Transparent conductive film, solar cell using same, sputtering target for forming said transparent conductive film, and manufacturing method therefor

A transparent conductive film, sputtering target technology, applied in sputtering coating, conductive layers on insulating carriers, circuits, etc., can solve the problems of solar cell power generation efficiency decline, conductivity deterioration, brightness decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

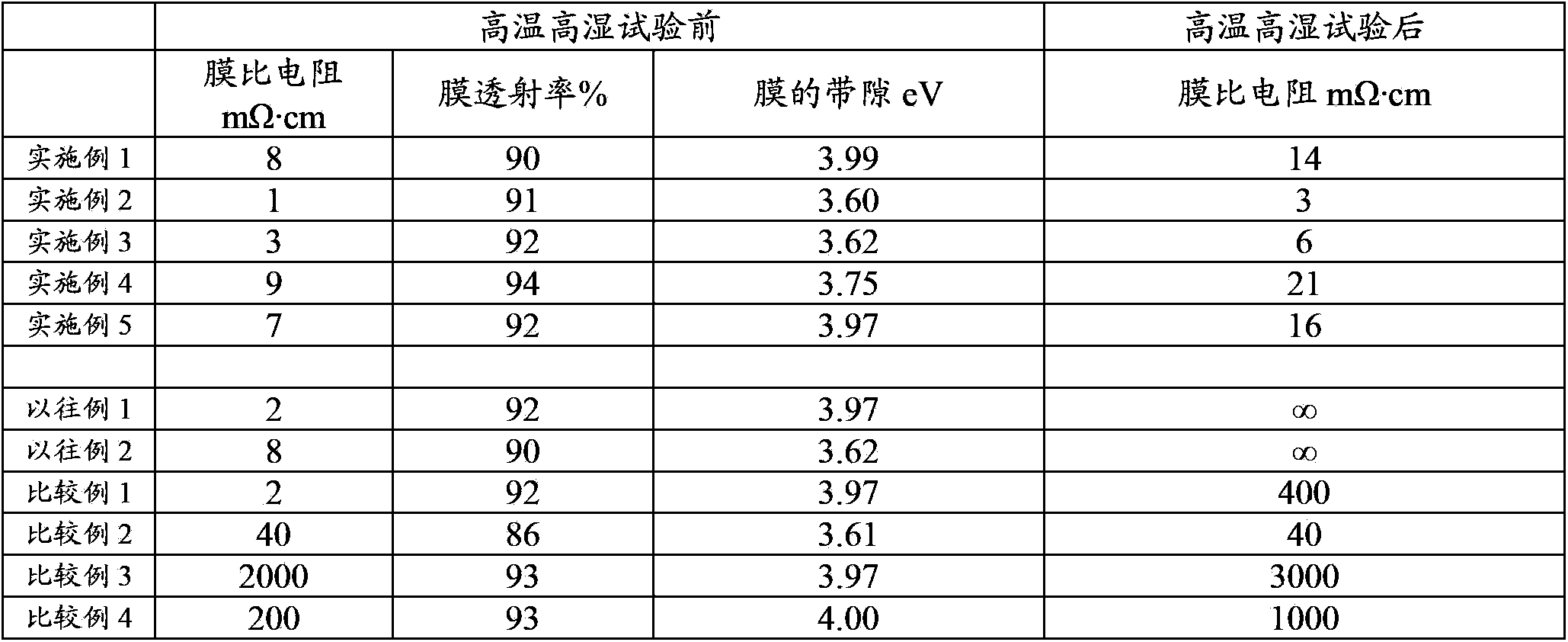

[0091] Hereinafter, the Example at the time of actually manufacturing the sputtering target for transparent conductive films is demonstrated based on said this embodiment.

[0092] The making of sputtering target of the present invention:

[0093] As a raw material powder, Al with a purity of 99.9% or more and an average particle size of 0.4 μm is weighed and blended 2 o 3 Raw material powder, MgO raw material powder with a purity of 99.9% or higher and an average particle size of 1 μm, Ga with a purity of 99.9% or higher and an average particle size of 0.3 μm 2 o 3 Raw material powder and ZnO raw material powder with a purity of 99.9% or more and an average particle size of 0.4 μm, so that it becomes the predetermined composition shown in Table 1, is put into a polyethylene pot, and ZrO with a diameter of φ3 (diameter φ3mm) is used 2 The balls are ball milled, and the average particle size of the mixed powder is pulverized to less than 0.4 μm (in addition, the solvent used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com