Patents

Literature

43results about How to "Lower densification temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing compact ultrafine-grain boron carbide ceramic material with reduced sintering temperature

ActiveCN106854080ALow melting pointLower densification temperatureHigh entropy alloysEnergy consumption

The invention discloses a method for preparing a compact ultrafine-grain boron carbide ceramic material with a reduced sintering temperature. The method comprises the following steps: selecting coarse boron carbide powder with an average particle size of less than 20 [mu]m and carrying out ball milling and settlement so as to obtain ultrafine boron carbide powder with a particle size of less than 1 [mu]m; mixing the ultrafine boron carbide powder with MnNiCoCrFeX high-entropy alloy powder and carrying out ball milling so as to obtain B4C-MnNiCoCrFeX mixed powder; and subjecting the mixed powder to pressure sintering so as to obtain the compact ultrafine-grain boron carbide ceramic material with a reduced sintering temperature. According to the invention, the MnNiCoCrFeX high-entropy alloy powder is added into a boron carbide matrix, so a liquid phase is formed during high-temperature sintering and can fill in pores, and thus, the sintering densification temperature of the boron carbide ceramic material is effectively reduced, and energy consumption is decreased; and a boron carbide product with a density of greater than 99% is obtained after a temperature of 1900 DEG C is maintained for 5 min, and compared with the prior art, sintering temperature is reduced by 200 DEG C and heat preservation time is substantially shortened.

Owner:CENT SOUTH UNIV

Preparation method of high-thermal-conductivity silicon nitride substrate

ActiveCN111170745AImprove thermal conductivityLarge specific surface areaOrganic solventGas pressure sintering

The invention discloses a preparation method of a high-thermal-conductivity silicon nitride substrate, which belongs to the technical field of ceramic material preparation. Silicon nitride powder is adopted as a raw material, rare earth oxide and alkaline earth metal oxide are added to serve as a mixed sintering aid, the adding amount is 6 wt%-10 wt%, a high-molecular compound is added, ball milling and mixing are conducted in an organic solvent, and slurry is formed. Tape casting is carried out to form a green body, presintering of the green body in nitrogen at 1400-1600 DEG C for 1-5 hours is conducted, and heat preservation in an air pressure sintering furnace at 1800-2000 DEG C for 2-10 hours is carried out under the nitrogen pressure of 0.5-3 MPa. The silicon nitride powder used in the invention is high-purity alpha-phase silicon nitride, has very high specific surface area and high sintering activity, and can effectively reduce the densification temperature. The added high-molecular carbon-containing compound is a multi-component compound and is degreased and pre-sintered in an inert atmosphere, so that the thermal conductivity of the product can be improved. The thermal conductivity of the prepared silicon nitride ceramic substrate is not lower than 90 W / m.K, and the bending strength is not lower than 800 MPa.

Owner:UNIV OF SCI & TECH BEIJING

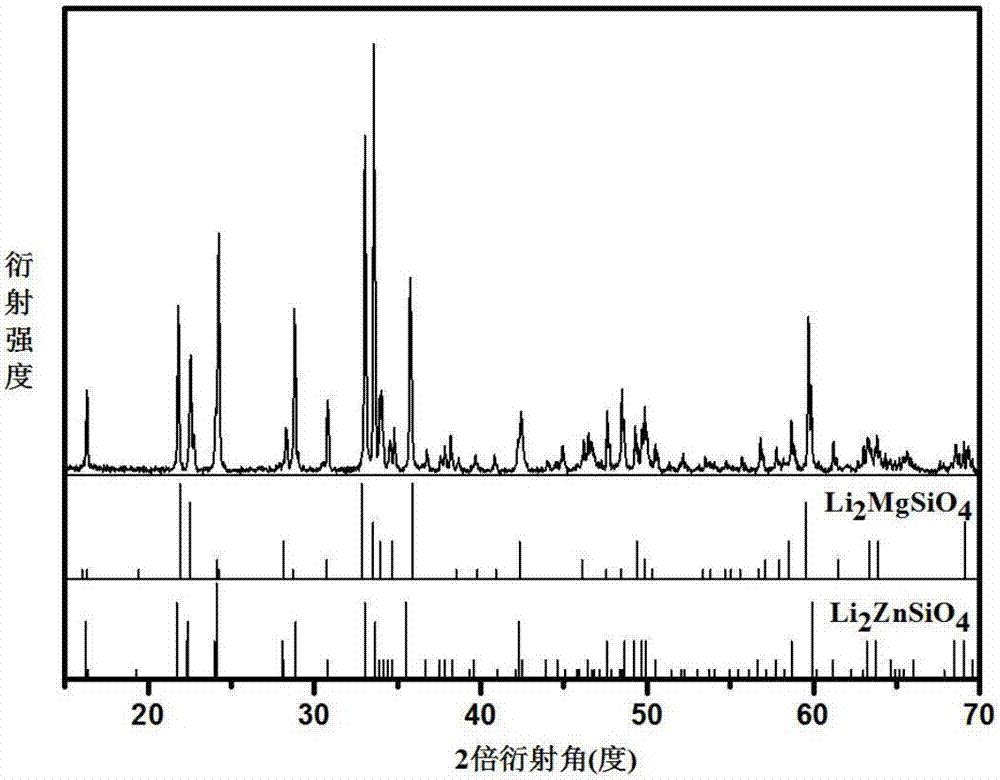

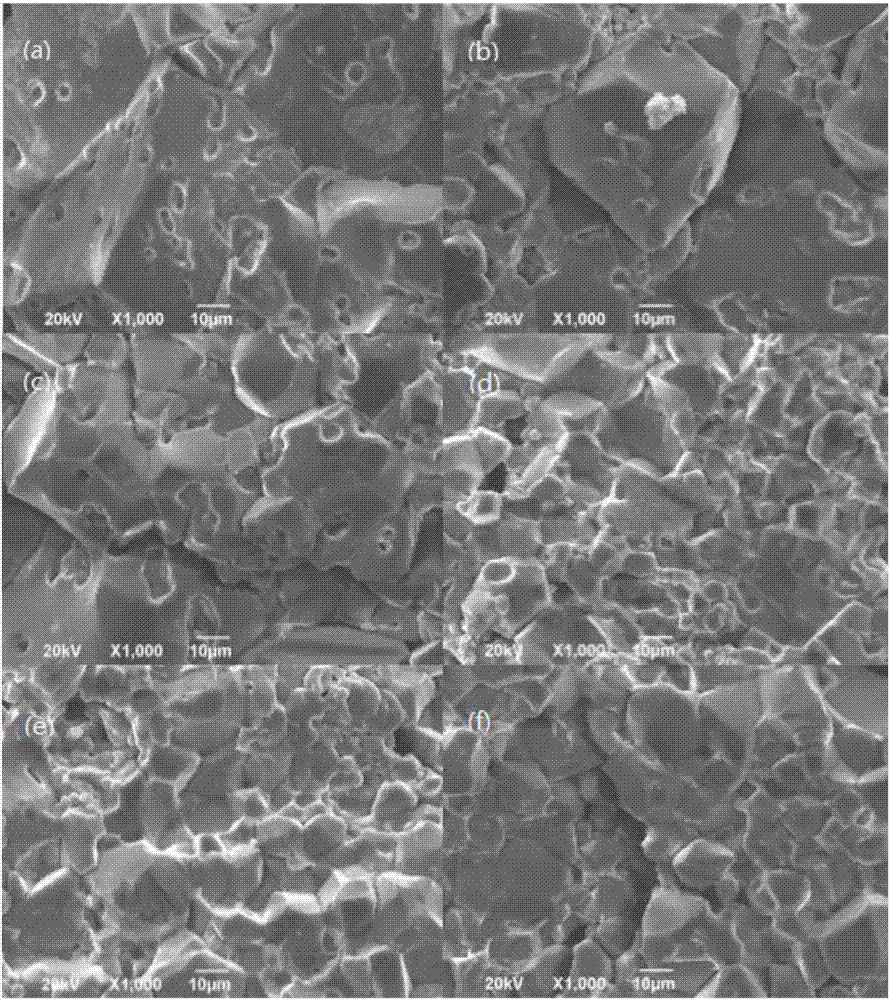

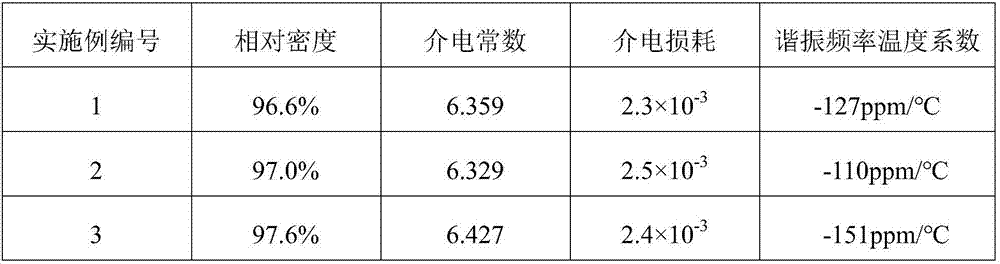

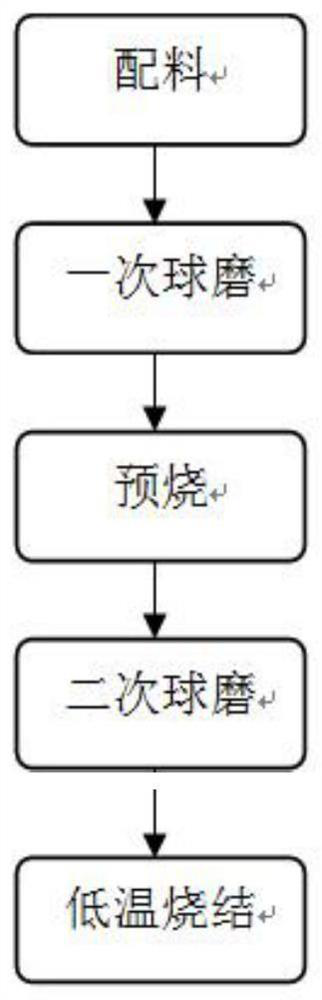

Low-temperature preparation method of low-dielectric microwave medium ceramic

The invention discloses a low-temperature preparation method of low-dielectric microwave medium ceramic, and belongs to the technical field of microwave medium ceramic. According to a chemical formula Li2(Mg1-xZnx)SiO4, burdening, ball mixing, drying and presintering are carried out to form a crystal phase, and then, compound sintering aids are added into presintered powder to carry out secondary ball mixing, drying and low-temperature sintering, so as to finally obtain the microwave medium ceramic material. Zn<2+> is used for replacing Mg<2+> so as to preliminarily lower the densifying temperature of the microwave medium ceramic and improve the dielectric property of the microwave medium ceramic; the compound sintering aids form a liquid phase in a subsequent sintering process, so that the sintering temperature is further lowered to 900DEG C, and in addition, the compactness of a microwave medium ceramic material is improved. Preparation with the method provided by the invention is favorable for application of Li2MgSiO4-based microwave medium ceramic with a low dielectric constant and a high quality factor into LTCC (Low Temperature Co-Fired Ceramic), and the requirements of the microwave communication industry are met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

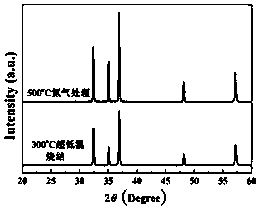

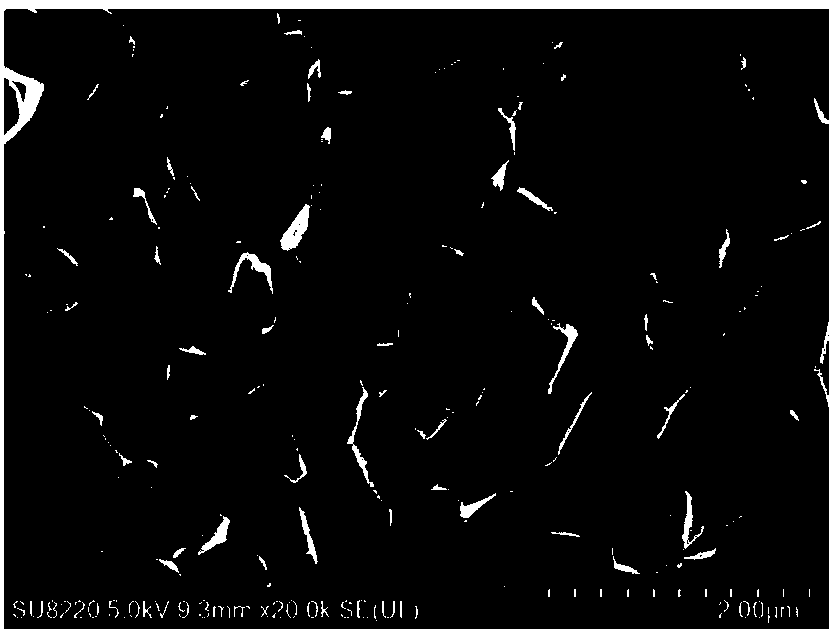

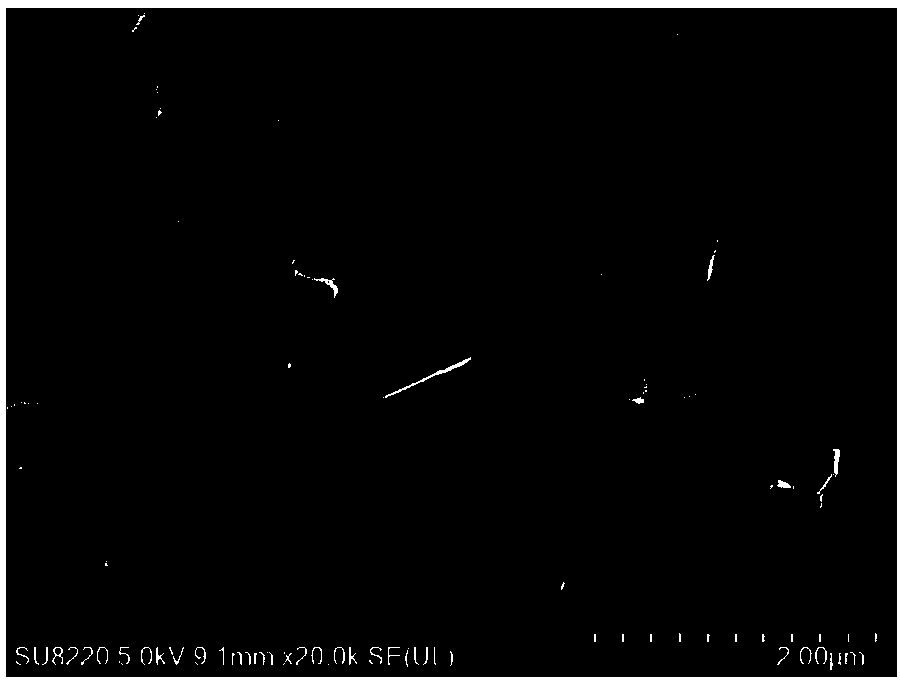

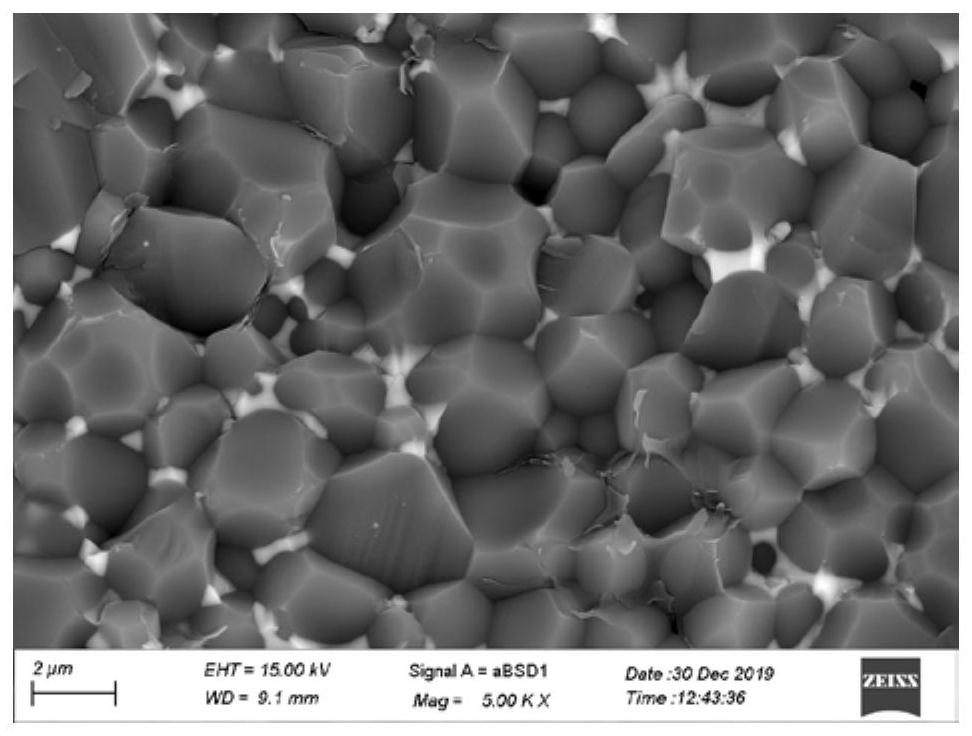

Method for preparing high-conductivity zinc oxide ceramic at ultralow temperature

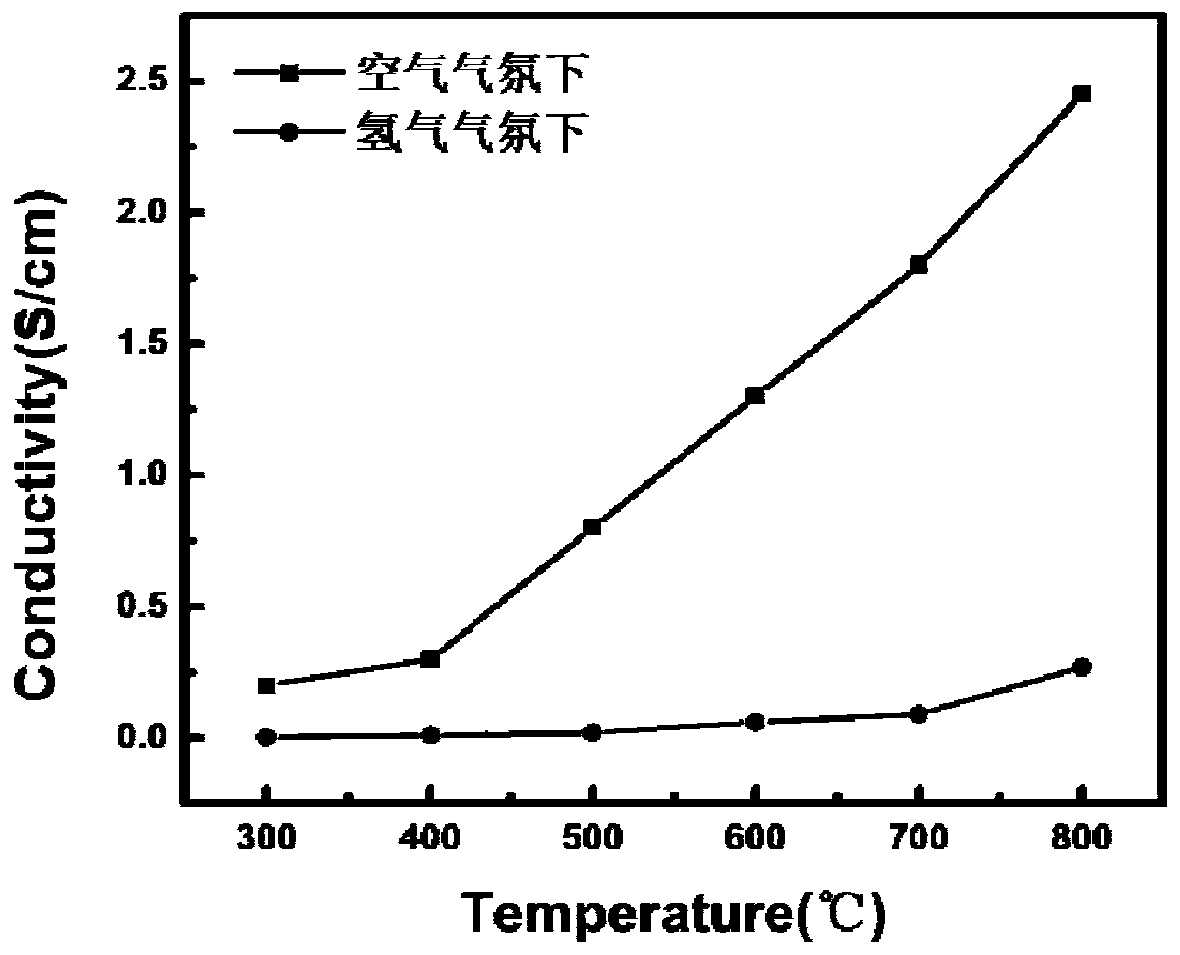

ActiveCN108546110ALower densification temperatureImprove crystallization propertiesEnvironmental resistanceOxide ceramic

The invention discloses a method for preparing high-conductivity zinc oxide ceramic at ultralow temperature. The method comprises the following steps: taking zinc oxide powder as a raw material and anorganic acid solution or a zinc acetate solution as a solvent, grinding, pelleting, performing ultralow temperature sintering, and thermally treating in an inert atmosphere, thereby obtaining the zinc oxide ceramic. The densification temperature of the zinc oxide ceramic prepared according to the preparation method is far lower than that in a traditional sintering method, the density of the zincoxide ceramic prepared according to the preparation method can reach 99.0% or above, the crystalline grain size can be controlled to be below 2 mu m, and the conductivity can reach 1.5 S / cm or higher.The preparation method has the advantages of being simple in process, low in energy consumption, greens environmental protection, high practicability and good application prospect.

