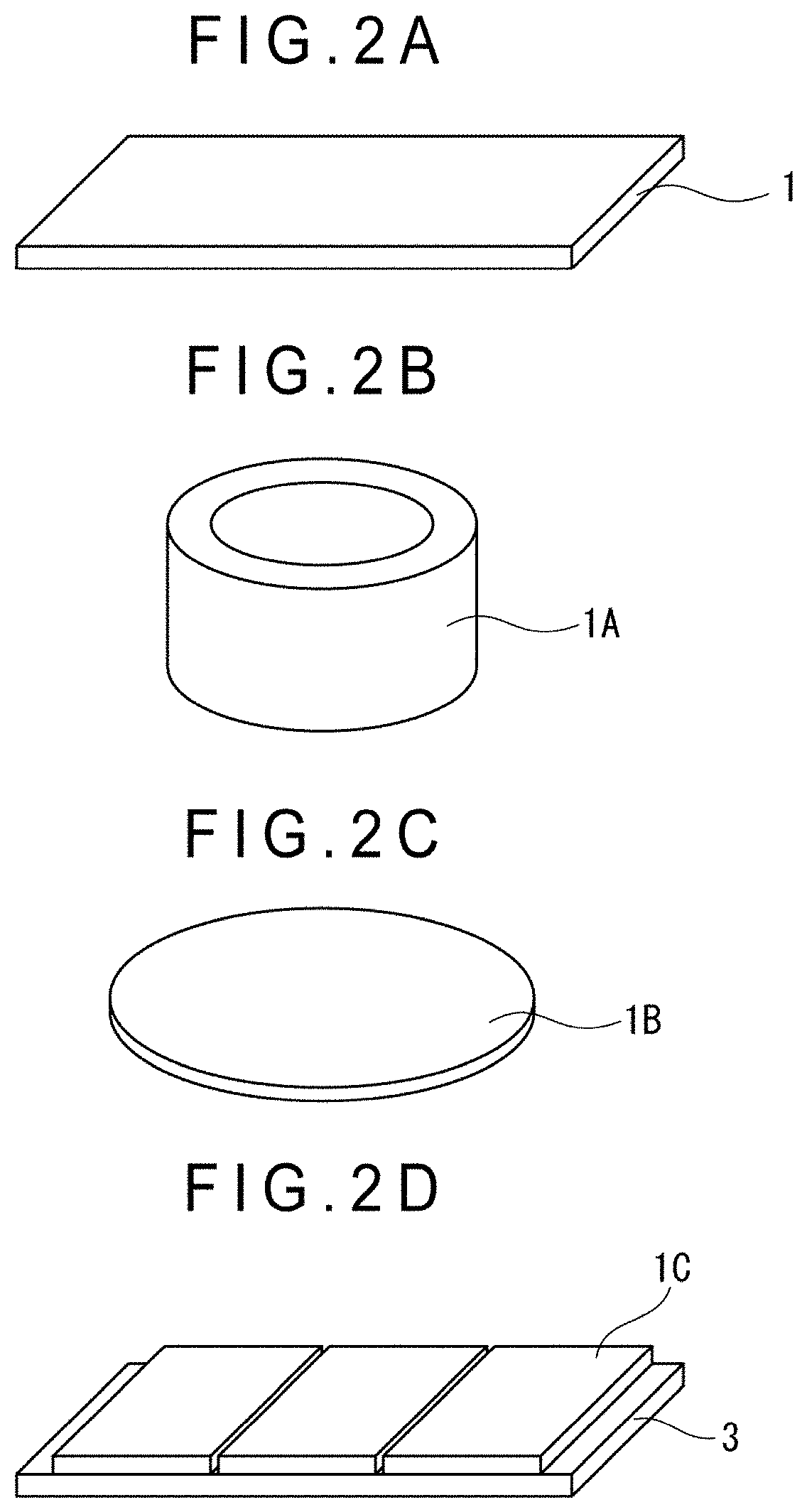

Niobium oxide sputtering target, production method therefor, and niobium oxide film

InactiveCN105074046AStable sputteringLower target specific resistanceVacuum evaporation coatingSputtering coatingSputteringMetallurgy

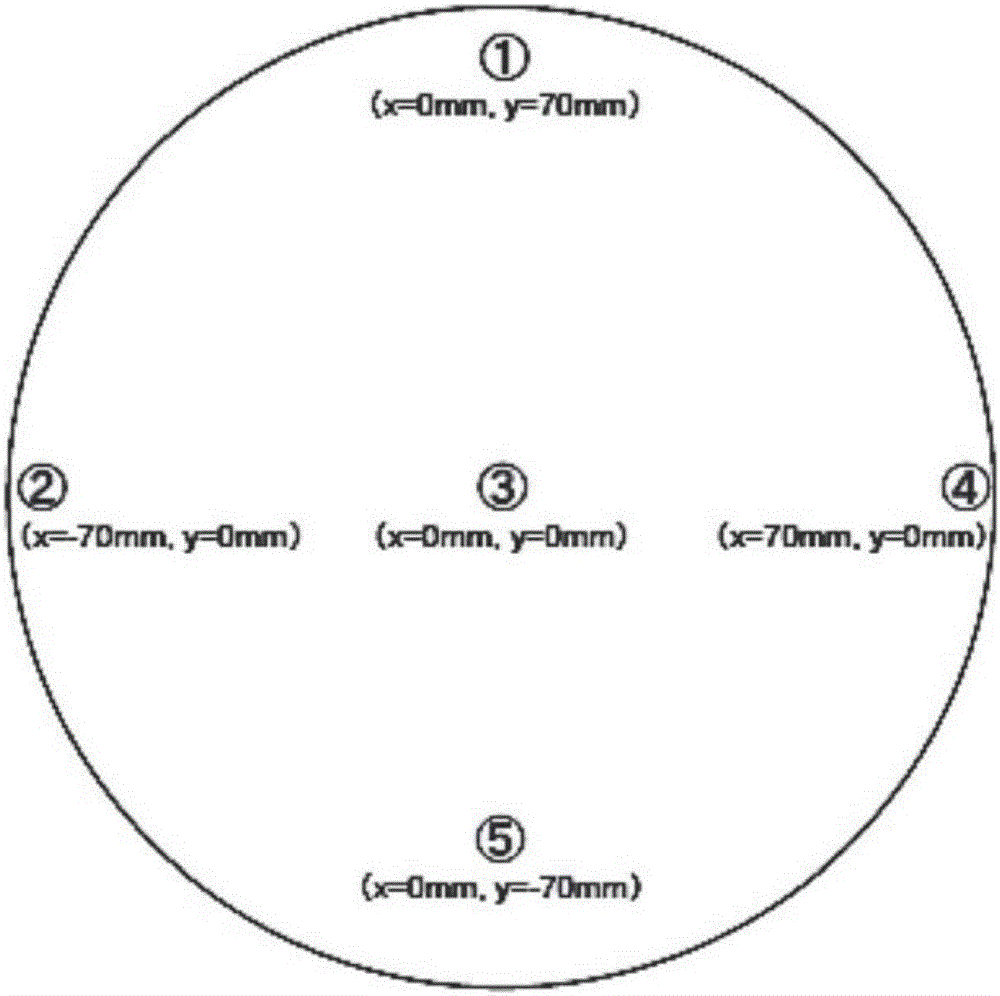

The present invention provides a niobium oxide sputtering target that enables direct current (DC) sputtering, and a production method. This niobium oxide sputtering target is characterized by being a niobium oxide sintered body and in that the specific resistance thereof is 0.001-0.05 Ω⋅cm over the entire area of the sintered body in the thickness direction.

Owner:MITSUBISHI MATERIALS CORP

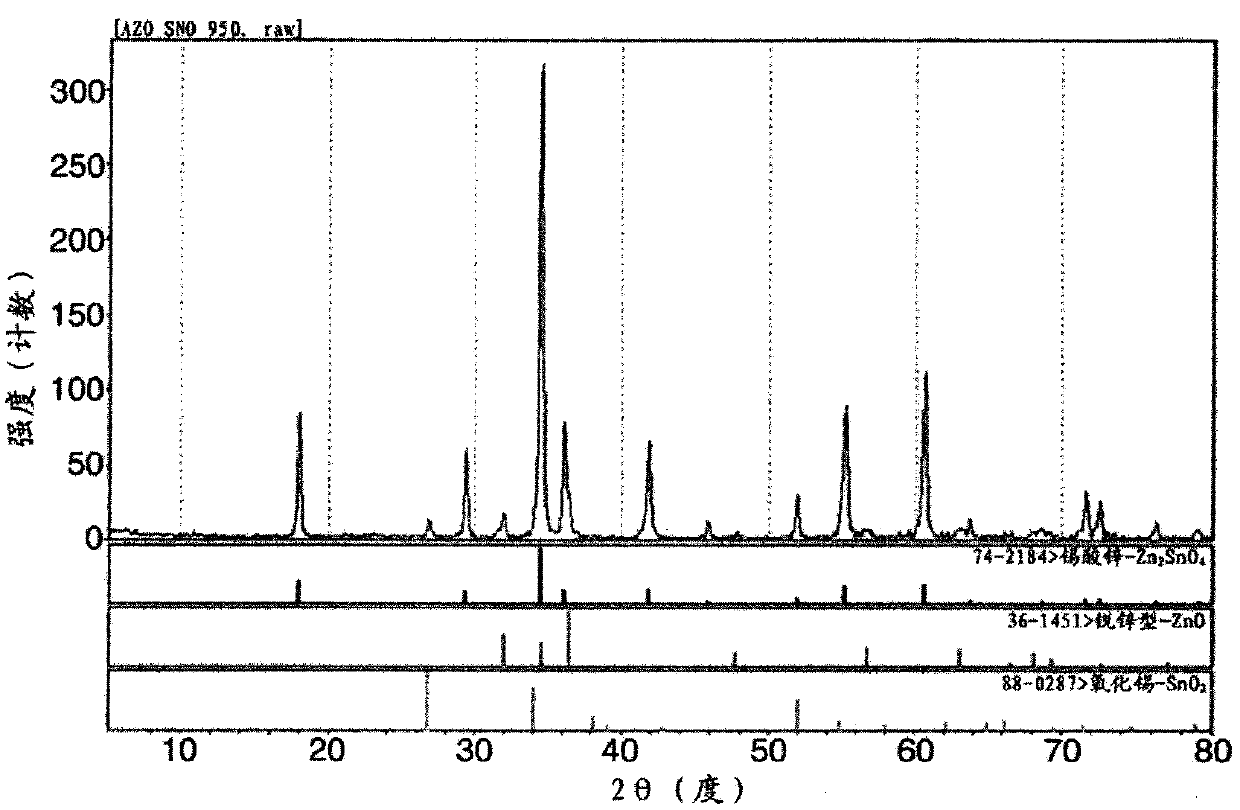

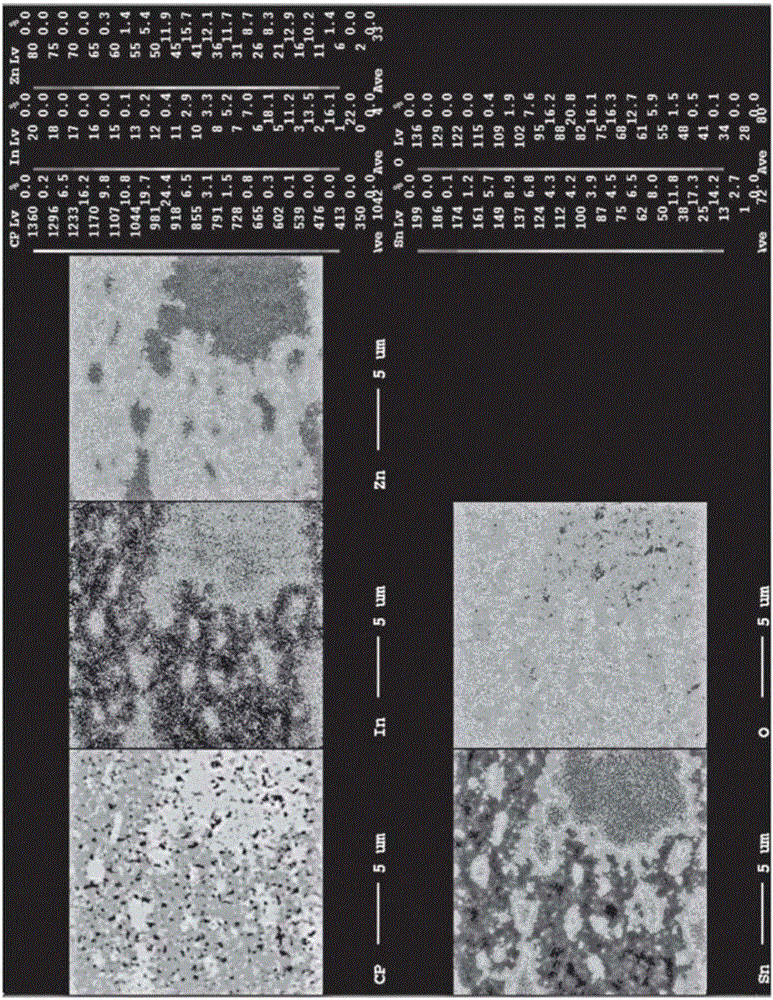

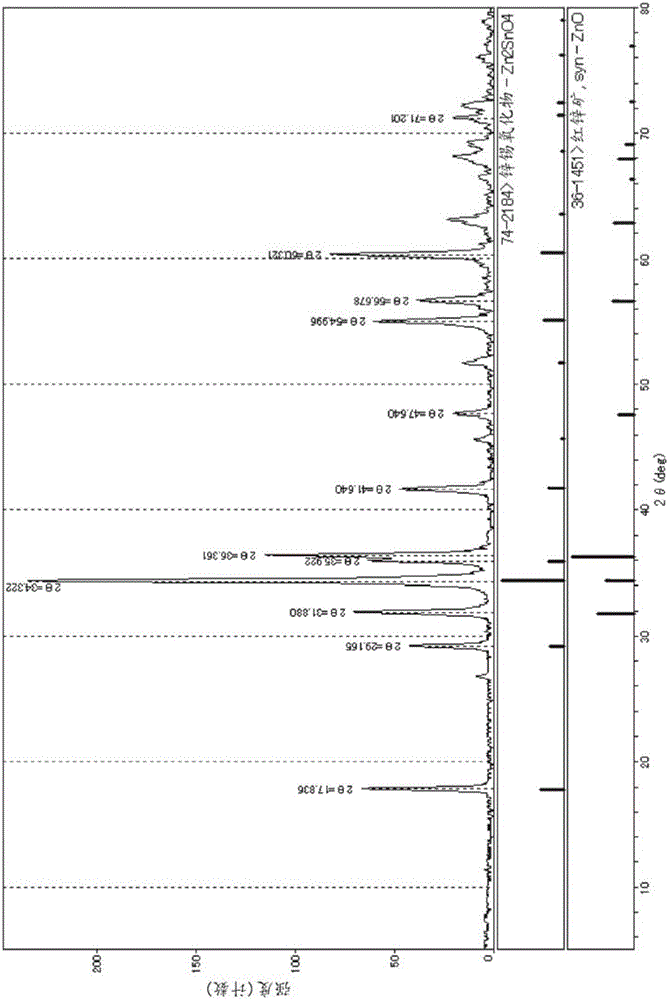

Oxide sputtering target and method for producing same, and protective film for optical recording media

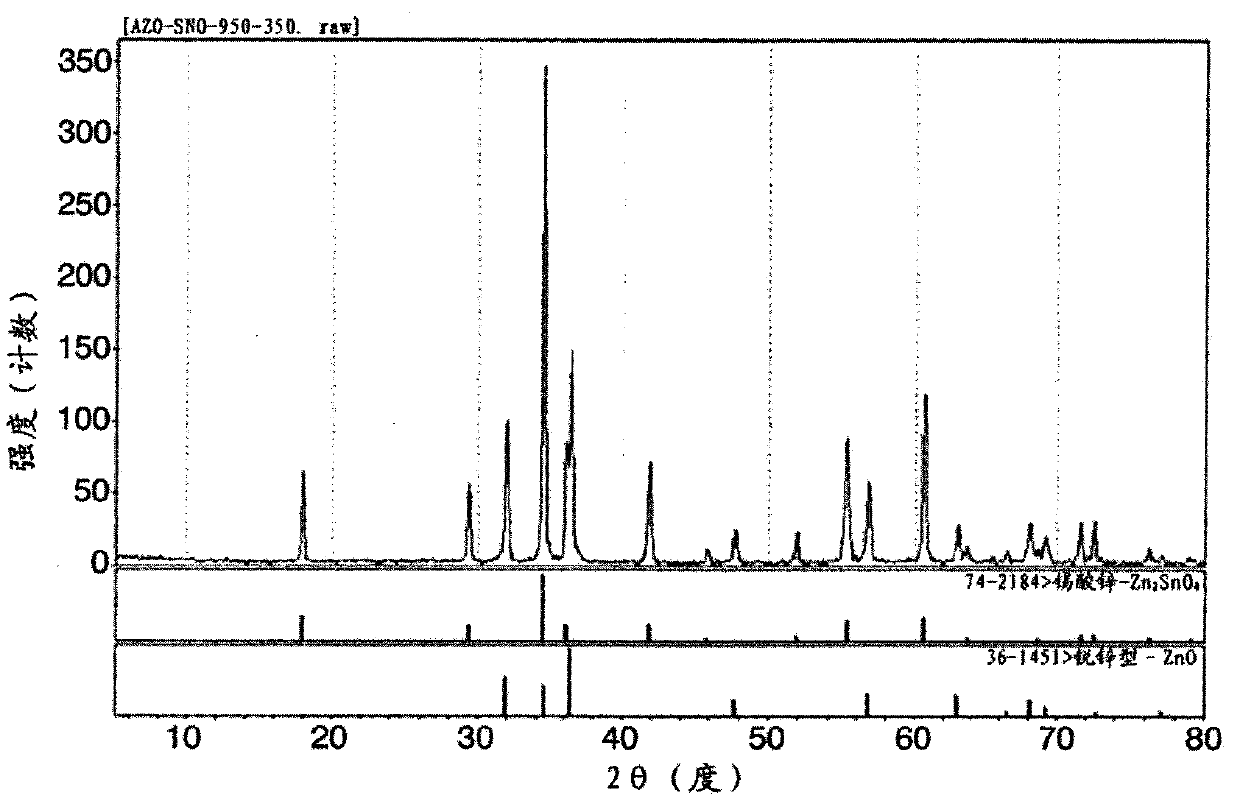

ActiveCN105074045AStable sputteringAvoid breakingVacuum evaporation coatingSputtering coatingSolid solutionOptical recording

An oxide sputtering target according to the present invention comprises a sintered oxide that comprises Sn in an amount of 7 at% or more and In in an amount of 0.1 to 35.0 at% both relative to the total amount of all of metal components, with the remainder made up by Zn and unavoidable impurities. In the sintered oxide, the atom content ratios of Sn to Zn, i.e., Sn / (Sn+Zn), is 0.5 or less. The sintered oxide has a structure that contains, as the main phase, Zn2SnO4 in which In exists in the form of a solid solution.

