Mgo-tio sintered compact target and method for producing same

A manufacturing method and technology of sintered bodies, which are applied in the manufacture of record carriers, disk-shaped carriers, paint carrier supports, etc., can solve problems such as poor productivity, slow film forming speed, and film quality deterioration, and achieve cost reduction and particle generation. The effect of reducing the amount and increasing the film forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

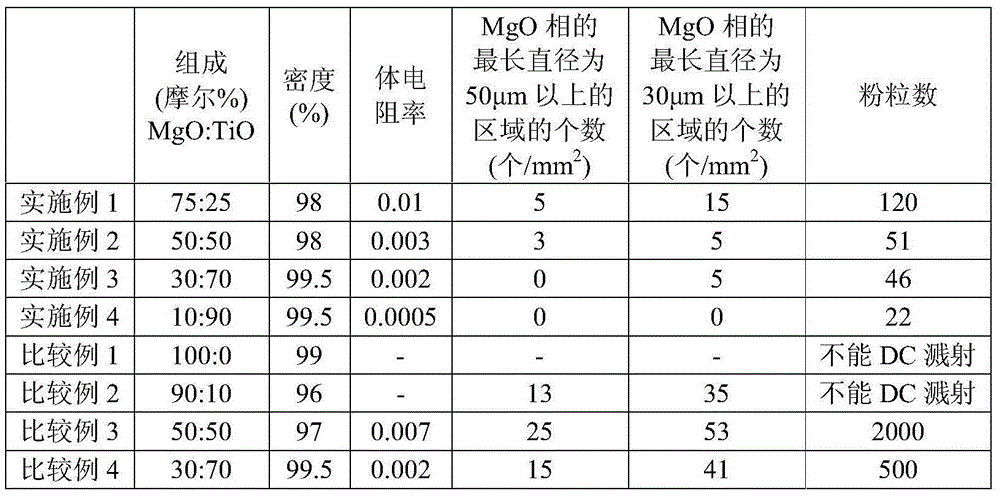

Embodiment 1

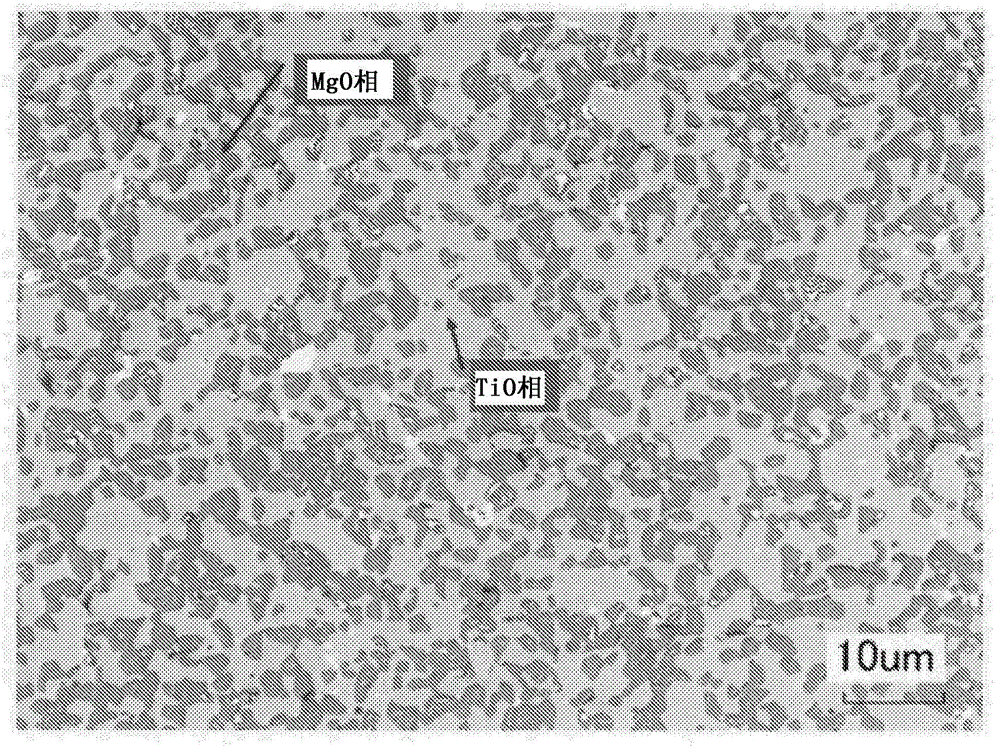

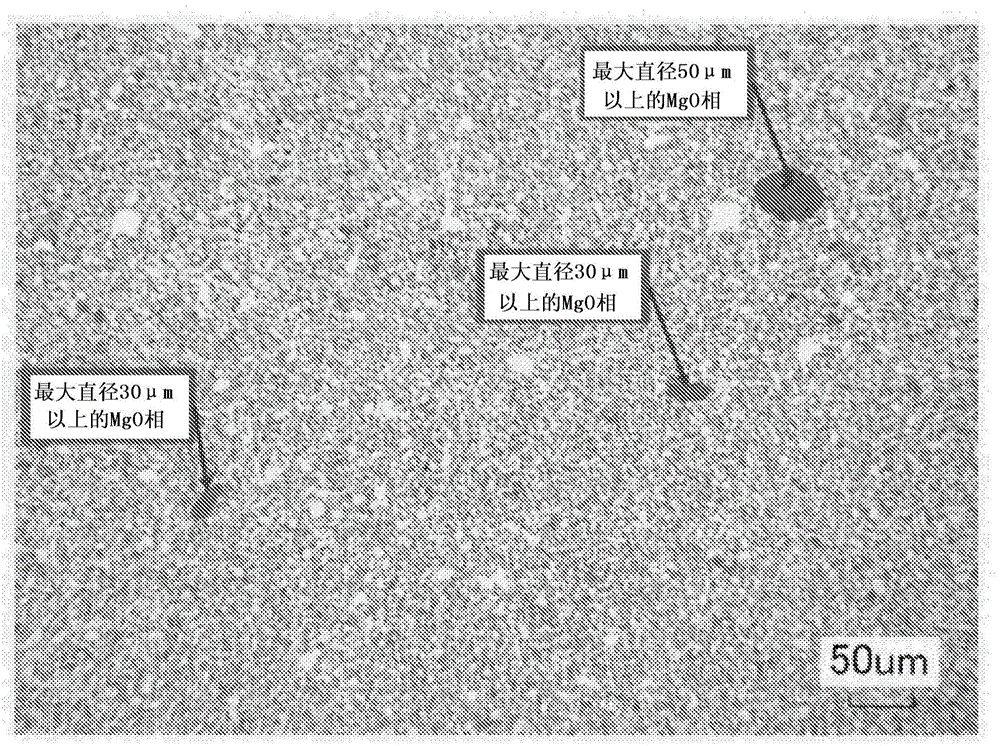

[0058] As raw material powders, MgO powder with an average particle diameter of 1 μm and a purity of 4N (99.99%) and TiO powder with an average particle diameter of 30 μm and a purity of 3N (99.9%) were prepared. Then, these raw material powders were blended so that the composition ratio shown in Table 1 was obtained.

[0059] Then, put the weighed powder together with the grinding medium zirconia balls into a ball mill tank with a capacity of 10 liters under Ar atmosphere, and rotate for more than 20 hours for mixing and grinding, so that the two powders are evenly dispersed.

[0060] Then, the powder taken out of the tank was filled into a graphite mold with a diameter of 180 mm, and shaped and sintered using a hot press device. The conditions of hot pressing are: vacuum atmosphere, holding temperature of 1400 ° C, from the beginning of heating to the end of holding at 250kgf / cm 2 The pressure is pressurized.

[0061] The sintered body thus produced had a relative density ...

Embodiment 2

[0067] As raw material powders, MgO powder with an average particle diameter of 1 μm and a purity of 4N (99.99%) and TiO powder with an average particle diameter of 20 μm and a purity of 3N (99.9%) were prepared. Then, these raw material powders were blended so that the composition ratio shown in Table 1 was obtained.