Owner:GUANGXI UNIV

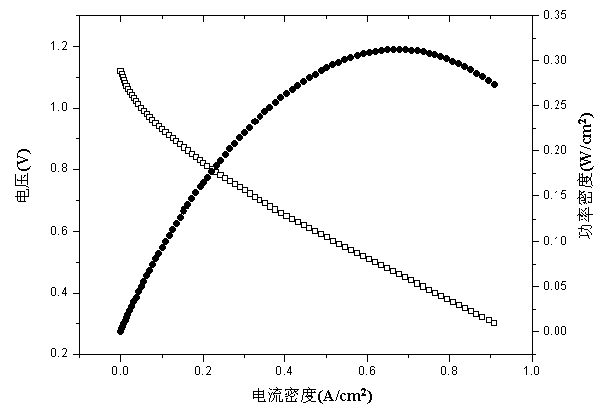

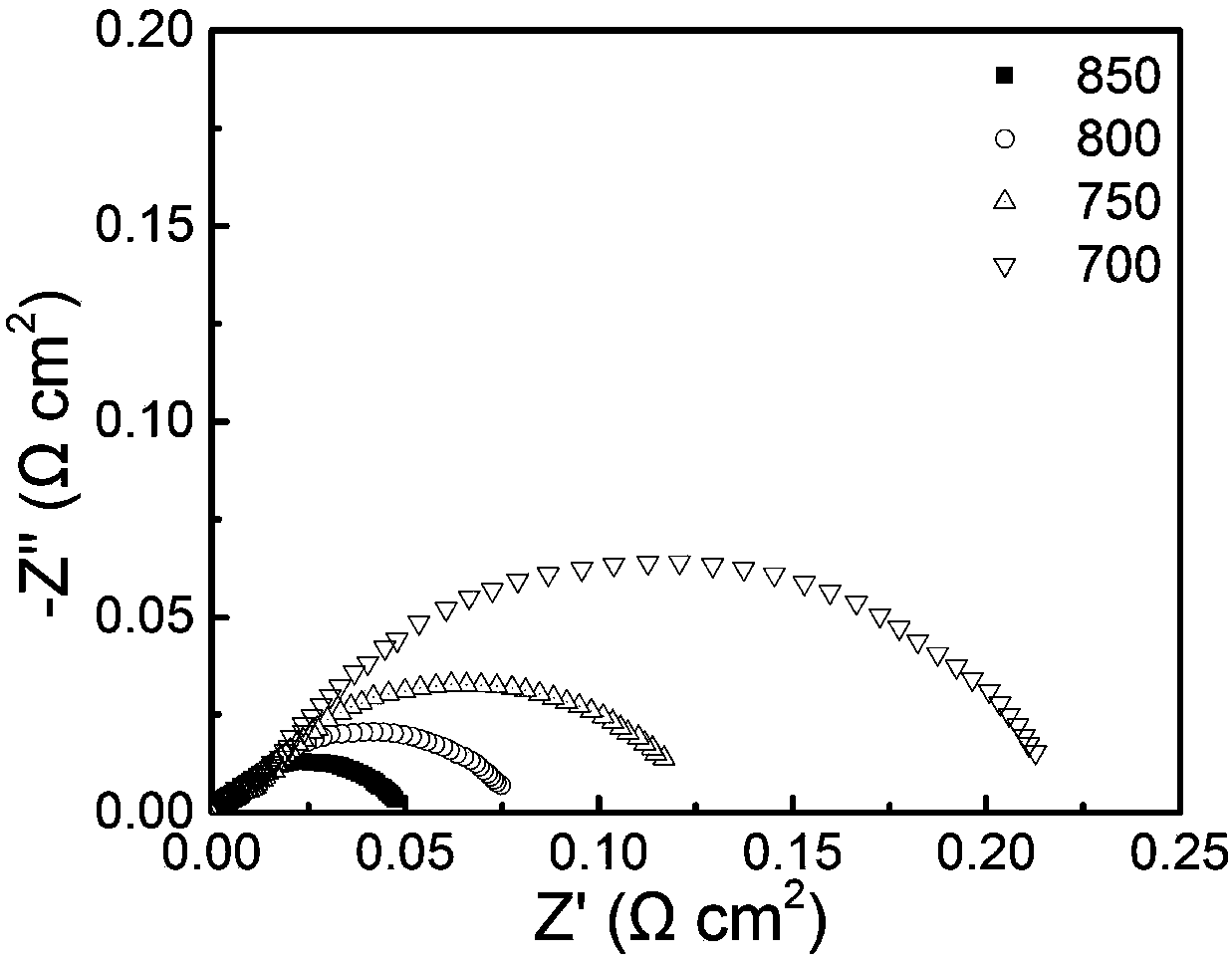

Sintering method of electrolytes for solid oxide fuel cell

ActiveCN105140548ALower densification temperatureSintered denseSolid electrolyte fuel cellsFurnace temperatureFuel cells

The invention relates to a sintering method of electrolytes for a solid oxide fuel cell, and belongs to the field of solid oxide fuel cells. The method comprises the steps as follows: a binder is added to solid oxide electrolyte powder which is pressed into a block; different electric fields are applied to different electrolytes; the field intensity can be adjusted from 30Vcm<-1> to 200Vcm<-1>; meanwhile, the electrolytes are heated in a furnace; the current is instantly increased when the electrolytes are heated to 500-1250 DEG C; the current is limited; and constant-current heat-insulated sintering is carried out, so that the electrolytes are densely sintered. Compared with a conventional electrolyte sintering method, the sintering method provided by the invention has the advantages that the sintering method is low in furnace temperature requirements and high in sintering rate; electrolyte ceramic which is difficult to sinter can be densified; a sintering aid does not need to be added; and a device is simple and convenient.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

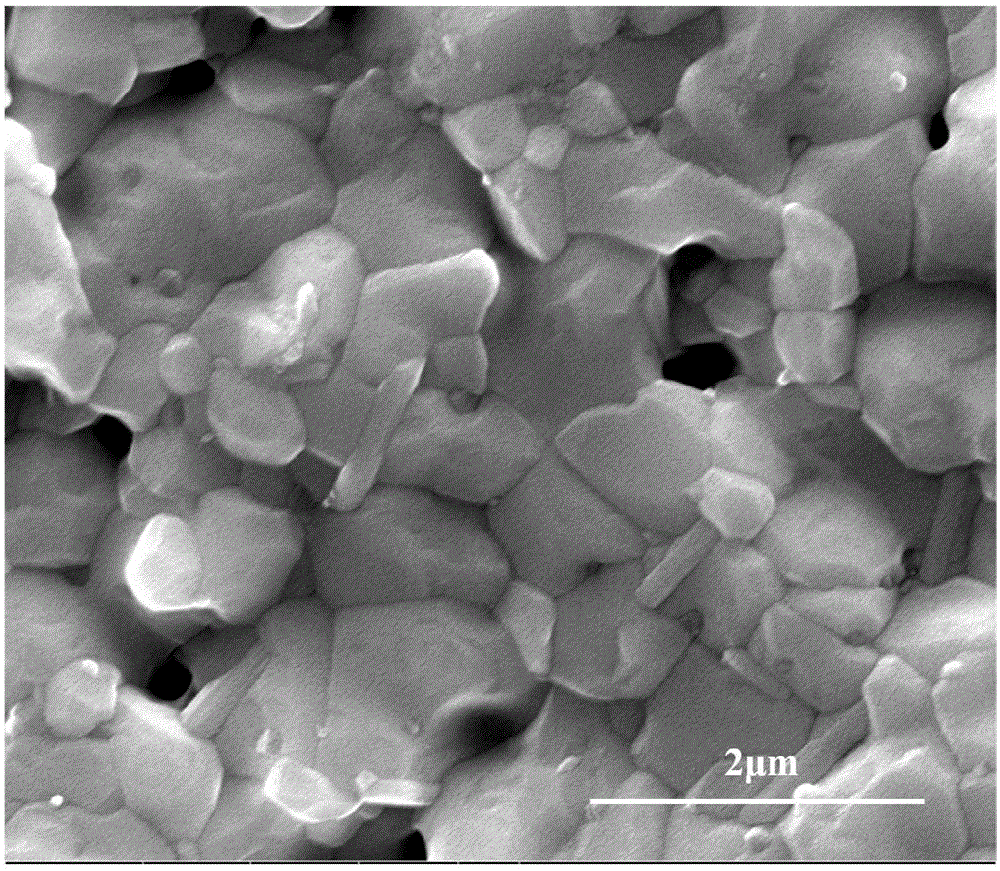

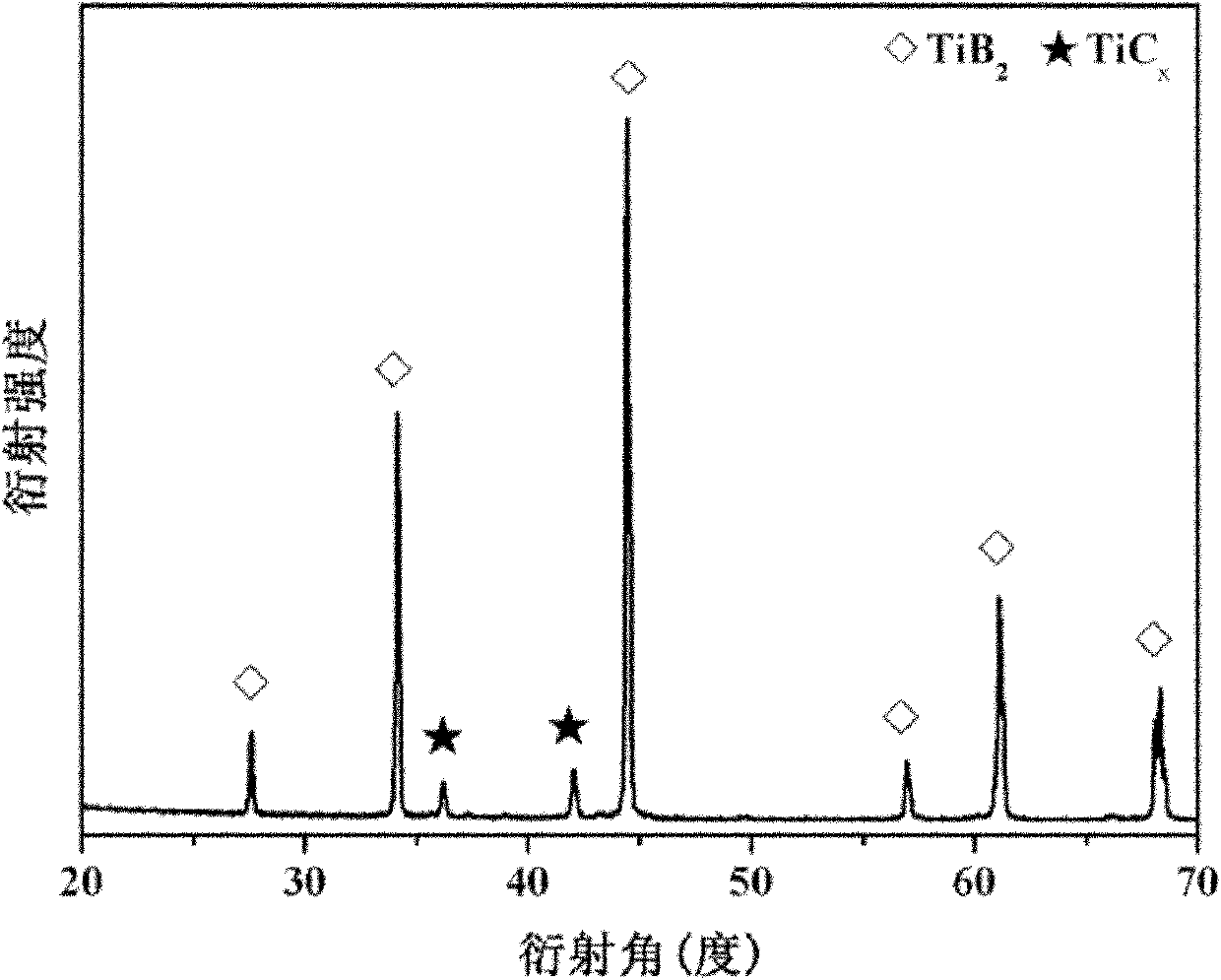

Method for preparing titanium diboride ceramic with titanium aluminum carbon as sintering aid

The invention relates to the field of boride ceramics, and particularly provides a method for preparing a compact titanium diboride (TiB2) bulk material with ternary layered carbide titanium aluminum carbon (Ti3AlC2) as a sintering aid at a low temperature. By adopting the method of the invention, a problem that titanium diboride ceramic is difficult to sinter can be solved. The method comprises the steps of adopting TiB2 powder and Ti3AlC2 powder with different mass ratios as raw materials, mixing the raw materials for 5-40h through a physical mechanical method, cold pressing to a cake shapeat a pressure of 5-20Mpa, placing into a graphite mould and heating to 1400-1600 DEG C and reacting for 0.5-4h in situ at a pressure of 20-40MPa under the circumstance that an inert gas is introducedto serve as protective atmosphere. By adopting the method provided by the invention, the TiB2 ceramic material with excellent mechanical property can be synthetized at a low temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

