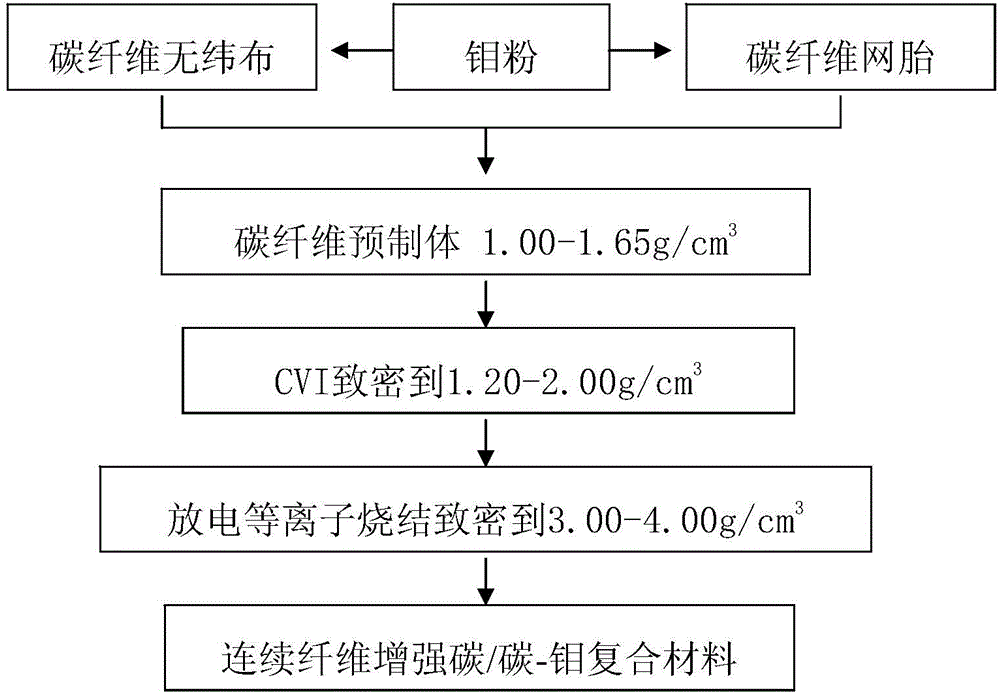

Preparation method of continuous-fiber reinforced carbon/carbon-molybdenum composite material

A technology of carbon composite materials and continuous fibers, applied in the field of preparation of carbon/carbon-molybdenum composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

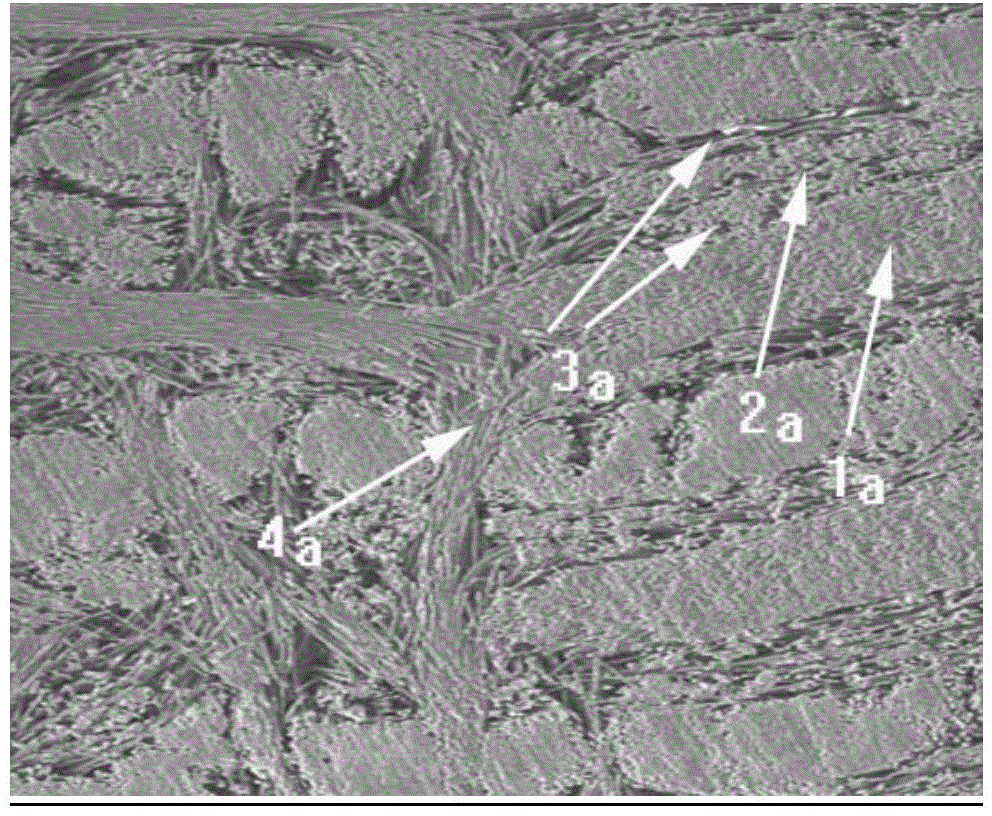

[0049](1) Lay molybdenum powder with a particle size of 50-100 microns evenly on each layer of non-weft cloth and net tire, and lay 12 layers of non-weft cloth and net tire layer by layer, and prepare carbon fiber prefabricated body by needle punching and hooking. The initial density of the preform is 1.00g / cm 3 , The mass fraction of molybdenum in the prefabricated body is 50%;