[0068] Then, put the weighed powder together with the grinding medium zirconia balls into a ball mill tank with a capacity of 10 liters under Ar atmosphere, and rotate for more than 20 hours for mixing and grinding, so that the two powders are evenly dispersed.

[0069] Then, the powder taken out of the tank was filled into a graphite mold with a diameter of 180 mm, and shaped and sintered using a hot press device. The conditions of hot pressing are: vacuum atmosphere, holding temperature 1400°C, from the beginning of heating to the end of holding at 300kgf / cm 2 The pressure is pressurized.

[0070] The sintered body thus produced had a relative density of 98...

Embodiment 3

[0073] As raw material powders, MgO powder with an average particle diameter of 1 μm and a purity of 4N (99.99%) and TiO powder with an average particle diameter of 30 μm and a purity of 3N (99.9%) were prepared. Then, these raw material powders were blended so that the composition ratio shown in Table 1 was obtained.

[0074]Then, put the weighed powder together with the grinding medium zirconia balls into a ball mill tank with a capacity of 10 liters under Ar atmosphere, and rotate for more than 20 hours for mixing and grinding, so that the two powders are evenly dispersed.

[0075] Then, the powder taken out of the tank was filled into a graphite mold with a diameter of 180 mm, and shaped and sintered using a hot press device. The conditions of hot pressing are: vacuum atmosphere, holding temperature of 1400 ° C, from the beginning of heating to the end of holding at 250kgf / cm 2 The pressure is pressurized.

[0076] The sintered body thus produced had a relative density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com