A rapid preparation method of superhard and lightweight diamond-b4c-sic ternary composite ceramics

A ternary composite, -b4c-sic technology, which is applied in the field of lightweight ceramic materials, can solve the problems of limiting final application, long sintering time, and high energy consumption, and achieves simple preparation methods and technological processes, excellent mechanical properties, and preparation costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

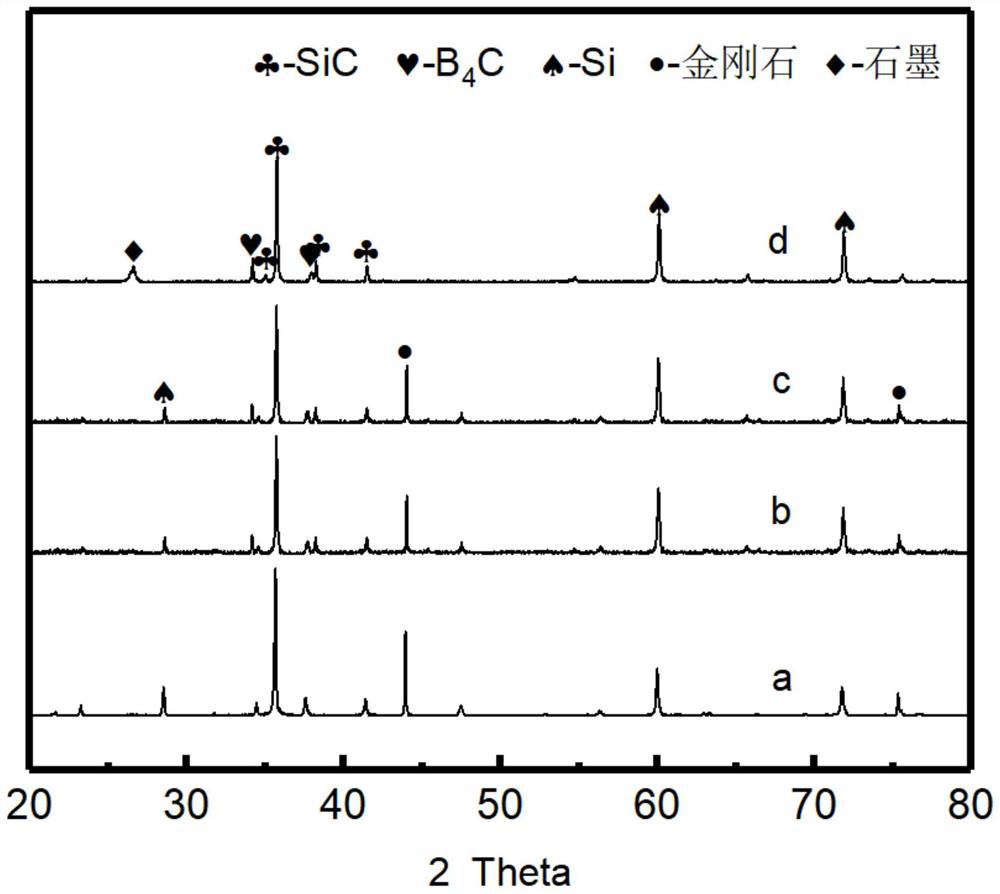

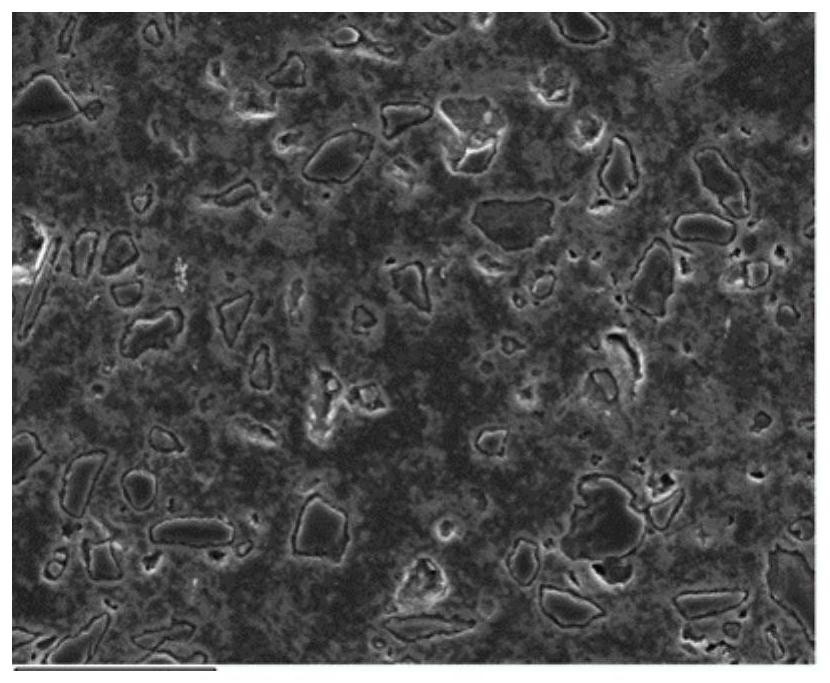

[0031]Example 1figure 1 versusfigure 2 :

