Silicon nitride ceramic with hard outside and tough inside and preparation method thereof

A technology of silicon nitride ceramics, which is hard on the outside and tough on the inside, is applied in the field of preparation of silicon nitride ceramics, which can solve the problems of insufficient hardness and wear resistance of ceramics that cannot meet application requirements, so as to reduce the densification temperature, enhance toughness, and promote The effect of phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

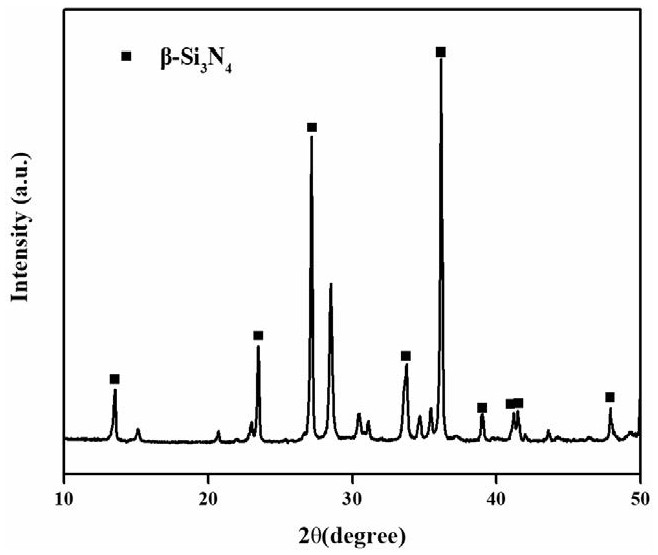

[0038] S1: Weigh 89.5g Si 3 N 4 , 0.51g Al 2 o 3 , 9.49g Er 2 o 3 and 0.5g ZrSi 2 A total of 100g, configured into a slurry with a certain solid content, and planetary ball milled at a speed of 300rpm for 4 hours; the obtained slurry was dried and ground, passed through a 100-mesh sieve, and preformed under a pressure of 5.0MPa;

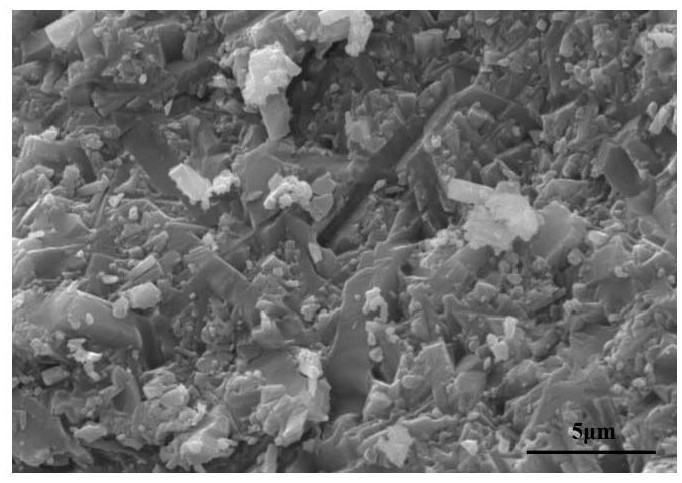

[0039] S2: Put the ceramic biscuit obtained in step S1 into a graphite mold, place it in a hot pressing sintering furnace, and fill it with N 2 As a protective gas, the temperature was raised to 1750°C at a certain rate, and kept for 2 hours, and a sintering pressure of 20MPa was applied to obtain a bending strength of 1252±15.2MPa and a fracture toughness of 11.91±0.11MPa m 1 / 2 , Si with a Vickers hardness of 15.34±0.04GPa 3 N 4 ceramics;

[0040] S3: Grinding and polishing the surface of the inner layer ceramic block obtained in step S2 to obtain a flat sample with a certain surface finish;

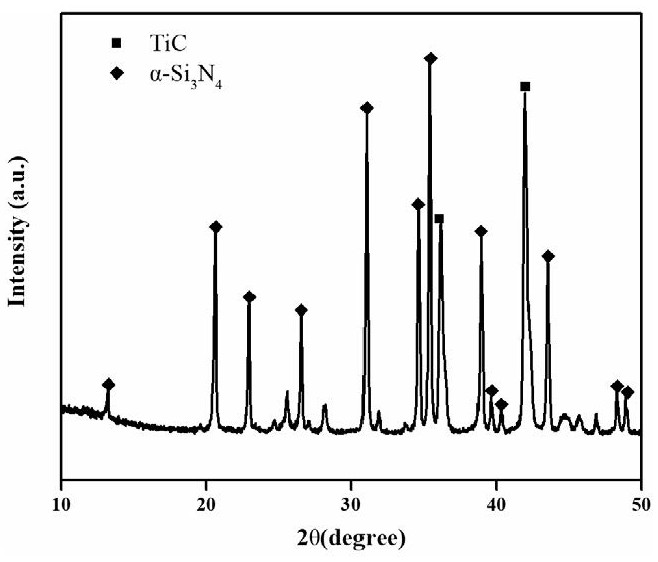

[0041] S4: Weigh 71.5g Si 3 N 4 , 1.81g Al ...

Embodiment 2

[0046] S1: Weigh 88.5g Si 3 N 4 , 0.63g Al 2 o 3 , 9.37g Er 2 o 3 and 1.5g ZrSi 2 A total of 100g, configured into a slurry with a certain solid content, and planetary ball milled at 400rpm for 3 hours; the obtained slurry was dried and ground, passed through a 200-mesh sieve, and preformed under a pressure of 2.5MPa;

[0047] S2: Put the ceramic biscuit obtained in step S1 into a graphite mold, place it in a hot pressing sintering furnace, and fill it with N 2 As a protective gas, the temperature was raised to 1775°C at a certain rate, and kept for 2.5 hours, and a sintering pressure of 40MPa was applied to obtain a bending strength of 1384.6±24.9MPa and a fracture toughness of 13.57±0.17MPa m 1 / 2 , Si with a Vickers hardness of 14.78±0.08GPa 3 N 4 ceramics;

[0048] S3: Grinding and polishing the surface of the inner layer ceramic block obtained in step S2 to obtain a flat sample with a certain surface finish;

[0049] S4: Weigh 71.5g Si 3 N 4 , 1.65g Al 2 o 3 ...

Embodiment 3

[0053] S1: Weigh 89.5g Si 3 N 4 , 0.82g Al 2 o 3 , 9.17g Er 2 o 3 and 0.5g ZrSi 2 A total of 100g, configured into a slurry with a certain solid content, and planetary ball milled at 400rpm for 3 hours; the obtained slurry was dried and ground, passed through a 200-mesh sieve, and preformed under a pressure of 2.5MPa;

[0054] S2: Put the ceramic biscuit obtained in step S1 into a graphite mold, place it in a hot pressing sintering furnace, and fill it with N 2 As a protective gas, the temperature was raised to 1800°C at a certain rate and kept for 3 hours, and a sintering pressure of 60MPa was applied to obtain a bending strength of 1456.2±19.2MPa and a fracture toughness of 15.4±0.21MPa m 1 / 2 , Si with a Vickers hardness of 14.9±0.18GPa 3 N 4 ceramics;

[0055] S3: Grinding and polishing the surface of the inner layer ceramic block obtained in step S2 to obtain a flat sample with a certain surface finish;

[0056] S4: Weigh 71.5g Si 3 N 4 , 1.43g Al 2 o 3 , 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com