Owner:MITSUBISHI MATERIALS CORP

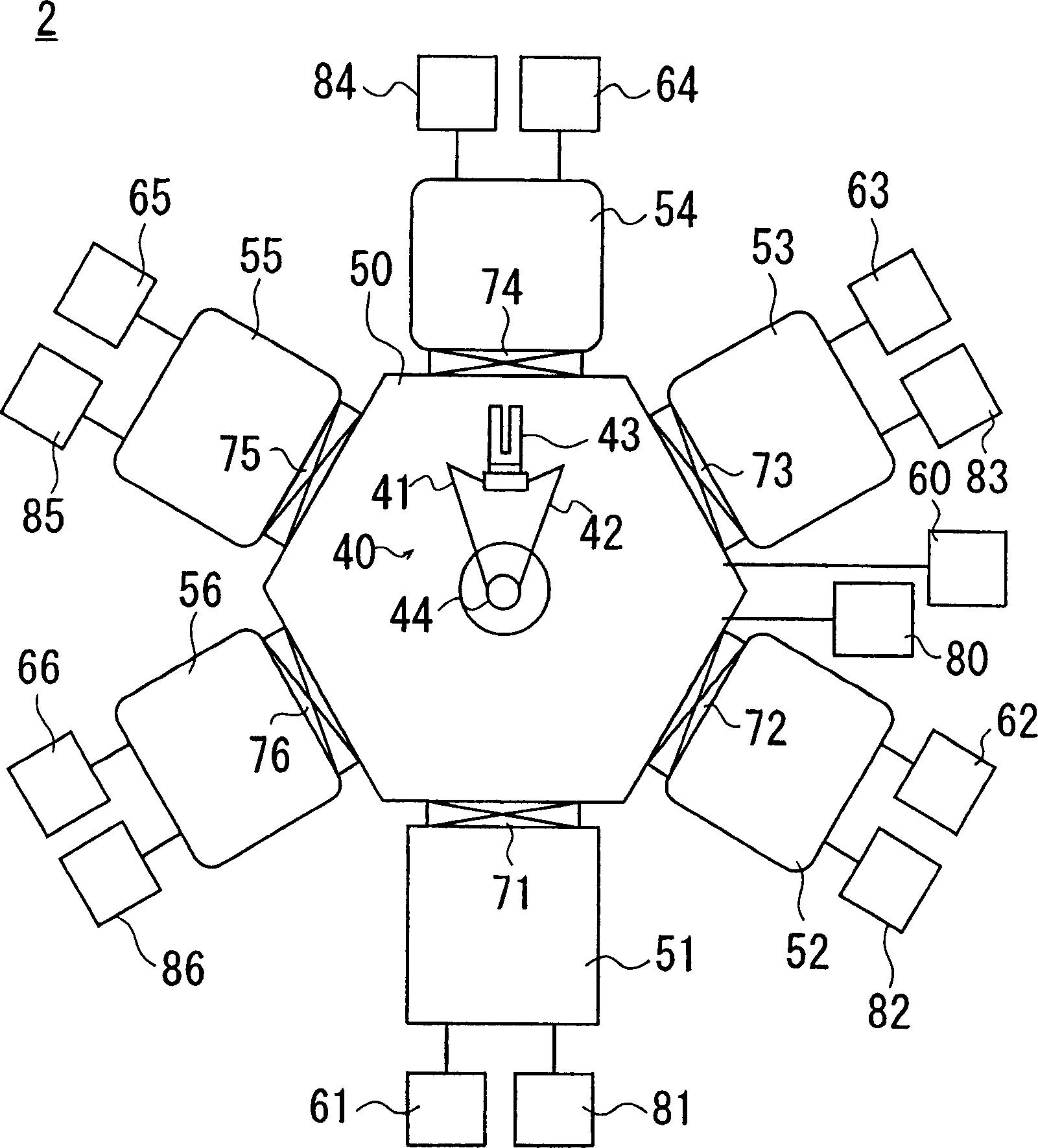

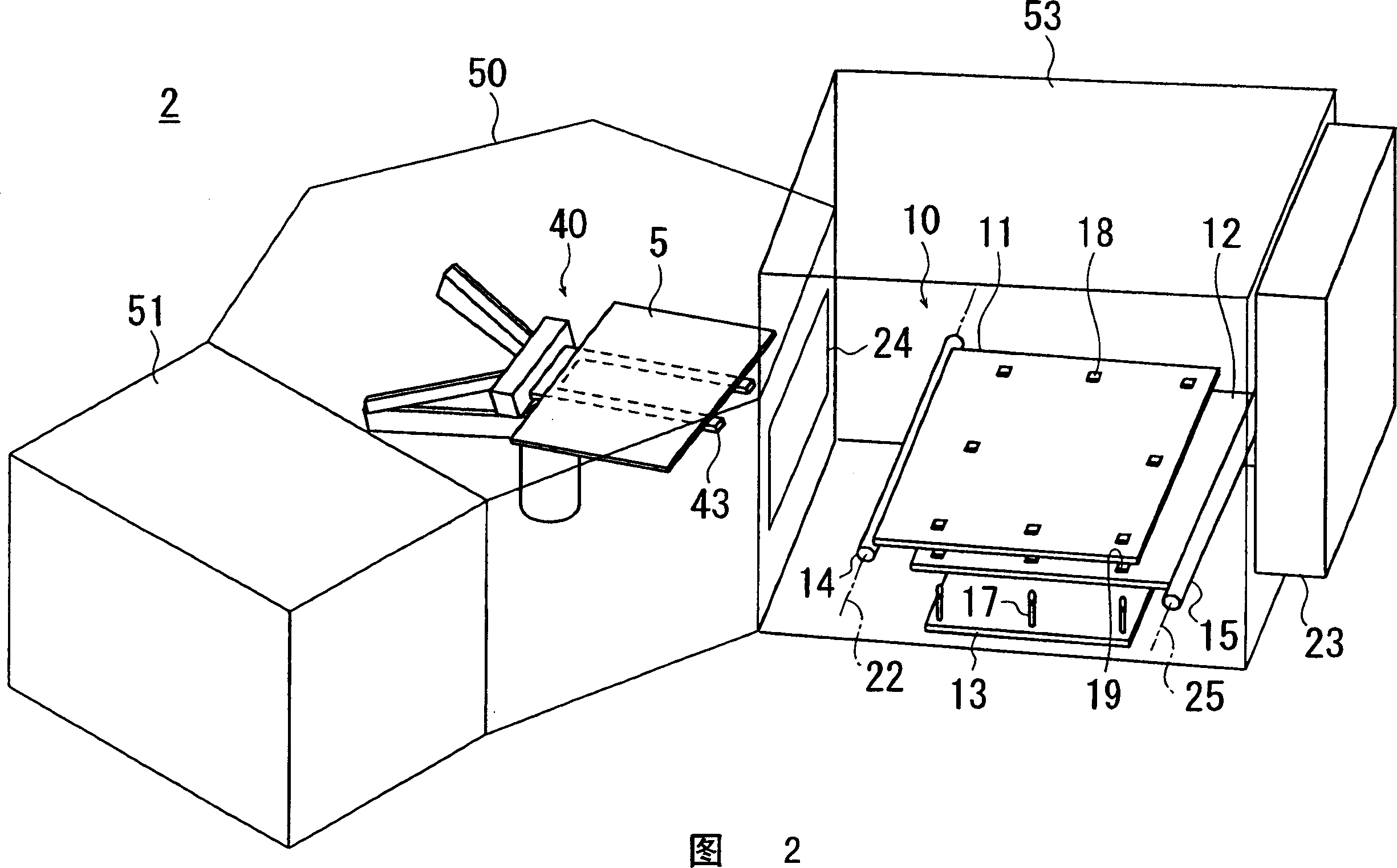

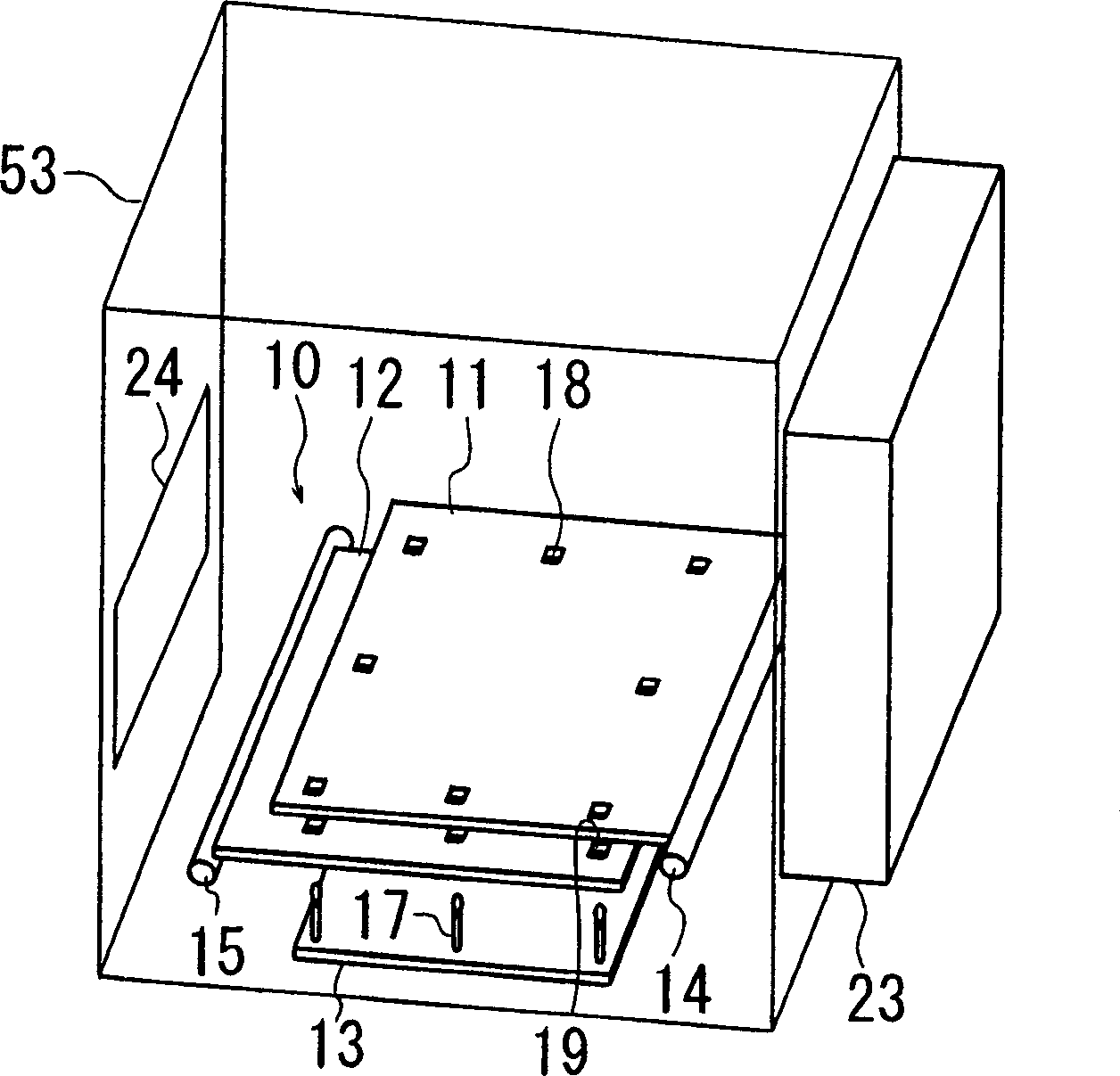

Sputtering method

InactiveCN1414134AReduce processing timeStable sputteringVacuum evaporation coatingSputtering coatingSputteringEngineering

This invention is to provide a technique of continuously performing sputtering. During a film is formed on the surface of a substrate 5a held by a holding plate 12 by keeping the holding plate 12 inside a treatment chamber in an erected position and sputtering a target 26, an untreated substrate 5b is mounted on the hand 43 of a substrate conveying robot in a conveying chamber, the pressure in the conveying chamber is adjusted to a value substantially equal to the pressure in the treatment chamber, and the substrate 5b is conveyed into the treatment chamber and is mounted on the holding plate 12 kept in a horizontal position. The conveying time does not add any additional time because the untreated substrate can be conveyed into the treatment chamber during sputtering.