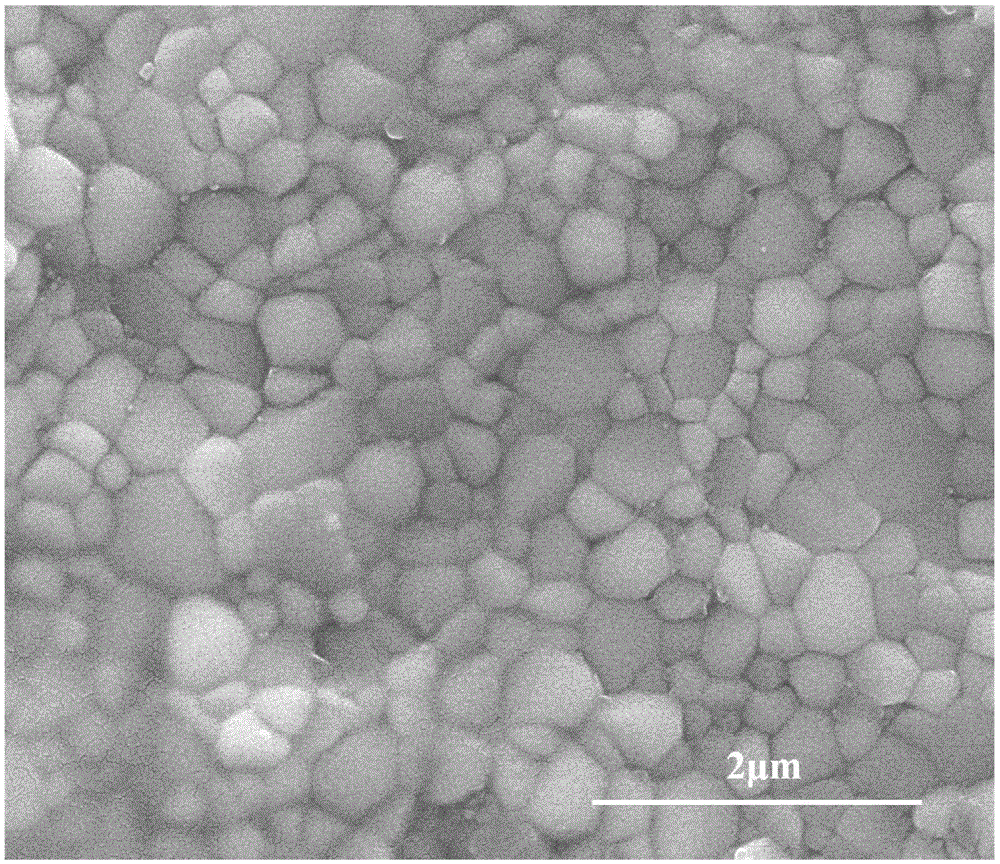

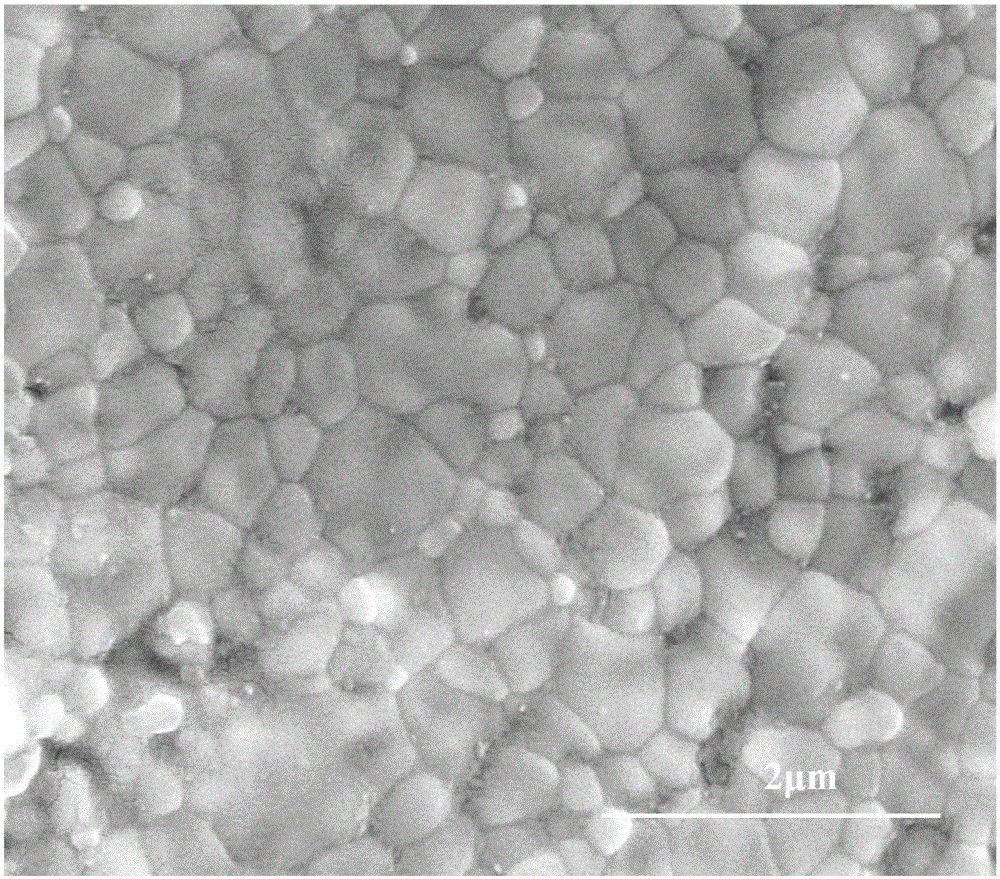

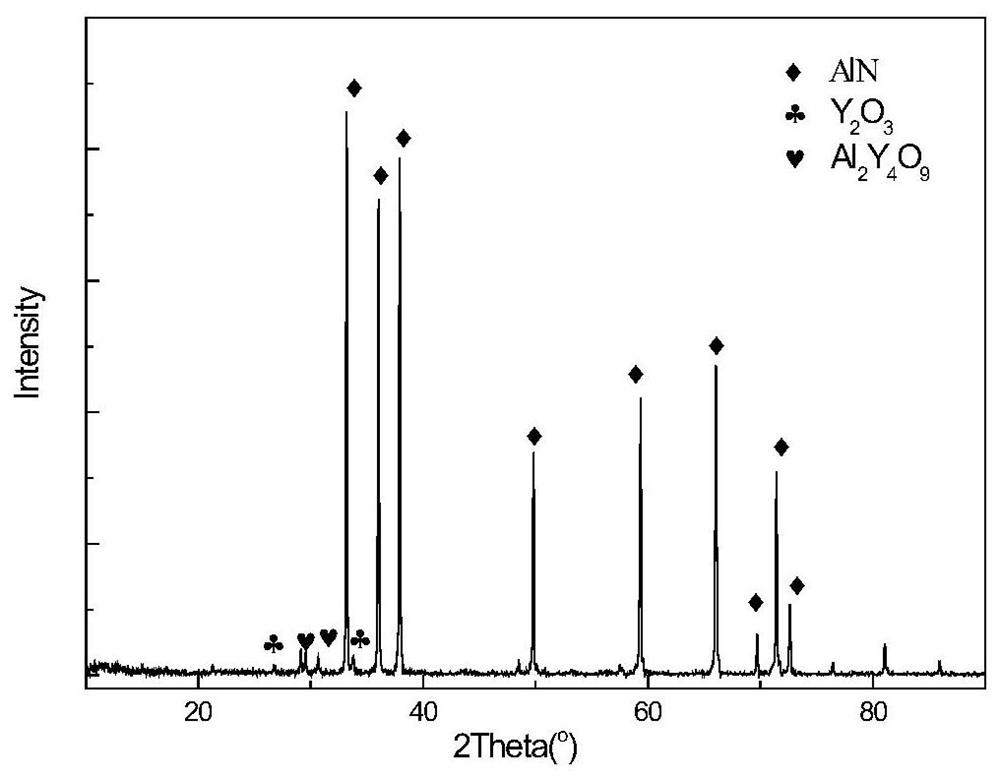

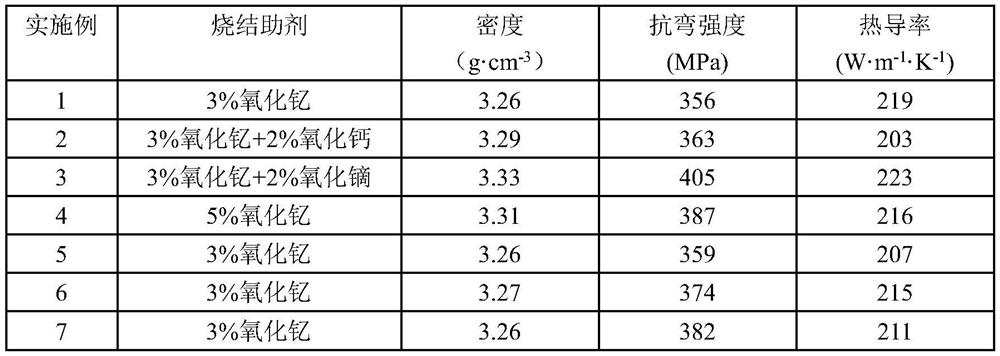

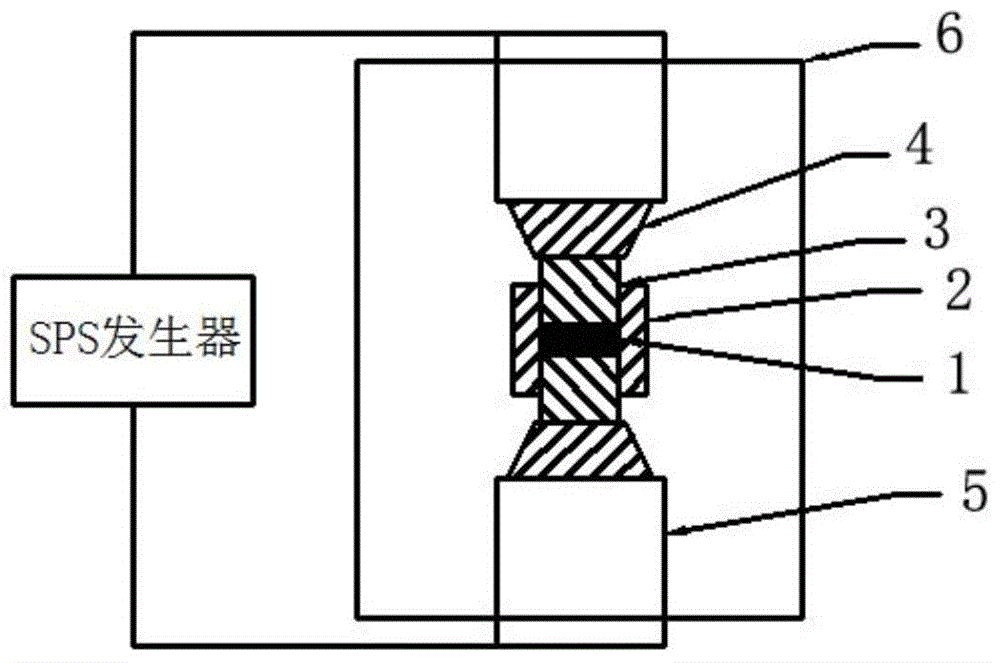

Method for preparing aluminum nitride ceramics with high heat conduction and high strength by SPS sintering

The invention discloses a method for preparing aluminum nitride ceramics with high heat conduction and high strength by SPS sintering, and belongs to the technical field of ceramic material preparation. Aluminum nitride powder with the primary particle size of less than 200 nm is used as a raw material, rare earth metal fluoride is added as a sintering aid, and the addition amount is 1 wt%-4 wt%.The raw material powder is subjected to powder mixing, formed and pre-sintered in a nitrogen-containing reducing atmosphere, and then is sintered by spark plasma under the protection of high-purity nitrogen, wherein the sintering temperature is 1500 DEG C-1700 DEG C, the heat preservation time is 1-6 min, and the axial pressure is 30-50 MPa. The aluminum nitride ceramics having grain size of lessthan 1 micron, the thermal conductivity of not less than 100 W / m.K, the bending strength of not less than 700 MPa and the hardness of not less than HRC 94 are prepared.

Owner:UNIV OF SCI & TECH BEIJING

Zirconia nano ceramic material

The invention discloses a zirconia nano ceramic material simply prepared by conventional low-temperature sintering. The material can be sintered and densified without pressure at the temperature of lower than 1,000 DEG C, and has a two-phase composite structure consisting of a single oblique phase and a square phase; and the grain sizes of the two phases are less than 100 nanometers. The material has the characteristics of simple preparation process, small sintered grains and high compactness.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Silicon nitride ceramic with hard outside and tough inside and preparation method thereof

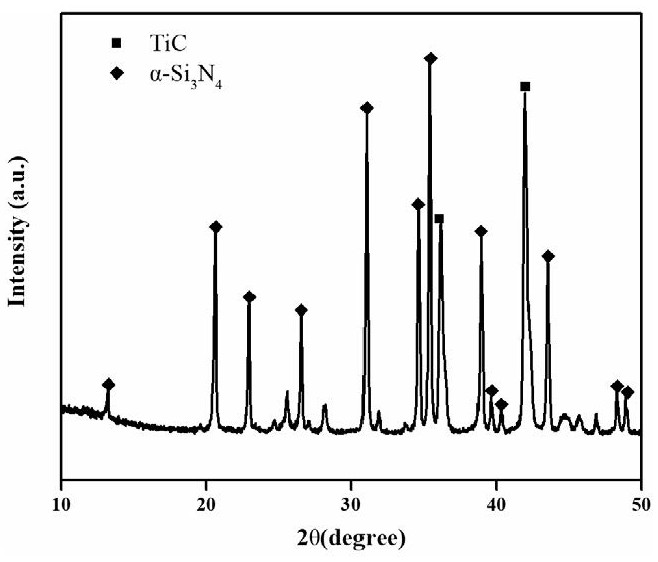

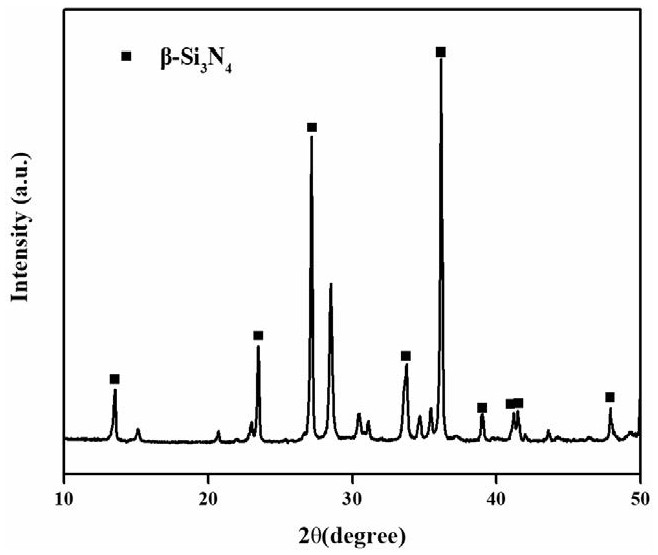

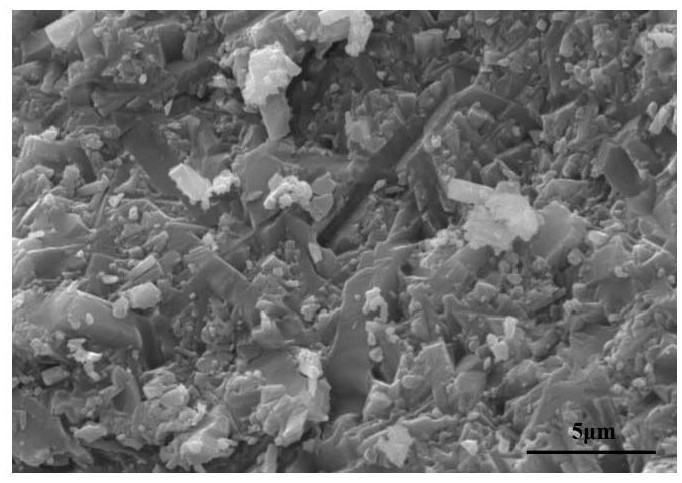

The invention relates to silicon nitride ceramic with hard outside and tough inside and a preparation method thereof. The Si3N4 ceramic with hard outside and tough inside comprises three layers of silicon nitride ceramic; wherein the middle layer is an inner layer, and the upper and lower layers are outer layers; the main phase of the inner layer is beta-Si3N4, preferably, 88-89.5 wt% of silicon nitride powder is used as a raw material, 10.5-12 wt% of Al2O3-Er2O3-ZrSi2 is used as a sintering aid, and the inner layer is prepared through hot pressed sintering; the main phase of the outer layer is alpha-Si3N4, preferably, 60.5-71.5 wt% of silicon nitride powder is used as a raw material, 8.5-9.5 wt% of Al2O3-Nd2O3-LiF is used as a sintering aid, 20-30 wt% of TiC is used as a second phase, and the outer layer is obtained through secondary hot pressing sintering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

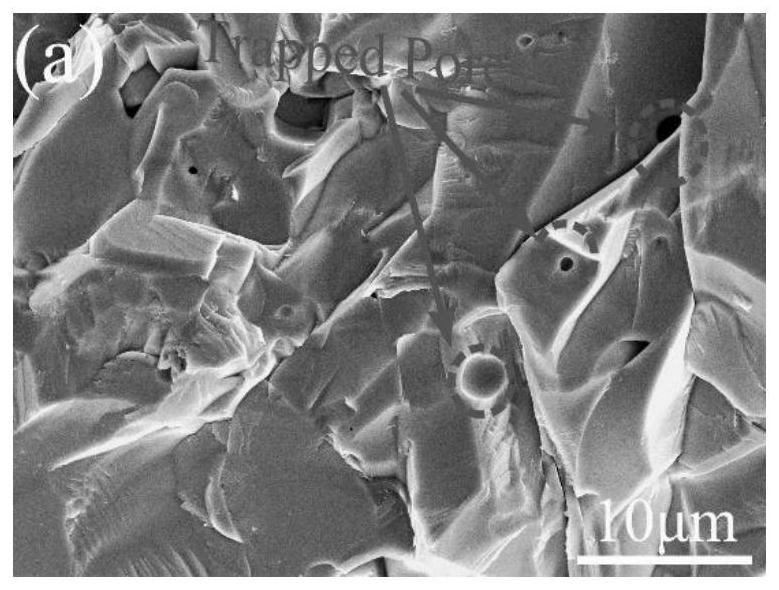

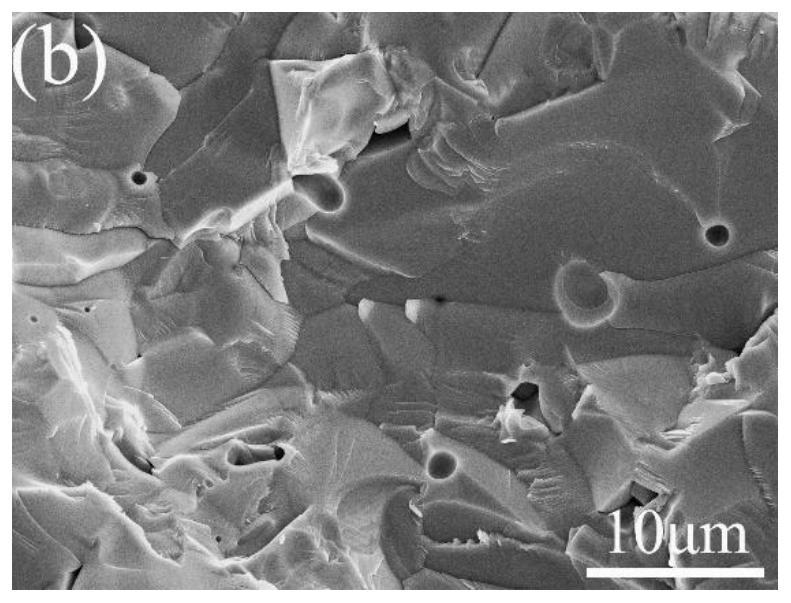

High flux ferrite powder capable of reducing cracking

ActiveCN109665829AImprove one-dimensional compressibilityHigh dimensional consistencyInorganic material magnetismSesquioxideSlurry

The invention discloses high flux ferrite powder capable of reducing cracking. The raw materials of the high flux ferrite powder capable of reducing the cracking comprise the following components in parts by mole: 51.0 to 55.0 parts of iron sesquioxide, 21.0 to 25.0 parts of zinc oxide, and 20.0 to 28.0 parts of manganese oxide; glue with 0.7 to 1.5 weight parts of solid is added and a certain weight of an inert nano-composite material. Polyvinyl acetate with the glass transition temperature of less than 40 DEG C is added so that the one-dimensional compressibility of the powder is greatly improved; the inert nano-composite particles which are prepared by the main components of nano-amorphous iron oxide (or hydroxyl ferric oxide) and manganous-manganic oxide are adopted, so that the a gluedischarging channel can be provided in an early stage, and the inert nano-composite particles can be molten in original crystal particles without affecting the main component of the ferrite in a lateperiod; and the wear of slurry and a spraying piece of a spraying gun of a spraying tower can be reduced by performing spray-granulating by adopting the ferrite slurry which is coated by the inert nano-material which is coated by adopting a resistance reducing agent, namely a hydroxyethyl cellulose solution, so that the cost is reduced, and meanwhile, the size consistency of the particles is improved.

