Method for preparing clay modified polyvinyl alcohol antifouling hydrogel

A technology of polyvinyl alcohol and clay, applied in the field of preparation of anti-sewage gel, can solve the problems of poor mechanical properties of hydrogel coating, complicated preparation process, expensive raw materials, etc., achieve excellent anti-fouling effect and simple preparation process , The effect that the raw material is easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

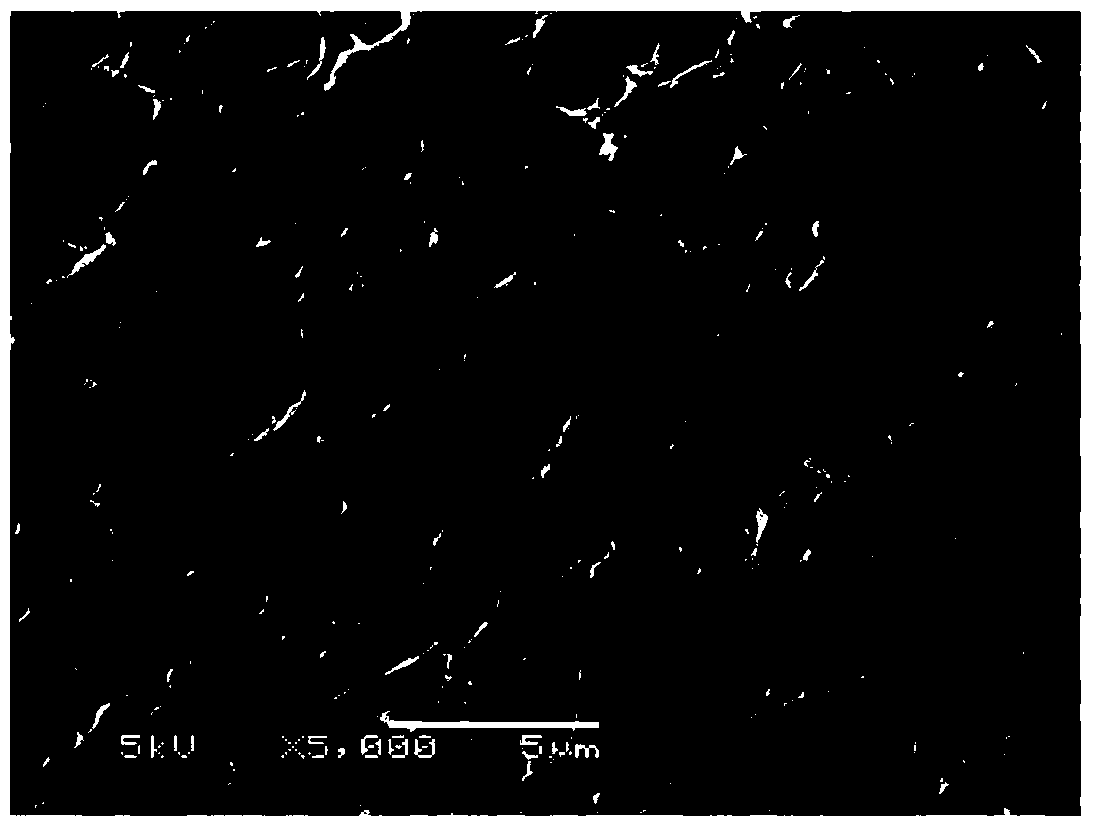

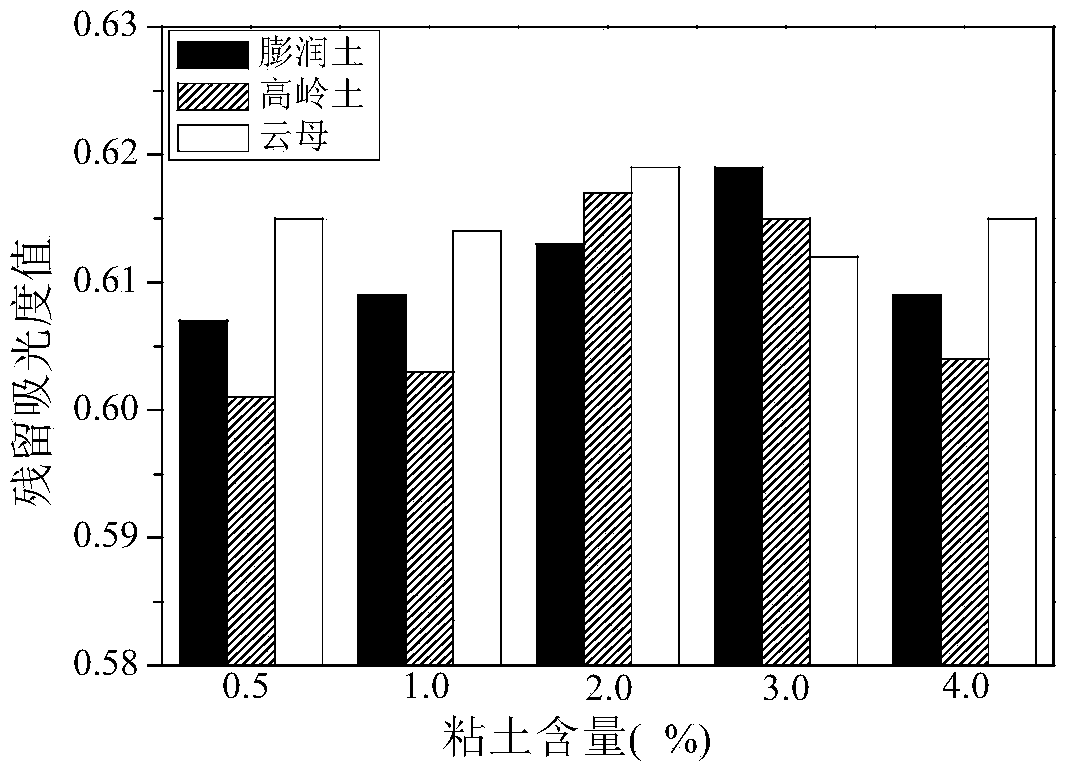

[0021] Embodiment 1: take by weighing 4 parts of bentonite (accounting for the mass percent of whole composite hydrogel system), quantitatively add in the aqueous solution, make the clay disperse evenly in the solution, then add 10 parts of polyvinyl alcohol, make it fully dissolve, pass Preparation of clay-modified polyvinyl alcohol hydrogel by physical cross-linking method.

Embodiment 2

[0022] Embodiment 2: take by weighing 4 parts of kaolin (accounting for the mass percent of whole composite hydrogel system), quantitatively add in the aqueous solution, make the clay disperse evenly in the solution, then add 10 parts of polyvinyl alcohol, make it fully dissolve, repeat Clay-modified polyvinyl alcohol hydrogels were prepared through three freeze-thaw processes.

Embodiment 3

[0023] Embodiment 3: Weigh 4 parts of kaolin (accounting for the mass percentage of the whole composite hydrogel system), quantitatively add to the aqueous solution, and magnetically stir at room temperature for 2 hours to obtain a clay dispersion, and then ultrasonically 20min the suspension to make the clay in Disperse evenly in the solution, then add polyvinyl alcohol with a degree of polymerization of 1750 and a degree of alcoholysis of 50%, stir for 3 hours to fully dissolve, and repeat the freezing-thawing process three times to obtain a clay-modified polyvinyl alcohol hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com