Owner:ULVAC INC

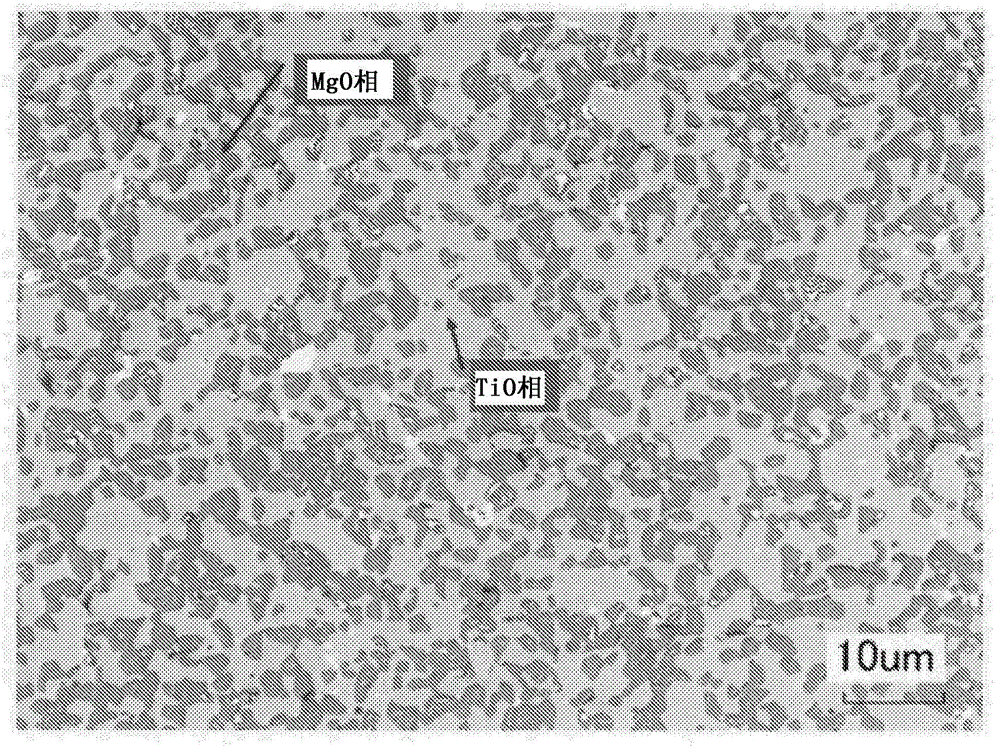

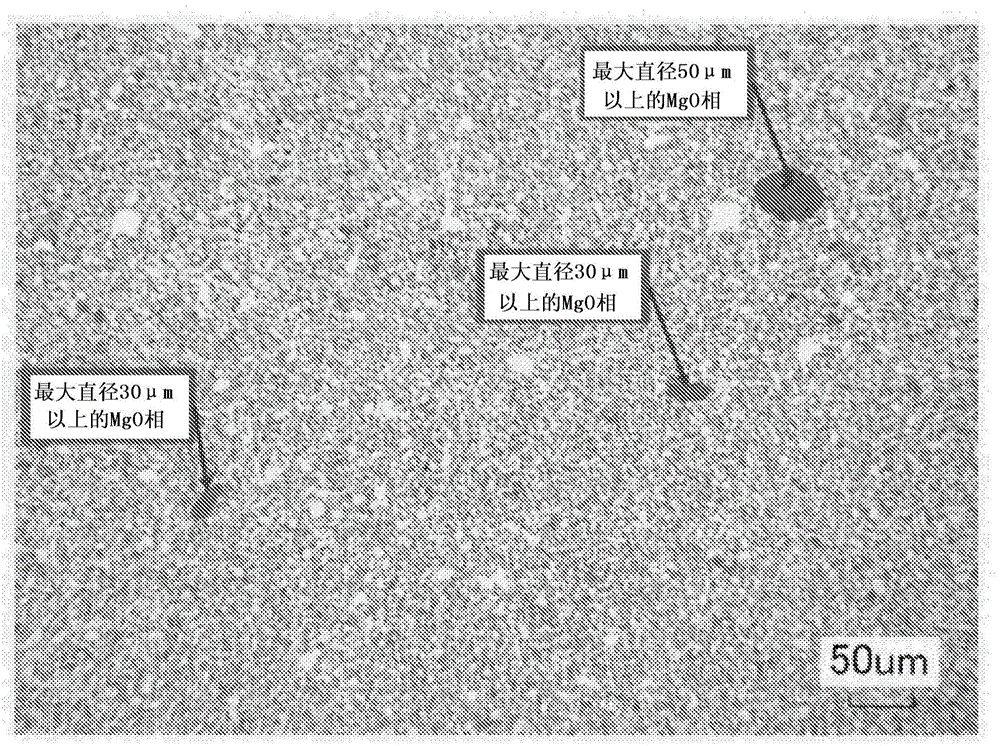

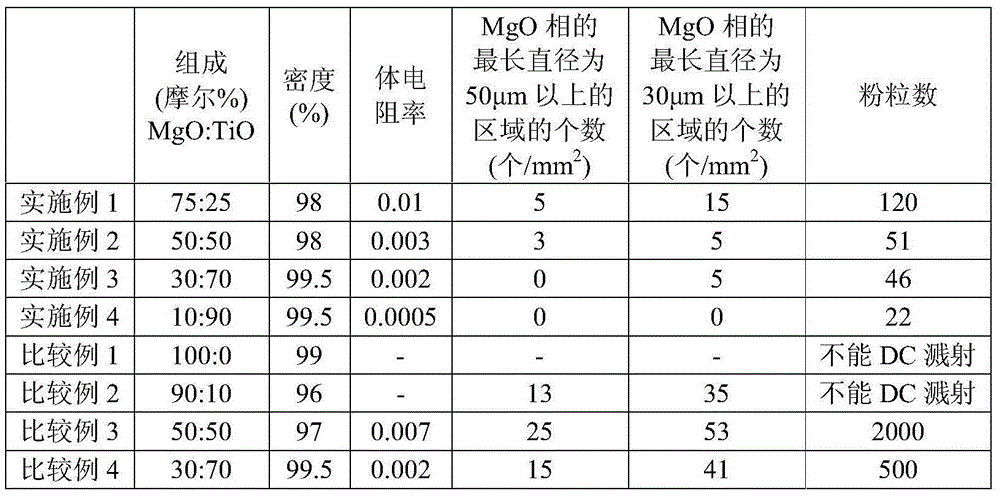

Mgo-tio sintered compact target and method for producing same

InactiveCN104661983AHigh densityReduce bulk resistivityVacuum evaporation coatingSputtering coatingSputteringMetallurgy

A MgO-TiO sintered compact comprising 25 to 90 mol% of TiO, with the remainder made up by MgO and unavoidable impurities. The present invention addresses the problem of providing: a highly dense target which has a high film deposition speed and can be subjected to direct-current (DC) sputtering by which particles are formed in a reduced amount; and a method for producing the target.

Owner:JX NIPPON MINING & METALS CO LTD

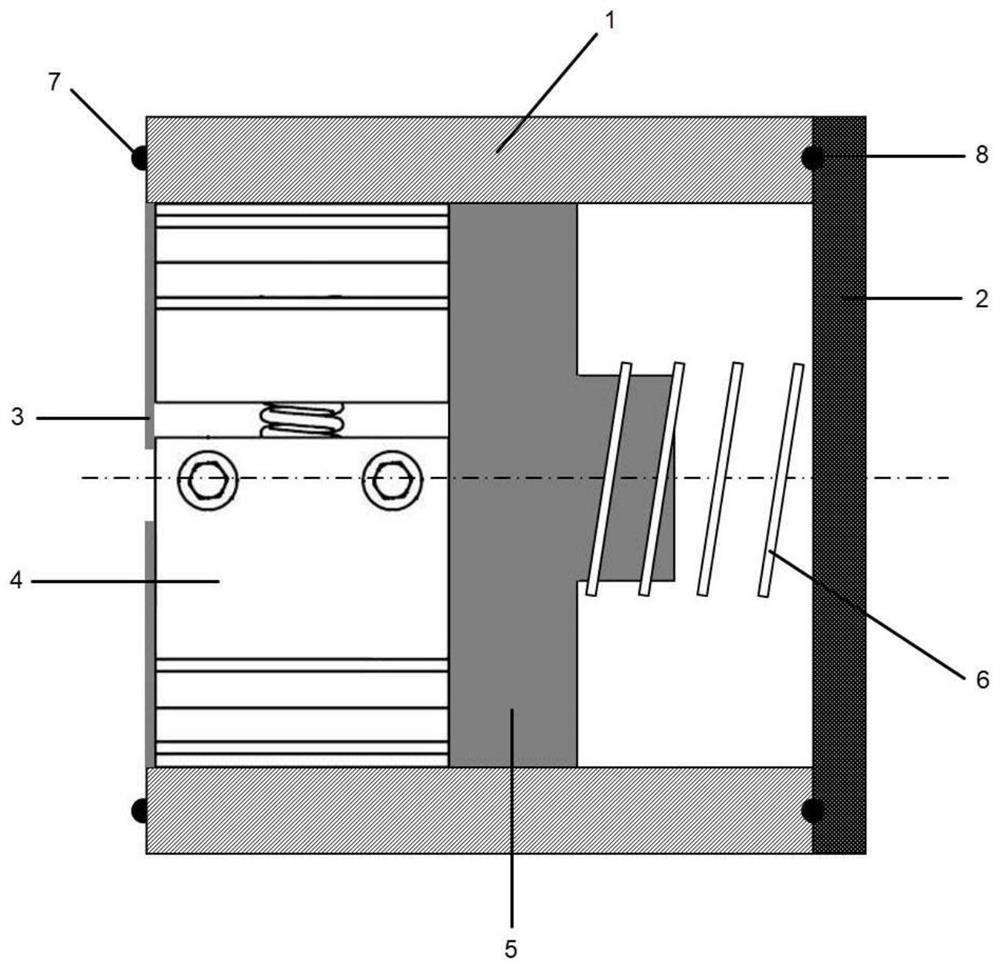

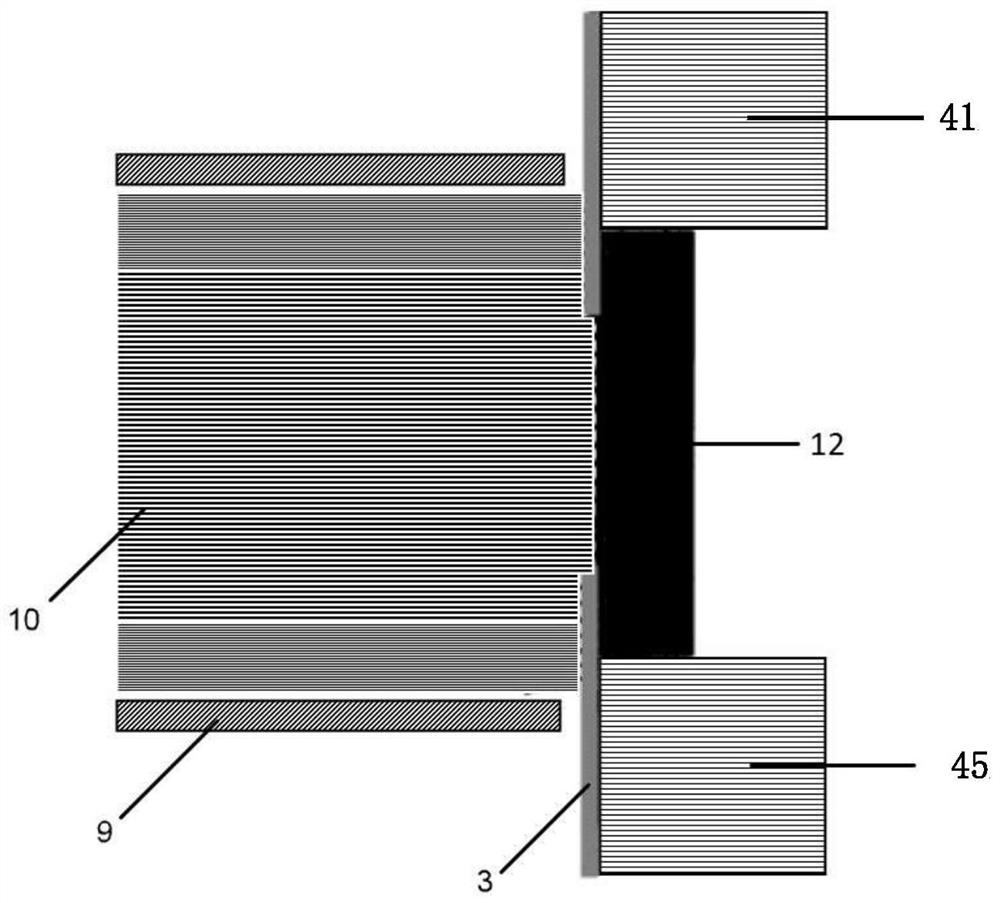

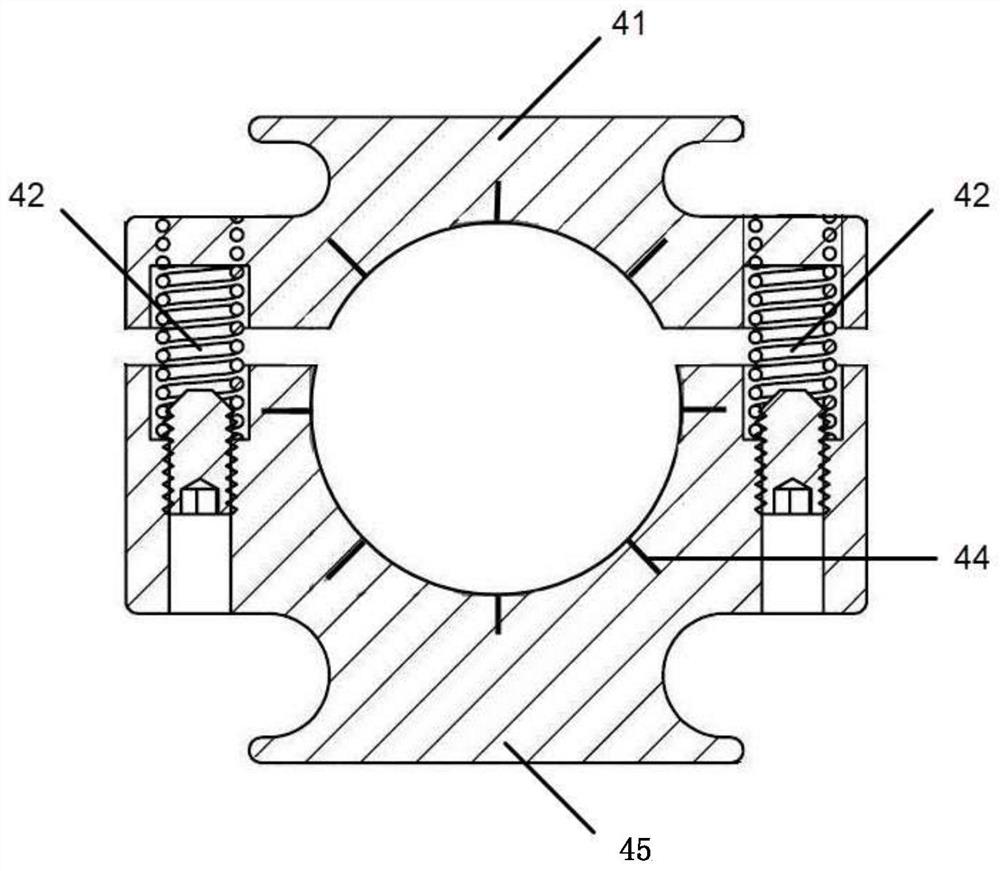

Sample box for glow discharge analysis and characterization and use method

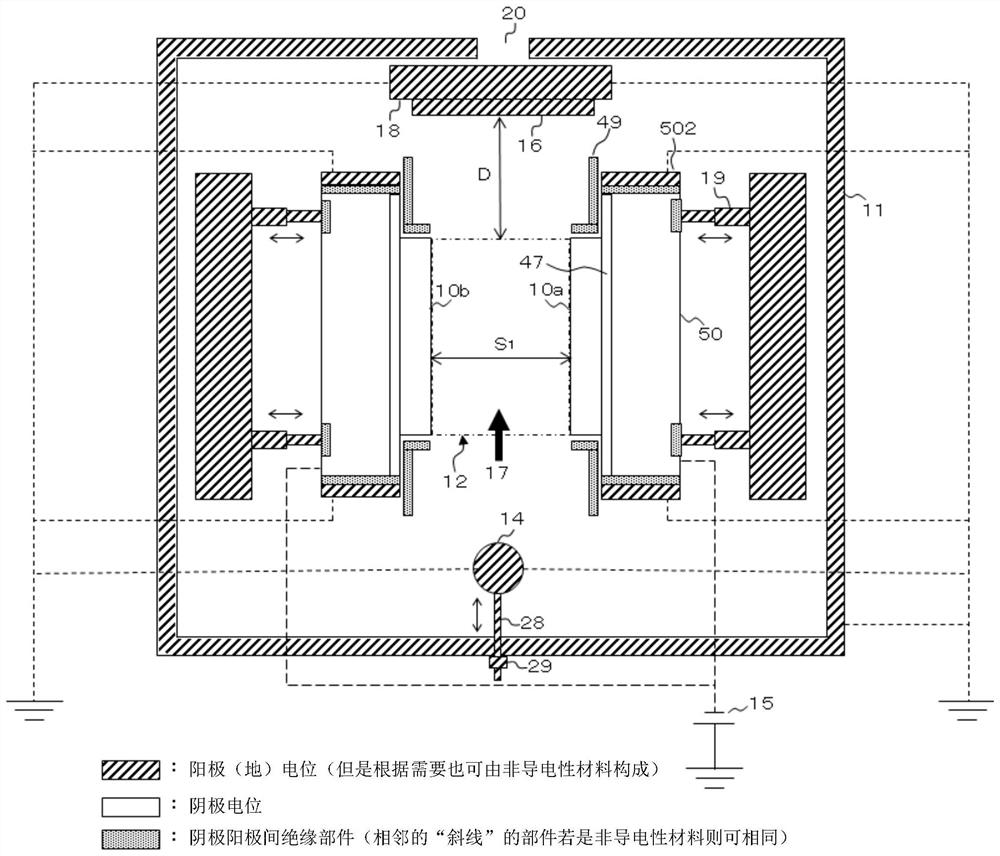

PendingCN114216895AImproved depth resolutionStable sputteringAnalysis by electrical excitationPhysicsGlow discharge

The invention relates to a sample box for glow discharge analysis and characterization and a use method. The sample box comprises a sample box body, a sample box cover, a second cathode plate, a sample accurate positioning clamp, a top block and a positioning spring; the sample box cover and the second cathode plate are respectively arranged at the front end and the rear end of the sample box body; the sample accurate positioning clamp is detachably and fixedly connected to the inner wall of the sample box body and used for clamping a sample and accurately positioning the sample through scale marks, and the rear end face of the sample accurate positioning clamp and the analysis surface of the sample are located on the same plane and both make close contact with the second negative plate; and the top block and the positioning spring are sequentially arranged between the sample accurate positioning clamp and the sample box cover to press and position the sample accurate positioning clamp. The application range of sample analysis of glow discharge analysis characterization is greatly expanded, the glow discharge analysis characterization performance is improved, and the device has the advantages of being accurate in sample position positioning, simple in structure and convenient and reliable to use.

