Vacuum impregnation coating method and device for planar solid oxide fuel cell (SOFC) electrolyte

A solid oxide and vacuum impregnation technology, which is applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell parts, etc., can solve the problems of inapplicability, and achieve the reduction of densification temperature, flexible design of size and placement, Efficiency and the effect of scalable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The following describes the vacuum immersion coating method of the present invention and the single cell preparation method according to the method, including the following operation steps.

[0059] (1) Preparation of battery support: In the present invention, the support can be pre-heat-treated porous anode composite substrate or porous cathode composite substrate. The blank can also be anode / active layer composite blank or cathode / active layer composite blank. The blank is pre-fired to obtain a substrate. The temperature of the pre-fire can be between 900-1200°C. The porous anode composite substrate can use nickel oxide / yttrium stabilized zirconia composite material (NiO / YSZ). Strontium doped lanthanum manganate / yttrium stabilized zirconia composite (LSM / YSZ) can be used as the porous cathode composite substrate.

[0060] (2) Preparation of electrolyte slurry: commercially produced electrolyte powder was used to prepare a slurry that meets the requirements of electro...

Embodiment 1

[0072] [Electrolyte Vacuum Impregnation Coating on Supported Anode Sheet and Its Single Cell Preparation and Performance Characterization]

[0073] Weigh an appropriate amount of commercial 8YSZ (8% yttria fully stabilized zirconia), 3YSZ (3% yttrium oxide partially stabilized zirconia) and NiO, use alcohol and methyl ethyl ketone as solvents, add appropriate amount of additives, and make it suitable for casting of slurry. Using the method of ZL100479245 to tape-cast to obtain an anode support with a certain thickness. After the support green body is fully dried, it is pre-fired at 1000° C. for 2 hours to become the support substrate for impregnating the electrolyte. Weigh an appropriate amount of commercially produced SSZ (scandium-stabilized zirconia) powder, use alcohol as a solvent, add appropriate additives, and make a slurry suitable for impregnation. Use the above-mentioned vacuum impregnation method to impregnate the electrolyte once, and dry it at 1400 ℃ sintering f...

Embodiment 2

[0075] [Support / Active Anode Bilayer Substrate Electrolyte Vacuum Impregnation Coating and Its Single Cell Preparation and Performance Characterization]

