A kind of preparation method of rare earth permanent magnet material

A rare earth permanent magnet and rare earth rich alloy technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of high material utilization, small magnet grains, high cost, low densification temperature, inhibit crystallinity, etc. The effect of grain growth and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

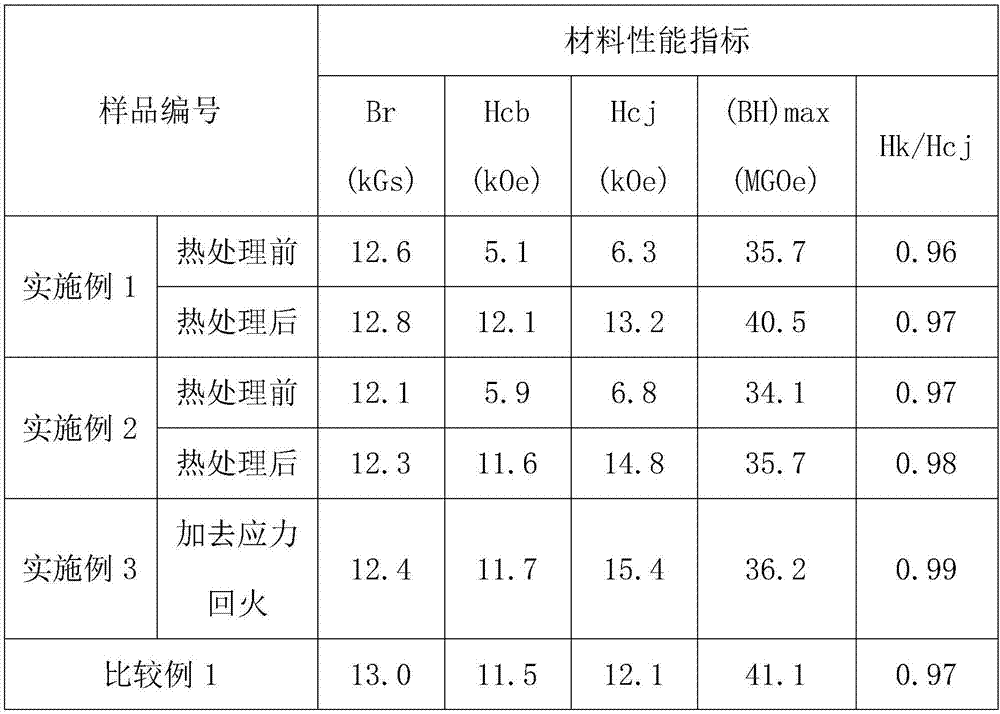

Embodiment 1

[0029] 1. The NdFeB alloy is prepared in a vacuum melting furnace, and the alloy whose main alloy composition is Nd26.25Pr8.75Fe64B1 (mass percentage content) is made into thin slices by using the quick-setting thin slice technology; The flakes are made into a powder with an average particle size of 3.5 μm;

[0030] 2. Apply a magnetic field of 1.5T, and obtain a blank with a size of R8.1×R3.6×10 and a blank weight of 29.97g;

[0031] 3. Put the blank obtained by the primary molding into the mold of the secondary molding. The mold of the secondary molding is in a closed space, first evacuate to 8×10 -3 Pa, then filled with argon to 8×10 4 Pa, then raise the temperature to 780°C, pressurize 200MPa along the direction of thickness 10, hold the pressure for 6 minutes, cool and take it out;

[0032] 4. Put the secondary molded magnet into a vacuum furnace for secondary heat treatment, and heat-treat the hot-pressed blank by adopting the process of holding at 900°C for 8 hours an...

Embodiment 2

[0034] 1, adopt the magnet among the embodiment 1, add 5%Nd70Cu30 (mass percentage composition) rich rare earth alloy powder in the neodymium-iron-boron alloy powder that makes after step 1, wherein the average particle diameter of neodymium-copper alloy powder is 3 μ m;

[0035] 2. In step 3, the hot pressing temperature is 680° C., and other processes are the same as in embodiment 1.

Embodiment 3

[0037] After the heat treatment in Step 4, the magnet in Example 2 was subjected to a stress relief tempering treatment at 340° C. for 2.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com