Owner:NCS TESTING TECH

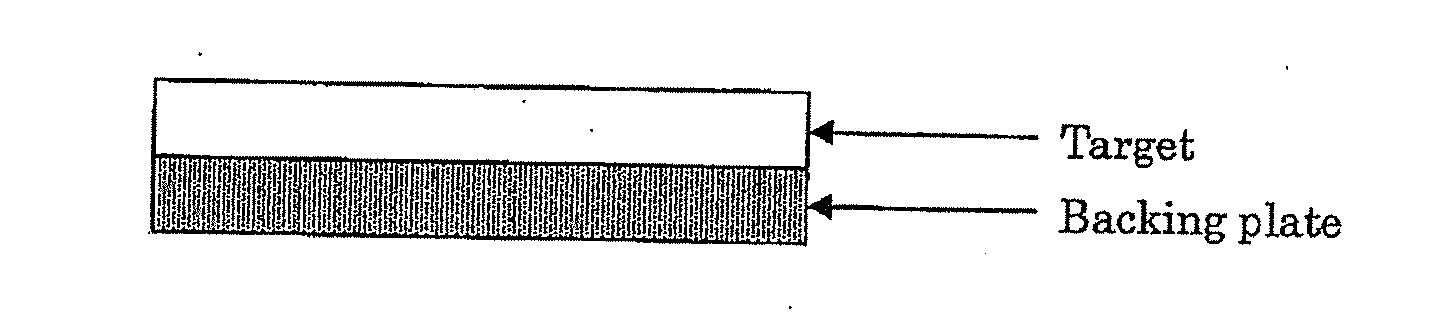

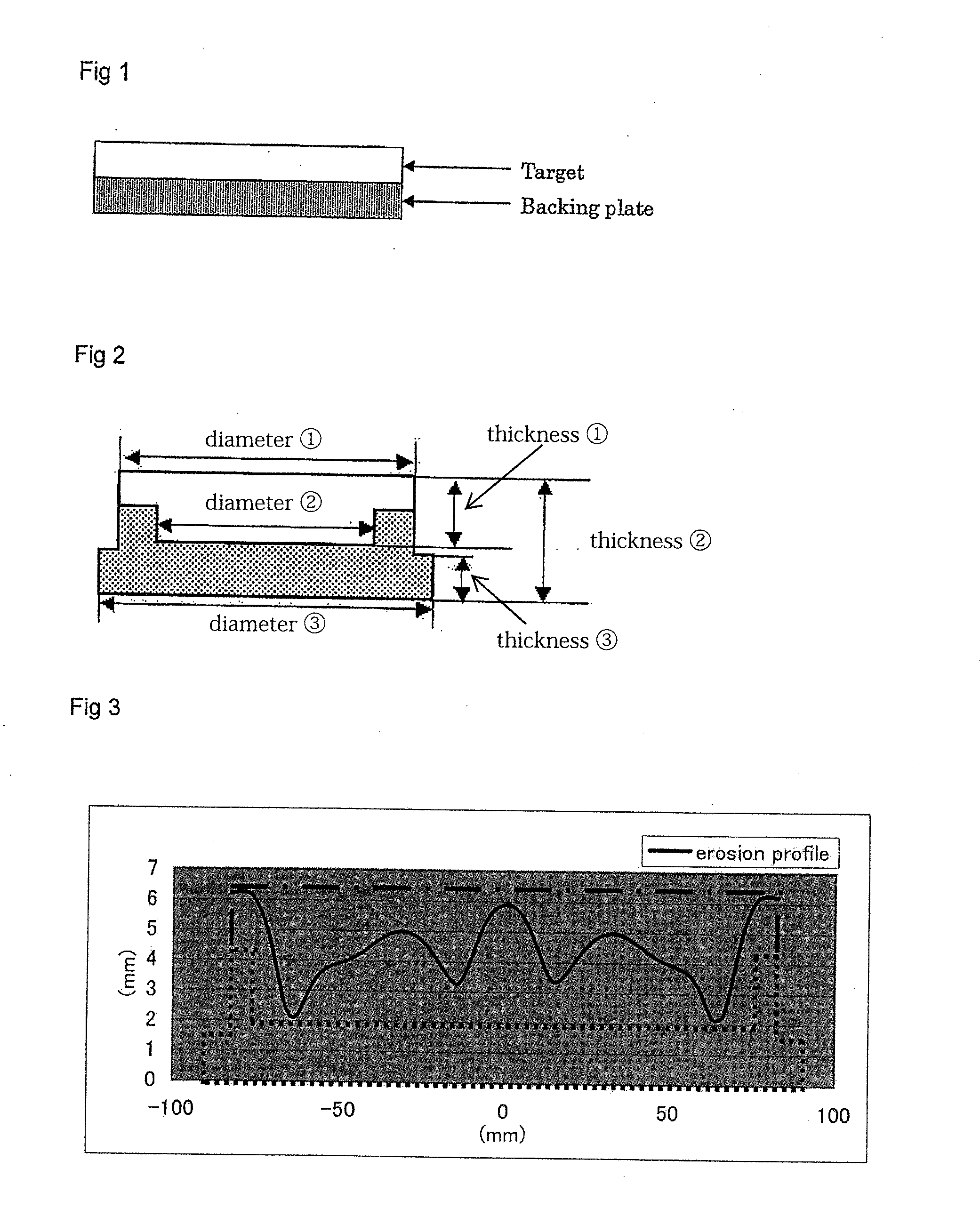

Method for manufacturing a sputtering target structure

InactiveUS20120097356A1Stable sputteringStructural economyCellsVacuum evaporation coatingCopperMachinability

To provide a sputtering target structure which has good machinability and thermal conductivity and has good wettability with soldering materials, which is inexpensive and can be used repeatedly for a long period of time, and which is free from problems of cracking and peeling of the sputtering target therein, a sputtering target structure is formed by bonding a sputtering target and a backing plate. The backing plate is formed of a material that has the difference in the linear expansion coefficient between it and the sputtering target material of at most 2×10−6 / K, and a copper plate having a thickness of from 0.3 to 1.5 mm is disposed on at lest one face of the backing plate.

Owner:PLANSEE SE

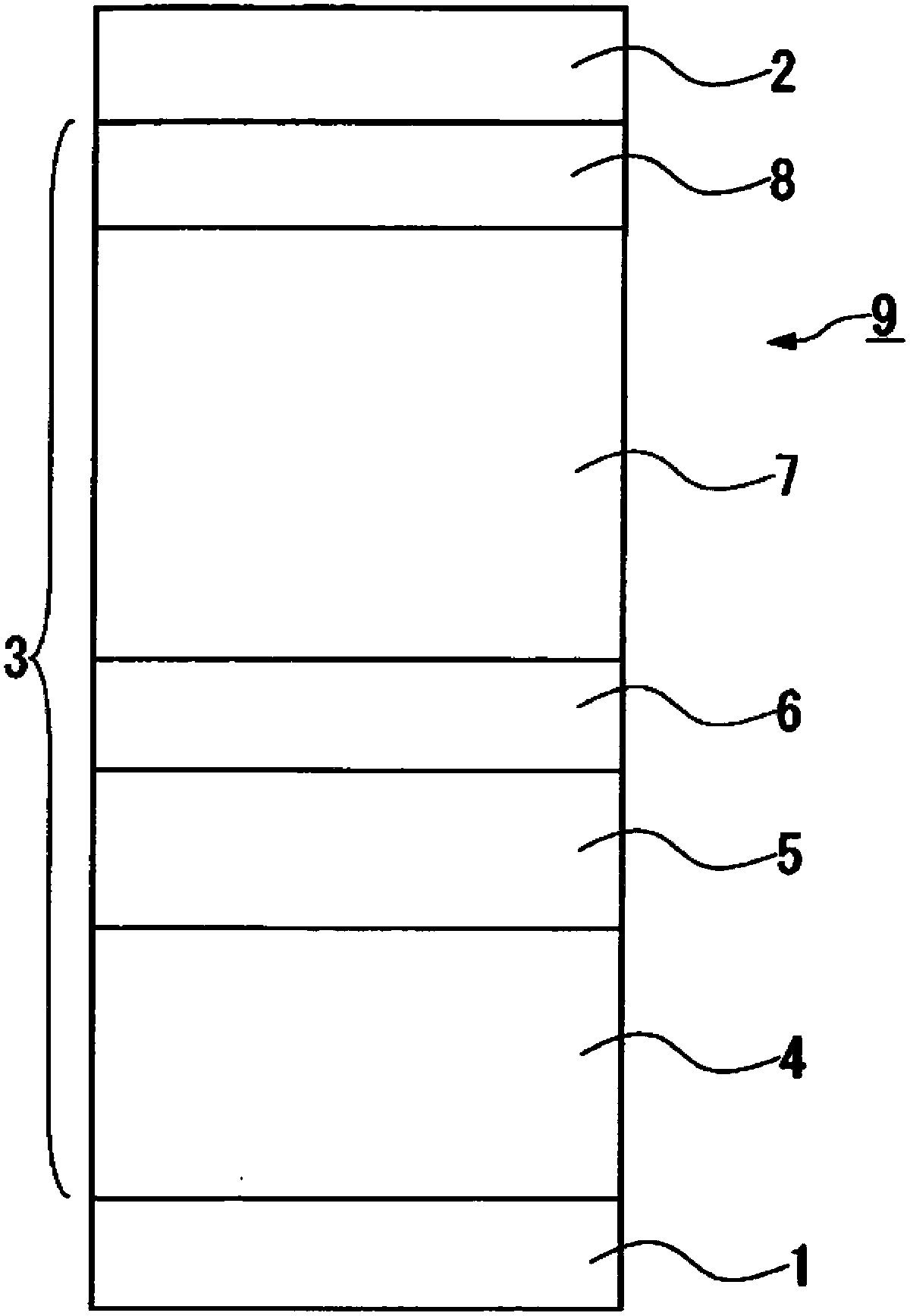

Low-Emissivity Glass

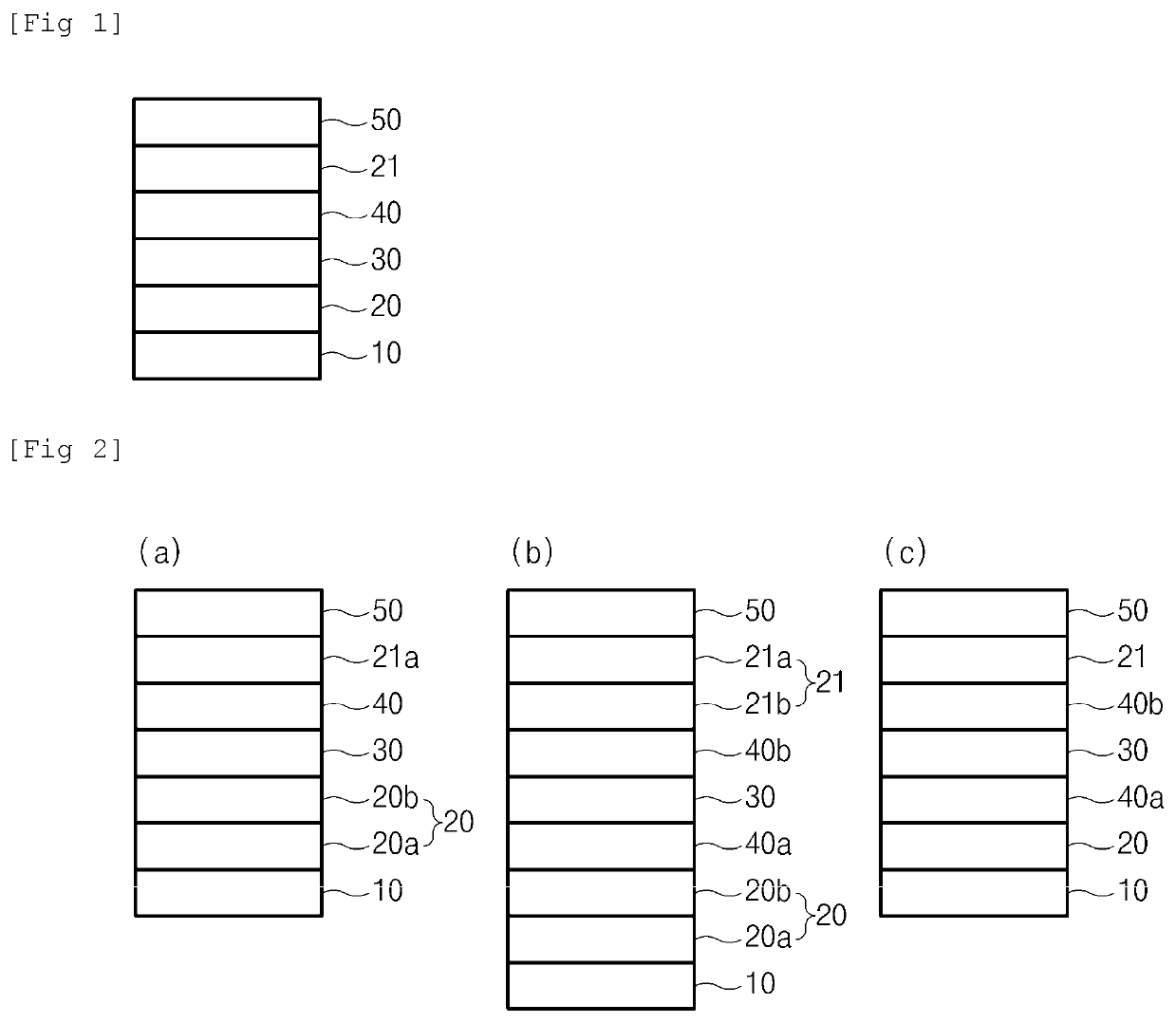

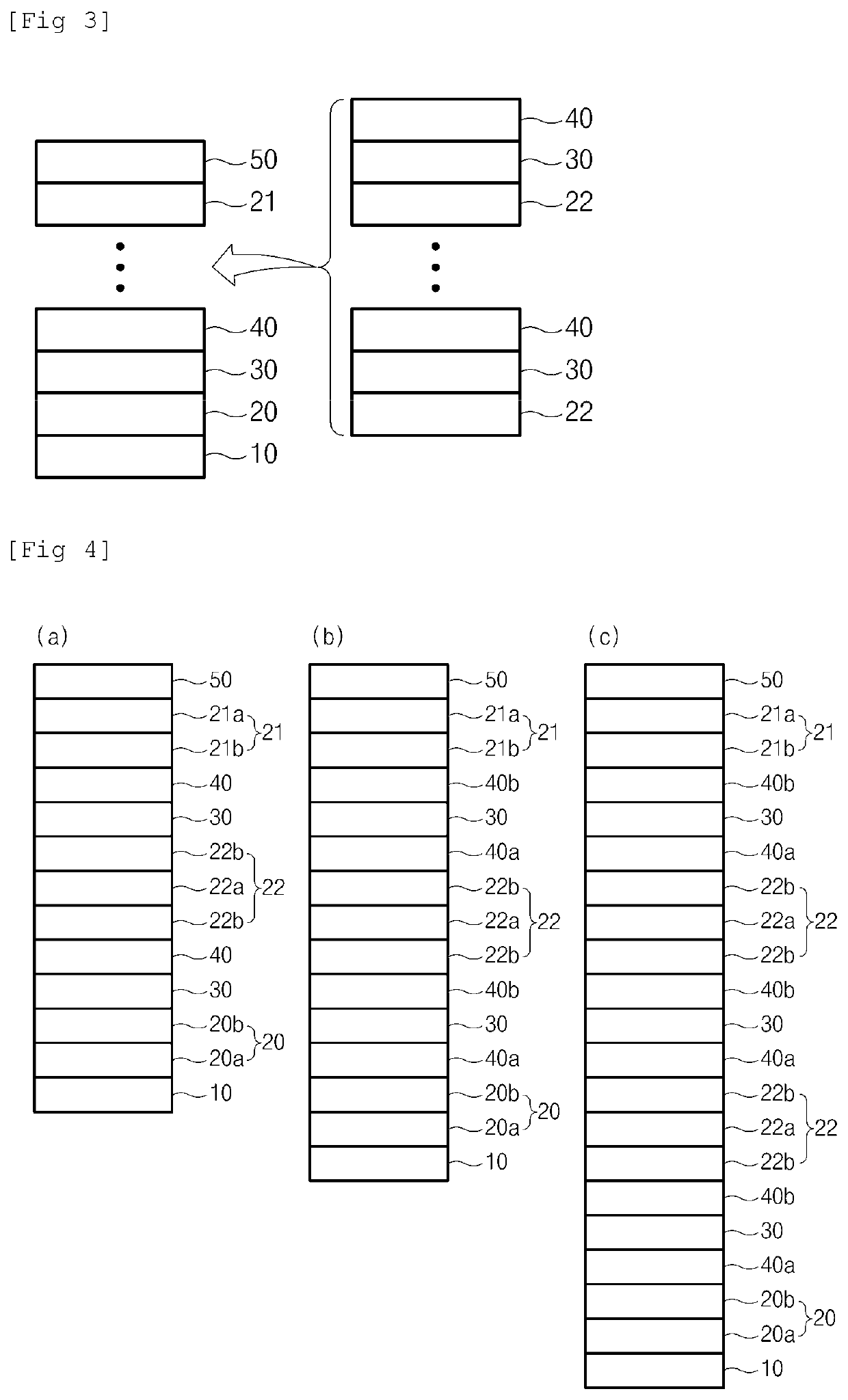

InactiveUS20200189972A1Stable sputteringGood deposition rateCoatingsDielectric layerAbsorption layer

The present invention relates to low-emissivity glass comprising: a glass substrate; a first dielectric layer formed on the glass substrate; a metal layer formed on the first dielectric layer; an absorbent layer formed on the metal layer; a second dielectric layer formed on the absorbent layer; and a coating layer formed on the second dielectric layer and containing Zr, whereby a low-emissivity glass having good and excellent handling and long-term storage properties is provided.

