Mullite silicon carbide complex-phase fireproof material and preparation method thereof

A technology of mullite silicon carbide and refractory materials, which is applied in the field of mullite silicon carbide composite refractories and its preparation, can solve problems such as unfavorable energy conservation and heat preservation of cement kilns, reduction of material service life, and easy alkali erosion of silicon mullite bricks. problem, to achieve the effect of excellent sulfide gas erosion performance, energy saving, and improved erosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

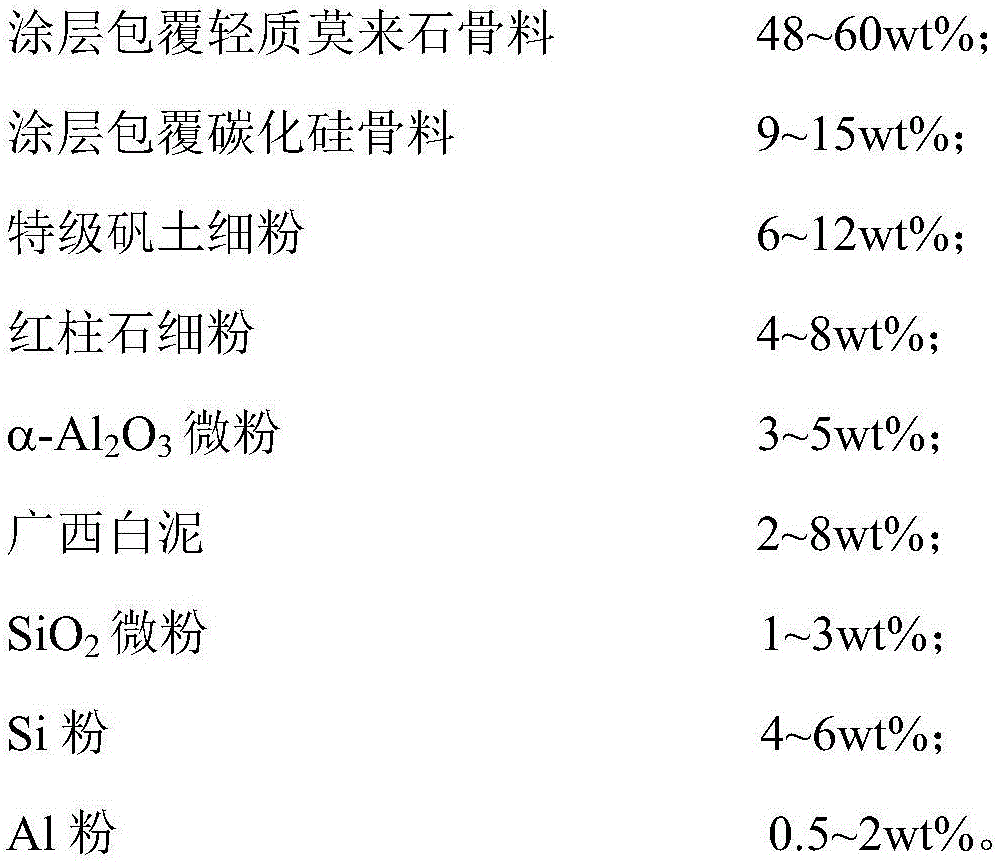

[0034] A mullite silicon carbide composite refractory material and a preparation method thereof. The raw materials and content of the mullite silicon carbide composite refractory material are:

[0035]

[0036] The preparation method of the mullite silicon carbide composite refractory material is as follows: batching is carried out according to the above-mentioned raw materials and their contents, and the coating-coated mullite lightweight aggregate and the coating-coated silicon carbide aggregate are mixed for 3 ~ After 4 minutes, add 3-4wt% dextrin of the raw material, knead for 4-6 minutes, and prepare the mixture. Then add special-grade bauxite fine powder, andalusite fine powder and premixed powder into the mixture, and knead for 12 to 16 minutes to make mud. The mud is trapped for 24-30 hours, pressed and formed under the condition of 20-30MPa, dried at 90-100°C, and fired at 1250-1300°C to obtain the mullite silicon carbide composite phase refractory material.

[...

