Sputtering cathode, sputtering cathode assembly, and sputtering device

A cathode, sputtering technology, used in sputter coating, electrical components, sustainable manufacturing/processing, etc., which can solve the problems of low plasma density, inability to obtain, high film forming speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0073] [sputtering device]

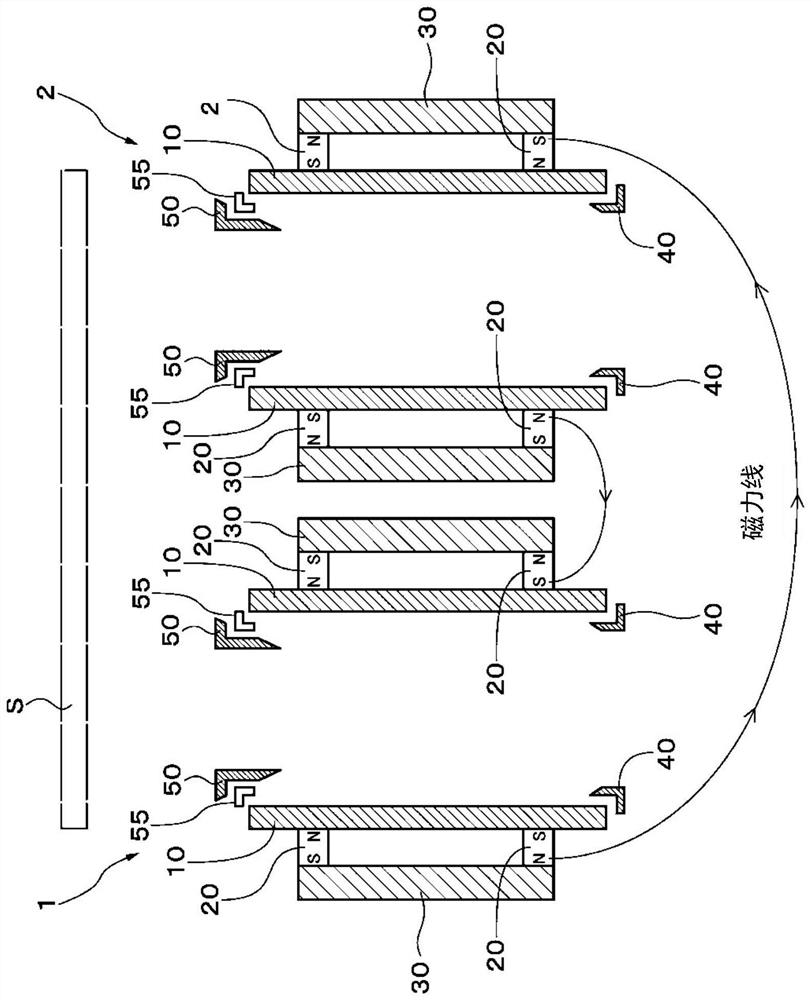

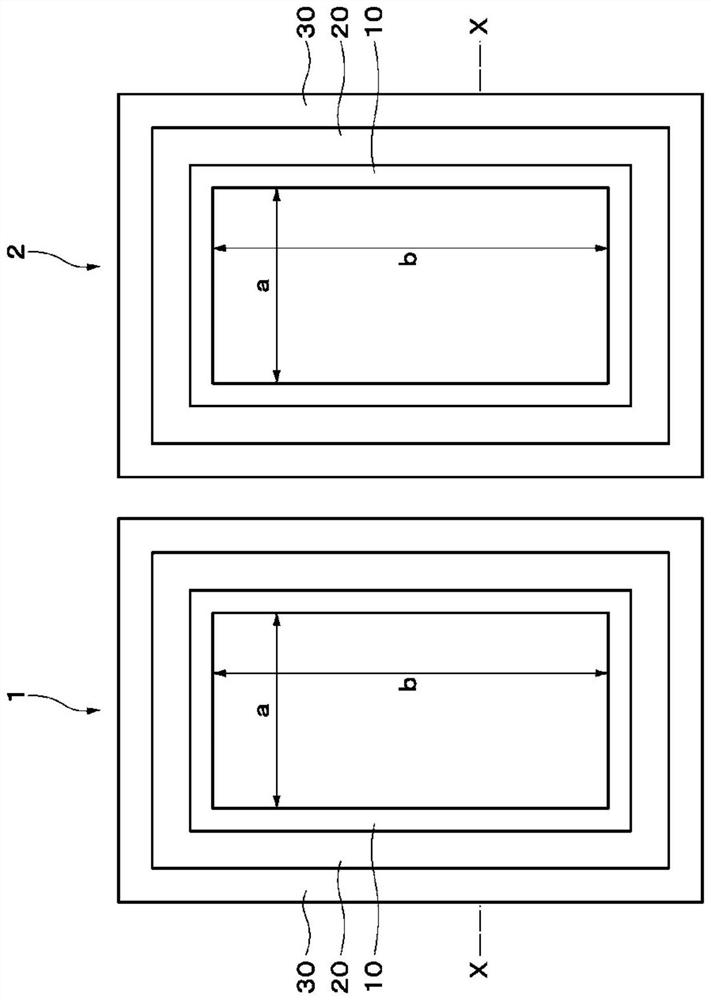

[0074] figure 1 and figure 2 It is a longitudinal sectional view and a plan view showing the sputtering apparatus according to the first embodiment, showing the structure near the sputtering cathode assembly provided inside the vacuum container of the sputtering apparatus. figure 1 is along figure 2 The cross-sectional view of the XX line.