Owner:KCC GLASS CORP

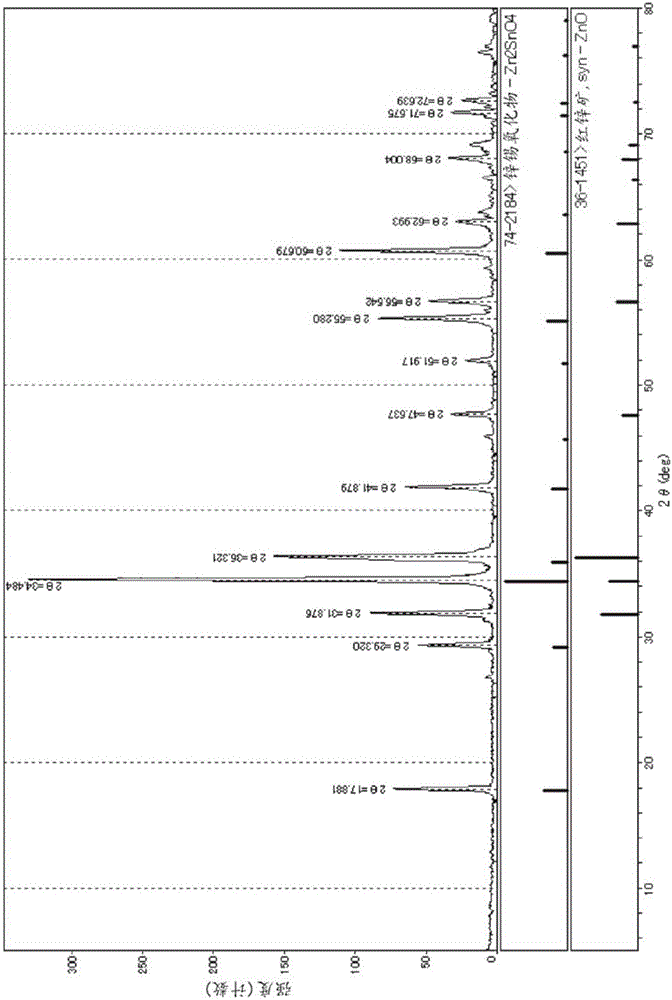

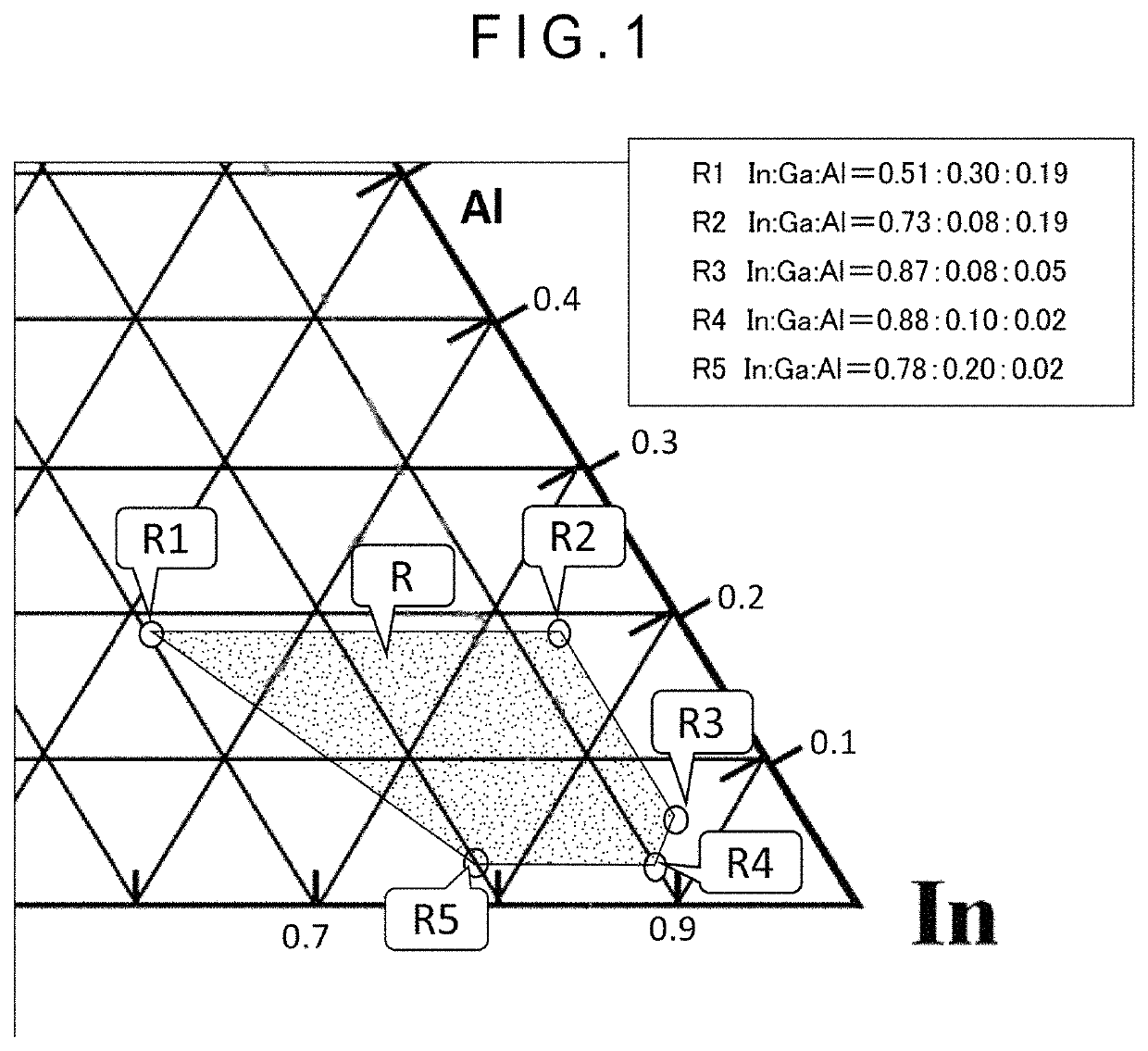

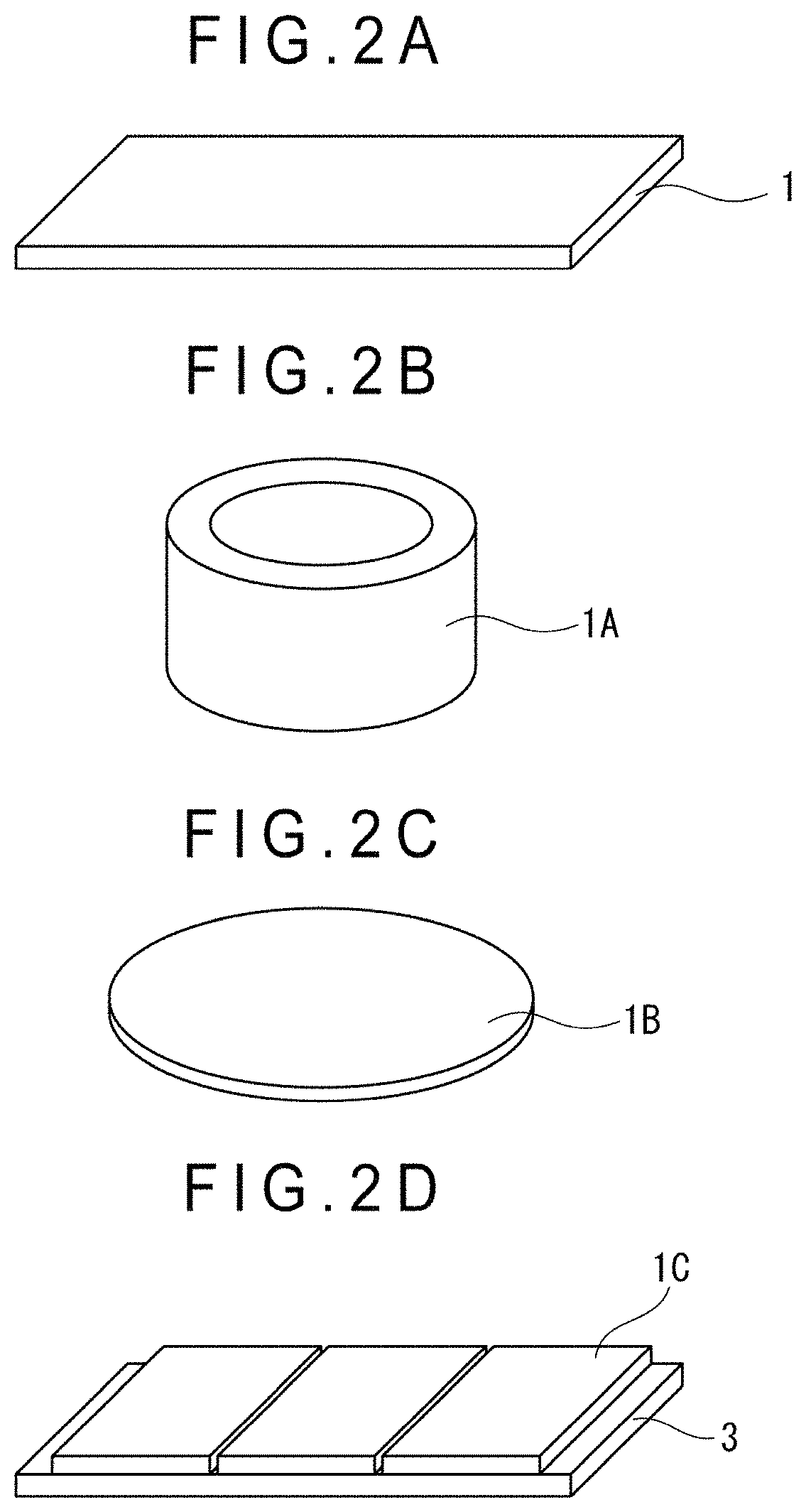

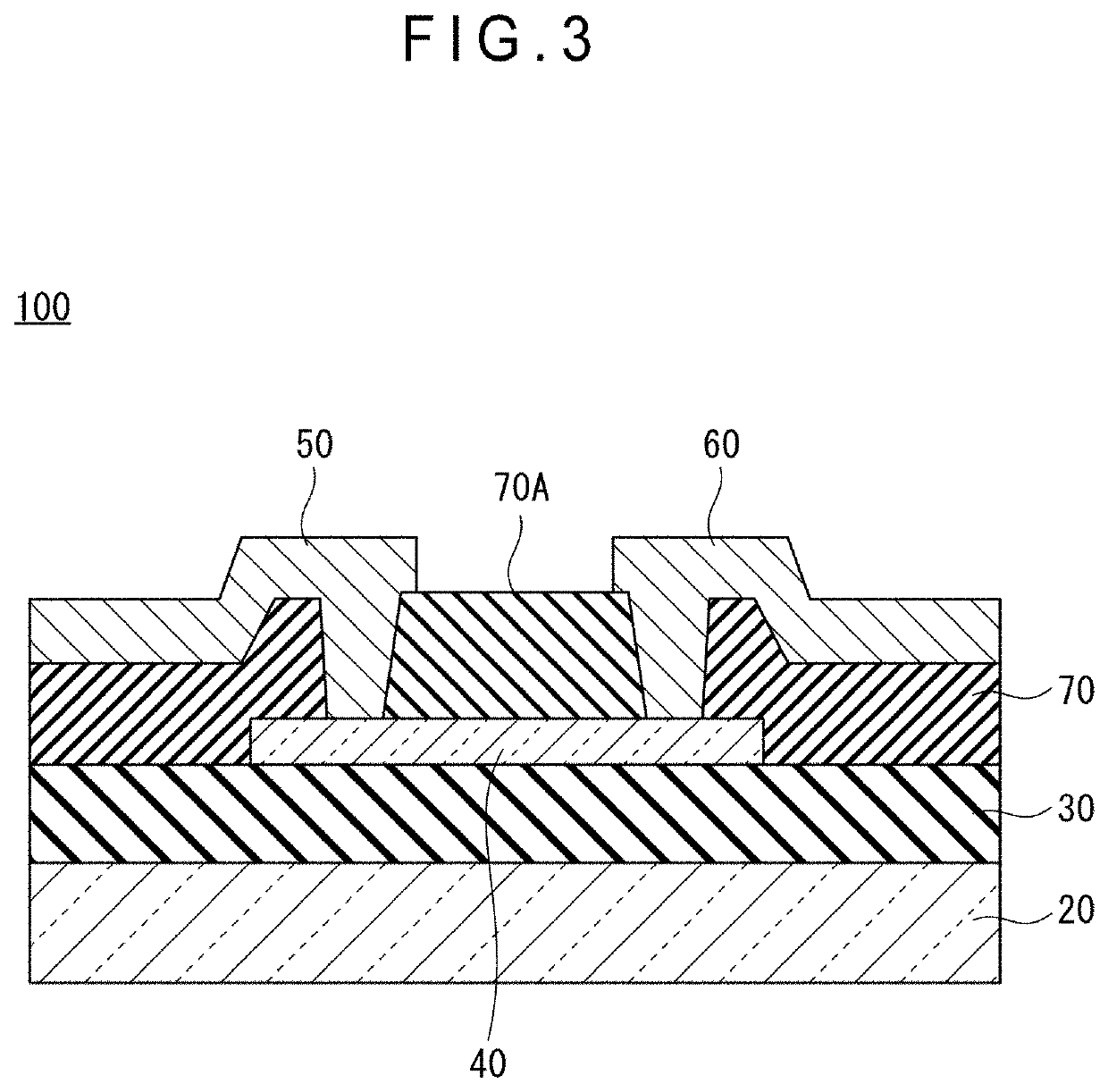

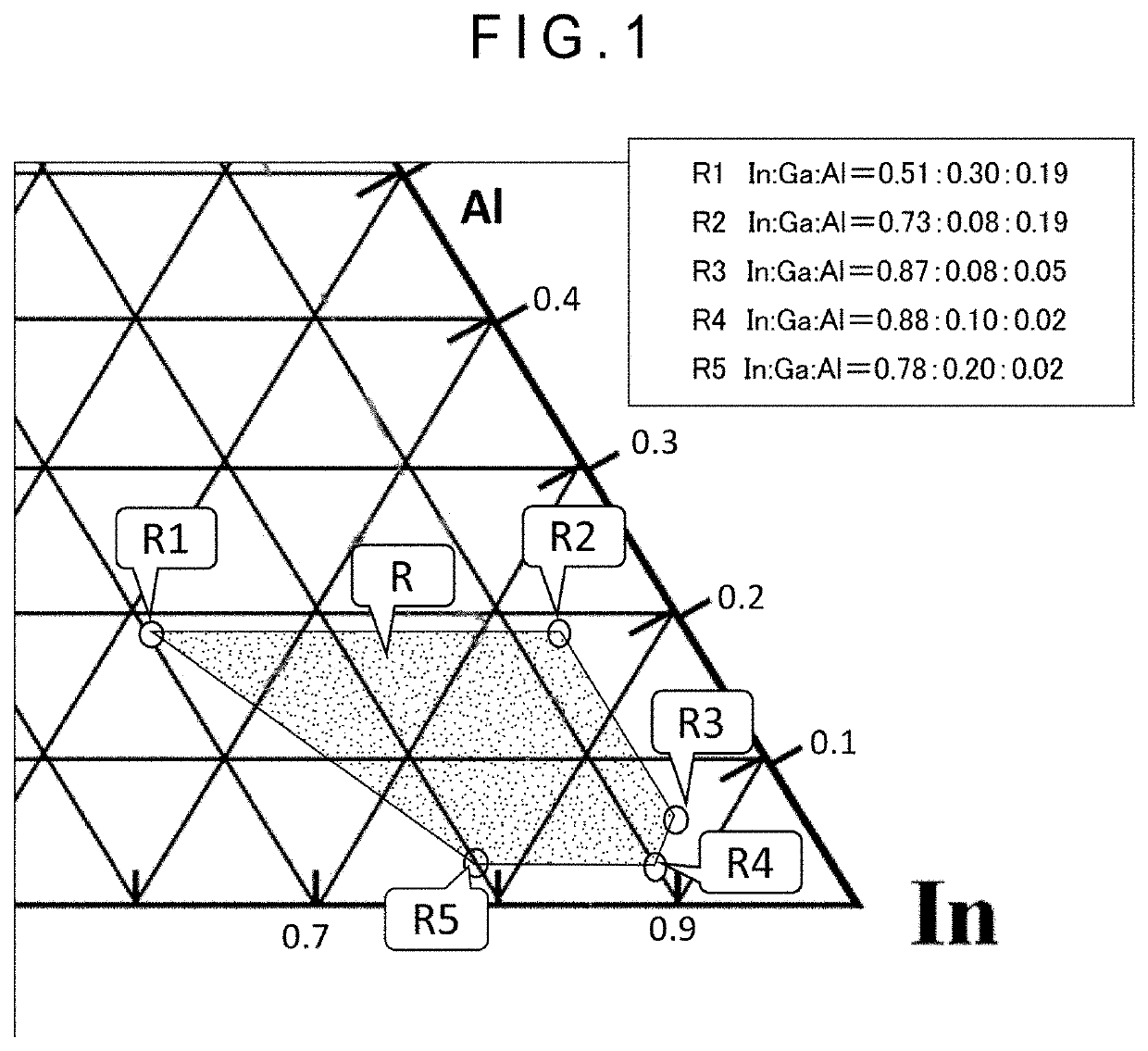

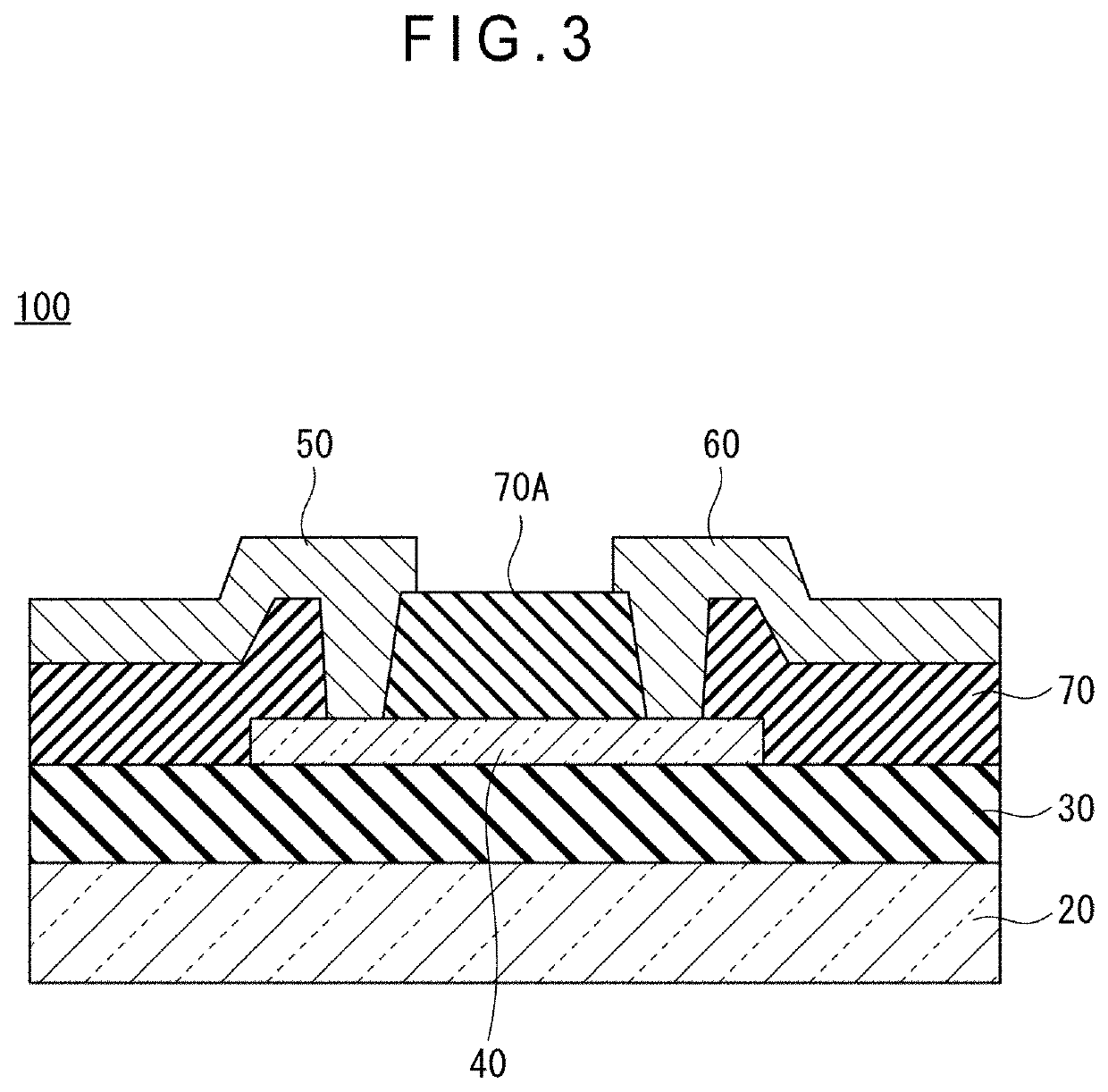

Amorphous oxide semiconductor film, oxide sintered body, thin film transistor, sputtering target, electronic device, and amorphous oxide semiconductor film production method

ActiveUS11342466B2High carrier mobilityStable sputteringTransistorSolid-state devicesCrystallographyAngle of incidence

Owner:IDEMITSU KOSAN CO LTD

Amorphous oxide semiconductor film, oxide sintered body, and thin film transistor

ActiveUS20200052130A1Small change in propertyHigh carrier mobilityTransistorSolid-state devicesAngle of incidenceThin membrane

A sintered oxide includes an In2O3 crystal, and a crystal A whose diffraction peak is in an incidence angle (2θ) range defined by (A) to (F) below as measured by X-ray (Cu—K α ray) diffraction measurement: 31.0 to 34.0 degrees . . . (A); 36.0 to 39.0 degrees . . . (B); 50.0 to 54.0 degrees . . . (C); 53.0 to 57.0 degrees . . . (D); 9.0 to 11.0 degrees . . . (E); and 19.0 to 21.0 degrees . . . (F).

Owner:IDEMITSU KOSAN CO LTD

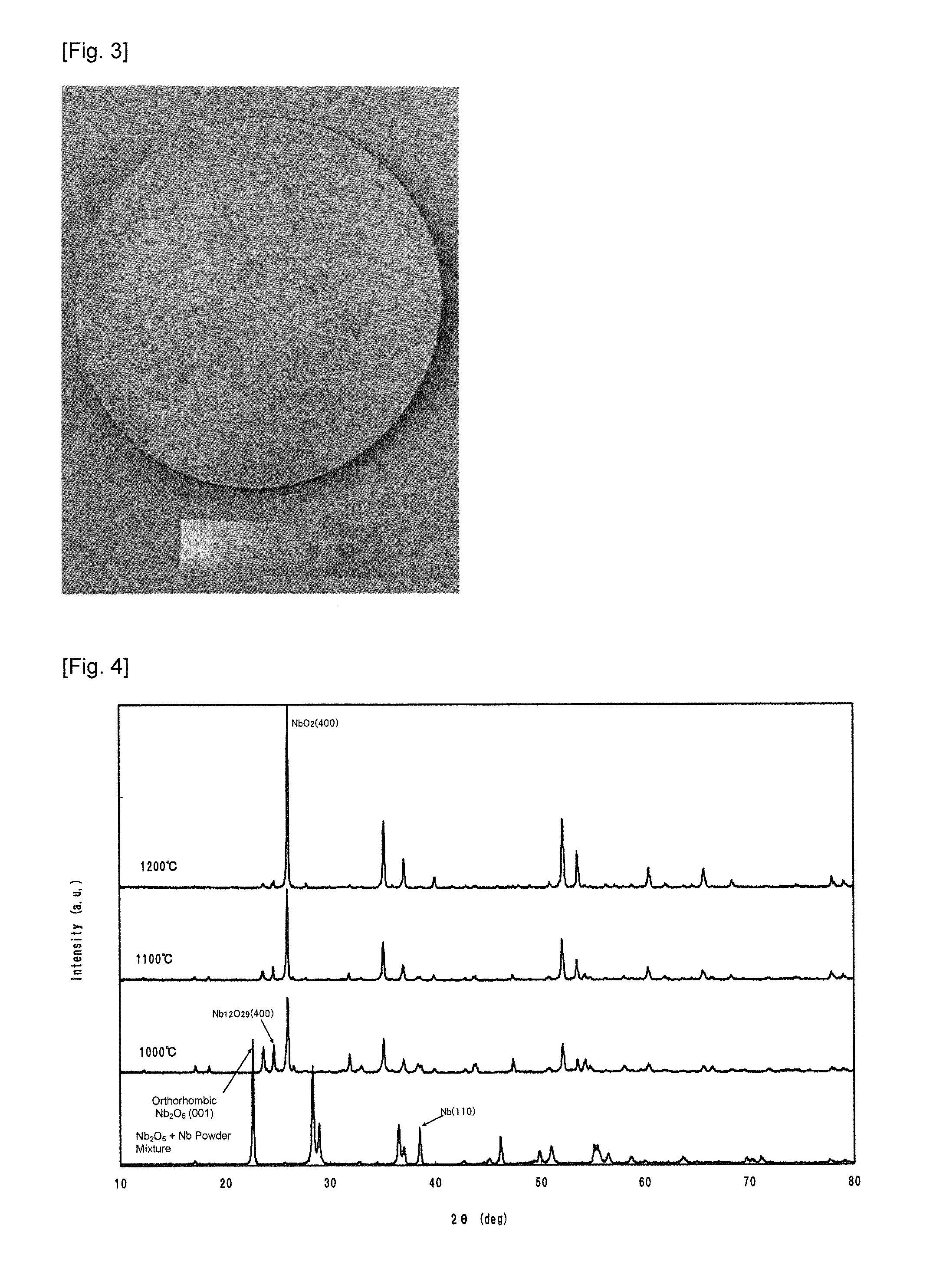

NbO2 Sintered Compact, Sputtering Target Comprising the Sintered Compact, and Method of Producing NbO2 Sintered Compact

ActiveUS20150255260A1Reduce generationHigh densityCellsElectric discharge tubesSputteringHigh density

The present invention relates to a NbO2 sintered compact characterized in that the intensity proportion of the X-ray diffraction peak intensity of a (001) plane or (110) plane of Nb2O5 relative to the X-ray diffraction peak intensity of a (400) plane of NbO2 is 1% or less. The present invention provides, without using an expensive NbO2 material, a NbO2 sintered compact that can be applied to a sputtering target for forming a high-quality variable resistance layer for a ReRAM. In particular, it is an object of the present invention to provide a single phase NbO2 sintered compact having a high density suitable for stabilizing sputtering.

Owner:JX NIPPON MINING & METALS CO LTD

Preparation method of intelligent glass anode electrochromic layer coating material

InactiveCN108658474AGood chemical stabilityImprove compactnessVacuum evaporation coatingSputtering coatingOxygen vacancyIntermediate frequency