Owner:山东春光磁电科技有限公司

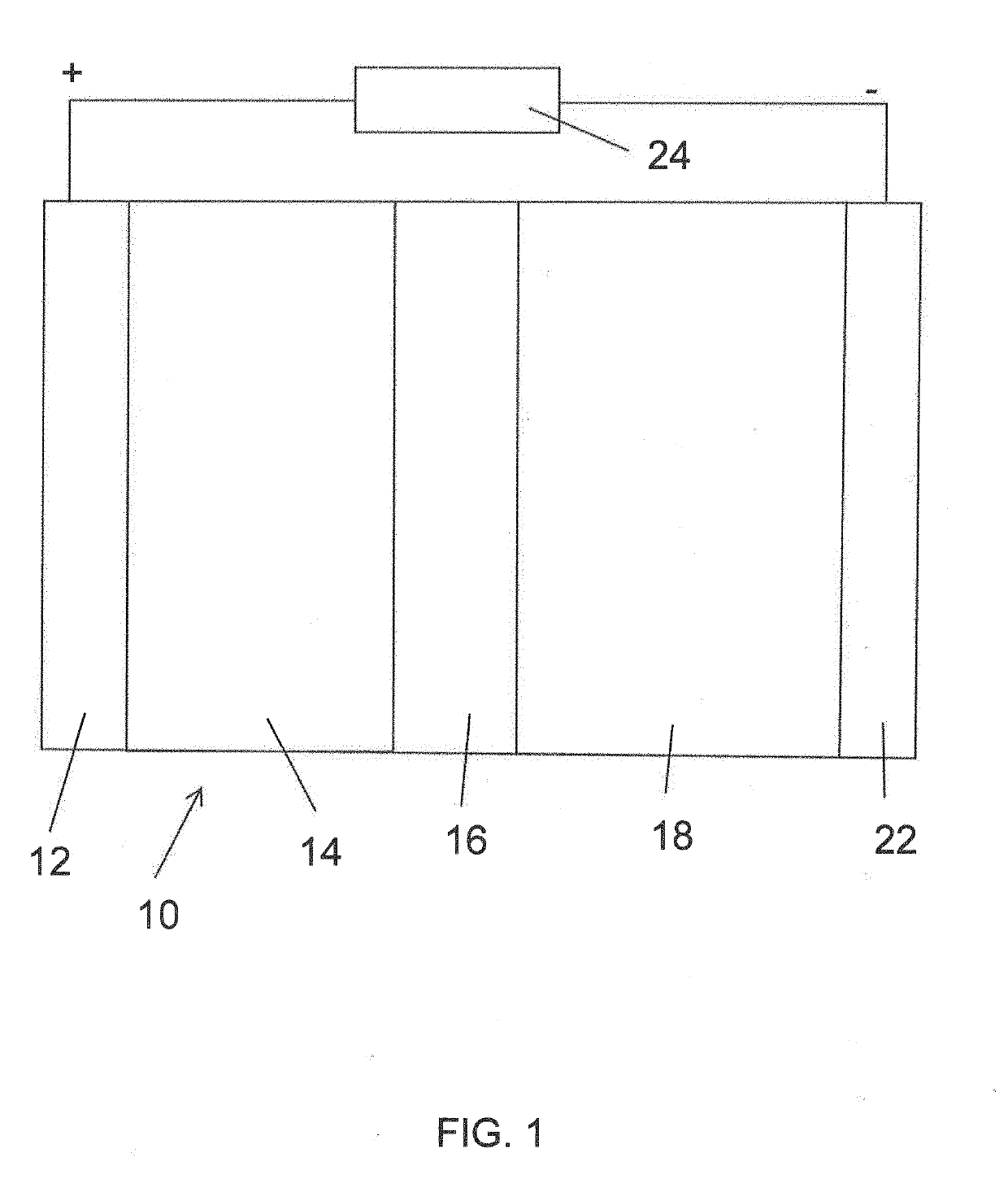

Bi Containing Solid Oxide Fuel Cell System With Improved Performance and Reduced Manufacturing Costs

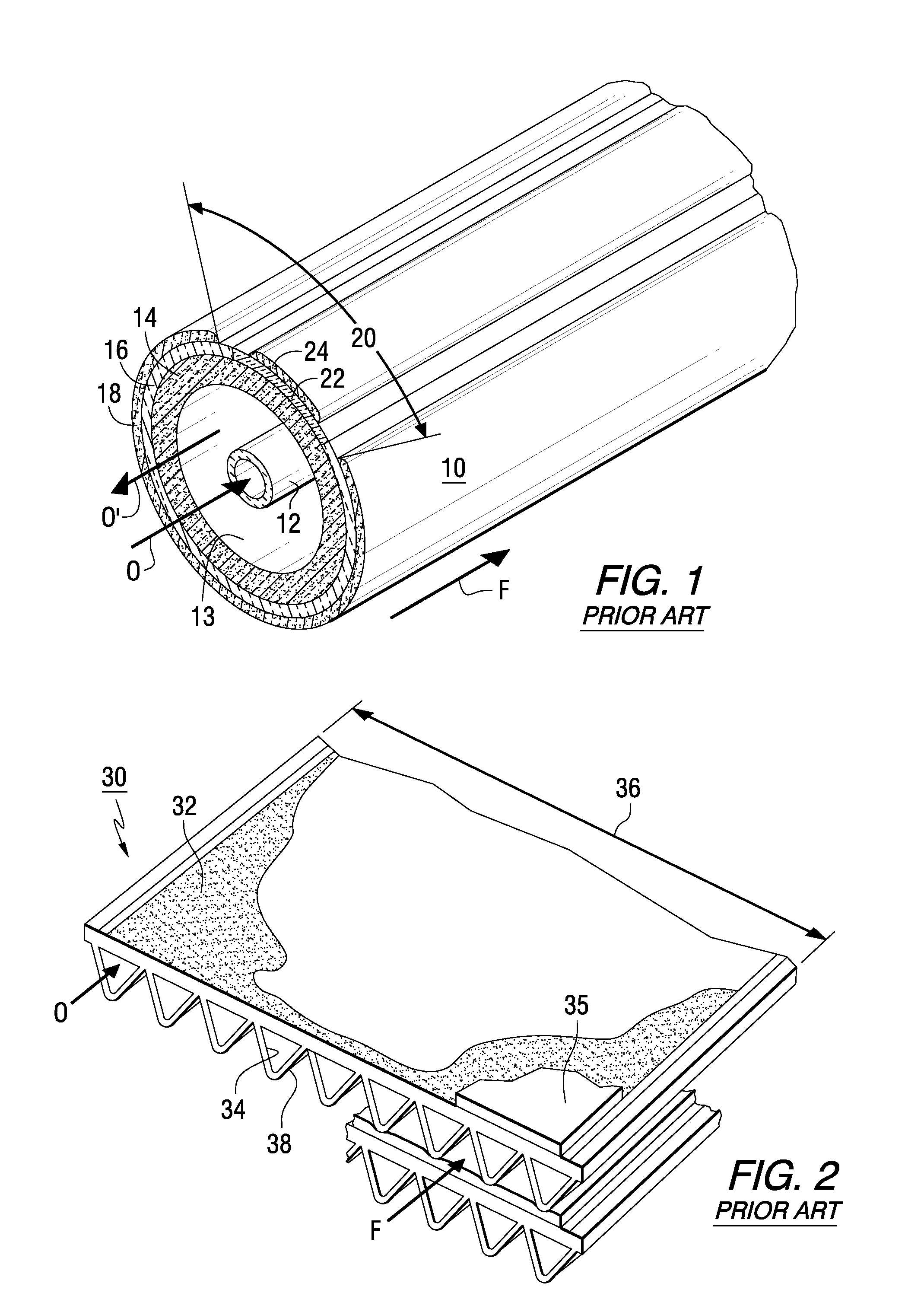

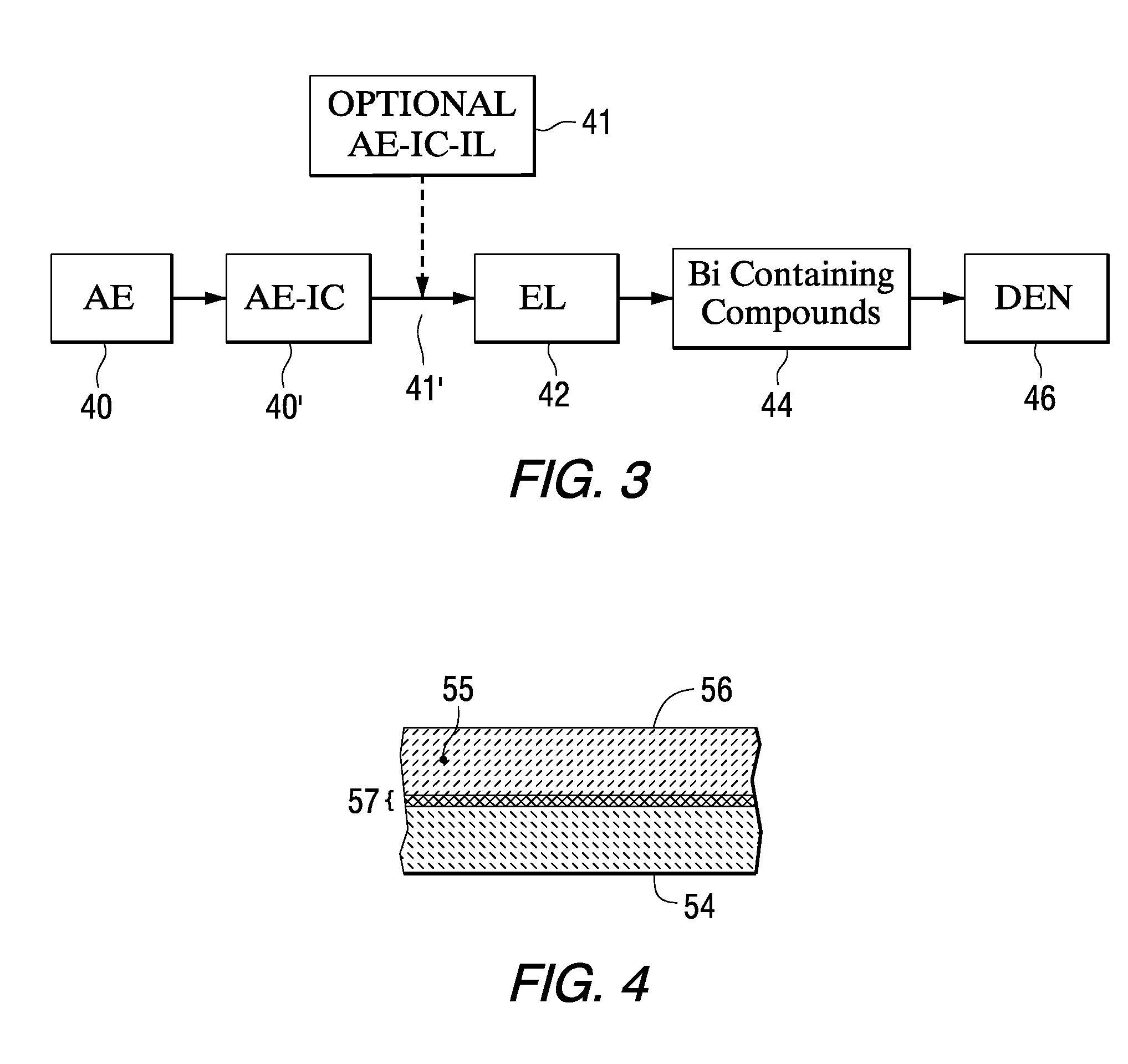

InactiveUS20100325878A1Elimination of plasma spraying techniquesReduce resistanceFinal product manufacturePrimary cellsFuel cellsBismuth compound

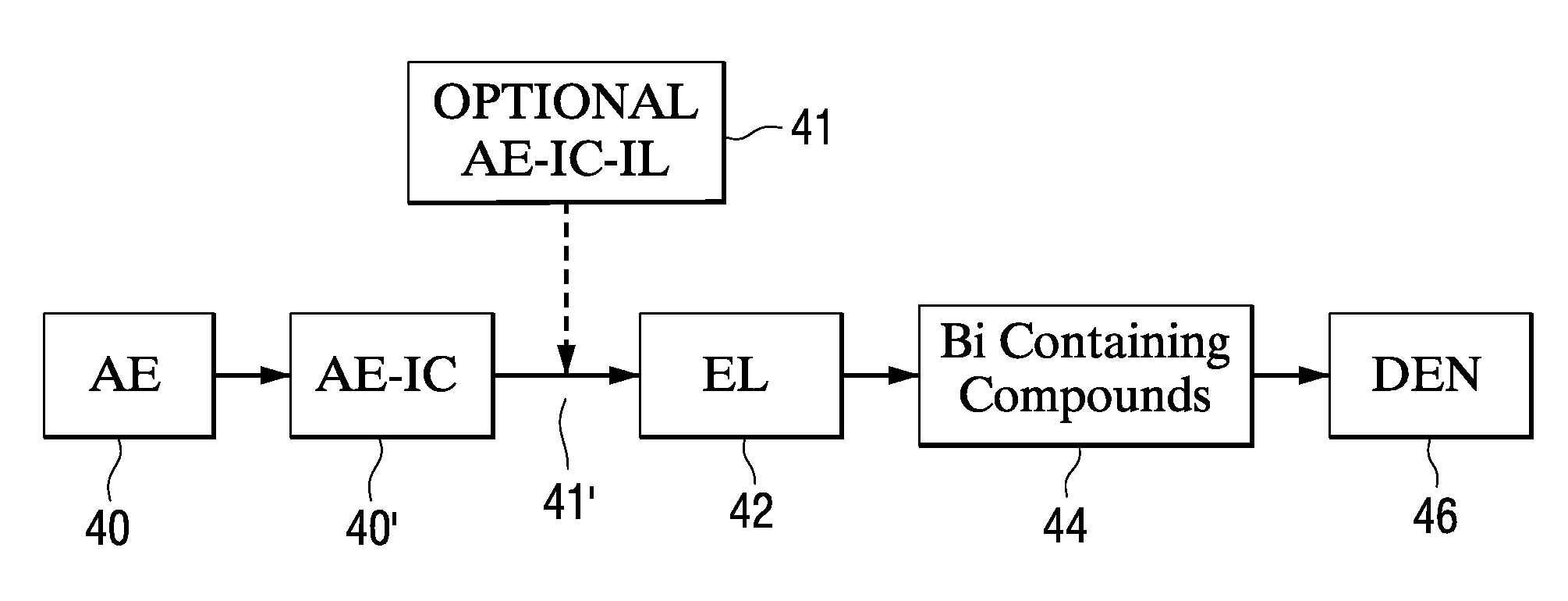

A method to provide a tubular, triangular or other type solid oxide electrolyte fuel cell has steps including providing a porous air electrode cathode support substrate, applying a solid electrolyte and cell to cell interconnection on the air electrode, applying a layer of bismuth compounds on the surface of the electrolyte and possibly also the interconnection, and sintering the whole above the melting point of the bismuth compounds for the bismuth compounds to permeate and for densification.

Owner:SIEMENS ENERGY INC

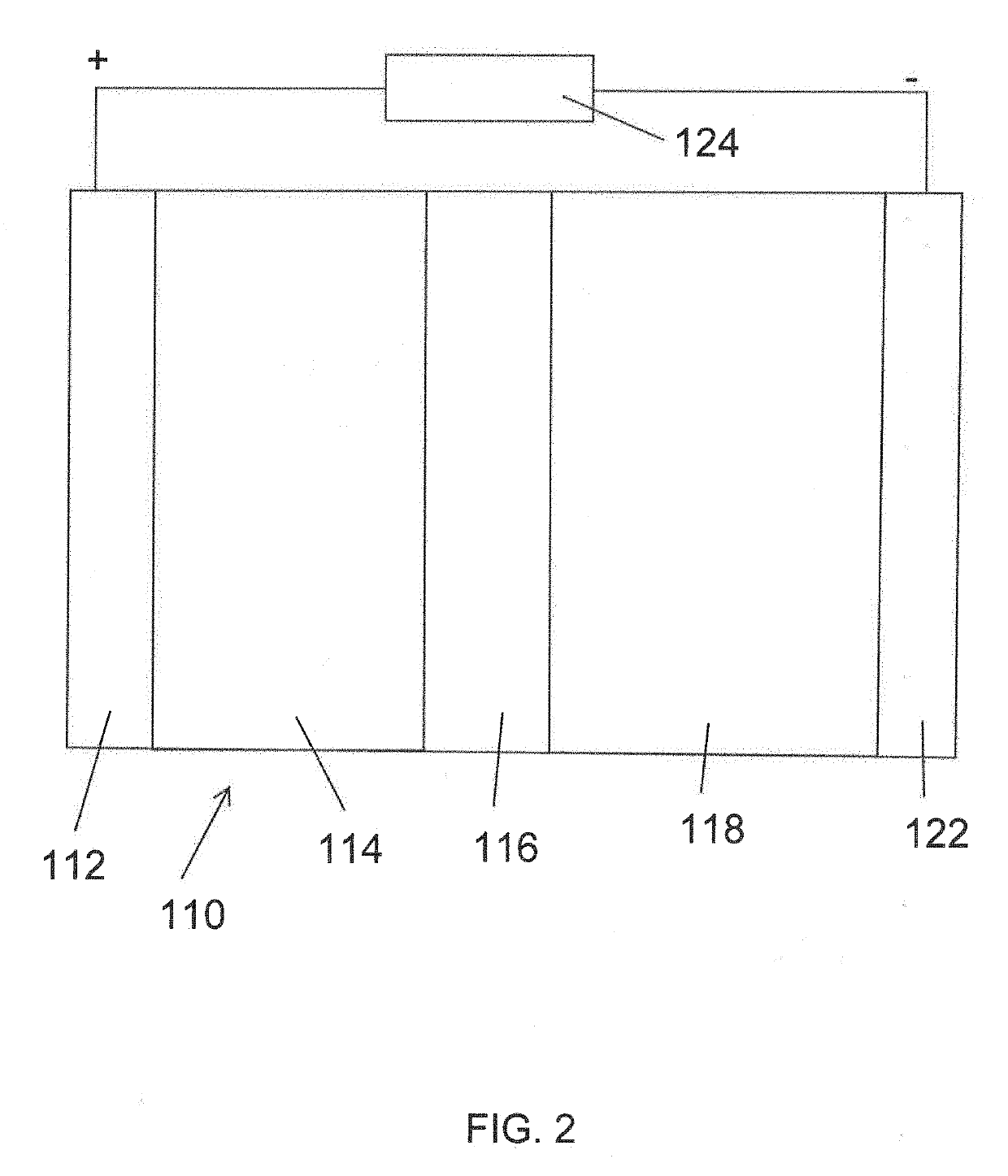

Vacuum impregnation coating method and device for planar solid oxide fuel cell (SOFC) electrolyte

InactiveCN103682388AHigh solid contentLower densification temperatureSolid electrolyte fuel cellsFuel cell detailsOxideSolid oxide fuel cell

The invention relates to a vacuum impregnation coating method and device for planar solid oxide fuel cell (SOFC) electrolyte. The method comprises the step of impregnating a planar solid oxide fuel cell supporting body into electrolyte slurry under a vacuum state, wherein the supporting body can keep still so as to lift a slurry tank containing the electrolyte slurry in the impregnation process. The method not only can be used for preparing a large-area anode supporting panel SOFC, but also can be used for preparing a large-area cathode supporting panel SOFC.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of high thermal conductivity and high strength aluminum nitride ceramics

The invention discloses a preparation method of high thermal conductivity and high strength aluminum nitride ceramics, belonging to the technical field of preparation of ceramic materials. According to the preparation method, aluminum nitride powder with a primary particle size less than 200nm is used as a raw material; an oxide or a halide of a rare earth metal is added as a sintering aid, and the adding amount is 1-6wt%. The method comprises the steps of mixing and molding the raw material powder, then pre-sintering for 1-5h at the temperature of 1300-1500 DEG C in a nitrogen-containing reducing atmosphere under the normal pressure, and then sintering for 3-10h at the temperature of 1500-1800 DEG C in a nitrogen atmosphere. The prepared aluminum nitride ceramics has a grain size of lessthan 3mu m, a thermal conductivity of not less than 150W / m.K, a bending strength of not less than 500MPa, and a hardness of not less than HRC 88.

Owner:UNIV OF SCI & TECH BEIJING

Microwave dielectric ceramic material as well as preparation method and application thereof

ActiveCN111807831ALow component complexityLow dielectric constantLow-k dielectricDielectric ceramics

The invention provides a microwave dielectric ceramic material as well as a preparation method and application thereof. The microwave dielectric ceramic material comprises two materials, namely Zn3B2O6 and Mg3B2O6, the molar ratio of Zn3B2O6 to Mg3B2O6 is (1-x): x, and x is equal to 0.05-0.40. The microwave dielectric ceramic material is prepared from the following oxides in percentage by mole: 71.25-45.00% of a main material ZnO, 25.00% of a main material B2O3, and 3.75-30.00% of a substitute material MgO, wherein the sum of the molar percentages of the components is 100%, and the molar ratioof ZnO to MgO is (0.95: 0.05)-(0.60: 0.40). The microwave dielectric ceramic material has the excellent characteristics of low dielectric constant, high quality factor, high relative density, relatively stable temperature characteristic and low densification temperature.