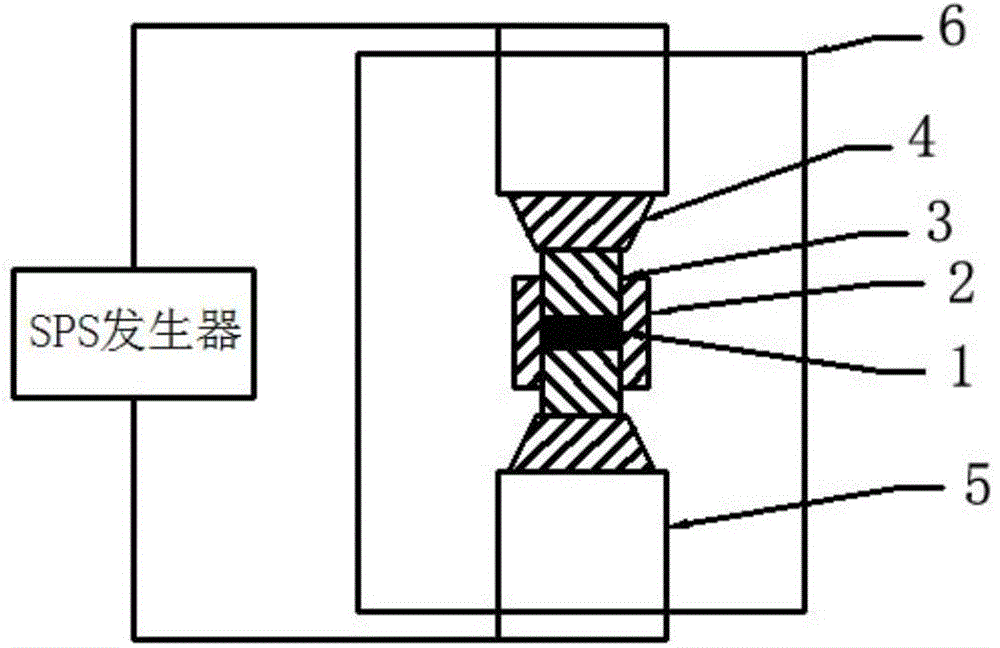

[0050] (2) Densify the preform to 1.20g / cm through CVI 3 , control the pyrolytic carbon microstructure of the matrix to rough layer structure pyrolytic carbon; machine it into a workpiece with a diameter of 40mm and a height of 10mm, put it into the graphite mold of the SPS furnace, and pre-press it with a force of 5KN to keep the surface of the sample smooth.

[0051] (3) Using SPS furnace, vacuumize to 10 -2 After Pa, the carbon / carbon-molybdenum composite material is rapidly heated to a temperature of 1800°C, then slowly pressurized to a pressure of 26MPa, the temperature rise rate is controlle...

Embodiment 2

[0054] (1) Lay molybdenum powder with a particle size of 50-100 microns evenly on each layer of non-weft cloth and net tire, and lay 15 layers of non-weft cloth and net tire layer by layer, and prepare carbon fiber prefabricated body by needle-punching. The initial density of the preform is 1.11g / cm 3 , The mass fraction of molybdenum in the prefabricated body is 55%;

[0055] (2) The preform is densified to 1.33g / cm by CVI 3 , control the pyrolytic carbon microstructure of the matrix to rough layer structure pyrolytic carbon; machine it into a workpiece with a diameter of 40mm and a height of 10mm, put it into the graphite mold of the SPS furnace, and pre-press it with a force of 5KN to keep the surface of the sample smooth.

[0056] (3) Using SPS furnace, vacuumize to 10 -2 After Pa, the carbon / carbon-molybdenum composite material is rapidly heated to a temperature of 1780°C, then slowly pressurized to a pressure of 27MPa, the temperature rise rate is controlled to be 130...

Embodiment 3

[0059] (1) Lay molybdenum powder with a particle size of 50-100 microns evenly on each layer of non-weft cloth and net tire, and lay 10 layers of non-weft cloth and net tire layer by layer, and prepare carbon fiber prefabricated body by needle-punching. The initial density of the preform is 1.25g / cm 3 , The mass fraction of molybdenum in the prefabricated body is 60%;

[0060] (2) Densify the preform to 1.50g / cm through CVI 3 , control the pyrolytic carbon microstructure of the matrix to rough layer structure pyrolytic carbon; machine it into a workpiece with a diameter of 40mm and a height of 10mm, put it into the graphite mold of the SPS furnace, and pre-press it with a force of 5KN to keep the surface of the sample smooth.

[0061] (3) Using SPS furnace, vacuumize to 10 -2 After Pa, the carbon / carbon-molybdenum composite material is rapidly heated to a temperature of 1820°C, and then slowly pressurized to a pressure of 25MPa, the temperature rise rate is controlled to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com