The invention discloses a preparation method of an intelligent glass anode electrochromic layer coating material. A relative target material is manufactured by using a mode of slip casting and vacuumhigh-temperature sintering; vacuum treatment is carried out in a high-temperature sintering process, and a second element is added into nickel oxide, so that the conductivity of the material is improved through the electric carrier mobility generated by caused oxygen vacancy, the uniformity and the density of the target material are improved, the generation of abnormal electric arc during a sputtering process is greatly reduced, the service life and the utilization rate of the target material are prolonged, and the quality and the performance of the sputtering film are improved. A stable sputtering arc can be obtained by using a pulse direct current (DC) power supply, an alternating current (AC) power supply, an intermediate frequency (MF) power supply, or other power supplies in a sputtering process, and only the introduction of a small amount of oxygen is required in the sputtering process, so that dustfall is not easily caused. In addition, the process of staged heating sintering isadopted, and other gas is added into argon, so that the sputtering film forming rate can be increased by about 5-10 times, and the flatness and the large-area uniformity of the film can be improved.

Owner:SHENZHEN KING CHUANG TECH & ELECTRONICS

Uniform film-forming fine-grained nickel alloy rotating target and its hot extrusion optimization preparation method

ActiveCN105734507BUniform internal organizationUniform thicknessVacuum evaporation coatingSputtering coatingNickel alloyWork in process

Provided is a hot extrusion optimizing preparation method of a fine grain nickel alloy rotary target capable of achieving even film forming. Nickel with the purity larger than or equal to 99.99% and other element metal with the purity larger than or equal to 99.95% are adopted as alloy raw materials to be molten into a high-purity nickel alloy ingot; and the high-purity nickel alloy ingot is placed in an extrusion die placed in a double-acting backward extrusion machine after being heated by one to two hours, the high-purity nickel alloy ingot is subjected to hot extrusion to form a semi-finished nickel alloy pipe target, the total deformation in the extruding process is larger than 80%, and recrystallization annealing is carried out after cooling. The structure in the nickel alloy is more even, the obvious layering phenomenon is eliminated, the alloy target is high in finished product rate, fine in grain, even in inner structure and more stable in sputtering, film forming is even when the target is used, a high-quality thin film with even thickness can be obtained, and the utilization rate of the target is increased.