Owner:YANCHUANG PHOTOELECTRIC TECH GANZHOU

Pressureless sintering preparation method of Ti2SC ceramic

A pressureless sintering preparation method of Ti2SC ceramic is characterized by comprising the following steps: (1) evenly mixing Ti2SC ceramic powder with polyvinyl alcohol PVA, and then filling into a die for preforming; (2) performing cold isostatic pressing treatment on the preformed Ti2SC ceramic; (3) putting the cold isostatic pressing treated Ti2SC ceramic into a microwave sintering furnace filled with inert gas protective atmosphere for sintering for 20-60 minutes at 800-1100 DEG C to obtain the Ti2SC bulk ceramic; the preparation method not only improves the density of the ceramic material, realizes the controllable density of the Ti2SC ceramic material, can prepare Ti2SC ceramic materials with complex shapes, and has the advantages of low sintering temperature, short time, saving energy and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

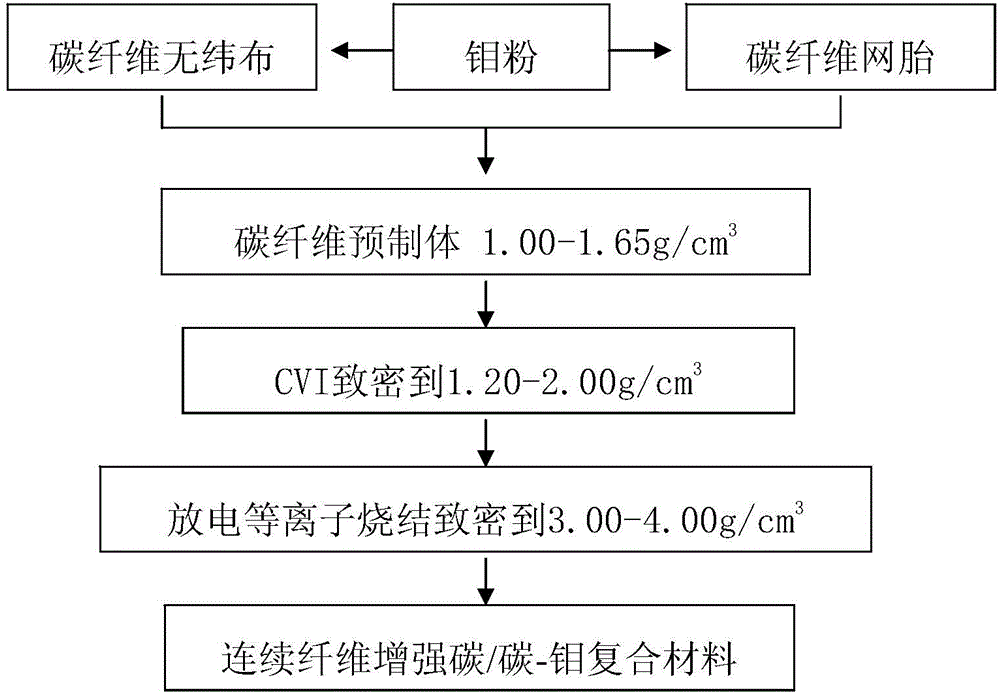

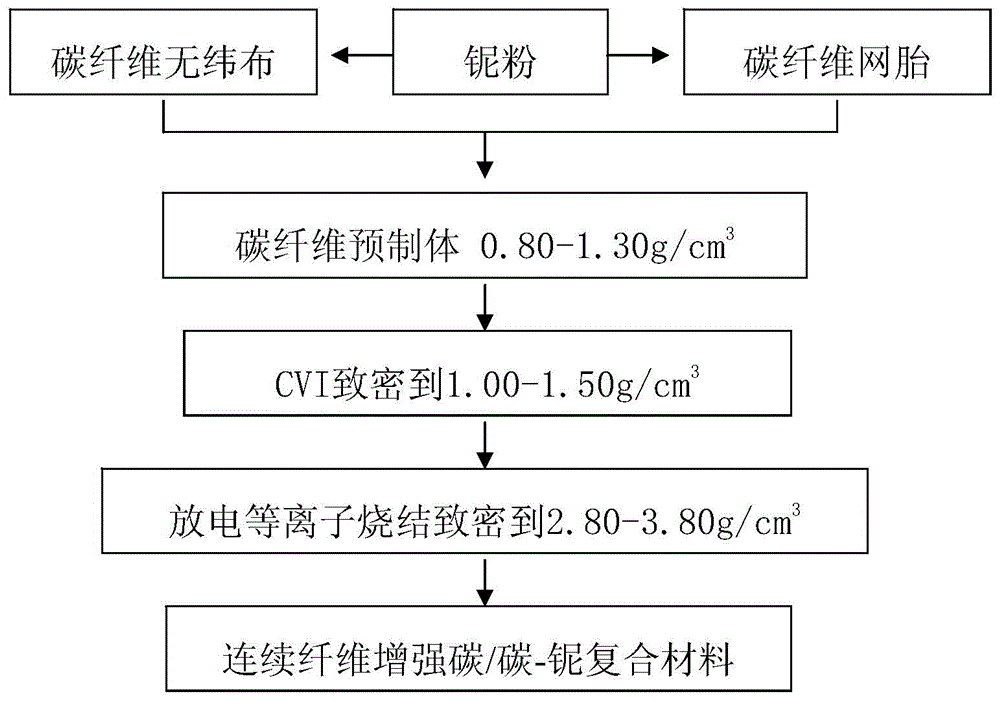

Preparation method of continuous-fiber reinforced carbon/carbon-molybdenum composite material

ActiveCN104446590ASmall mechanical propertiesProtected against high temperature molybdenum damageFiberCarbon composites

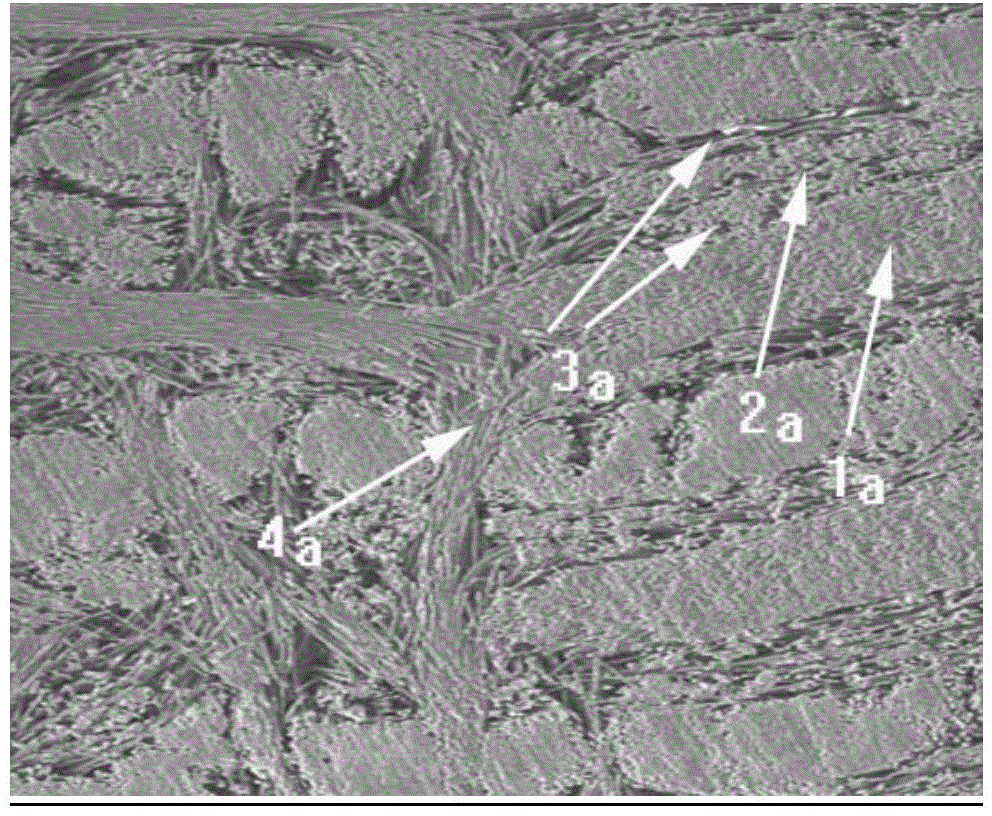

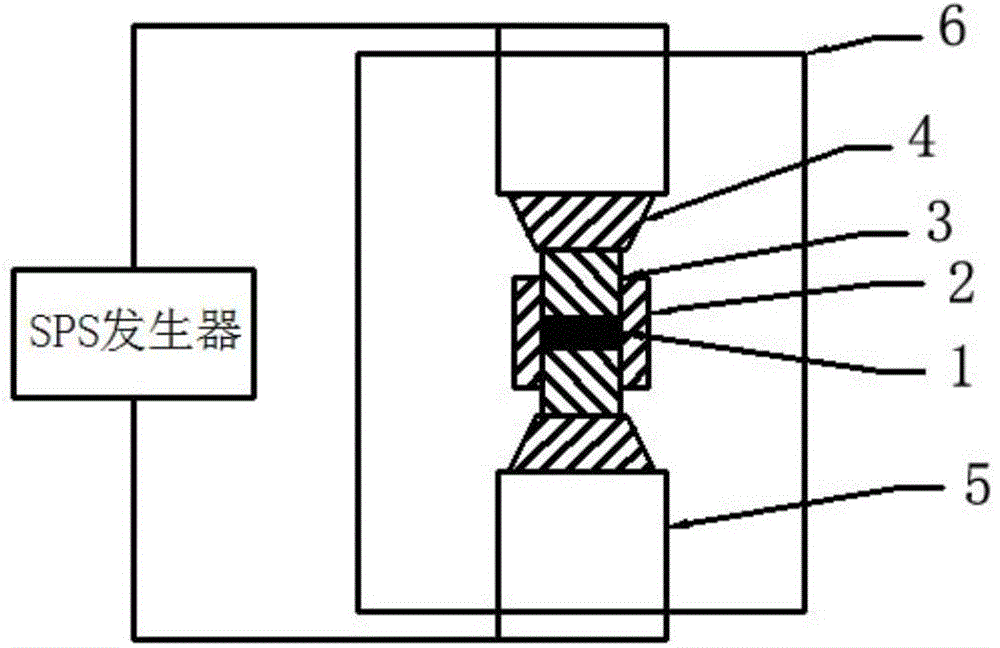

The invention discloses a preparation method of a continuous-fiber reinforced carbon / carbon-molybdenum composite material. The preparation method comprises the following steps: (1) scattering molybdenum powder on the surface of each carbon fiber felt and each carbon-fiber non-woven fabric on each layer uniformly to obtain carbon fiber felts with molybdenum powder and carbon-fiber non-woven fabrics with molybdenum powder, superposing the carbon fiber felts with molybdenum powder and the carbon-fiber non-woven fabrics with molybdenum powder layer by layer alternatively, and weaving to obtain a molybdenum containing carbon fiber preform; (2) putting the molybdenum containing carbon fiber preform obtained in the step (1) into a depositing furnace, and depositing with pyrolytic carbon to obtain a molybdenum containing carbon / carbon composite blank with pyrolytic carbon, wherein the pyrolytic carbon is in a coarse layered structure, and the temperature is controlled at 1,170-1,220 DEG C in the process of depositing with pyrolytic carbon; and (3) putting the molybdenum containing carbon / carbon composite blank into an SPS (spark plasma sintering) furnace, increasing the temperature to 1,750-1,850 DEG C, pressing, and preserving temperature and pressure under pressure to obtain the continuous-fiber reinforced carbon / carbon-molybdenum composite material.

Owner:CENT SOUTH UNIV

Method for preparing high-strength and high-thermal-conductivity aluminum nitride through hot pressed sintering

The invention aims to prepare an aluminum nitride ceramic material with high strength and high thermal conductivity, and belongs to the technical field of ceramic material preparation. In order to obtain the aluminum nitride ceramic with low oxygen content and fine grain structure, a novel method of pre-sintering, hot pressed sintering and high-temperature annealing is designed, wherein the pre-sintering temperature is 1400-1600 DEG C, the sintering time is 2-5 hours, the hot pressing sintering temperature is 1650-1800 DEG C, the sintering time is 0.5-3 hours, the sintering pressure is 15-45 MPa, the annealing temperature is 1750-1800 DEG C, and the annealing time is 3-8 hours. According to the method, presintering oxygen reduction and annealing deoxidation are utilized, so that the impurity oxygen content, especially the lattice oxygen content, of the aluminum nitride ceramic is effectively reduced. Therefore, under the condition of ensuring the strength, the heat conductivity of the aluminum nitride ceramic is remarkably improved, and the aluminum nitride ceramic has high practical value. The ceramic prepared by the method has the advantages of fine grains and low impurity oxygen content, the average grain size is less than 3 microns, the thermal conductivity is higher than 200W / m.k, the total oxygen content is lower than 1%, and the bending strength is higher than 350MPa.

Owner:UNIV OF SCI & TECH BEIJING

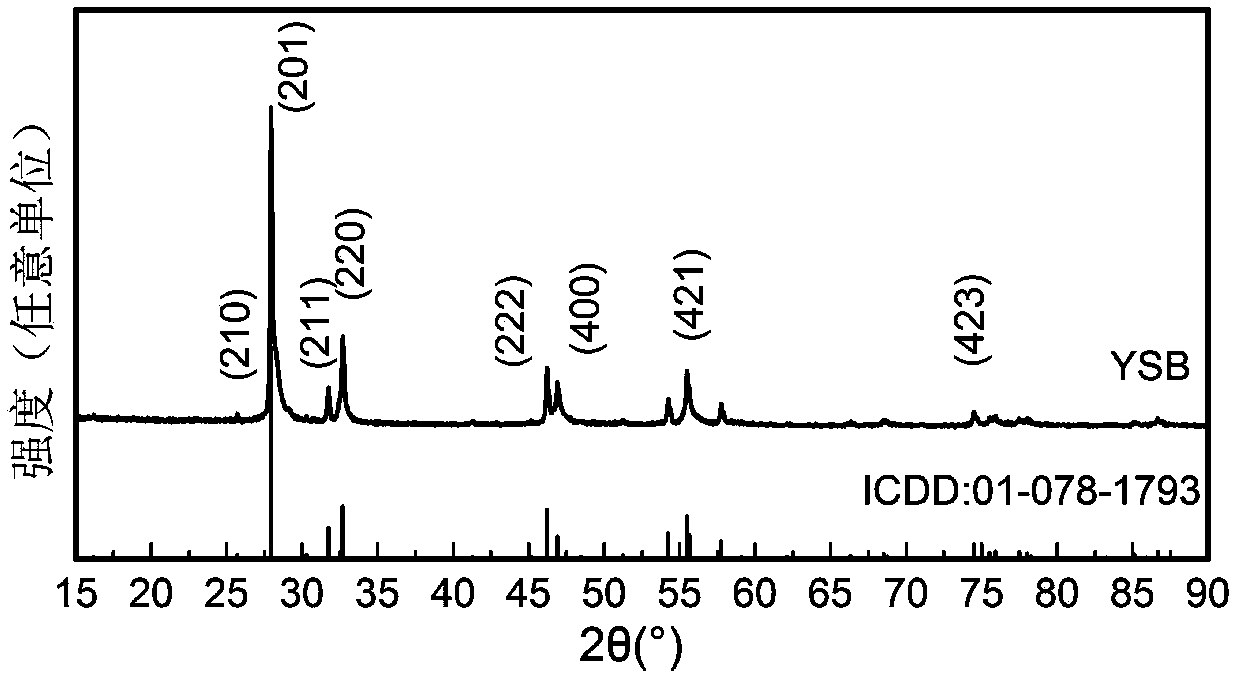

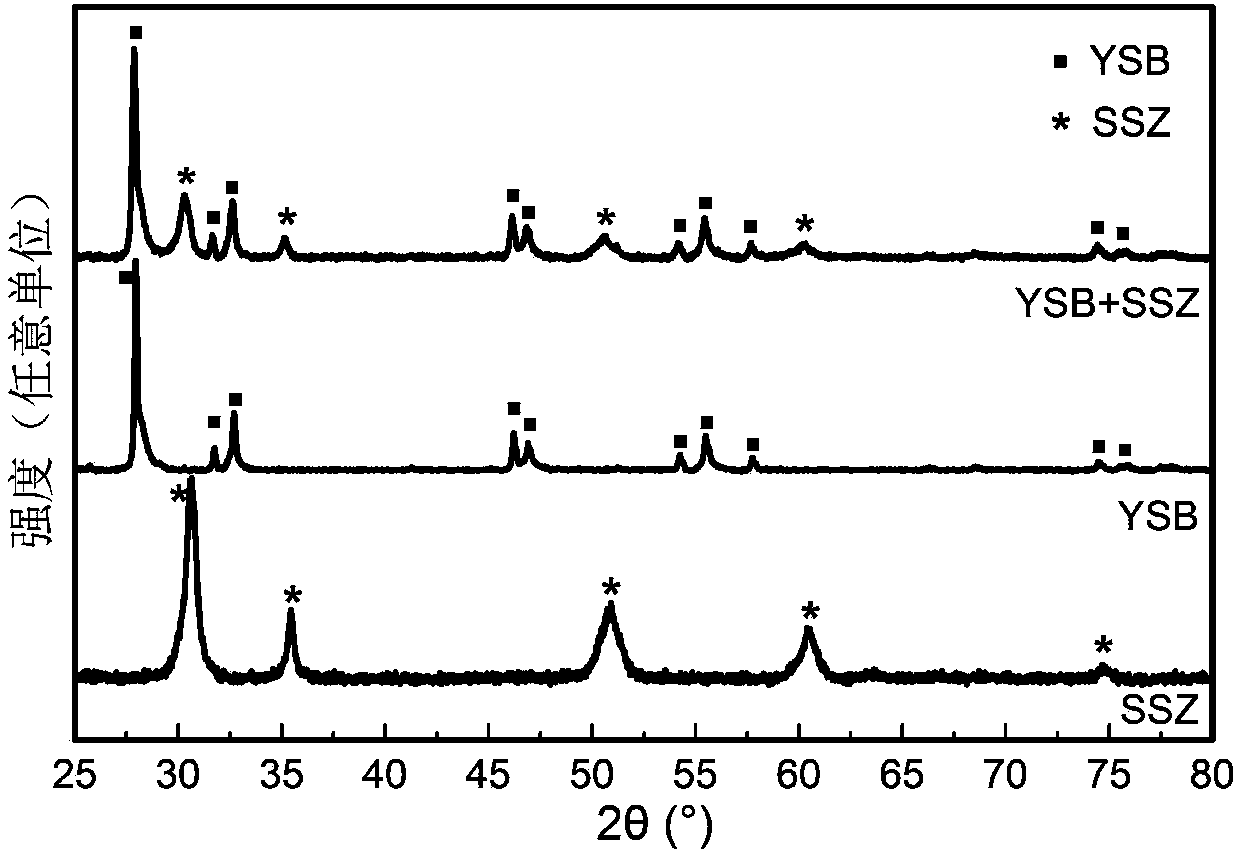

Preparation method of barrier layer yttrium oxide-doped bismuth oxide of solid oxide fuel cell

InactiveCN107799788AAlleviate thermal expansion mismatchStress reliefBismuth compoundsCollectors/separatorsThermal expansionCobalt

The invention discloses a preparation method of a barrier layer yttrium oxide-doped bismuth oxide of a solid oxide fuel cell, and belongs to the technical field of preparation of a battery material. The preparation method comprises the following steps of 1, taking Bi(NO<3>).5H<2>O and Y(NO<3>).6H<2>O as the raw materials, and preparing Y<x>Bi<2-x>O<3> powder through a coprecipitation method; 2, adding ethyl cellulose into Y<x>Bi<2-x>O<3>; 3, adding terpilenol, and grinding for 10-30min through an agate mortar; 4, performing silk screen printing on the obtained Y<x>Bi<2-x>O<3> paste on an electrolyte; 5, performing drying; 6, performing silk screen printing and drying for 1-3 times repeatedly to obtain Y<x>Bi<2-x>O<3> barrier layers of different thicknesses; and 7, performing heat treatmenton the electrolytes of the Y<x>Bi<2-x>O<3> barrier layers. The preparation method has the advantages as follows: by taking Y<x>Bi<2-x>O<3> with high oxygen ionic conductivity as the barrier layer, the problem of mismatching of coefficients of thermal expansion between a negative electrode and the electrolyte and between the barrier layer and the electrolyte can be effectively relieved, a reactionbetween a cobalt-based and a barium ferrite-based negative electrode material and a zirconium-based electrolyte can be avoided, and the interface resistance can be lowered; and the preparation methodis free of complex equipment, simple in preparation process, low in cost, and amplification and popularization can be realized easily.