[0032]The present invention provides a rapid preparation method of superhard and light diamond-B4C-SiC ternary composite ceramics, including the following steps:

[0033](1) Selection of raw material powder: Select the purity greater than 98%, the average particle diameter is 38 μm diamond, 1 μm of B powder, 3 μm Si powder, 40% by weight of the total mass of the raw material, B powder and Si according to the total mass of the raw material, respectively. The mass ratio of powder is 1: 1;

[0034](2) Preparation of the three-membered mixture: The above-described powder is mixed by the ball mill, the ball milling medium is ethanol, the ball milling time is 6 h; rotates the slurry of the ball to rotate, then put it into the vacuum drying box Drying, drying time is 24 h; after 100 mesh, 200 mesh sieve is obtained by diamond, Si, and B;

[0035](3) The in-situ reaction of the powder is rapidly sintered: the three-membered mixture is placed in the graphite mo...

Embodiment 2

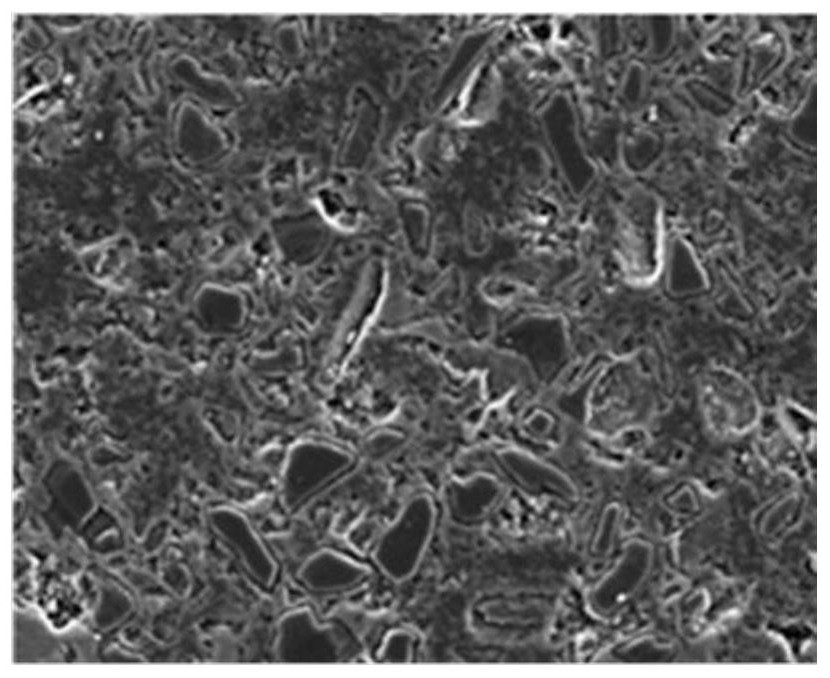

[0038]Example 2figure 1 versusimage 3 :

[0039]The present invention provides a rapid preparation method of superhard and light diamond-B4C-SiC ternary composite ceramics, including the following steps:

[0040](1) Selection of raw material powder: Select the purity greater than 98%, the average particle diameter is 35 μm diamond, 1 μm of B powder, 3 μm Si powder, 45% by weight, B powder and Si of the total mass of the raw material, B powder and Si The mass ratio of powder is 2: 1;

[0041](2) Preparation of the three-dimensional mixed powder: The above-mentioned powder is mixed by a ball mill, the ball milling medium is ethanol, the ball milling time is 8 h; rotating the slurry of the ball grinding, then put it into the vacuum drying box Drying, drying time is 48 h; after 100 mesh, 200 mesh sieve is obtained from diamond, Si, and B mixed powder;

[0042](3) The in-situ reaction of the powder is rapidly sintered: the three-membered mixture is placed in the graphite mold, and the inner wall of ...

Embodiment 3

[0045]Example 3figure 1 versusFigure 4 :

[0046]The present invention provides a rapid preparation method of superhard and light diamond-B4C-SiC ternary composite ceramics, including the following steps:

[0047](1) Selection of raw material powder: Select the purity greater than 98%, the average particle diameter is 40 μm of diamond, 2 μm of B powder, 2 μm Si powder, 50% by weight, B powder and Si of the total mass, B powder and Si The mass ratio of powder is 1: 1;

[0048](2) Preparation of the three-dimensional mixed powder: The above-mentioned powder is mixed by the ball mill, the ball milling medium is ethanol, the ball milling time is 12 h; rotates the slurry of the ball to rotate, then put it into the vacuum drying box Drying, drying time is 30 h; after 100 mesh, 200 mesh sieve is obtained from diamond, Si, and B mixed powder;

[0049](3) The in-situ reaction of the powder is rapidly sintered: the three-membered mixture is placed in the graphite mold, and the inner wall of the graphite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com