Owner:GEMCH MATERIAL TECH SUZHOU

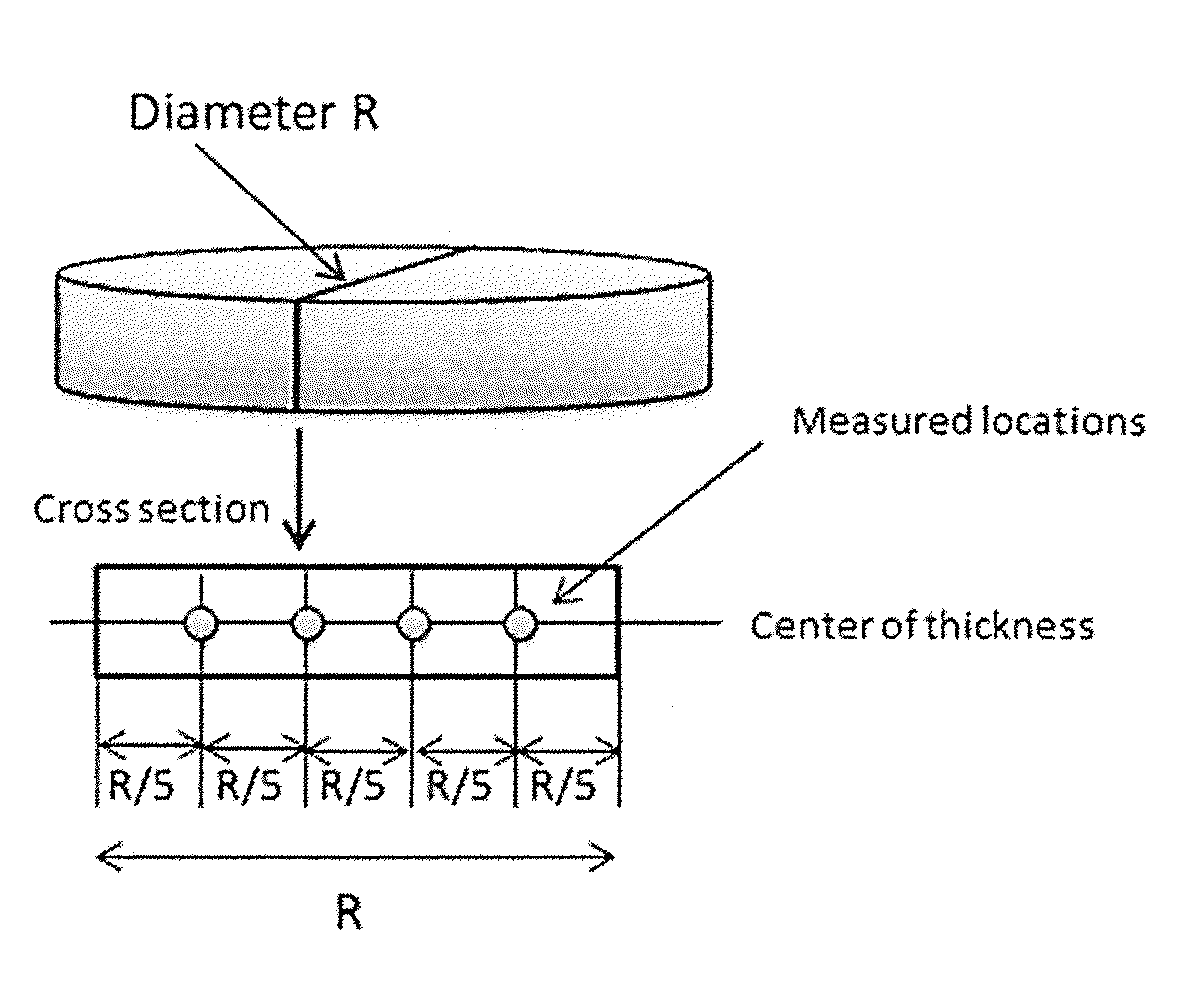

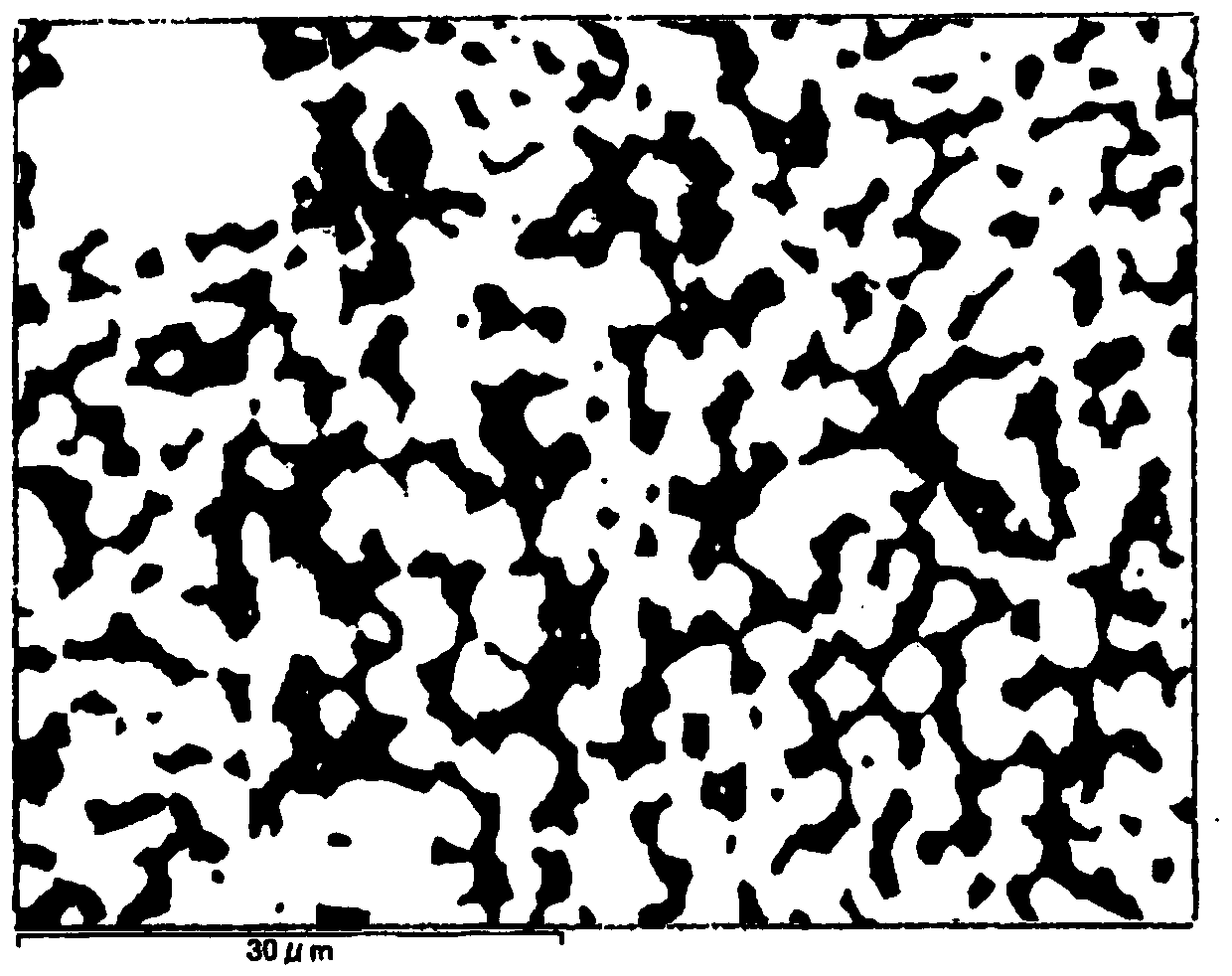

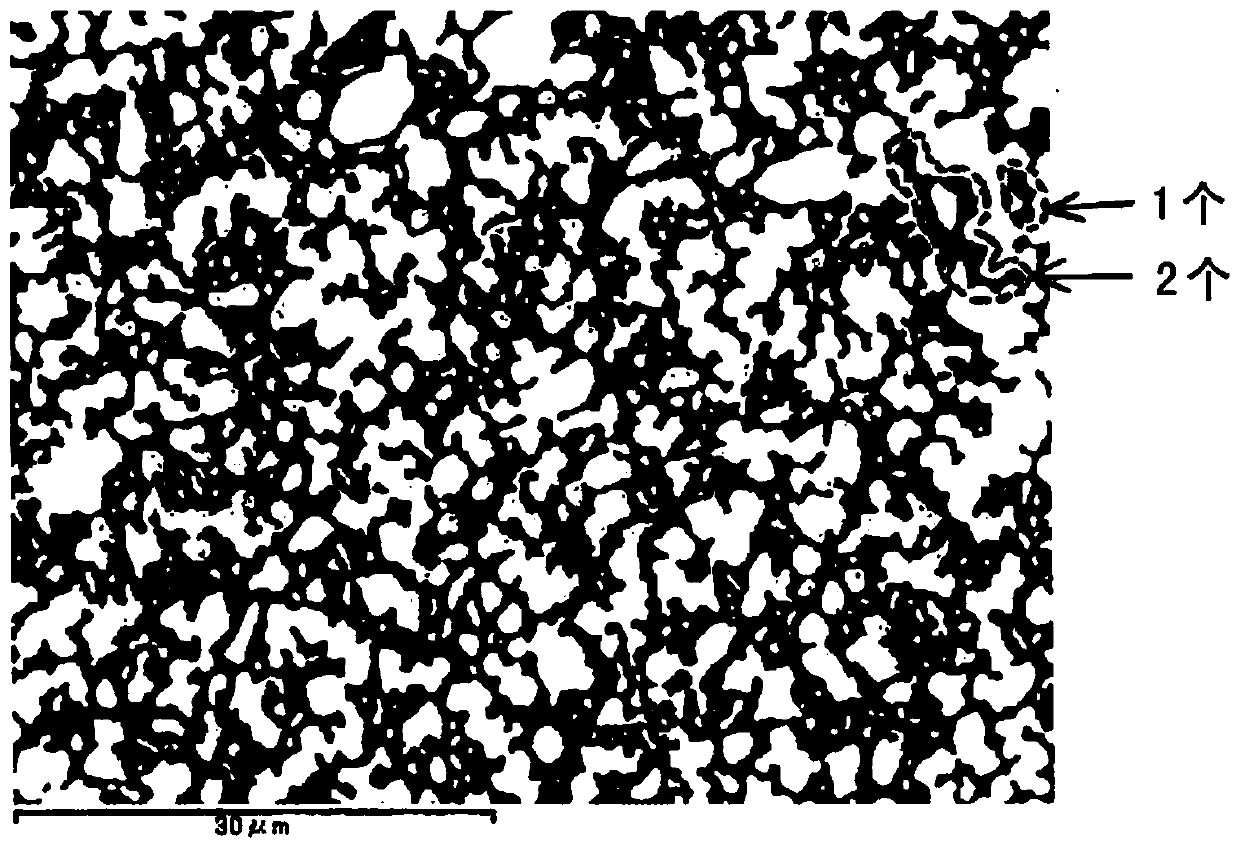

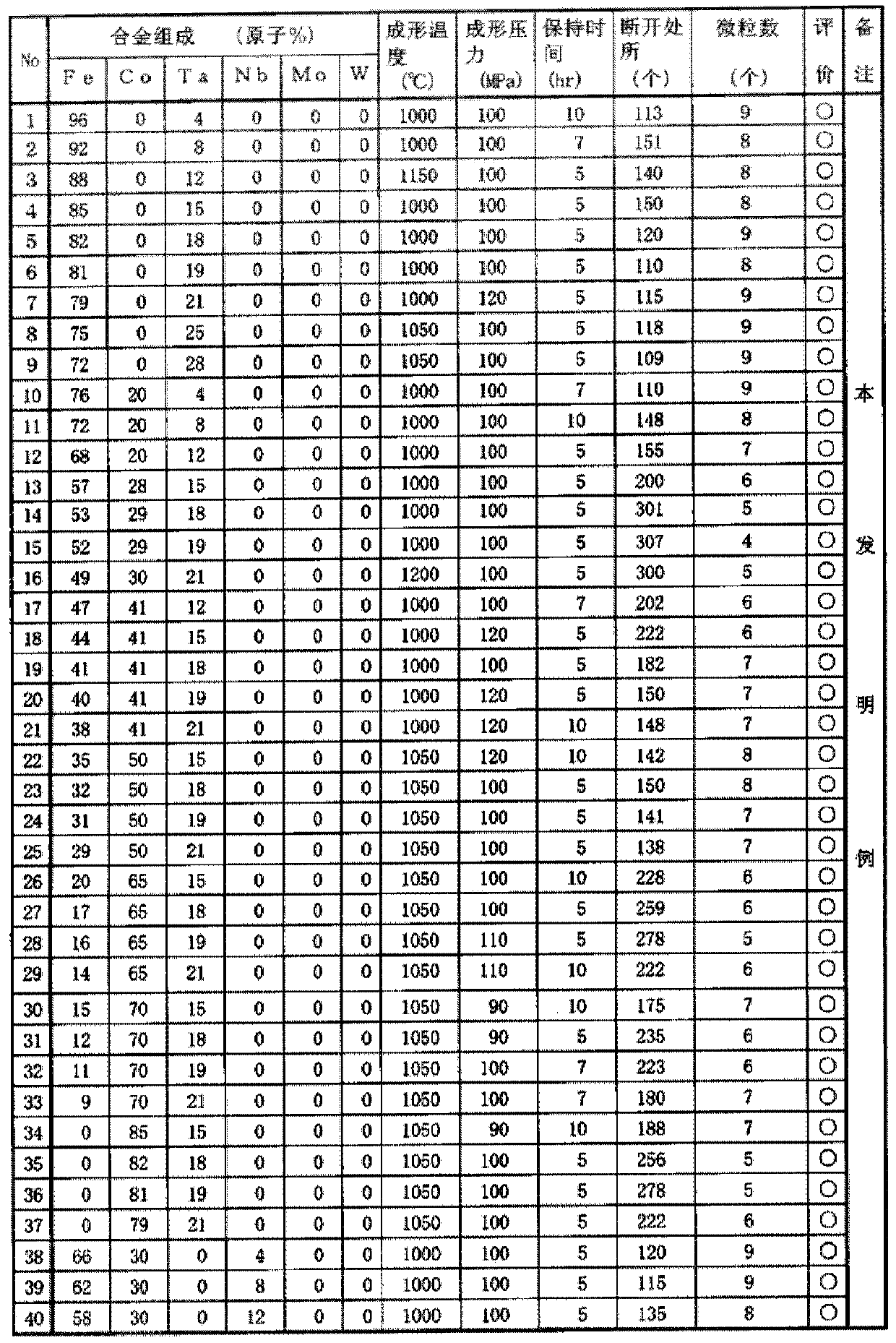

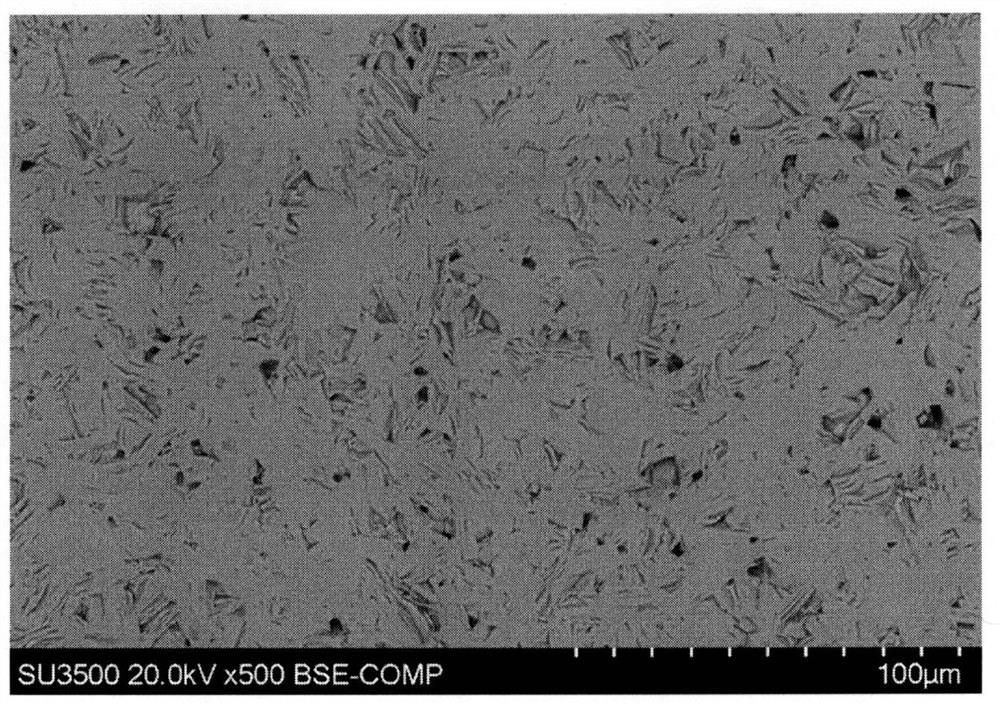

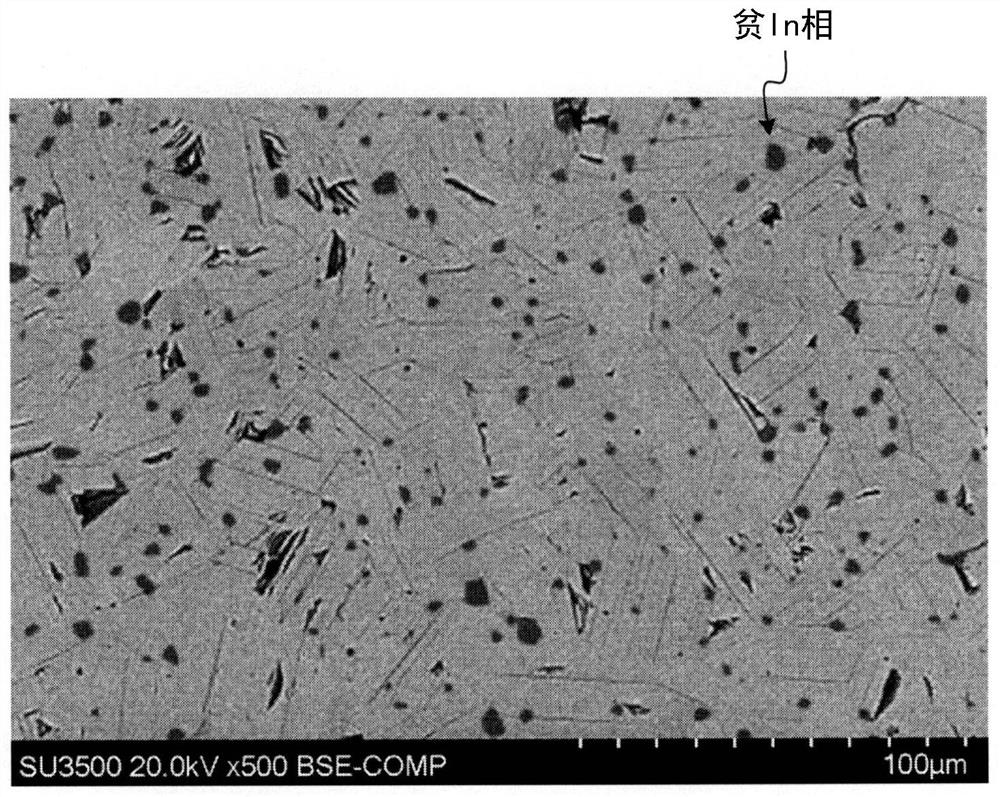

fe-co alloy sputtering target material and soft magnetic thin film layer, and perpendicular magnetic recording medium using it

The target material of the present invention is composed of at least one M element selected from Nb, Ta, Mo, and W, and the remainder as one or both of Fe and Co and inevitable impurities, and satisfies the following Formula (1): (Fex‑Co100‑x)100‑Y MY…(1) [In the formula, the atomic ratios are 0≤X≤100 and 4≤Y≤28. ] Sputtering target composed of Fe-Co alloy, the microstructure of the sputtering target has a phase mainly composed of Fe and Co, and a metal containing one or both of Fe and Co and M element The intermetallic compound phase grows in a network of one or both of Fe and Co and the intermetallic compound phase composed of M element, and surrounds and disconnects the phase dominated by Fe and Co to isolate it. The number of isolated phases mainly composed of Fe and Co is 300 or more per 10000 μm 2 in the sputtering target.