Owner:HARBIN INST OF TECH

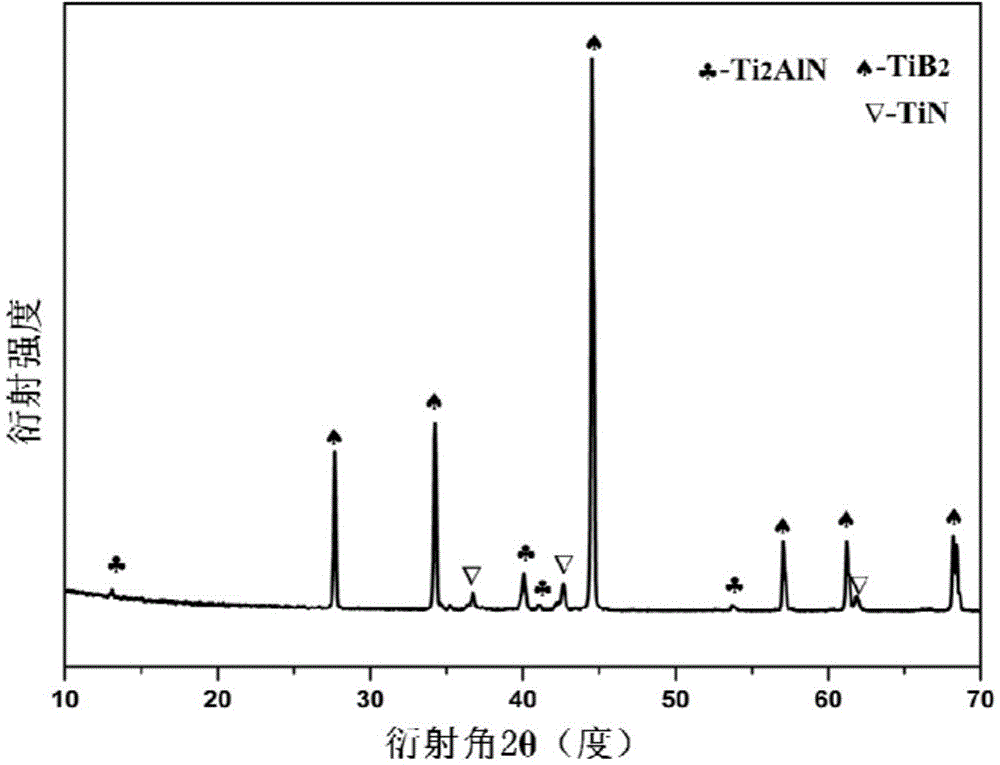

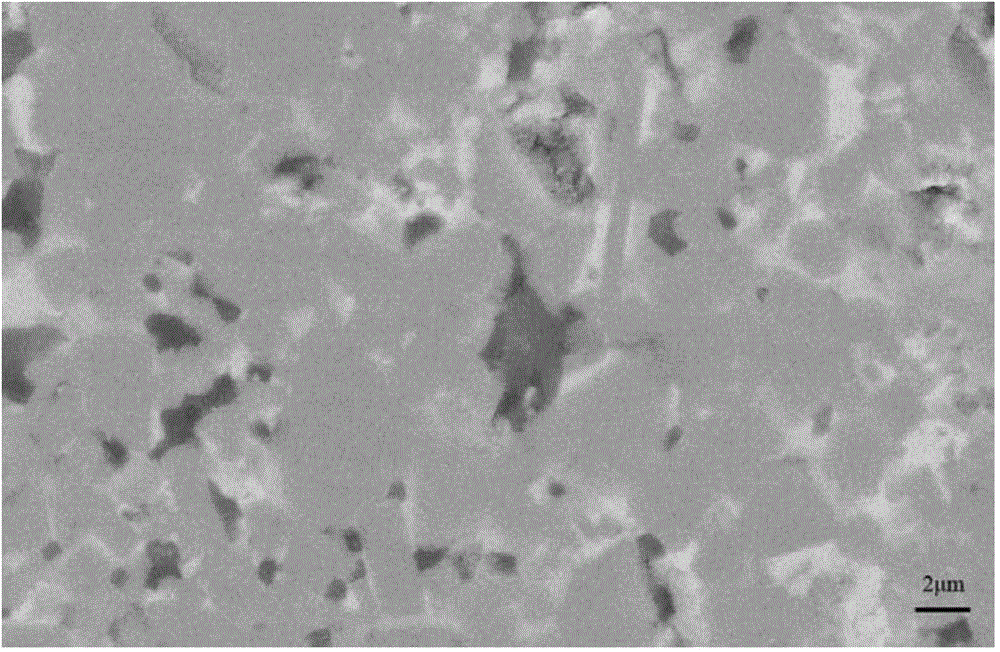

Method for obtaining compact titanium diboride material by using in-situ reaction between sintering aids

The invention belongs to the field of structural ceramics, and particularly discloses a method for obtaining a compact titanium diboride material by using in-situ reaction between sintering aids. Mixed powder of Ti, Al and BN capable of reacting at a low temperature is utilized as a sintering aid; TiB2 ceramic of which the relative density is more than 98% is obtained at a low temperature (1250-1550 DEG C); meanwhile, the material also has the characteristics of high strength, high hardness, high elasticity modulus and the like. In addition, the final products of in-situ reaction between the sintering aids such as Ti, Al, BN and the like and amorphous oxide reaction of the TiB2 surface are TiB2, TiN, Ti2A1N, Al5O6N and the like. Except for the TiB2, the TiN, the Ti2A1N, the Al5O6N and the like also have high melting points and chemical stability, so that the TiB2 ceramic becomes a latent high-temperature structure material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for continuous fiber-reinforced carbon/carbon-niobium composite material

ActiveCN104561846ASmall mechanical propertiesFree from high temperature niobium damageFiberCarbon composites

The invention discloses a preparation method for a continuous fiber-reinforced carbon / carbon-niobium composite material. The method comprises the following steps: (1), uniformly dispersing niobium powder on the surface of each layer of carbon fiber web and carbon fiber non-woven cloth to obtain carbon fiber web layers and carbon fiber non-woven cloth layers with niobium powder; then crosswise laying and weaving the obtained carbon fiber web layers and carbon fiber non-woven cloth layers with the niobium powder layer by layer to obtain a niobium-containing carbon fiber preform; (2), performing pyrolytic carbon deposition on the niobium-containing carbon fiber preform obtained in step (1) in a deposition furnace to obtain a niobium-containing carbon / carbon composite blank with pyrolytic carbon, wherein the pyrolytic carbon is pyrolytic carbon with a rough laminar microstructure, and the temperature is controlled to be 1,100 to 1,150 DEG C when the pyrolytic carbon is deposited; (3), heating the niobium-containing carbon / carbon composite blank to 1,670 to 1,720 DEG C in an SPS furnace, applying pressure, and preserving heat and pressure to obtain the continuous fiber-reinforced carbon / carbon-niobium composite material under a pressure condition.

Owner:CENT SOUTH UNIV

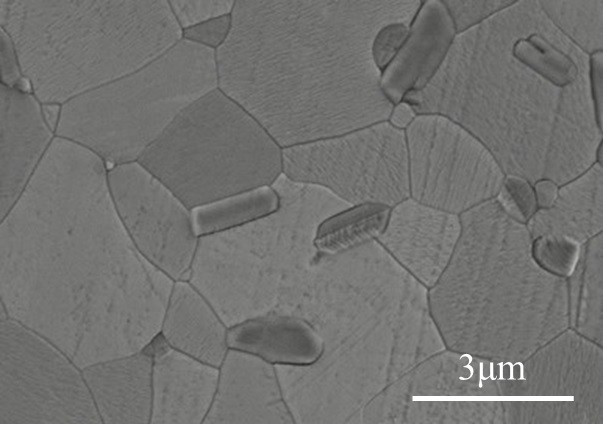

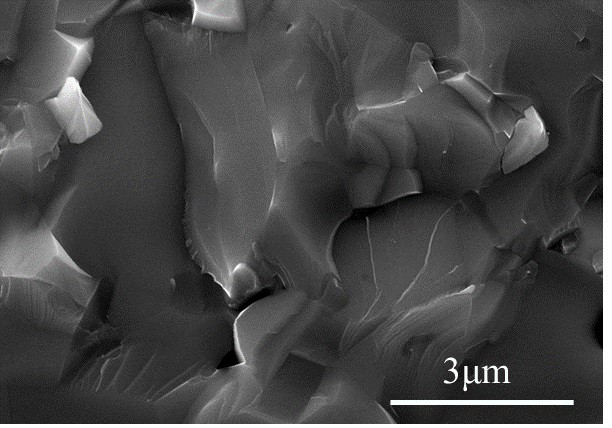

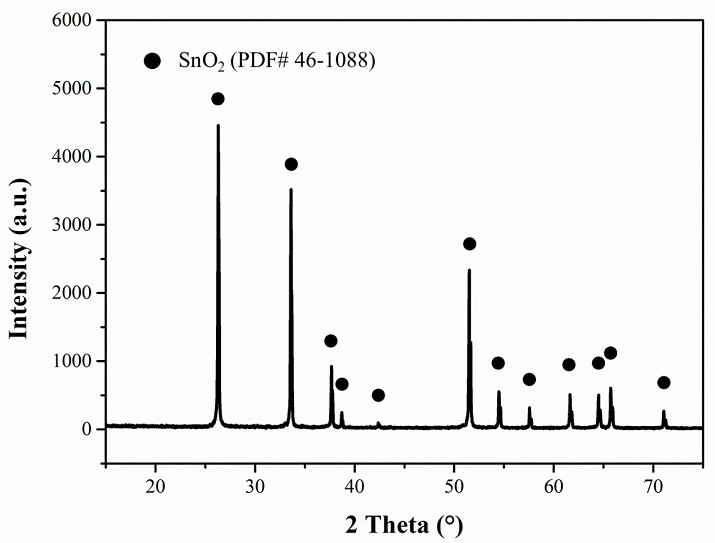

Gallium oxide doped tin oxide ceramic target material and preparation method thereof

The invention provides a gallium oxide doped tin oxide ceramic target material and a preparation method thereof. The gallium oxide doped tin oxide ceramic target material comprises the following raw materials in percentage by mass: 2-10% of gallium oxide and 90-98% of tin oxide high-purity nano powder. The preparation method comprises the following steps: weighing and mixing the powder, adding ammonium polyacrylate, polyvinyl alcohol and pure water, carrying out ball milling on the mixed slurry, granulating, drying to obtain mixed powder, sequentially carrying out compression molding by using an oil press and an isostatic press, and preparing the gallium oxide-doped tin oxide ceramic target material at different sintering temperatures by using a degreasing multi-step sintering integrated sintering technology. According to the doped gallium oxide, the sintering performance of the tin oxide ceramic is effectively improved, the density of the tin oxide ceramic target material is remarkably improved, and meanwhile the gallium oxide doped tin oxide target material which is uniform in structure and fine in grain is obtained through effective control over the preparation process.

Owner:ZHENGZHOU UNIV

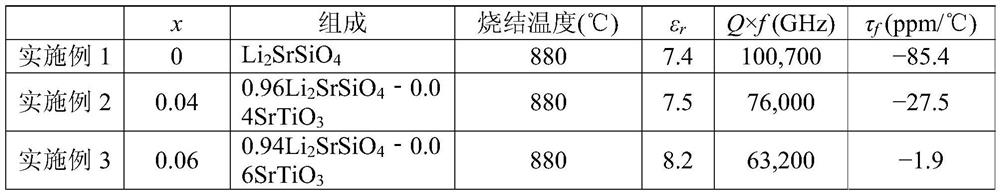

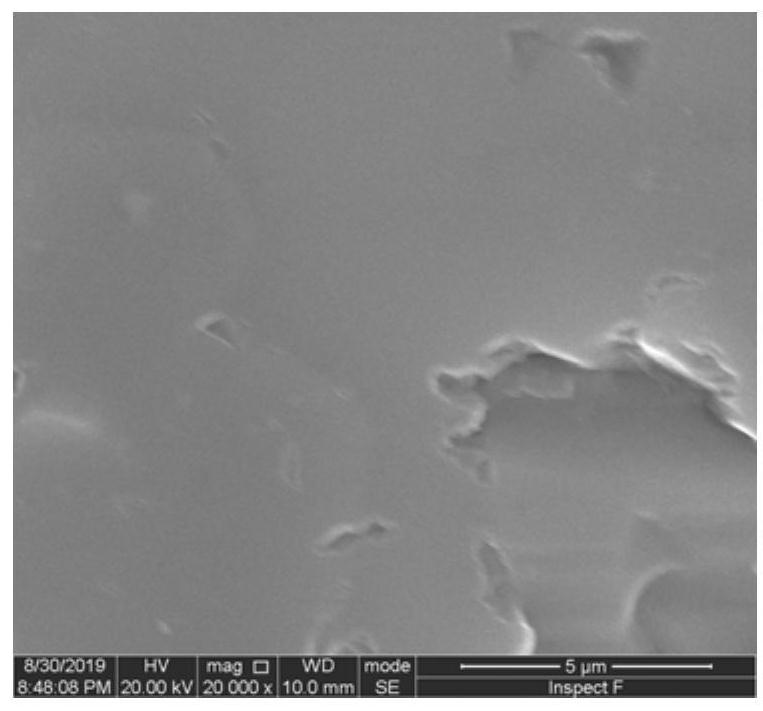

Preparation and application of silicon-based low-dielectric high-quality-factor microwave dielectric ceramic capable of being sintered at low temperature

PendingCN113754419ALower densification temperatureSynthetic raw materials are cheapImpedence networksResonatorsCompression moldingMicrowave

The invention discloses preparation and application of silicon-based low-dielectric high-quality-factor microwave dielectric ceramic capable of being sintered at low temperature. The preparation comprises the steps: (1) weighing and proportioning Li2CO3, SrCO3 and SiO2 according to the composition of Li2SrSiO4; (2) ball-milling and mixing for 6 hours by using alcohol as a ball-milling medium, drying and then pre-sintering; and (3) weighing the pre-sintered powder and SiTiO3 powder according to (1-x)Li2SrSiO4-xSrTiO3 (wherein x is the volume percent (0<=x<=0.06)), after ball milling is carried out again, adding a polyvinyl alcohol solution is added, carrying out granulation, carrying out compression molding, and finally sintering in the air atmosphere. The prepared silicon-based low-dielectric high-quality-factor microwave dielectric ceramic has the dielectric constant of 7.4-8.2, the quality factor up to 63,200-100,700 GHz and the temperature coefficient of resonance frequency close to zero, and can be applied to manufacturing of microwave components such as various ceramic substrates, dielectric resonators and filters.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