[0075] Such as figure 1 and figure 2 As shown, in this sputtering device, a plurality of sputtering cathodes are arranged side by side on a horizontal plane, and these sputtering cathodes form a sputtering cathode assembly. The number of sputtering cathodes constituting the sputtering cathode assembly is appropriately selected according to the size of the substrate to be film-formed, the film-forming method, and the like. exist figure 1 and figure 2 In , as an example, only a pair of sputtering cathodes 1 and 2 adjacent to each other are shown, but it is not limited thereto. The distance between th...

no. 2 approach

[0092] [sputtering device]

[0093] The sputtering apparatus according to the second embodiment differs from the sputtering apparatus according to the first embodiment in that as the sputtering target 10 Figure 11 The sputtering target shown. That is, if Figure 11 As shown, the sputtering target 10 is composed of a pair of long side portions facing each other in parallel and a semicircular portion connected to these long side portions. Both the permanent magnet 20 provided outside the sputtering target 10 and the yoke 30 provided outside the permanent magnet 20 have the same shape as the sputtering target 10 . Other configurations of the sputtering device are the same as those of the sputtering device according to the first embodiment.

[0094] [Film formation method using a sputtering device]

[0095] The method of forming a film using this sputtering device is the same as that of the first embodiment.

[0096] According to this second embodiment, the same advantages a...

no. 3 approach

[0098] [sputtering device]

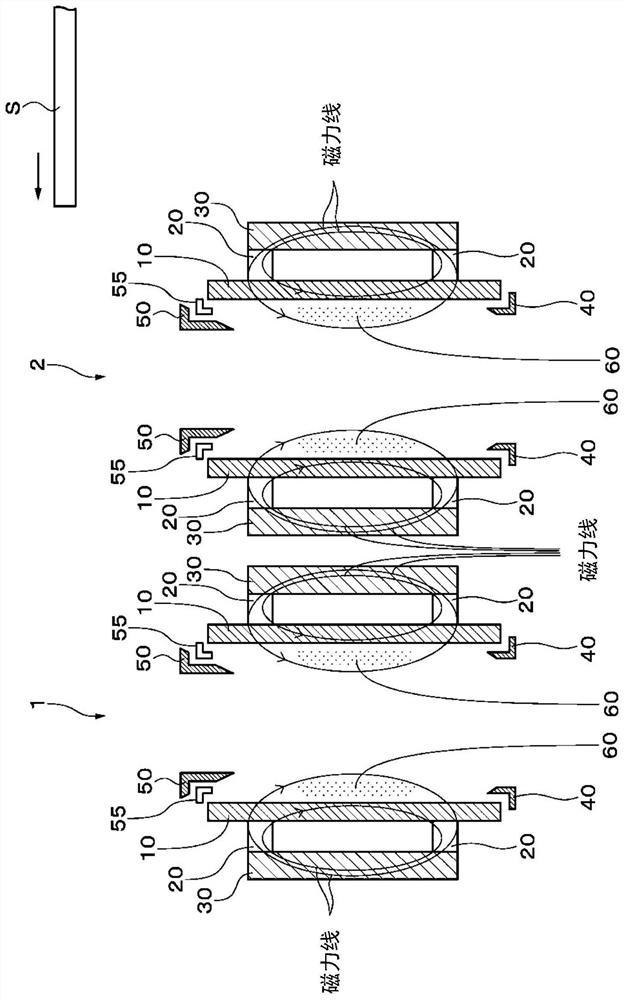

[0099] Figure 12 and Figure 13 It is a longitudinal sectional view and a plan view showing a sputtering apparatus according to a third embodiment, and shows a structure near a sputtering cathode assembly provided inside a vacuum container of the sputtering apparatus. Figure 13 is along Figure 12 A cross-sectional view of the Y-Y line.

[0100] Such as Figure 12 and Figure 13 As shown, in the sputtering device, a plurality of sputtering cathodes are arranged side by side on a vertical plane, and these sputtering cathodes form a sputtering cathode assembly. The number of sputtering cathodes constituting the sputtering cathode assembly is appropriately selected according to the desired film formation speed and the like. exist Figure 12 and Figure 13 In , as an example, only a pair of sputtering cathodes 1 and 2 adjacent to each other are shown, but it is not limited thereto. The distance between the sputtering cathodes 1 and 2 is appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com