Sintering method of electrolytes for solid oxide fuel cell

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of long sintering time and high temperature, and achieve the effect of improving sintering rate and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

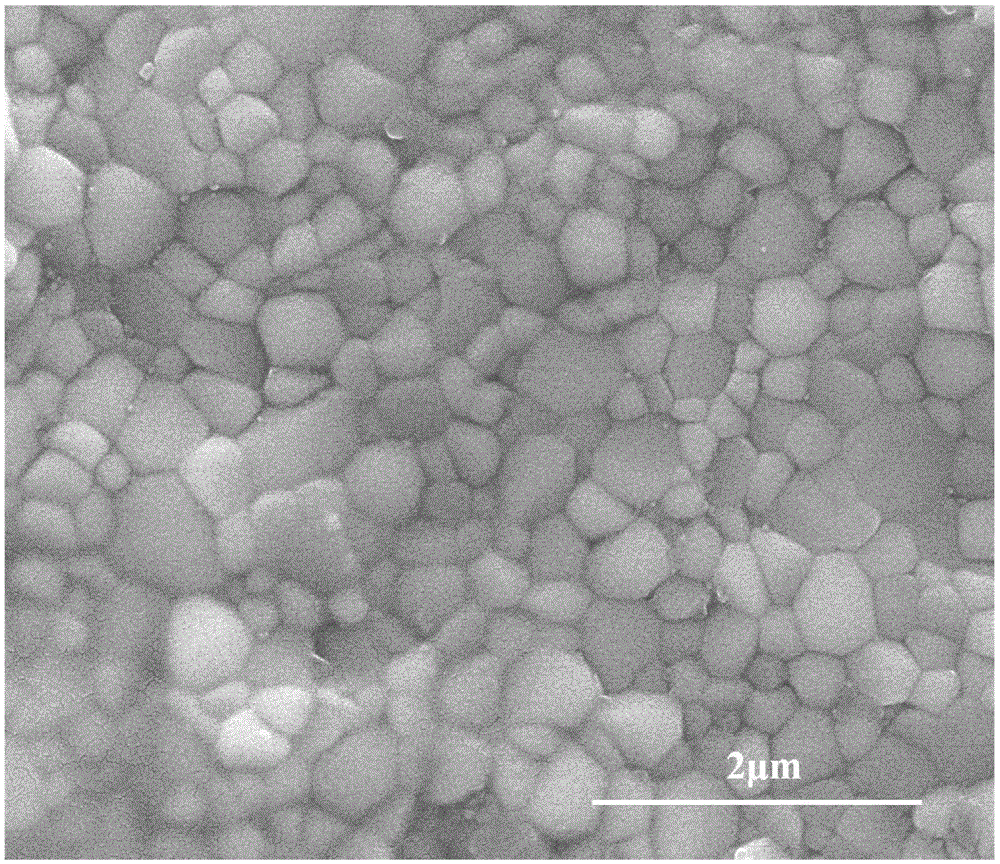

[0028] Add the binder to the SDC electrolyte powder, grind it evenly, dry it and press it into a strip; then connect platinum wires to both ends of the electrolyte sample, and connect them in series to the circuit; then place the whole in the furnace and raise it from room temperature to 680 ℃, apply 90Vcm to the electrolyte spline in the circuit when the temperature starts to rise -1 Field strength; set the furnace temperature rise rate to 10℃min -1 , When the temperature rises to 670℃, flashing occurs, record the temperature at this time; at the same time, the current will be changed stepwise, that is, the current will be limited at 0.10A and maintained for 100s, and then the current will change to 0.20A and maintained for 100s , And so on, until the current rises to 0.6A, and sintering at a constant current of 0.6A for 25min, the electrolyte is sintered densely. Then the furnace temperature is naturally cooled to room temperature, and the SEM image of the surface of the SDC e...