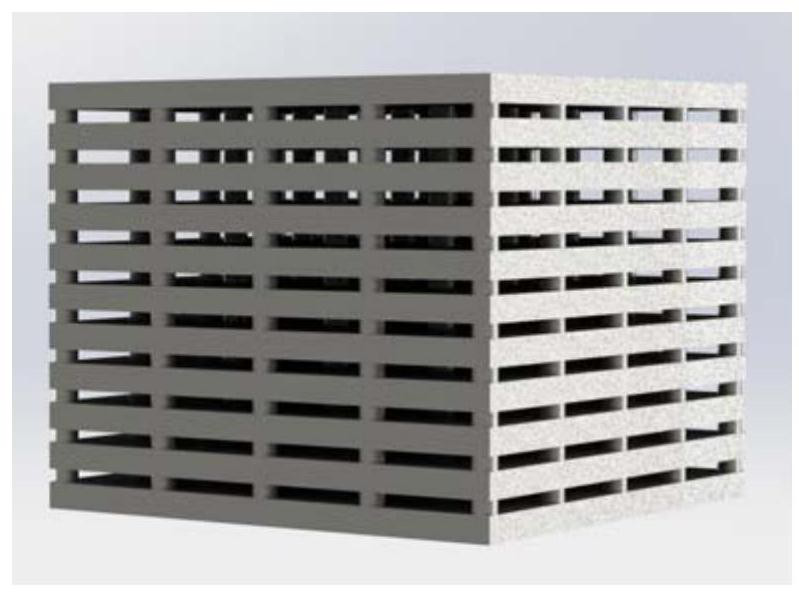

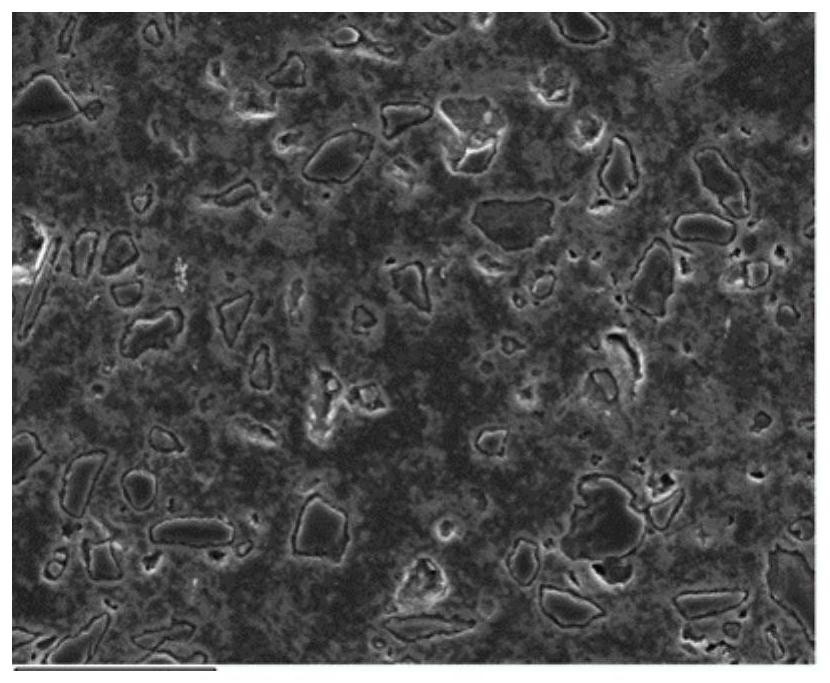

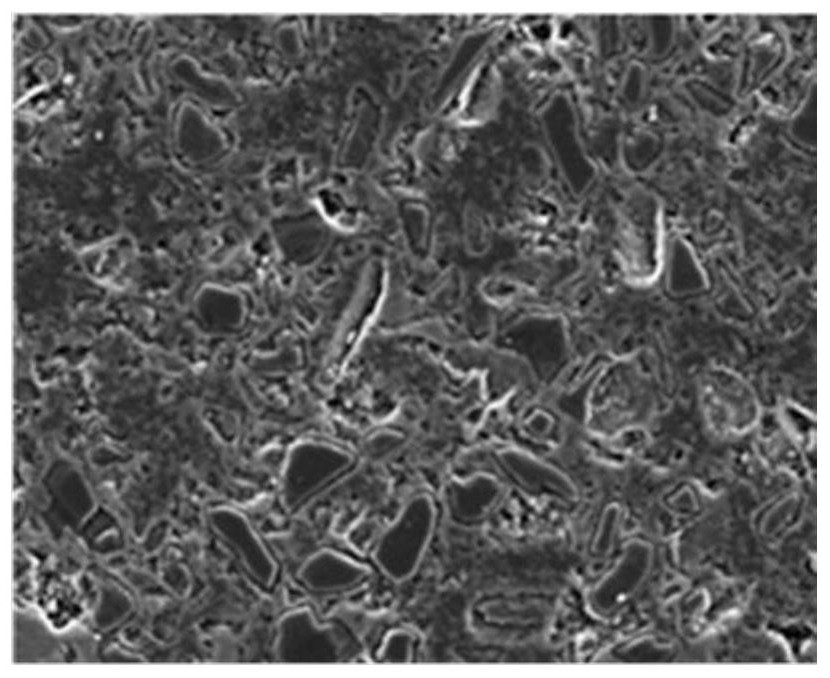

Compact layered silicon carbide ceramic and preparation method thereof

The invention relates to a preparation technology of layered ceramic, in particular to a compact layered silicon carbide ceramic and a preparation method thereof. According to the compact layered silicon carbide ceramic, lamellar silicon carbide ceramics are used as basic units, and each basic unit is of a structure with more than three layers connected by discrete silicon carbide ceramic columns in a laminated manner; in the layered silicon carbide ceramic, the relative density of the silicon carbide ceramic basic units and the silicon carbide ceramic columns is greater than or equal to 99%; the silicon carbide ceramic basic units and the silicon carbide ceramic columns are composed of, by weight, 90%-98% of silicon carbide and 10%-2% of silicon, and the average grain size ranges from 50 nm to 50 microns. According to the compact layered silicon carbide ceramic and the preparation method thereof of the invention, the layered structure gaps of the layered silicon carbide ceramic are filled with tough phases(such as metal, polymer and the like), so that when the layered silicon carbide ceramic bears an impact load, the transmission path and the expansion mechanism of cracks can be changed, the sensitivity of the material to the cracks is reduced, and the toughness of the ceramic is further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

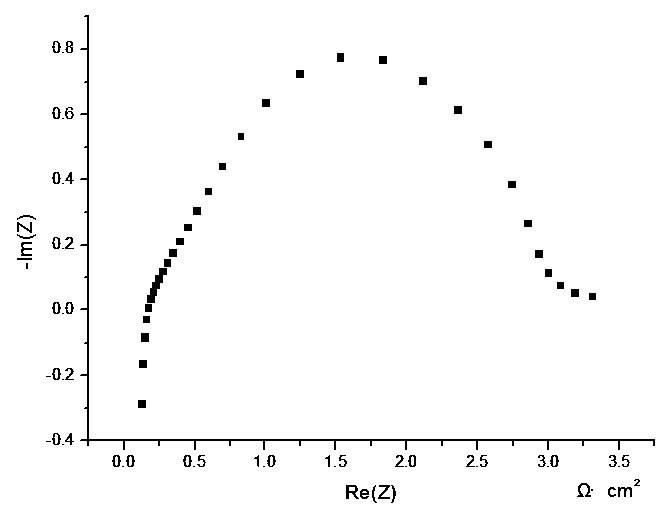

Methods for lowering the hot-pressing temperatures of garnet structured ionic conductors

PendingUS20190165414A1High-energy-density solid-stateLower densification temperatureHybrid capacitor electrolytesFuel and secondary cellsBismuthLanthanum

Disclosed is a method for forming a solid state electrolyte. The method includes a first step of combining a solid comprising lithium, a second solid comprising lanthanum, a third solid comprising zirconium, and a fourth solid comprising bismuth to form a mixture. The method includes a second step of applying simultaneous heat and pressure to the mixture to form a ceramic material. The solid state electrolyte is ionically conducting and can be used as an electrolyte for an electrochemical device such as a battery or supercapacitor.

Owner:RGT UNIV OF MICHIGAN

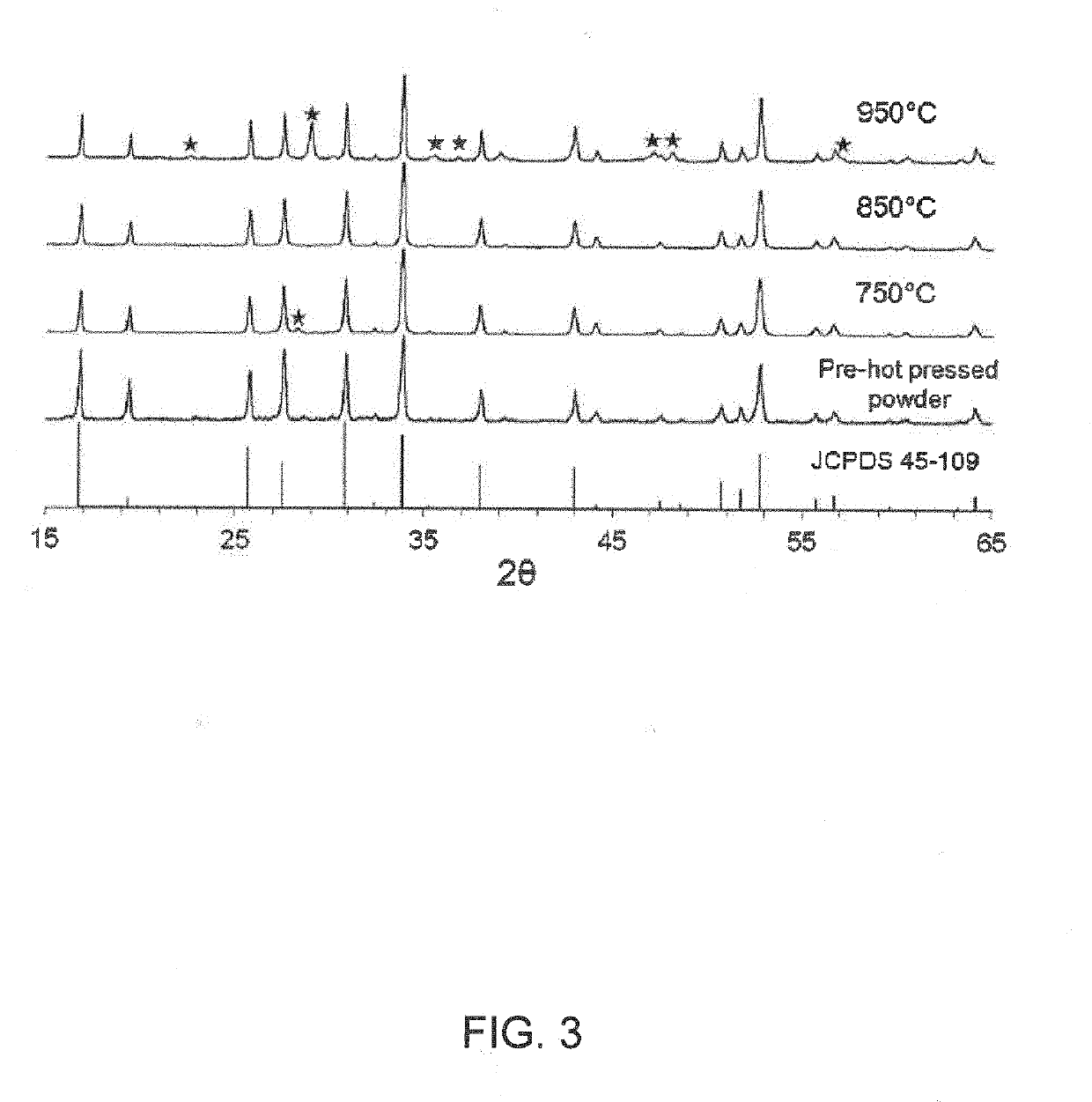

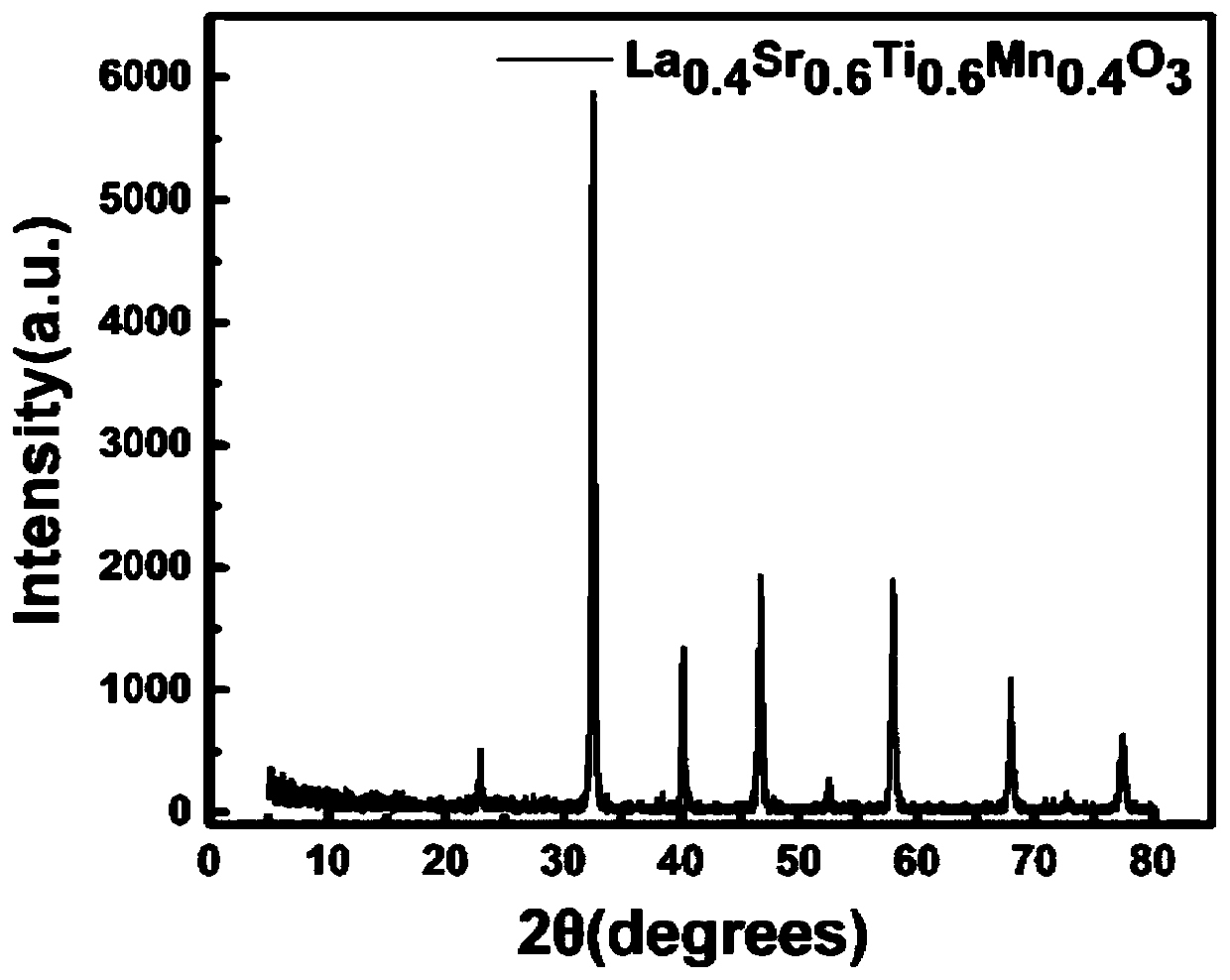

Synthesis method of strontium titanate-based materials for solid oxide fuel cells

ActiveCN108054394BReduce phase temperatureUniform particle size distributionCell electrodesMANGANESE ACETATEStrontium titanium oxide

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A method for preparing ti2sc ceramics by pressureless sintering

A pressureless sintering preparation method of Ti2SC ceramic is characterized by comprising the following steps: (1) evenly mixing Ti2SC ceramic powder with polyvinyl alcohol PVA, and then filling into a die for preforming; (2) performing cold isostatic pressing treatment on the preformed Ti2SC ceramic; (3) putting the cold isostatic pressing treated Ti2SC ceramic into a microwave sintering furnace filled with inert gas protective atmosphere for sintering for 20-60 minutes at 800-1100 DEG C to obtain the Ti2SC bulk ceramic; the preparation method not only improves the density of the ceramic material, realizes the controllable density of the Ti2SC ceramic material, can prepare Ti2SC ceramic materials with complex shapes, and has the advantages of low sintering temperature, short time, saving energy and the like.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

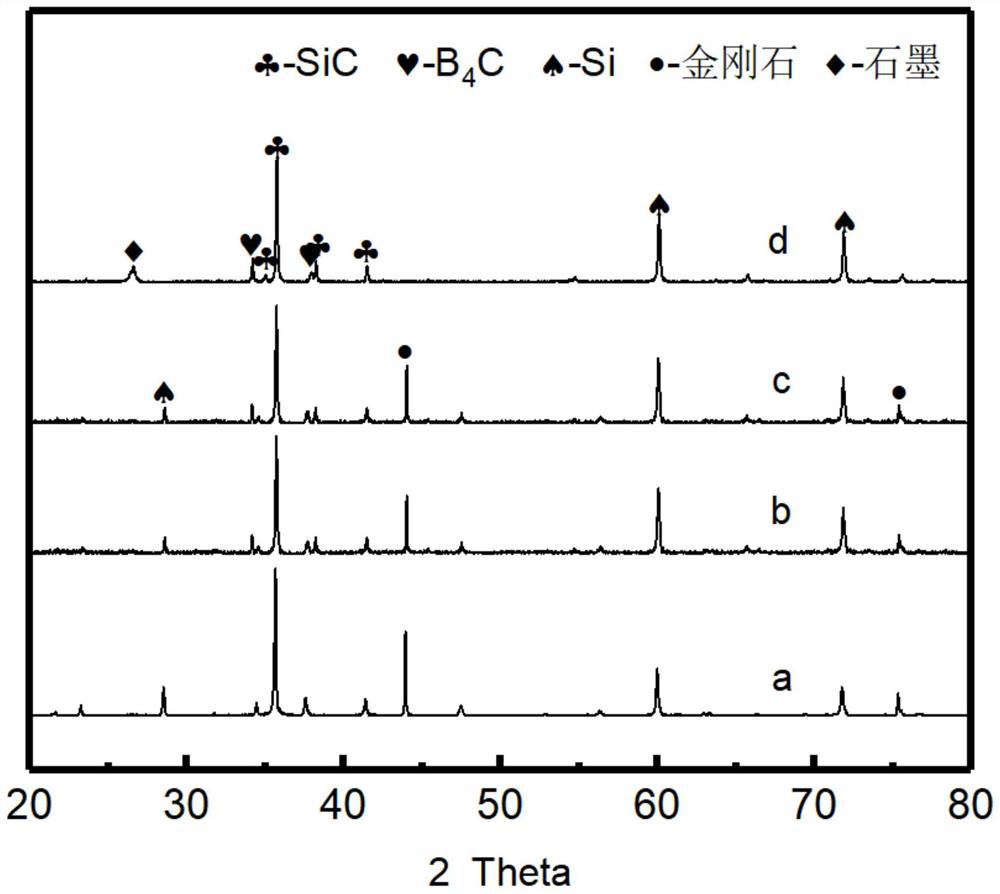

A rapid preparation method of superhard and lightweight diamond-b4c-sic ternary composite ceramics

The invention provides a rapid preparation method of ultra-hard light diamond-B4C-SiC ternary composite ceramics, comprising the following steps: selection of raw material powder; preparation of ternary mixed powder; rapid sintering of powder in situ reaction; Subsequent processing of the sample, the prepared superhard lightweight diamond‑B 4 B in C‑SiC ternary composite ceramics 4 The C‑SiC ceramic phase accounts for 70‑82%, and the diamond phase accounts for 18‑30%. In the present invention, diamond, boron powder and silicon powder are used as raw materials, and the ternary mixed powder is equipped with in-situ reaction and rapid sintering under the conditions of high heating rate and short holding time, which reduces the sintering temperature of ceramic densification, and effectively Inhibits the graphitization of diamond; at the same time, the liquid phase formed by silicon during sintering accelerates the reaction and promotes the densification of ternary composite ceramics; the preparation cost is low, the production cycle is short, and the diamond particles in the product are evenly dispersed in B 4 Between C and SiC ceramics, there is no graphite residue and the structure is dense, and it has the characteristics of ultra-high hardness, high strength, high toughness and light weight.