Embodiment 2

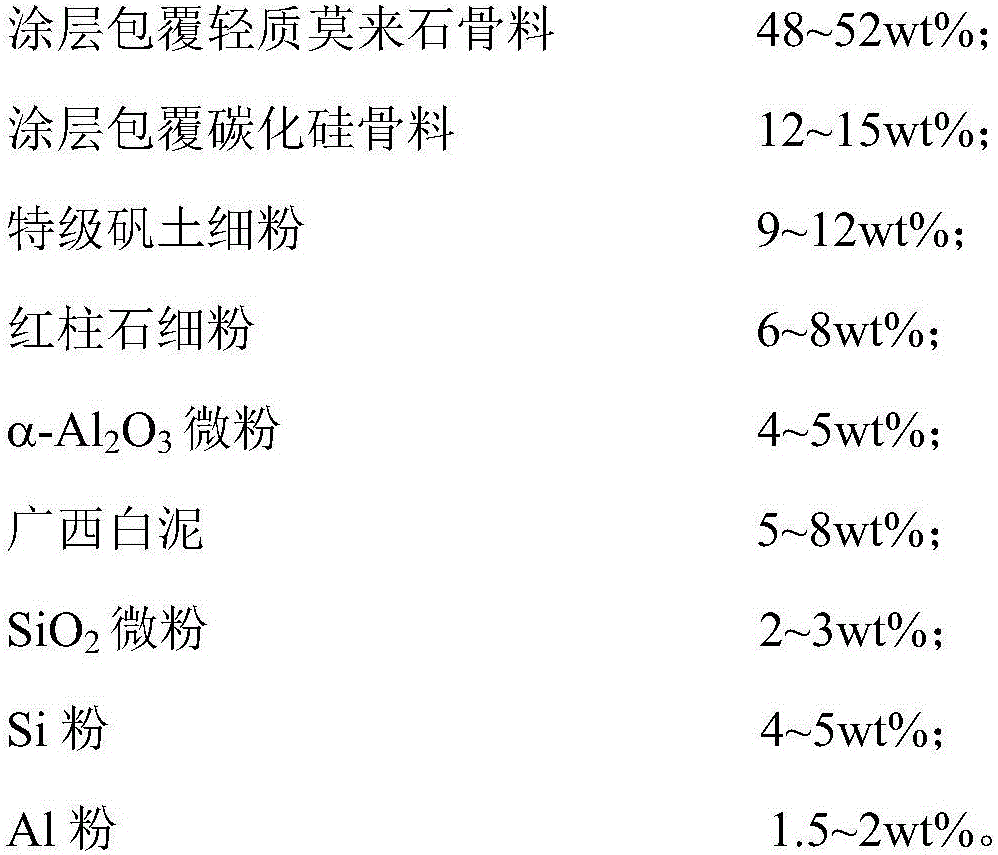

[0039] A mullite silicon carbide composite refractory material and a preparation method thereof. The raw materials and content of the mullite silicon carbide composite refractory material are:

[0040]

[0041]

[0042] The preparation method of the mullite silicon carbide composite refractory material is as follows: batching is carried out according to the above-mentioned raw materials and their contents, and the coating-coated mullite lightweight aggregate and the coating-coated silicon carbide aggregate are mixed for 4~ After 5 minutes, 3.5-4.5 wt % calcium lignosulfonate of the raw material is added, and kneaded for 5-7 minutes to prepare a mixture. Then add special-grade bauxite fine powder, andalusite fine powder and premixed powder into the mixture, and knead for 14 to 18 minutes to make mud. The mud is trapped for 30-36 hours, pressed and formed under the condition of 30-40MPa, dried at 100-110°C, and fired at 1300-1350°C to obtain the mullite silicon carbide co...

Embodiment 3

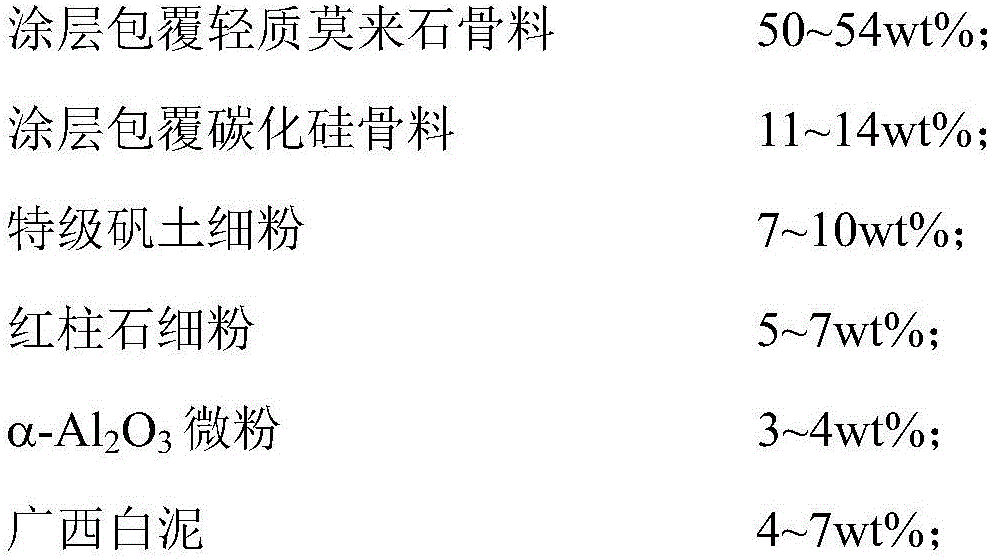

[0045] A mullite silicon carbide composite refractory material and a preparation method thereof. The raw materials and content of the mullite silicon carbide composite refractory material are:

[0046]

[0047] The preparation method of the mullite silicon carbide composite refractory material is as follows: batching is carried out according to the above-mentioned raw materials and their contents, and the coating-coated mullite lightweight aggregate and the coating-coated silicon carbide aggregate are mixed for 3 ~ After 4 minutes, add 4-5 wt% aluminum dihydrogen phosphate solution of the raw material, and knead for 4-6 minutes to form a mixture. Then add special-grade bauxite fine powder, andalusite fine powder and premixed powder into the mixture, and knead for 12 to 16 minutes to make mud. The mud is trapped for 24-30 hours, pressed and formed under the condition of 40-50MPa, dried at 90-100°C, and fired at 1350-1400°C to obtain the mullite silicon carbide composite pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com