Embodiment 2

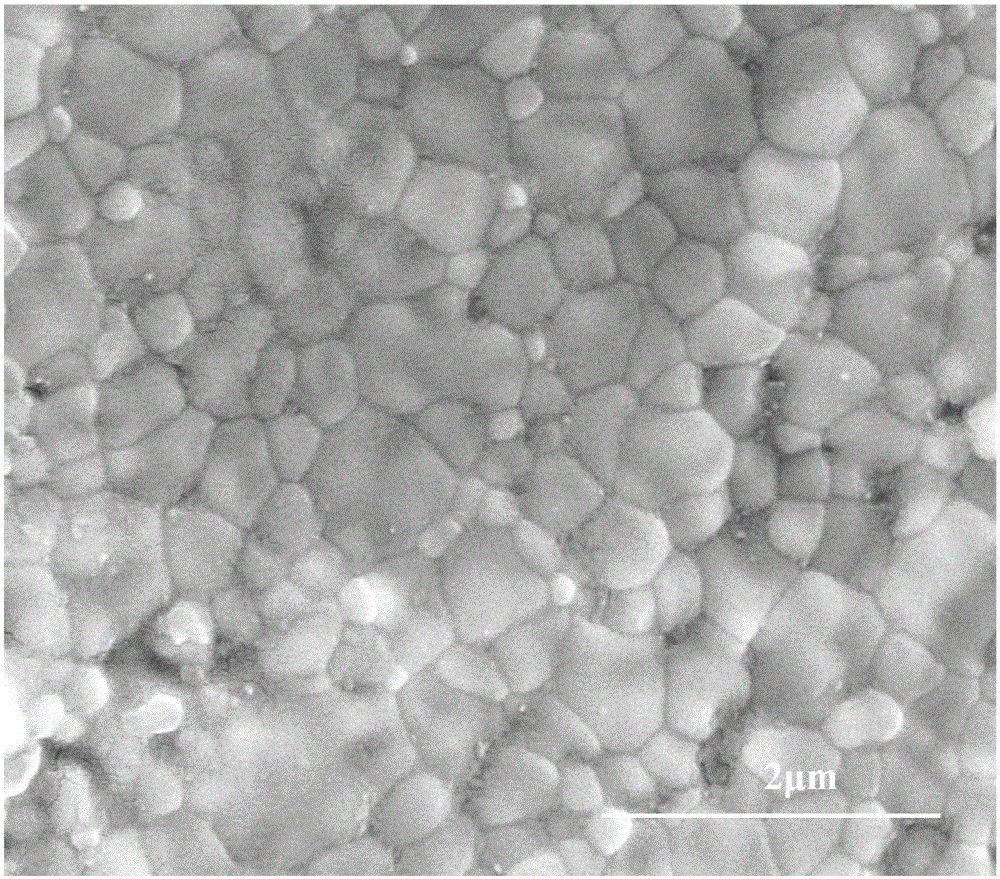

[0030] Add the binder to the YSZ electrolyte powder, grind it evenly, dry it and press it into a strip; then connect platinum wires to the two ends of the electrolyte sample and connect it in series to the circuit; then place the whole in the furnace and raise it from room temperature to 1160℃, when the temperature starts to increase, apply 30Vcm to the electrolyte spline in the circuit -1 Field strength; set the furnace temperature rise rate to 10℃min -1 , When the temperature rises to 1150℃, flashing occurs, record the temperature at this time; at the same time, the current will change stepwise, that is, the current will be limited at 0.05A and maintained for 100s, and then the current will change to 0.10A and maintained for 100s , And so on, until the current rises to 0.8A, and sintering at a constant current of 0.8A for 5 minutes, the electrolyte is sintered and dense. Then the furnace temperature is naturally cooled to room temperature, and the SEM image of the YSZ electrol...

Embodiment 3

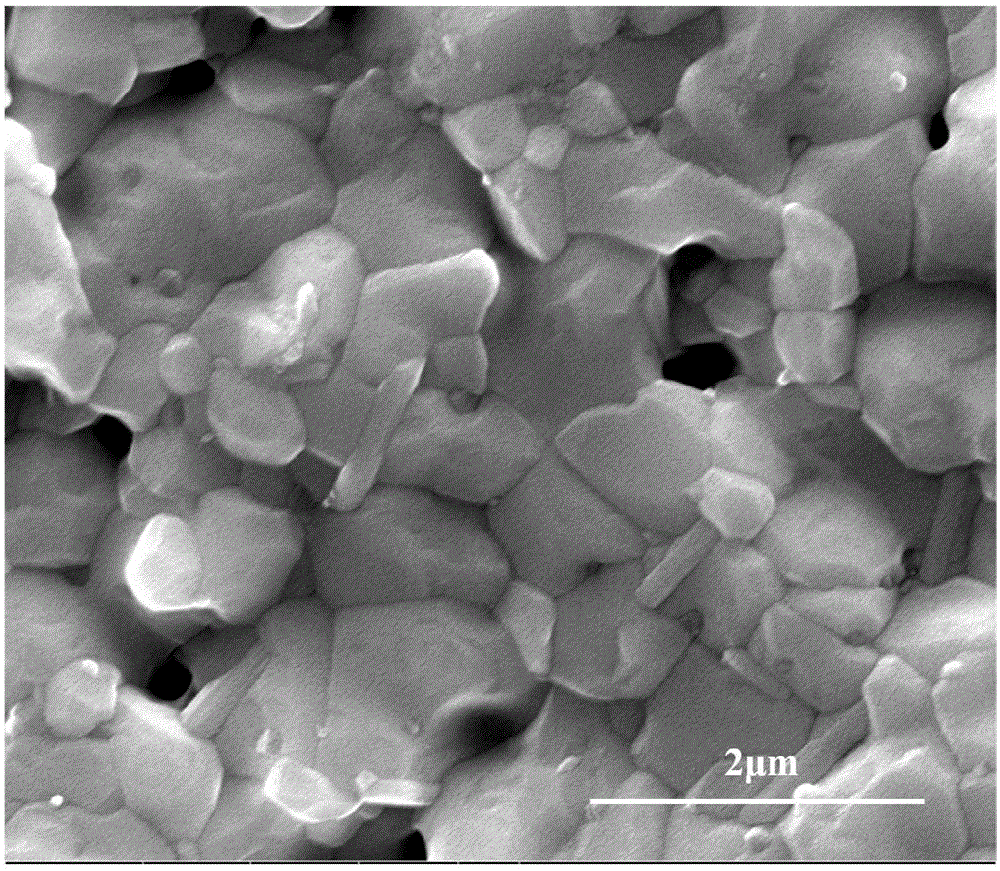

[0032] Add a binder to the LSGM electrolyte powder, grind it evenly, dry it, and press it into a strip; then connect platinum wires to both ends of the electrolyte sample and connect them in series to the circuit; then place the whole in the furnace and raise it from room temperature to 700 ℃, apply 100Vcm to the electrolyte spline in the circuit when the temperature starts to rise -1 Field strength; set the furnace temperature rise rate to 10℃min -1 , When the temperature rises to 690 ℃, flashing phenomenon occurs, record the temperature at this time; at the same time, the current will undergo a stepwise change, that is, when the current rises to 0.5A, the current will be limited, and the constant current will be sintered at 0.5A. After 10 minutes, the electrolyte is sintered and dense. Then the furnace temperature is naturally cooled to room temperature, and the SEM image of the LSGM electrolyte surface obtained by sintering is shown as image 3 Shown. The impedance value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com