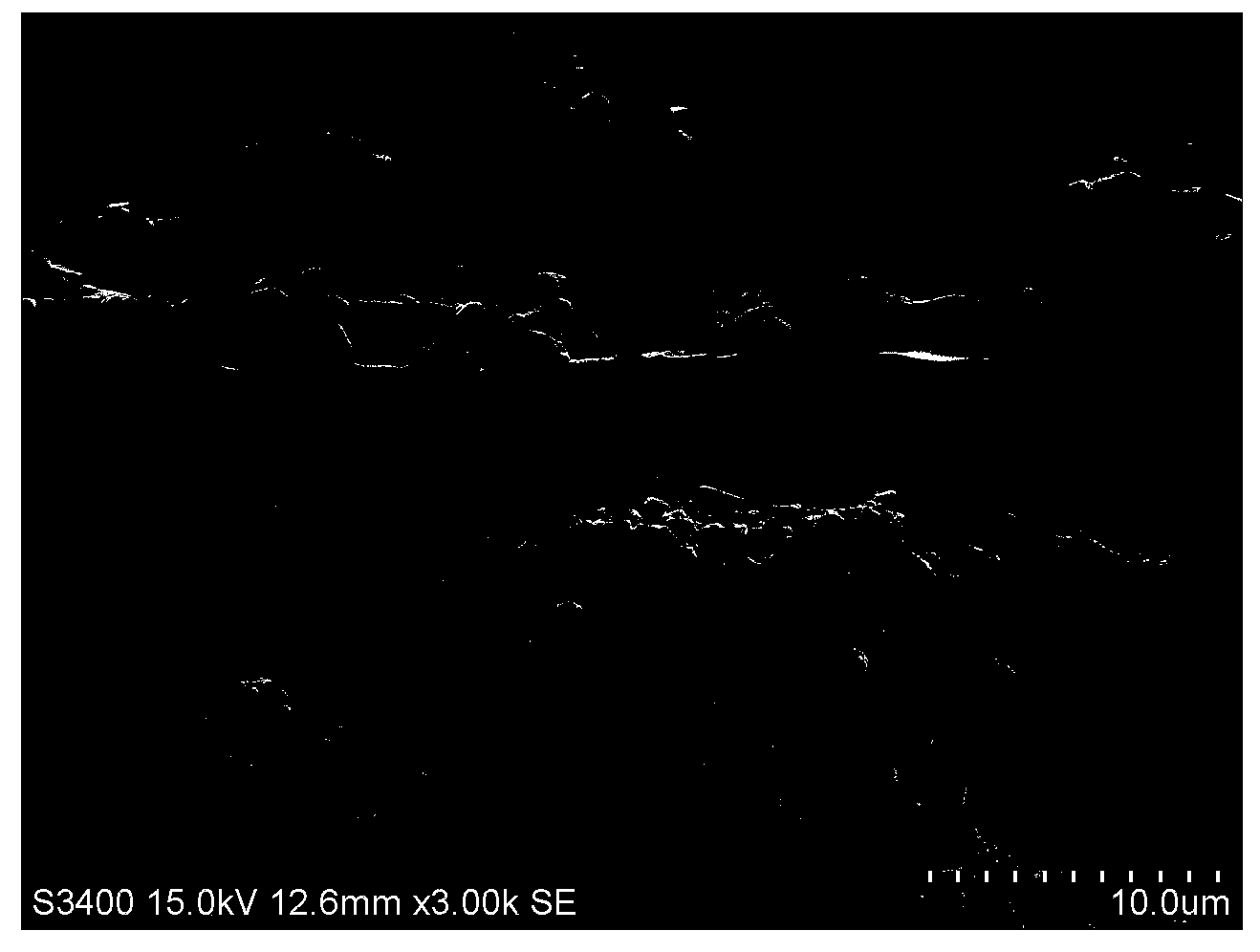

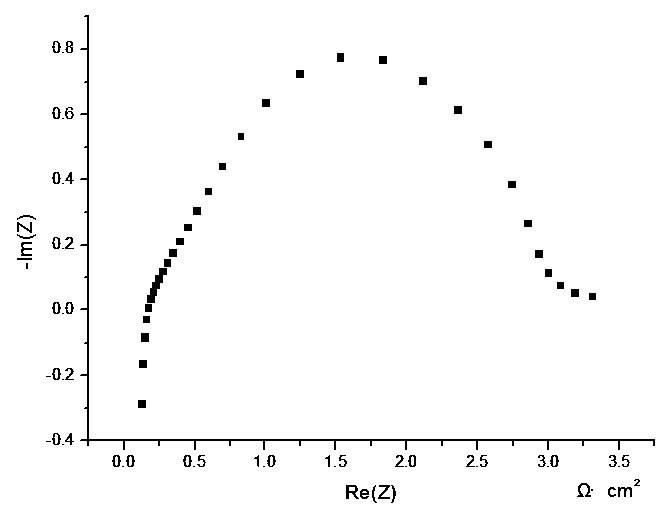

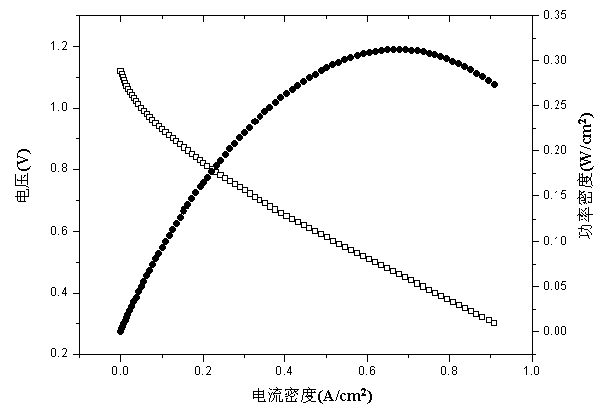

[0076] On the basis of Example 1, the support body anode is changed to a support body / active anode bilayer substrate. The composition of the active layer is obtained by mixing SSZ and NiO in a certain ratio (for example, a mass ratio of 1:1). The operating method of this embodiment is the same as that of Embodiment 1 except for the difference of the substrate. attached Figure 5 The cross-sectional SEM photograph of the obtained single cell shows that after one dipping, the thickness of the electrolyte is about 5 microns, and the electrolyte is dense. attached Image 6 For its electrochemical impedance spectrum, it can be seen from the impedance spectrum that the anode performance of the prepared single cell is sufficient, and the overall electrochemical catalytic activity is controlled by the cathode. Both the screen-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com