Owner:WUHAN UNIV OF TECH

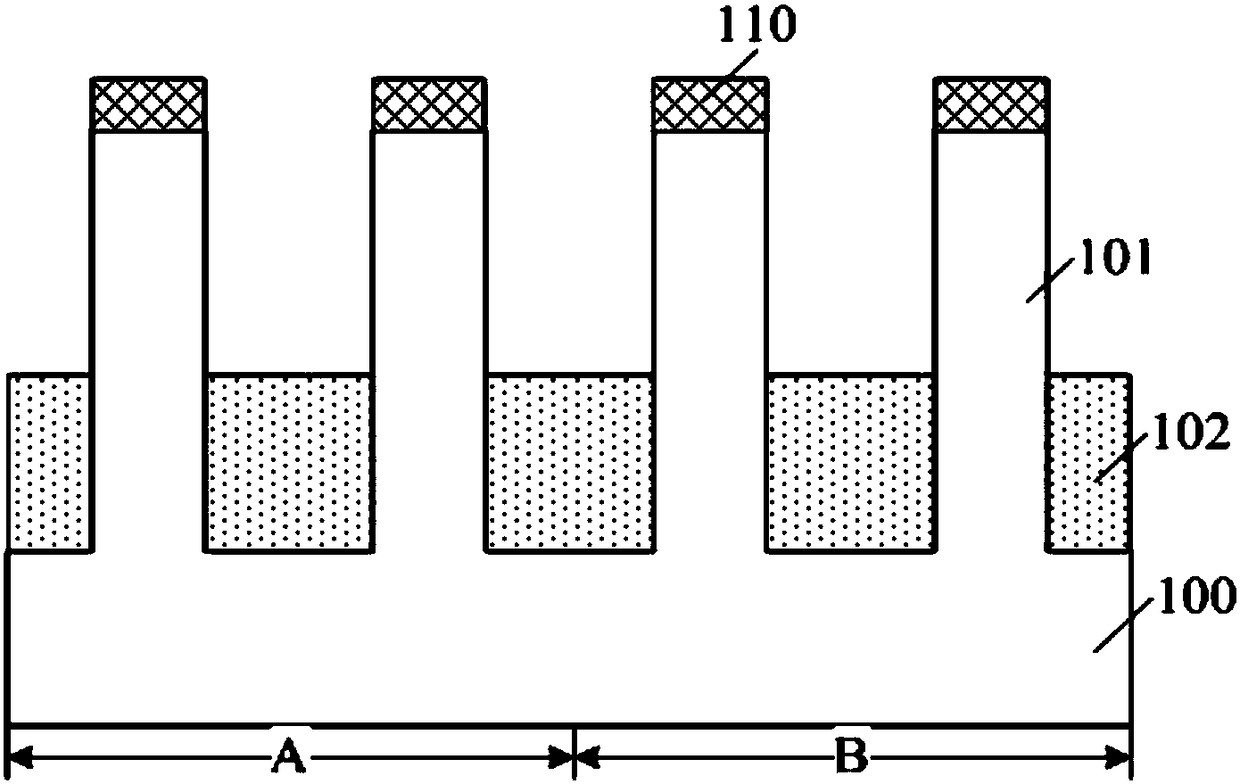

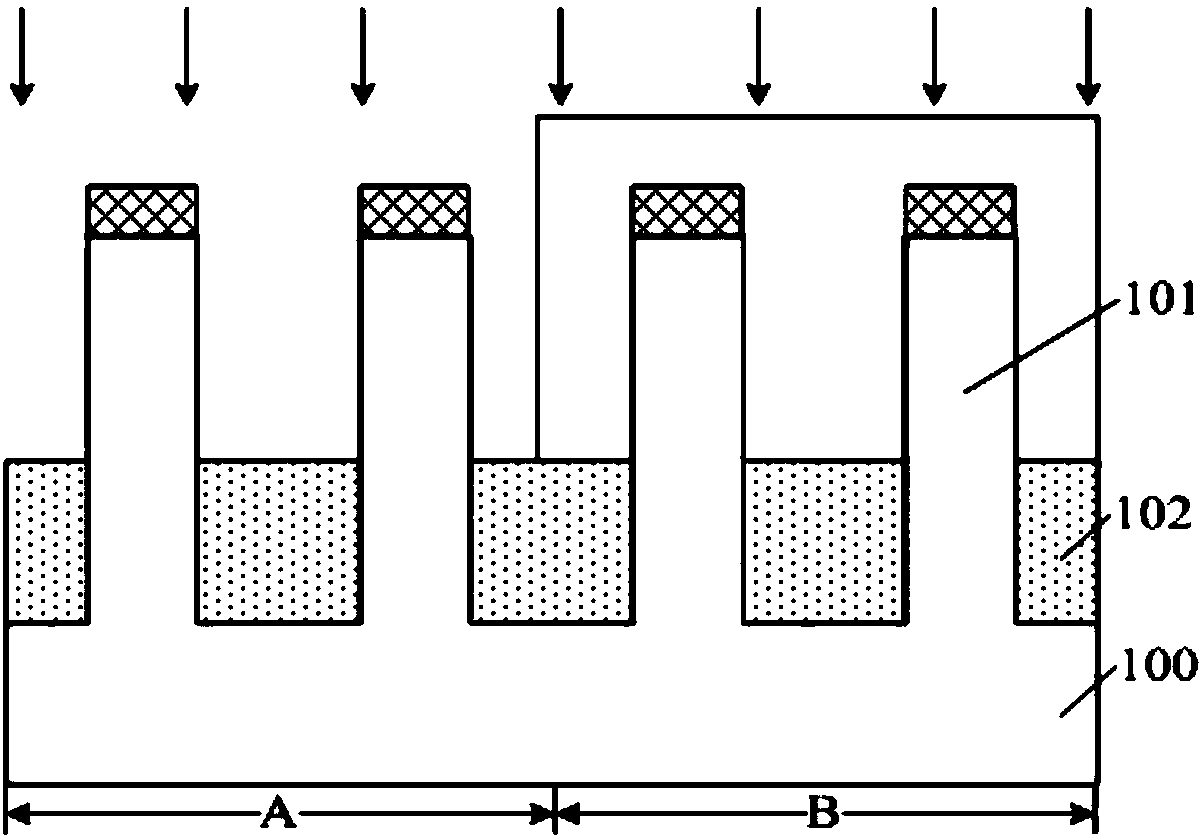

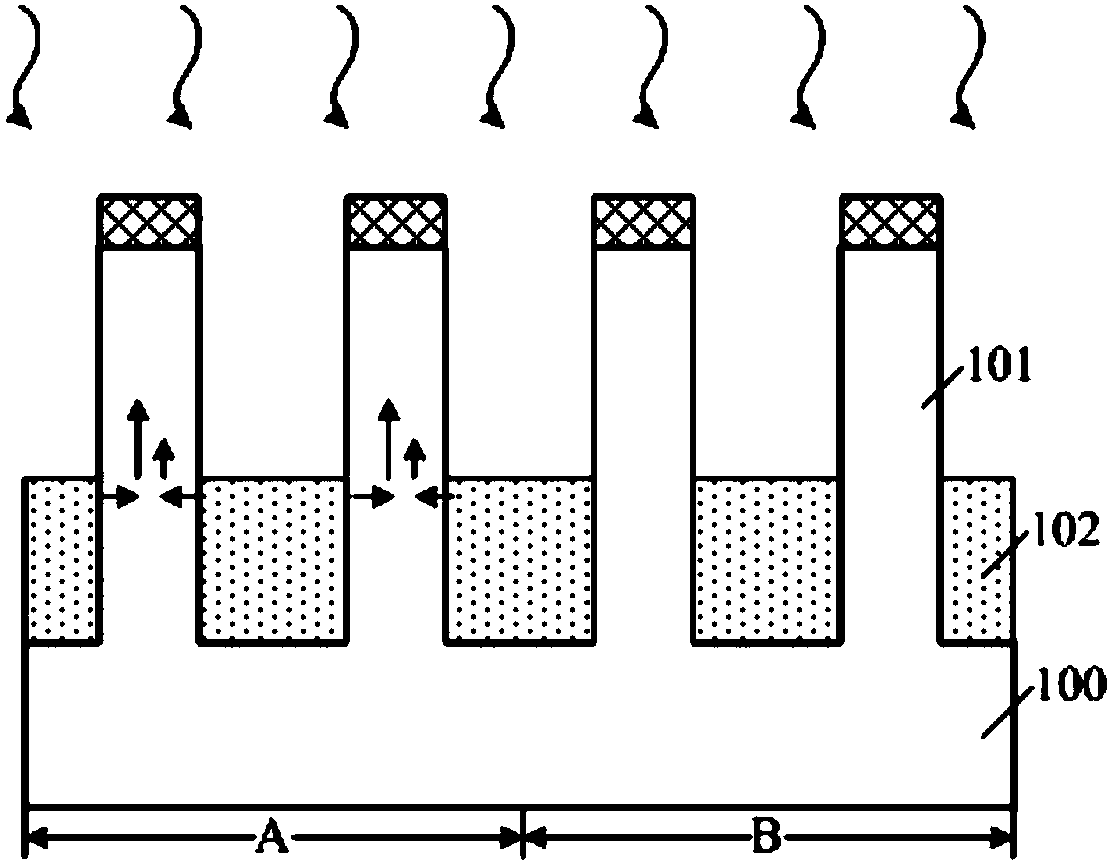

Semiconductor structure and formation method thereof

ActiveCN108878526AReduce leakage currentSimple process operationSemiconductor/solid-state device manufacturingSemiconductor devicesIonEngineering

A formation method of a semiconductor structure comprises the following steps: providing a substrate, wherein fin parts are arranged on the substrate, and a fin part gap is kept between every two adjacent fin parts; arranging a hard mask above the fin parts; forming a punchthrough-proof layer above the hard mask, wherein the punchthrough-proof layer is filled with punchthrough-proof ions; formingan anti-spreading layer which is lower than the fin parts, and injecting anti-spreading ions into the fin part gaps, wherein the anti-spreading ions can prevent the punchthrough-proof ions from beingspread to the tops of the fin parts; removing the hard mask; and annealing.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

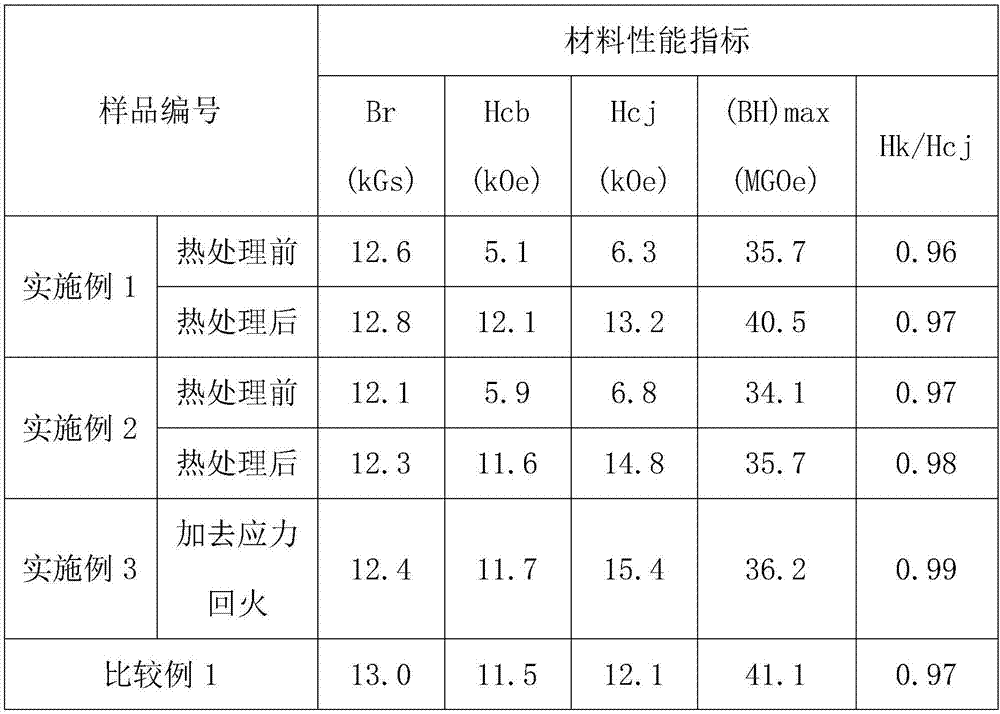

A kind of preparation method of rare earth permanent magnet material

ActiveCN105957675BInhibit growthNo significant growthInorganic material magnetismRare earthThermal deformation

A method for manufacturing a rare-earth permanent magnetic material comprises manufacturing a NdFeB magnetic from NdFeB alloy powder by two consecutive compression molding processes. An oriented magnetic field is applied in the first molding process to obtain an anisotropic NdFeB green body, and heating and pressing are applied in the second molding process to obtain a dense NdFeB magnetic having a size close to that of a final product. The performance of the magnetic is enhanced through a special thermal treatment process, which involves a low densification temperature that suppresses the enlargement of crystals, and thus provides crystals that are smaller compared to those of a sintered magnet and that have high magnetic performance. By adopting the molding processes, the size of a magnet is close to that of a final product, and the material utilization rate is much greater than that of a conventional sintered NdFeB magnet. Further, the method does not require a dedicated fast-quench magnetic powder or thermal deformation, providing a simple process, high production efficiency, production costs far lower than those of a thermal pressed / thermal deformed magnetic, and high magnetic performance achieving a maximum magnetic energy product above 200 kJm-3, much higher than that of a bonded NdFeB magnet.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

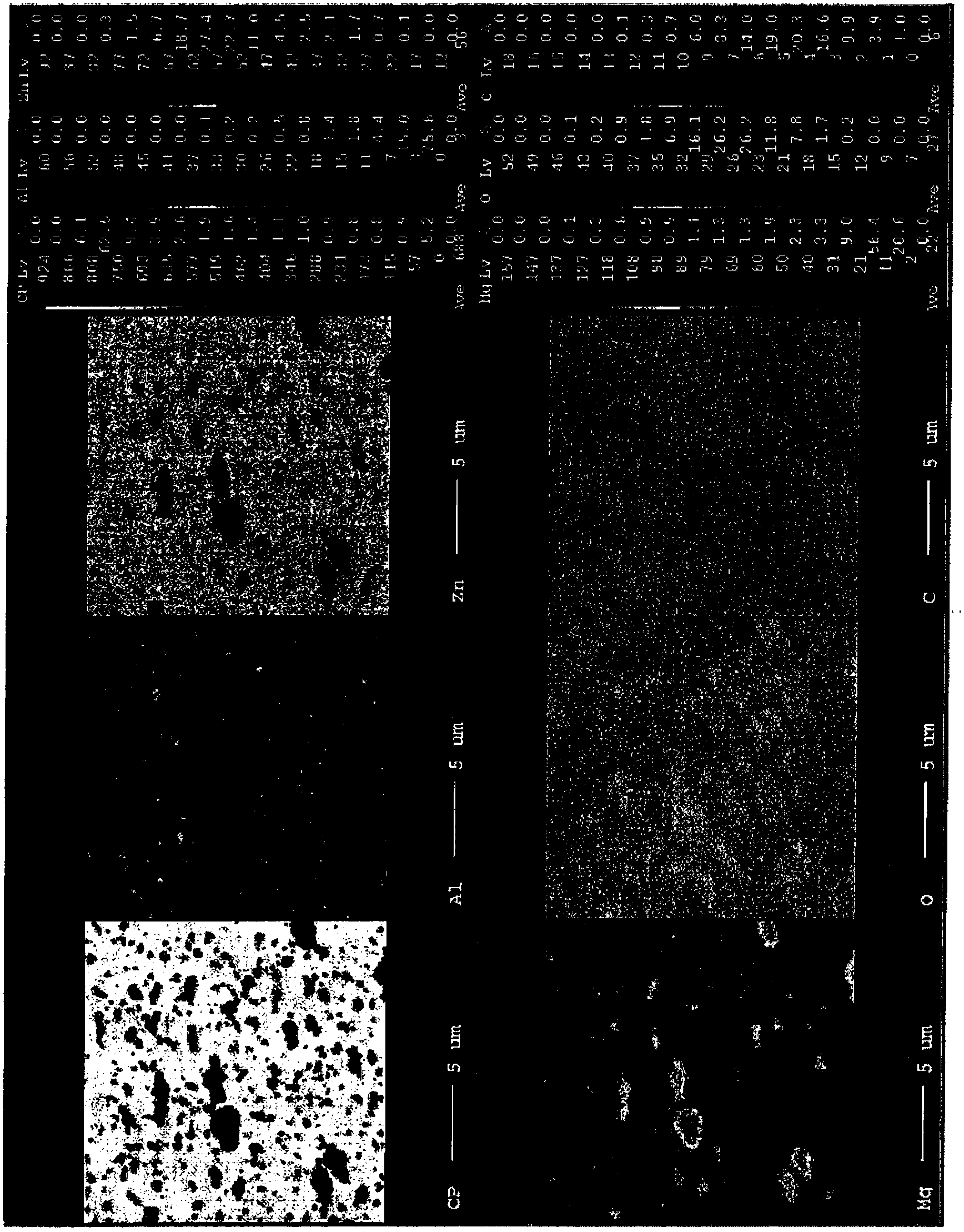

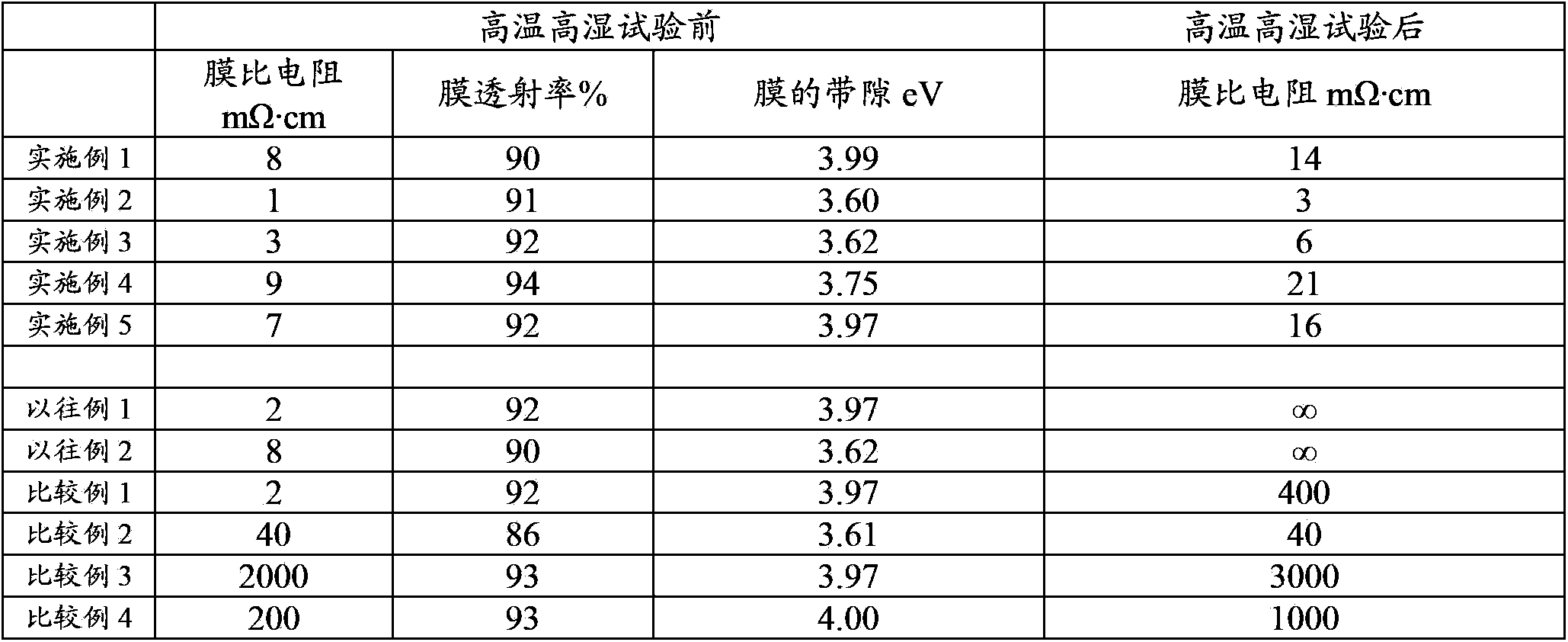

Transparent conductive film, solar cell using same, sputtering target for forming said transparent conductive film, and manufacturing method therefor

ActiveCN102666910BHigh densityImprove conductivityConductive layers on insulating-supportsVacuum evaporation coatingLiquid-crystal displayMoisture resistance

[Problems] Provided is a transparent conductive film used for a liquid-crystal display device, an electroluminescent display device, or the like, and particularly suitable for use in a solar cell. Also provided is a solar cell using the transparent conductive film and a sputtering target suitable for forming the transparent conductive film. [Solving Means] The provided transparent conductive film is composed of an Al-Mg-Ga-Zn-based oxide of which the content ratios of metal component elements are 0.7-7% Al, 9.2-25% Mg, 0.015-0.085% Ga, and the remainder is Zn, by atomic ratio, and is excellent in moisture resistance.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com