Owner:SANYO SPECIAL STEEL COMPANY

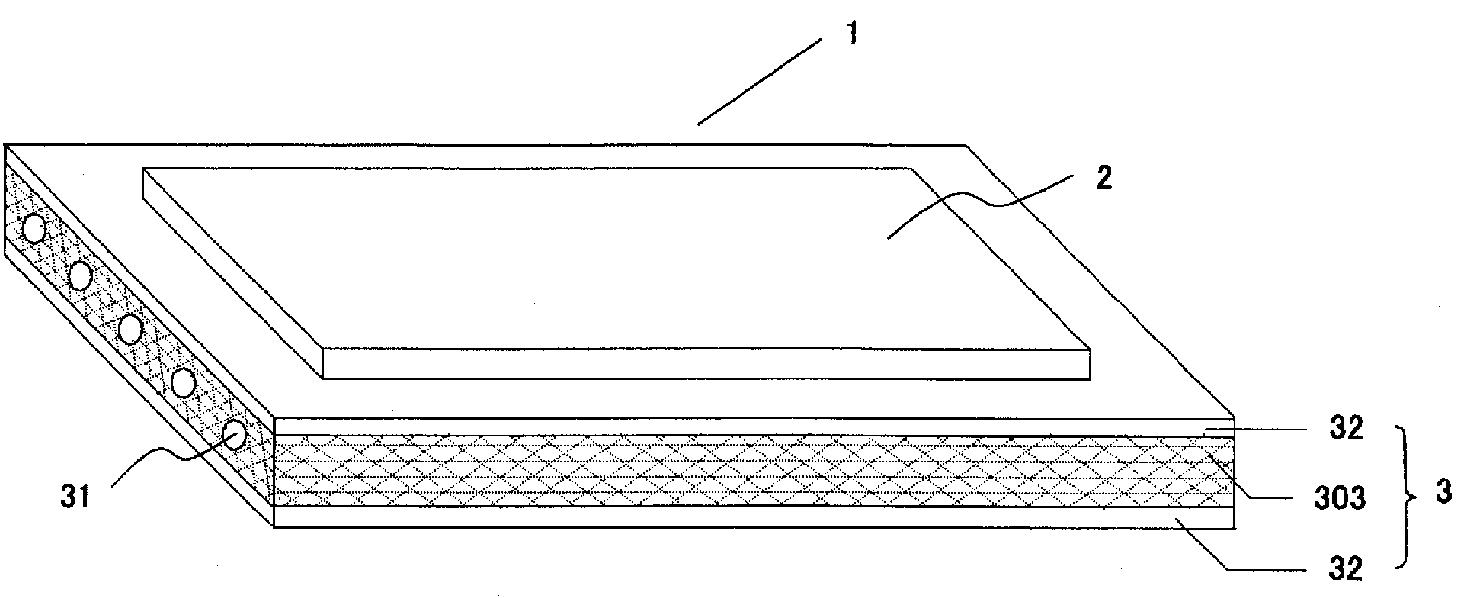

Gas flow sputtering device, target for gas flow sputtering, and manufacturing method of sputtering target raw material

ActiveCN110088352BIncrease productivityLow costVacuum evaporation coatingSputtering coatingPhysicsOptics

Owner:JX NIPPON MINING & METALS CO LTD

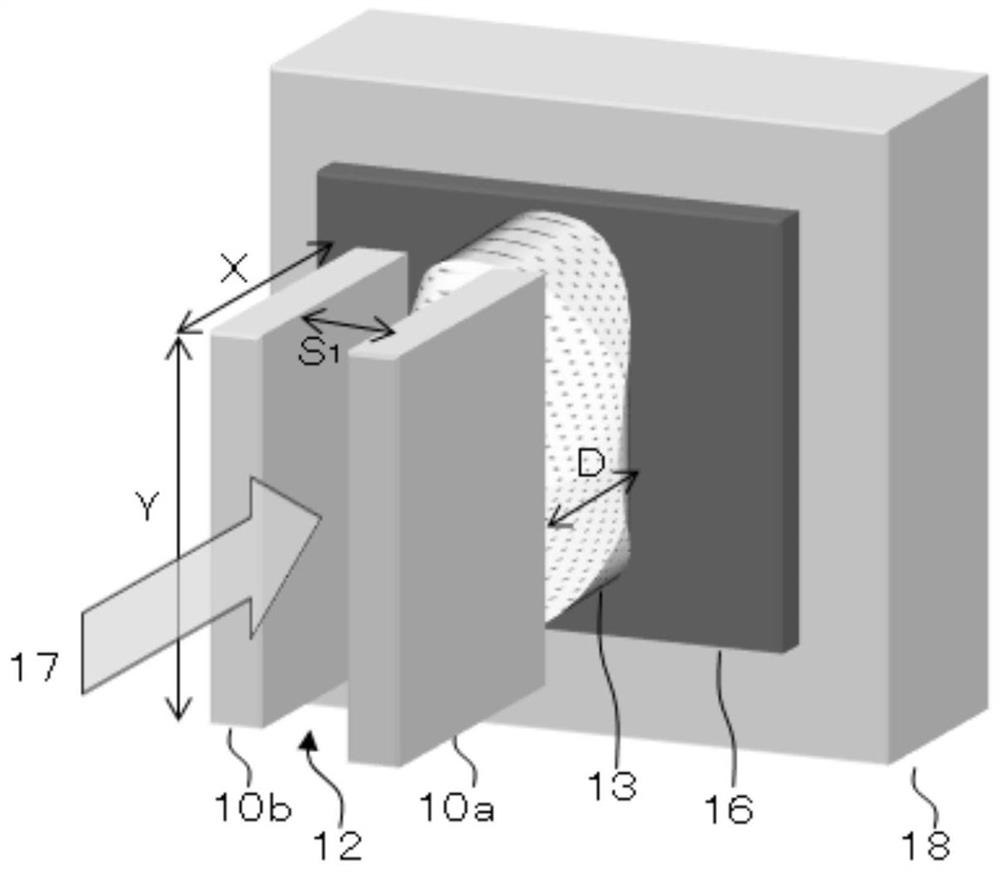

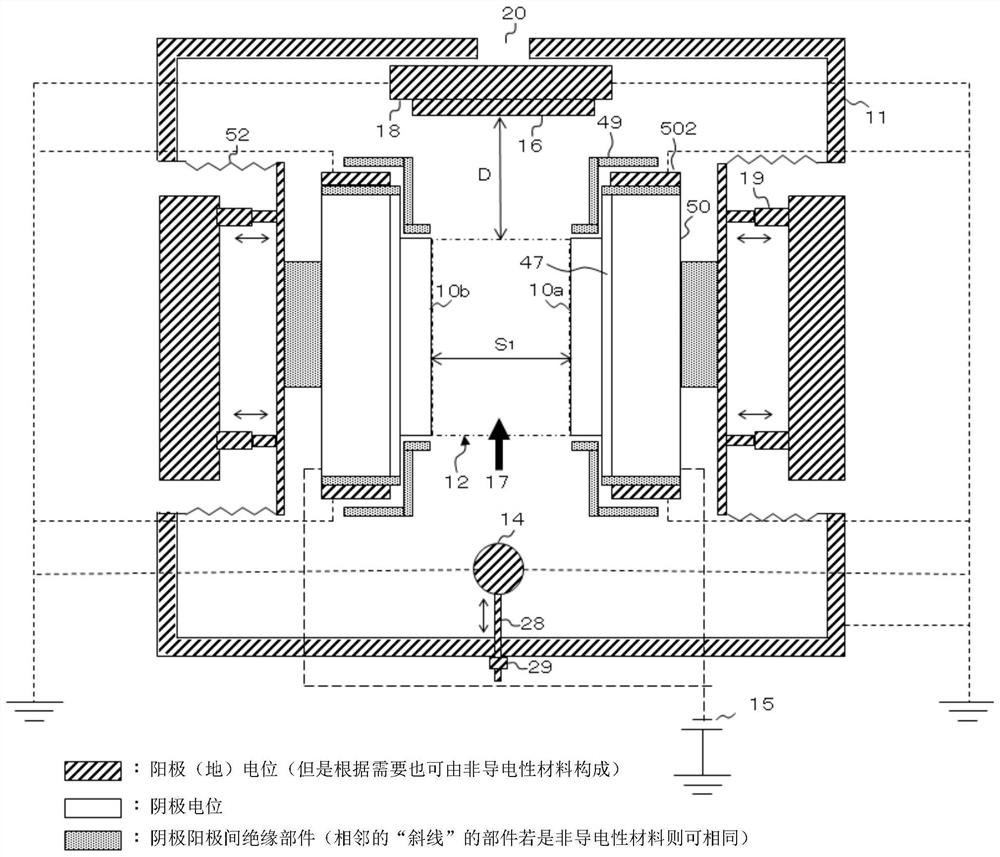

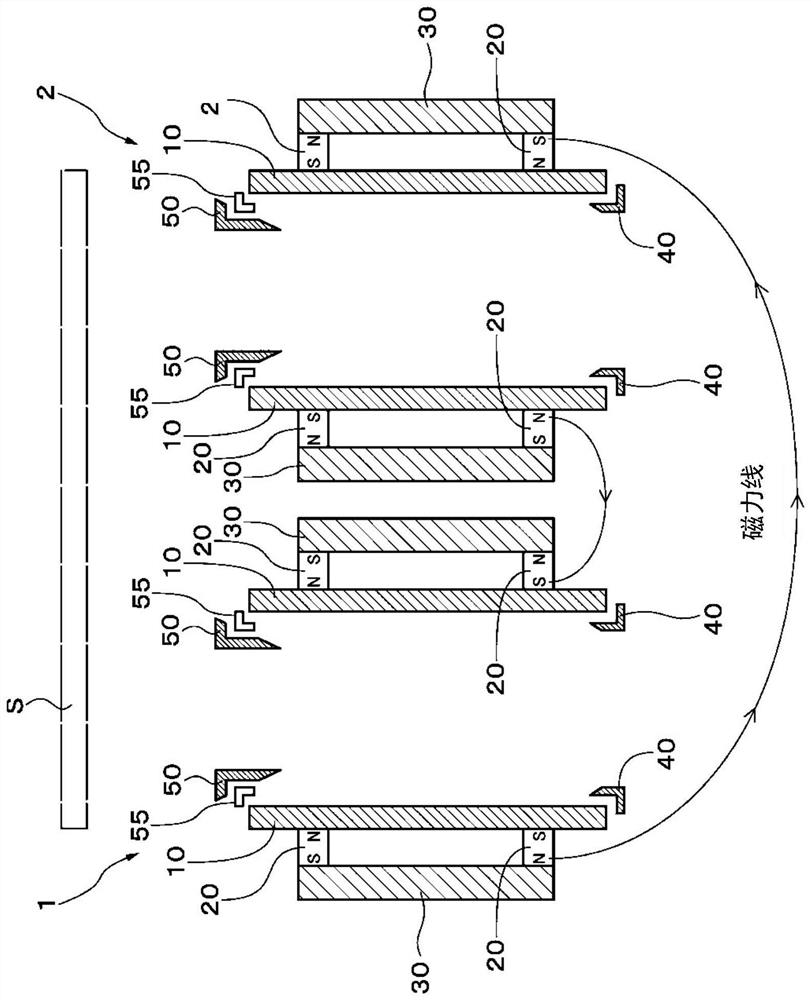

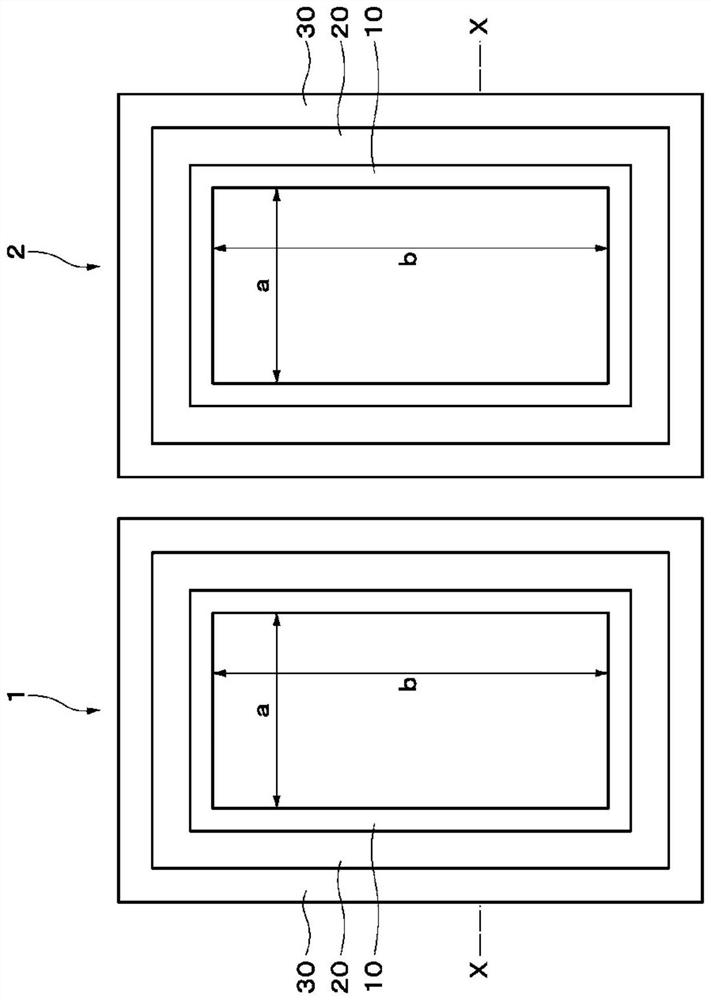

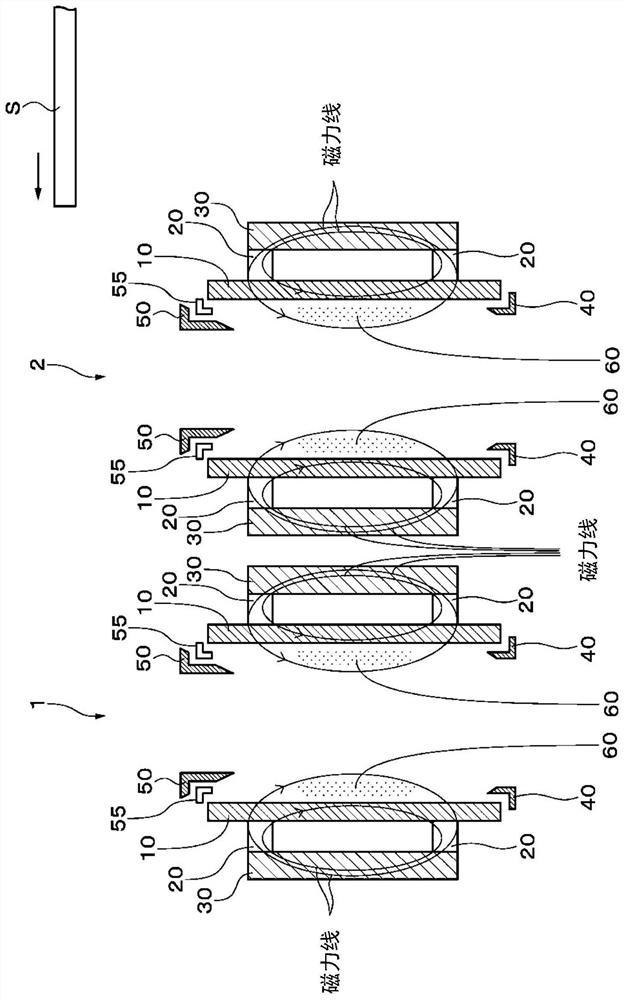

Sputtering cathode, sputtering cathode assembly, and sputtering device

ActiveCN112004958AImprove efficiencyHigh densityElectric discharge tubesVacuum evaporation coatingMaterials scienceAtomic physics

The present invention addresses the problem of providing a sputtering cathode and a sputtering device using this sputtering cathode by which a film can be deposited on various kinds of workpieces, including flat workpieces, not only at a sufficiently high deposition rate with low impact but also with high sputtering target utilization efficiency. The sputtering cathode comprises a sputtering target 10 which has a tubular shape with a cross section having an opposing pair of long sides and which is set so that the erosion surface of the sputtering target 10 is inward-facing; additionally a magnetic circuit is disposed along the sputtering target 10, and the pair of long sides are constituted by cylindrical rotary targets 11, 12. The rotary targets have magnetic circuits therein and are configured such that cooling water flows therethrough. The magnetic circuits are disposed parallel to the central axis of the rotary targets and have a rectangular cross-section with long sides perpendicular to the radial direction of the rotary targets.

Owner:KEIHIN RAM TECH

Transparent conductive film, solar cell using same, sputtering target for forming said transparent conductive film, and manufacturing method therefor

ActiveCN102666910BHigh densityImprove conductivityConductive layers on insulating-supportsVacuum evaporation coatingLiquid-crystal displayMoisture resistance

[Problems] Provided is a transparent conductive film used for a liquid-crystal display device, an electroluminescent display device, or the like, and particularly suitable for use in a solar cell. Also provided is a solar cell using the transparent conductive film and a sputtering target suitable for forming the transparent conductive film. [Solving Means] The provided transparent conductive film is composed of an Al-Mg-Ga-Zn-based oxide of which the content ratios of metal component elements are 0.7-7% Al, 9.2-25% Mg, 0.015-0.085% Ga, and the remainder is Zn, by atomic ratio, and is excellent in moisture resistance.

Owner:MITSUBISHI MATERIALS CORP

Sputtering target and thin film for optical information recording medium

ActiveCN101208451BStable sputteringExcellent adhesionVacuum evaporation coatingSputtering coatingTectorial membraneSputtering

Owner:JX NIPPON MINING & METALS CORP

Sputtering target, transparent conductive oxide, and method for preparing sputtering target

In a sputtering target comprising at least indium oxide and zinc oxide, the atomic ratio represented by In / (In-Zn) is set to a value within the range of 0.75 to 0.97, a hexagonal layered compound represented by In 2 O 3 (ZnO) m wherein m is an integer of 2 to 20 is contained, and the crystal grain size of the hexagonal layered compound is set to a value of 5 m or less .

Owner:JX NIPPON MINING & METALS CORP

Oxide sintered body, sputtering target and method for producing oxide thin film

ActiveCN110770191BStable sputteringGallium/indium/thallium compoundsVacuum evaporation coatingIndiumPhysical chemistry

The oxide sintered body according to one aspect of the embodiment is an oxide sintered body containing indium, gallium, and zinc at a ratio satisfying the following formulas (1) to (3), and is composed of a single-phase crystal phase, and the average value of the crystal phase is The particle size is 15.0 μm or less. 0.01≤In / (In+Ga+Zn)<0.20(1) 0.10≤Ga / (In+Ga+Zn)≤0.49(2)0.50≤Zn / (In+Ga+Zn)≤0.89(3).

Owner:MITSUI MINING & SMELTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com