Oxide sputtering target and method for producing same, and protective film for optical recording media

A manufacturing method and oxide technology, which are applied in the directions of recording/reproducing, optical recording medium, data recording, etc. by optical methods, to achieve the effects of lower specific resistance, less cracking, and high preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

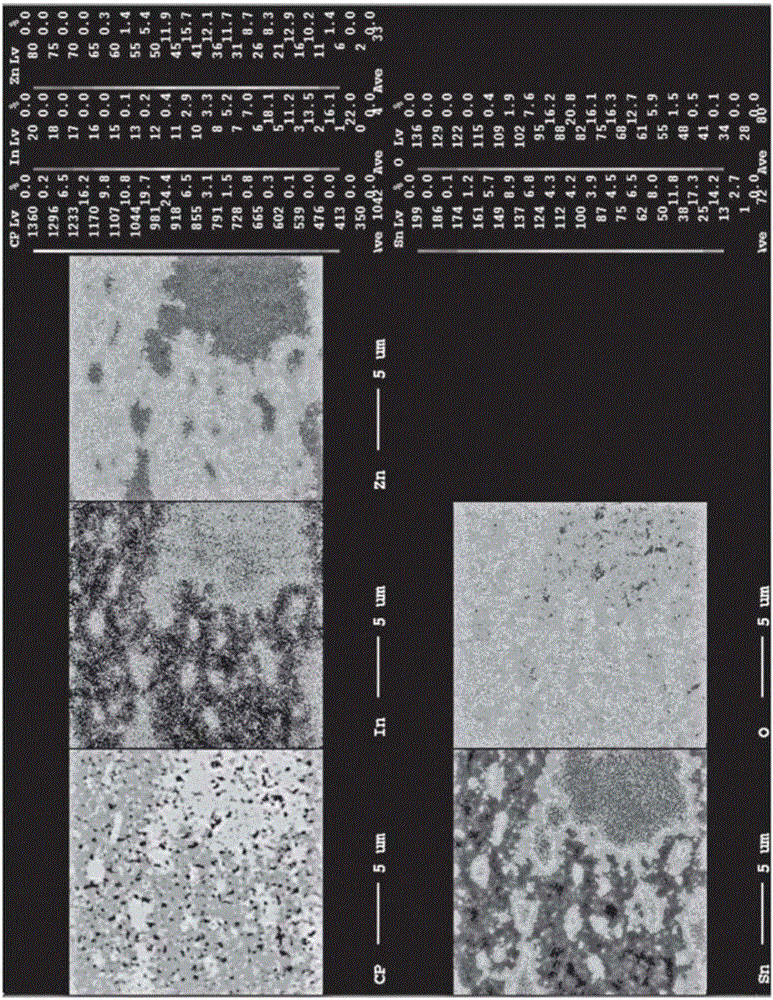

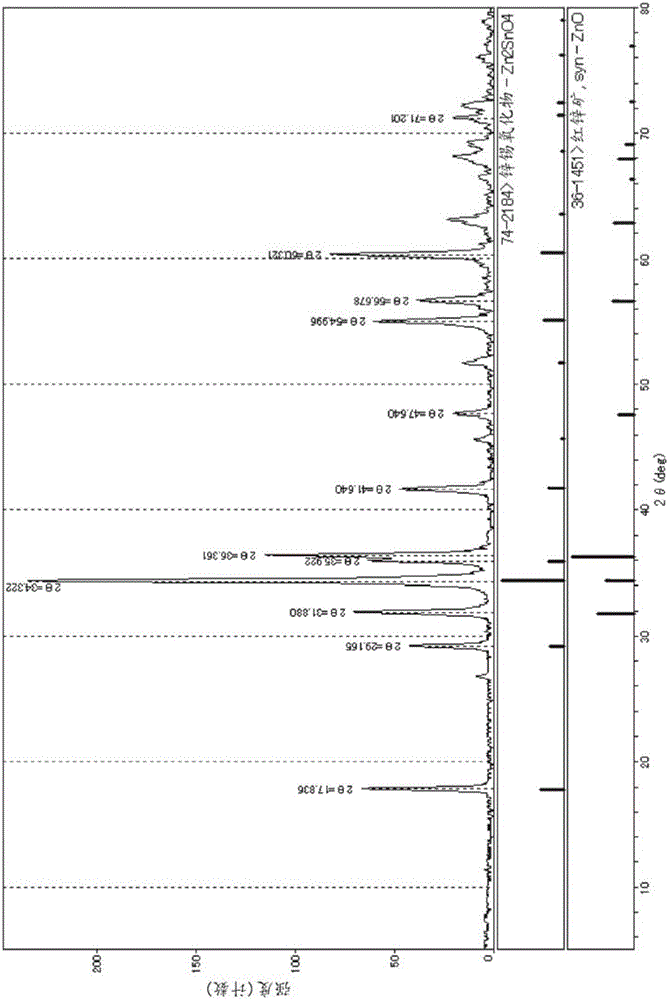

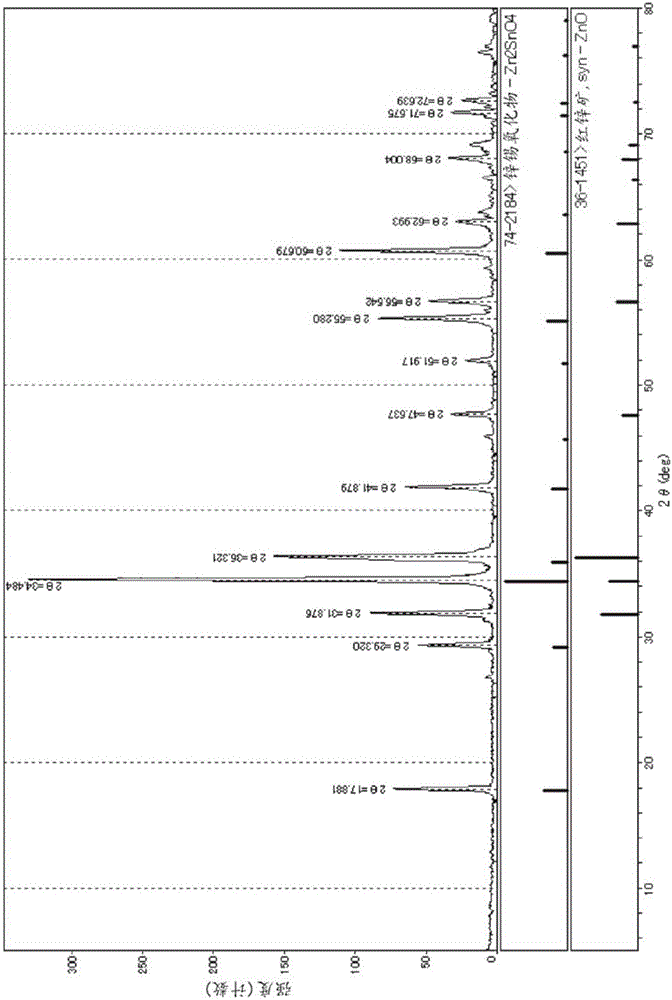

[0042] In the present example, an oxide sputtering target which is an oxide sintered body having a composition containing Sn: 7 at % or more and In: 0.1 ~35.0at%, the balance is composed of Zn and unavoidable impurities, the atomic ratio Sn / (Sn+Zn) of Sn and Zn is 0.5 or less, or an oxide sintered body with the following composition, that is, relative to the metal component The total amount contains Sn: 7at% or more and In: 0.1 to 35.0at%, and contains a total of 1.0 to 30.0at% of one or more of Ge and Cr, and the balance is composed of Zn and unavoidable impurities. Sn and The atomic ratio Sn / (Sn+Zn) of Zn is 0.5 or less, and the atomic ratio (Sn+Cr+Ge) / (Sn+Cr+Ge+Zn) of Sn, Cr, Ge, and Zn is 0.6 or less, and Zn with In as a solid solution 2 SnO 4 Organization as the primary phase. Prepare zinc oxide (chemical formula: ZnO, average particle size: D 50 =1μm), tin oxide (chemical formula: SnO 2 、D 50 =16μm), indium oxide (chemical formula: In 2 o 3 、D 50 =11μm), germani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com